Printa Systems 990 series User manual

1

990 PAD PRINTING SYSTEM QUICK GUIDE

2

990 Pad Printing System Quick Guide

Table of Contents

INITIAL SET UP :Product / Artwork /Pads.......................................Page 3

INITIAL SET UP: Ink Carriage Assembly...........................................Page 4

FIXTURE PUTTY AND MOLD MAKING.............................................Page 5

PLATE MAKING PROCESS.....................................................................Page 6

INK MIXING..............................................................................................Page 7

FINAL SET UP OF 990 SYSTEM............................................................Page 8

PRINTING...................................................................................................Page 9 &10

CLEANING.................................................................................................Page 11

INK INFORMATION.................................................................................Page 12

INK CURING INFORMATION.................................................................Page 13

3

990 Pad Printing System Quick Guide

Initial Set Up : Product to be printed / Artwork/ Pads

Step 2: Print out artwork on laser film. Do not use an Ink

Jet Printer! Check to see if artwork is dark enough: hold to

light, if you can see through it, then you will need a toner

enhancer such a Casey’s Ultra Black. Always double check

your artwork before proceeding as you cannot remake a

plate!

Step 3: Choose which pad will be appropriate for you job.

You want a pad that is generally a little larger than your

product. If pad is new, wipe down with rubbing alcohol to

remove silicone residue. Press into blank paper or card-

board to further remove silicone. Pad is now ready. Keep

pads in a dark environment out of direct sunlight, as it will

ruin the pads. Also keep pads stored upside down on the

wooden base and always clean pads with either packing

tape or rubbing alcohol: DO NOTuse thinners to clean

pads!

Step 1: Decide which product you are going to pad print. In

this example,we will pad print a sunglass holder.If you are

printing a plastic product, always check to see if it is solvent

sensitive: that is if the ink will adhere to your product after

drying. To test:gently wipe some medium thinner on a part

of the product you can test. If it melts or becomes dull, then

you can proceed with the process. If it does not, then a

pretreatment or different type of ink will need to be used.

Contact your Printa Systems representative for more infor-

mation. If your product is glass or metal, then simply wipe

with rubbing alcohol before printing to prep surface.

4

990 Pad Printing System Quick Guide

Ink Carriage Assembly

Step 1: Familiarize yourself with

the ink carriage assembly.Take a

moment or two to install and

uninstall the ink roller.

Step 2: Install doctor blade into the blade

keeper. Make note that grounded edge of

doctor blade is out and down. Press blade

against plate keeper screws and tighten.

Step 5: Practice a couple times

putting the ink carriage into inner

and outer posts. Do this until you get

comfortable. Make a note that the

post that has the angle adjustment

knob (black knob) has a spring inside

of it.

Step 3: Ink carriage assembly

should look like this.

Step 4: Hold ink carriage assembly as

follows.

Step 6: Once ink carriage is installed,

tighten down with nylon nut. Once firm,

turn back 1/16th of an inch.You do not

want the nut to be completely tightened

or the ink carriage will not work properly.

5

990 Pad Printing System Quick Guide

Fixture putty and mold making.

Step 1: Since many products are

unique in shape, included with the

990 System is fixture putty so you can

secure your product to print.The

putty requires a hardener to cure.

Step 2: Get appropriate amount of

putty to be used. Generally you

want to get an amount a little larger

than your product.

Step 3: Add about a 6” inch

bead of hardener to a palm

sized amount of putty.

Step 4: Mix thoroughly by

hand, make sure there are no

swirls as the putty must be an

even color. Mix quick as you

have about a minute.

Step 5: Press firmly

into turntable as to

make registration

marks in the bottom

of the putty for future

use.

Step 6: Place product into

fixture putty.Make sure the

putty goes up at least half of

the product to secure it.

Step 7: Gently mold

putty around edges of

product to secure

product.

Step 8: Let sit for at least ten

minutes for the putty to

harden. You now have a

fixture that can be reused for

the same product.

6

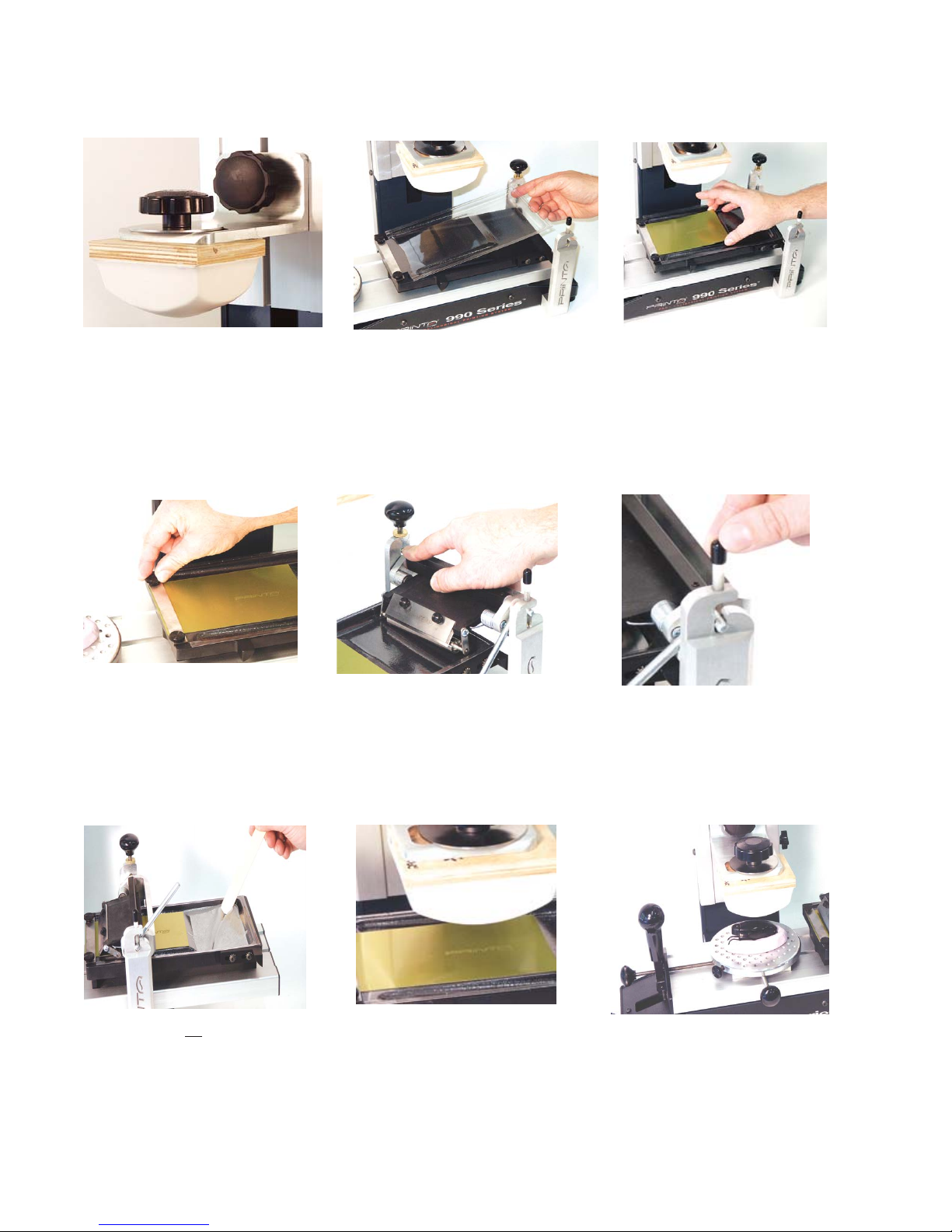

Step 1: Print out art-

work onto laser film.

Make sure artwork is

completely black. Cut

around artwork 1/2”

with sharp scissors.

Step 2: Remove

plate from package.

Plates are light

sensitive so remove

only one plate at a

time. Peel off protec-

tive covering.

Step 3: Remove

cassette from expo-

sure unit. Unlock

tabs and lift glass.

Place plate on foam,

and place artwork

on plate.

Step 4: Close

glass: lock down

tabs

Step 5: Place cassette into

exposure unit. Set timer for

60 seconds. Press start and

expose plate.

Step 6: After exposure,

remove cassette. Unlock tabs

and remove artwork from

plate. Store artwork for

future use.

Step 7: Place screen tint on top

of plate. The 200 DPI screen tint

will be used almost exclusively.

The 300 DPI will be used for

halftones and photographs.

Step 8: Place cassette back into exposure

unit. Expose for 90 seconds. Remove plate

from cassette. Store screen tint in enve-

lope as it is reusable.Take to sink and rinse

with HOT water. Image should appear

within 30 - 45 seconds.

Step 9: After rinsing, either used com-

pressed air or hair dryer to blow off excess

water. Cure plate with heat gun or place

in oven @ 110 degrees for 10 minutes.

Post expose in exposure unit for 10

minutes by placing plate on top of

cassette.

990 Pad Printing System Quick Guide

Plate making process

7

Ink Mixing

The inks that come standard with the 990 Pad

Printing System are a two-part epoxy based ink.

The inks need to be mixed with a hardener and a

thinner. There are two types of hardeners and

thinners that come with the kit: SE hardener and

medium thinner & VR hardener and VR thinner.

Remember: VR hardener is used for glass and

ceramics, while the SE is used for SOME plastics.

Remember to test your plastics before committing

to a print run to see if the ink with adhere to the

surface! There are other inks available for different

plastics, please call your Printa Systems representa-

tive for more information.

Step 1: You will need your

inks, hardener, thinner and

mixing supplies as well as

your gram scale. Because the

sunglass holder is plastic, SE

hardener and Medium

thinner will be used.

Step 2: Place cup and stick

on scale, press TARE button

so it calibrates the scale and

reads 0.

Step 3: Pour ink into cup.

You need to need to mix at

least 25 -30 grams. Do not

mix less as it will make the

ink unstable and dry out

quicker.

Step 4: Pour hardener

into cup. You add 20%

hardener to the weight

of the ink. Remember!

SE hardener for SOME

plastics,VR for glass and

ceramics.

Step 5: Mix hardener

and ink mixture.

Step 6: Add 20%

thinner to the mixture

of ink and hardener.

Step 7: Mix thor-

oughly!

990 Pad Printing System Quick Guide

8

990 Pad Printing System Quick Guide

Step 1: Install pad onto pad

mount. Leave pad loose in

mount so you can adjust pad

according to the artwork.

Step 2: Install ink tray. Slide

under plate keeper on far

left of ink tray.

Step 3: Place plate on top of

tray liner. Slide under plate

keeper bar: plate may extend

from end of bar but this will

not cause any problems.

Step 4:Tighten down plate

keepers bolts. Step 5: Install ink carriage

assembly. Step 6: Secure ink carriage

by locking down Nylon nut.

Remember not to over-

tighten!

Step 7: Pour all if ink into ink

tray.Note the cam lever bar

is in the 2 o’clock position.

Test ink by running mixing

stick through it.The ink

should close up in 3 seconds.

If it takes longer, then add

thinner to mixture.

Step 8: Lower pad to plate.

Check pad position in

reference to artwork. Move

pad until centered on art-

work, then tighten pad onto

pad mount.

Step 9: Slide bed slide to

right. Lower pad to product:

make sure that it is in the

general print area of the pad.

9

990 Pad Printing System Quick Guide

Printing

Step 1: Place packing tape

over product so you can

safely print without marking

on it.

Step 2: Slide bed-slide to

right, flooding plate.

Step 3: Plate should be

completely covered.

Step 4: Pull bed slide to left:

cleaning off plate with

doctor blade.

Step 5: Plate should be

cleaned off evenly like

above.

Step 6: If plate is not cleaned

evenly, then adjust angle of

ink carriage using angle

adjustment knob.

Step 7. After plate is cleaned

properly, wait several sec-

onds before coming down

onto plate.This will help the

thinner evaporate and ink

adhere to the pad.

Step 8: Lift pad and slide

bed-slide back to right. Hold

pad in air for several seconds

to let ink become tacky so it

will release fully from the

pad onto the product.

Step 9: Lower pad onto

product to release ink. Hold

for a second on the product.

The entire print cycle should

be around ten seconds.

10

990 Pad Printing System Quick Guide

Printing

Step 10: Look at print on

product to see if it is aligned

properly.

Step 11: If it is not, loosen

the turntable lock stud so

the table rotates freely.

Step 12:Use the X & Y Axis

adjusters to move the turn-

table assembly. When done,

secure turntable lock stud.

Step 13: Place packing tape

on product and repeat steps

1 - 12 until you are satisfied

with the print.

Step 14: Once you have aligned

print and are ready,remove tape

and begin print run. Remove

product after print while the plate

is flooded.

Step 15. The finished product!

Pad Printing Tips

* Print Cycle should be about 10 seconds on average.

* Always use 25 - 30 grams of ink, the correct thinner and hardener.

* If printing on plastic, always test by placing small dab of thinner on product: if it melts or becomes dull,

then continue with the printing process.If it wipes off, then you will need to either pretreat the product

before printing or use a special type of ink designed for plastics.

* SE hardener is for woods and plastics,VR is for glass and metals. DO NOT mix either thinner or hardener as

it will cause the ink to gel.

11

990 Pad Printing System Quick Guide

Cleaning

Step 1: Clean off pad using

packing tape.

Step 2: Gently remove ink

carriage.There will be a lot

of ink on the roller. Use a lint

free cloth to catch ink.

Step 3:Wipe down roller

with cloth.You may need a

few drops of medium thin-

ner to completely remove

ink.

Step 4: Remove doctor

blade.Wipe down with cloth.

Again, a few drops of thinner

may be needed.

Step 5: Loosen plate keeper

bolts.

Step 6: Using knife or small

screwdriver, remove plate

from ink tray.

Step 7: Place plate on clean

towel. Place a few drops on

plate and wipe down. You

do not need to use lots of

thinner! A little goes along

way!

Step 8: Flip plate over and

clean off back of plate.

Again, use medium thinner

sparingly.

Step 9. Remove ink tray and

throw in trash. Ink will

harden to ink tray and be

safe to dispose of in several

hours. Install clean parts and

you are ready to start again!

12

990 Pad Printing System Quick Guide

Ink Information

The inks that come standard with the 990 System are a two-part Epoxy ink called the KK Series. These inks

are excellent for standard pad printing applications,and printing on numerous substrates. However, there

are some different items (mostly plastics) that require either pretreatment or an additive to help the KK series

bond to it.Some products require a different series of ink for superior adhesion. The chart below is the major

inks that are sold through Printa Systems and should cover almost every application. There are other series

available for more specific applications. Please contact your Printa Systems Representative for more infor-

mation on these and other products.

SERIES APPLICATION

KK Comes standard with system. Use with glass, ceramics,

urethane, some polyfines (PE/PP), nylon, polyester, styrene,

painted surfaces and wood.

T-25 Use for printing on untreated polypropylene. Great for other

plastics also.Need T-25 thinner also.

VC & VC / SP Use on flexible items: koozies, vinyl some stress balls and foam

promotional goods. Also good for flexible magnets.

ADDITIVES APPLICATION

Primer Used to wipe down surface of polyfines (plastics). Use to treat surface

instead of flame treating.

May cause discoloration of product!

Adhesion Modifier Add to KK series ink to promote adhesion to polyfines (plastics). Also

can be used with other inks to provide extra adhesion.

13

990 Pad Printing System Quick Guide

Ink Curing Information

Most products that are pad printed require a heat curing afterwards to promote the bonding properties of

the inks. Some products such as solvent sensitive plastics, wood and paper may not require heat curing.

Most of your harder goods will require heat curing for the proper bonding. A good rule of thumb is the

harder the product, the more heat you will need. Because there are so many variables when dealing with

plastics, it is almost impossible to give an accurate temperature for curing. If a plastic is solvent sensitive: the

thinner melts into the plastic and bonds almost immediately,then a lower temperature can be used. If you

wipe some thinner on a product and it does not dull the surface and wipes off, then you will need a higher

temperature. Glass and ceramics always require a high temperature for superior adhesion.The chart below is

for the KK series inks. The inks can air dry depending on your substrate and application, but heat curing is

always recommended. ALWAYS TEST YOUR PRODUCT FOR RESISTANCE TO HEAT!

APPLICATION TIME & TEMPERATURE

Solvent sensitive plastics 1 - 2 minutes @ 120 - 160 degrees F

Hard plastics* 1-5 minutes @ 120 - 220 degrees F

Glass & Ceramics* 10 minutes @ 365 degrees F

* The harder the object to be printed, it is always advisable to wipe down the product with rubbing alcohol

to help promote a clean surface. DO NOT use thinners or windex to clean the product as this will leave a film

that can cause adhesion problems during the curing process.

Table of contents