Printronix SL5000r MP User manual

Online Data Validator User’s Manual

SL5000r™ and T5000r™

RFID Smart Label and Thermal Printers

SL5000r and T5000r

RFID Smart Label and Thermal Printers

Online Data Validator Administrator’s Manual

Software License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE

USING THIS PRINTER. USING THIS PRINTER INDICATES YOUR

ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU DO NOT

AGREE TO THESE TERMS AND CONDITIONS, PROMPTLY RETURN THE

PRINTER AND ALL ACCOMPANYING HARDWARE AND WRITTEN

MATERIALS TO THE PLACE YOU OBTAINED THEM, AND YOUR MONEY

WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encoded, machine-readable data and

program. The term “Software Product” includes the Software resident in the

printer and its documentation. The Software Product is licensed (not sold) to

you, and Printronix, Inc. either owns or licenses from other vendors who own,

all copyright, trade secret, patent and other proprietary rights in the Software

Product.

License.

1. Authorized Use. You agree to accept a non-exclusive license to use the

Software resident in the printer solely for your own customary business or

personal purposes.

2. Restrictions.

a. To protect the proprietary rights of Printronix, Inc., you agree to

maintain the Software Product and other proprietary information

concerning the typefaces in strict confidence.

b. You agree not to duplicate or copy the Software Product.

c. You shall not sublicense, sell, lease, or otherwise transfer all or any

portion of the Software Product separate from the printer, without the

prior written consent of Printronix, Inc.

d. You may not modify or prepare derivative works of the Software

Product.

e. You may not transmit the Software Product over a network, by

telephone, or electronically using any means; or reverse engineer,

decompile or disassemble the Software.

f. You agree to keep confidential and use your best efforts to prevent and

protect the contents of the Software Product from unauthorized

disclosure or use.

3. Transfer. You may transfer the Software Product with the printer, but only if

the recipient agrees to accept the terms and conditions of this Agreement. Your

license is automatically terminated if you transfer the Software Product and

printer.

Limited Software Product Warranty

Printronix, Inc. warrants that for ninety (90) days after delivery, the Software will

perform in accordance with specifications published by Printronix, Inc.

Printronix, Inc. does not warrant that the Software is free from all bugs, errors

and omissions.

Remedy

Your exclusive remedy and the sole liability of Printronix, Inc. in connection with

the Software is replacement of defective software with a copy of the same

version and revision level.

Disclaimer of Warranties and Limitation of Remedies

1. THE PARTIES AGREE THAT ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE AND MERCHANTABILITY ARE EXCLUDED.

Printronix, Inc. does not warrant that the functions contained in the

Software will meet your requirements or that the operation of the Software

will be uninterrupted or error free.

Printronix, Inc. reserves the right to make changes and/or improvements in

the Software without notice at any time.

2. IN NO EVENT WILL PRINTRONIX, INC. BE LIABLE FOR LOST

PROFITS, LOST DATA, BUSINESS INTERRUPTIONS, OR ANY OTHER

DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OF OR INABILITY TO USE THIS PRODUCT,

EVEN IF PRINTRONIX, INC. HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES, OR ANY DAMAGES CAUSED BY THE ABUSE OR

MANIPULATION OF THE SOFTWARE. SOME STATES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

3. Printronix, Inc. will not be liable for any loss or damage caused by delay in

furnishing a Software Product or any other performance under this

Agreement.

4. Our entire liability and your exclusive remedies for our liability of any kind

(including liability for negligence except liability for personal injury caused

solely by our negligence) for the Software Product covered by this

Agreement and all other performance or nonperformance by us under or

related to this Agreement are limited to the remedies specified by this

Agreement.

5. California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be terminated by

agreement between you and Printronix, Inc. or by Printronix, Inc. if you fail to

comply with the terms of this License and such failure is not corrected within

thirty (30) days after notice. When this License is terminated, you shall return to

the place you obtained them, the printer and all copies of the Software and

documentation.

U.S. Government Restricted Rights

Use, duplication or disclosure by the Government is subject to restrictions as

set forth in the Rights in Technical Data and Computer Software clause at FAR

242.227-7013, subdivision (b) (3) (ii) or subparagraph (c) (1) (ii), as appropriate.

Further use, duplication or disclosure is subject to restrictions applicable to

restricted rights software as set forth in FAR 52.227-19 (c) (2).

Acknowledgement of Terms and Conditions

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT,

UNDERSTAND IT, AND AGREE TO BE BOUND BY ITS TERMS AND

CONDITIONS. NEITHER PARTY SHALL BE BOUND BY ANY STATEMENT

OR REPRESENTATION NOT CONTAINED IN THIS AGREEMENT. NO

CHANGE IN THIS AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND

SIGNED BY PROPERLY AUTHORIZED REPRESENTATIVES OF EACH

PARTY. BY USING THIS PRINTER, YOU AGREE TO ACCEPT THE TERMS

AND CONDITIONS OF THIS AGREEMENT.

Communication Notices

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Unauthorized changes or modifications could void the user’s authority to

operate the equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Any change or modification to this product voids the user’s authority to operate

it per FCC Part 15 Subpart A Section 15.21 regulations.

This product contains an intentional radiator with the following parameters:

Operating Frequency: 902 to 928 MHz

Typical RF Power: 25 to 100 milliwatts (SL5x04 MP) or 25 to 205 milliwatts

(SL5x04 C1)

Maximum RF Power: 1 Watt under abnormal conditions

Printronix SL5000r and T5000r

Tested To Comply

With FCC Standards

FOR HOME OR OFFICE USE

Canada

This Class B digital apparatus complies with Canadian ICES-003 and RSS 210.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

This device has been designed to operate with the antennas listed below, and

having a maximum gain of –18 dBi. Antennas not included in this list or having a

gain greater than –18 dBi dB are strictly prohibited for use with this device. The

required antenna impedance is 50 ohms.

To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that permitted for successful communication.

CE Notice (European Union)

Marking by the CE symbol indicates compliance of this Printronix system to the

EMC Directive and the Low Voltage Directive of the European Union. Such

marking is indicative that this Printronix system meets the following technical

standards:

EN 300 220-1 (2000), Electromagnetic Compatibility and Radio Spectrum

Matters; Short Range Devices; Radio equipment to be used in the 25 MHz

to 1000 MHz frequency range with power levels ranging up to 500 mW.

EN 55022 —“Limits and Methods of Measurement of Radio Interference

Characteristics of Information Technology Equipment.”

EN 55024 —“Electromagnetic Immunity Requirements for Information

Technology Equipment”

EN 60950 —“Safety of Information Technology Equipment.”

Printronix cannot accept responsibility for any failure to satisfy the protection

requirements resulting from a non-recommended modification of the product,

including the fitting of non-Printronix option cards.

This product has been tested and found to comply with the limits of Class A

Information Technology Equipment according to European standard EN 55022.

The limits for Class A equipment were derived for commercial and industrial

environments to provide reasonable protection against interference with

licensed communication devices.

CE Symbol

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

WARNING

Taiwan

Lithium Battery Warning

The controller board contains a lithium battery sealed inside the real-time clock

chip. Do not disassemble the chip to replace the battery. Do not dispose of the

chip by incineration. Failure to comply may cause the battery to explode.

Contact your local waste agency for the correct disposal procedure.

Printronix makes no representations or warranties of any kind regarding this

material, including, but not limited to, implied warranties of merchantability and

fitness for a particular purpose. Printronix shall not be held responsible for

errors contained herein or any omissions from this material or for any damages,

whether direct, indirect, incidental or consequential, in connection with the

furnishing, distribution, performance or use of this material. The information in

this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part

of this document may be reproduced, copied, translated or incorporated in any

other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix.

COPYRIGHT © 2005, 2012 PRINTRONIX, INC. All rights reserved.

Trademark Acknowledgements

Printronix, LinePrinter Plus, IGP, and PGL are registered trademarks of

Printronix, Inc.

Code V is a trademark of Quality Micro Systems, Inc.

IPDS is a trademark of International Business Machines Corporation.

SL5000r and T5000r are trademarks of Printronix, Inc.

型式 合格 功 電 ,可,司、 或使用者 不得 自 更

、加大功 或 更原 性 功 。

功 電 使用不得 全 干擾合 通 ;現有干擾現 ,

用,並 善 干擾 得 使用。前項合 通 ,指 電 規 作業

電通 。 功 電 須 受合 通 或工業、科學 療用電波輻 性電

干擾。

Printronix Online Data Validator (ODV) Compliance Statement

The Printronix Online Data Validator gathers data per the ISO/ANSI method of

verification to perform practically all the industry standard bar code quality

parameter calculations. These include all ISO/ANSI method parameters, PCS,

ratio, X dimension calculation, modulo check digit calculations, average bar

deviation, etc., along with decoding the symbol.

Reflectance Compliance –660 nm Wavelength (Red) Light

The reflectance values embedded in the calibration symbol supplied with each

ODV are traceable to Applied Image Primary Verification Calibrated Standard

per ANSI X3.182 Step Reflectance Chart (see note 2.) Applied Image certified

Calibration Standards are manufactured to Applied Image, Inc. and Uniform

Code Council, Inc. specifications, using ANSI X3.182-1990 methodology, and

are calibrated using standards traceable to the National Institute of Standards

and Technology (N.I.S.T.)

ISO/ANSI Method Compliance

The Printronix ODV gathers data and performs all ISO/ANSI method parameter

calculations per the ISO/IEC 15416 and ANSI X3.182-1990 methodologies with

a few special considerations and exceptions. The ODV also conforms to

ISO/IEC 15426 per the requirements specified in Section 2. The exceptions and

considerations are related to the instrument’s design and mission. The design

incorporates a proprietary analog laser scanner that can be assembled with

various focus lengths to produce different beam spot sizes. The mission is to

not only analyze bar code quality, but also to detect any printer failures, process

failures or media problems. For maximum performance and to conform to

quality specifications, a fixed mounting distance and angle are required. A

beam spot size able to detect errors of the particular print method is highly

recommended. This beam spot size used may or may not correspond to the

recommendations in various specifications that it be related to the X dimension

of a particular symbol, but instead correspond to the printer’s resolution or

some other parameter(s) critical in the application. A major philosophy of an

on-line verification system is; if the printer and/or process is operating correctly

and the media has proper reflectance properties, the best print quality for that

particular print method and material is achieved by definition.

Special Considerations

1. Final system tests are performed at the proper focus distance and at an

angle of 22 degrees. Units with common focus distances are checked to yield

analysis results within +/- 4 % of all target values except +/- 3% for the Rmin

calculation.

2. The standard ODV has an 8 inch focus distance creating a spot size that

gathers light equivalent to a 6 mil round aperture. For these models, final test

includes analyzing UPC symbols on the Calibrated Conformance Standard

Test Card for EAN/UPC Symbol Verifiers. Results are checked to be within +/-

4% (+/- 3% for Rmin) of the marked values on the test card.

3. All ODV’s use the same laser diode with a wavelength of 660 +/- 10 nm.

Therefore, any ISO/ANSI overall symbol grade calculated by an ODV includes

660 as the wavelength portion of the grade.

Exceptions to the ISO/ANSI Method

1. The Defects calculation does not include the quiet zone area. A separate

quiet zone check is implemented to more easily isolate print problems vs. setup

problems in an on-line environment.

2. A laser spot is used instead of a round aperture. The spot size is dependent

on the focus distance of the unit’s optical system.

11

Table of Contents

1 Installation Instructions ............................................................ 13

Overview........................................................................................................ 13

Safety Notices ............................................................................................... 15

Installation and Removal ............................................................................... 16

Prepare the Printer..................................................................................16

Install the Ferrite ..................................................................................... 17

Install the Validator ................................................................................. 27

Attach the Power/Data Cable.................................................................. 30

Restore the Printer to Operation ................................................................... 32

Enable the Validator ...................................................................................... 32

Adjust the Scanning Beam ............................................................................33

Continuous, Tear-Off, and Tear-Off Strip ...............................................33

Peel-Off Media Handling Mode...............................................................34

Cut Media Handling Mode ......................................................................35

Scanning Beam Vertical Alignment......................................................... 38

Scanning Beam Skew Adjustment..........................................................38

Shifting the Scanning Beam .......................................................................... 39

Calibration...................................................................................................... 40

Bar Code Validation Demo Page ............................................................41

2Operation................................................................................. 43

Basic Validator Setup ....................................................................................43

VALIDATOR Menu.................................................................................. 44

Configuring the Validator ............................................................................... 48

Enabling and Disabling the Validator ...................................................... 48

Validator Reporting ................................................................................. 49

Validator Statistics ..................................................................................51

Defining Validator Options ...................................................................... 52

Advanced Validator Options ...................................................................55

General Process for Barcode Analysis ................................................... 71

Operation .......................................................................................................72

Print Speed Limits ...................................................................................72

On-Demand Printing ............................................................................... 74

Bar Code Failures.......................................................................................... 74

Bad Bar Code Error Detection ................................................................74

Missing Bar Code Error Detection ..........................................................74

Validator Action (Error Action) ................................................................ 75

Error Messages.......................................................................................79

Troubleshooting .............................................................................................85

Maintenance .................................................................................................. 88

AContact Information ................................................................. 89

Printronix Customer Support Center.......................................................89

Printronix Supplies Department ..............................................................90

Corporate Offices.................................................................................... 90

13

Installation Instructions1

Overview

The online data validator (ODV) is an external bar code scanning device attached

above the paper exit of the printer. When activated, it scans the printed output looking

for bar codes. When it finds a bar code, it determines what type of bar code it is and

monitors the bar code quality as it passes through the scan area.

After the entire bar code has passed under the scanning beam, the validator grades the

bar code and sends a report to the printer. How the printer responds is determined by

the validator settings, explained in “Configuring the Validator” on page 48.

Operational Parameters

The design parameters of the validator are as follows:

The validator can track the performance of up to four horizontal bar codes at one

time.

The validator requires a minimum distance of 1/2 inch or 20 times the minimum

element width (x-dimension), whichever is greater, between bar codes.

The validator recognizes the following linear, picket fence bar codes: Codabar, Code

39, Code 93, Code 128, Interleaved 2 of 5, and UPC/EAN.

The validator can also evaluate PDF 417 bar codes. For PDF 417 Limited, the val-

idator works best with security level 5 or higher, using the current default printer

settings for Defects Percentage, Percent Decode, and Decodeability. For lower

security levels, lower the Defects Percentage to 5% to enable checking for bar code

damage.

Stacked, 2D, and vertical (ladder) bar codes are not supported.

Bar codes must have a minimum x-dimension of 10 mil (0.010 inch) to be recognized

by the full width of the scanning beam. The validator can recognize bar x-dimension

as narrow as 6.6 mil (0.0066 inch) for 300 dpi printers, and 10 mil (0.010 inch) for

203 dpi printers. The validator cannot recognize x-dimensions smaller than 6.6 mil

(0.0066 inch) or larger than 40 mil (0.040 inch).

Refer to Table 1 for the minimum x-dimension requirements for each printer size of a

300 dpi printer.

Table 1: Minimum X-Dimension and Beam Width for

a 300 dpi Printer

Printer Size

Beam Width

Minimum X-Dimension

4 inch

4.5 inches

6.6 mil

6 inch

6.5 inches

10 mil

Chapter 1

14

8 inch

8.5 inches

13 mil

Tools and Materials You will Need

SL5000r/T5000r Administrator’s Manual

Static wrist strap*

2.5 mm hex key*

#2 Phillips Screwdriver*

Parts List

3 mm hex key

Validator and mounting screws

Validator bracket, mounting screws, and skew adjustment screw

Extended Media Width Guide*

Cable ties, black

Bar code calibration card

Ferrite*

Cable assembly*

Wire saddle*

Grommet*

ODV Interface PCBA (used for SL/T5000r Energy Star models only)

* Only for a field installation

15

Safety Notices

The validator is a Class 2 laser product. The following notices apply at all times when

the printer is powered on and the validator is active:

WARNING Class 2 laser light. Do not stare into the laser beam or a reflected image of the

laser beam.

WARNING Using controls, making adjustments, or performing procedures other than those

specified herein may result in hazardous radiation exposure.

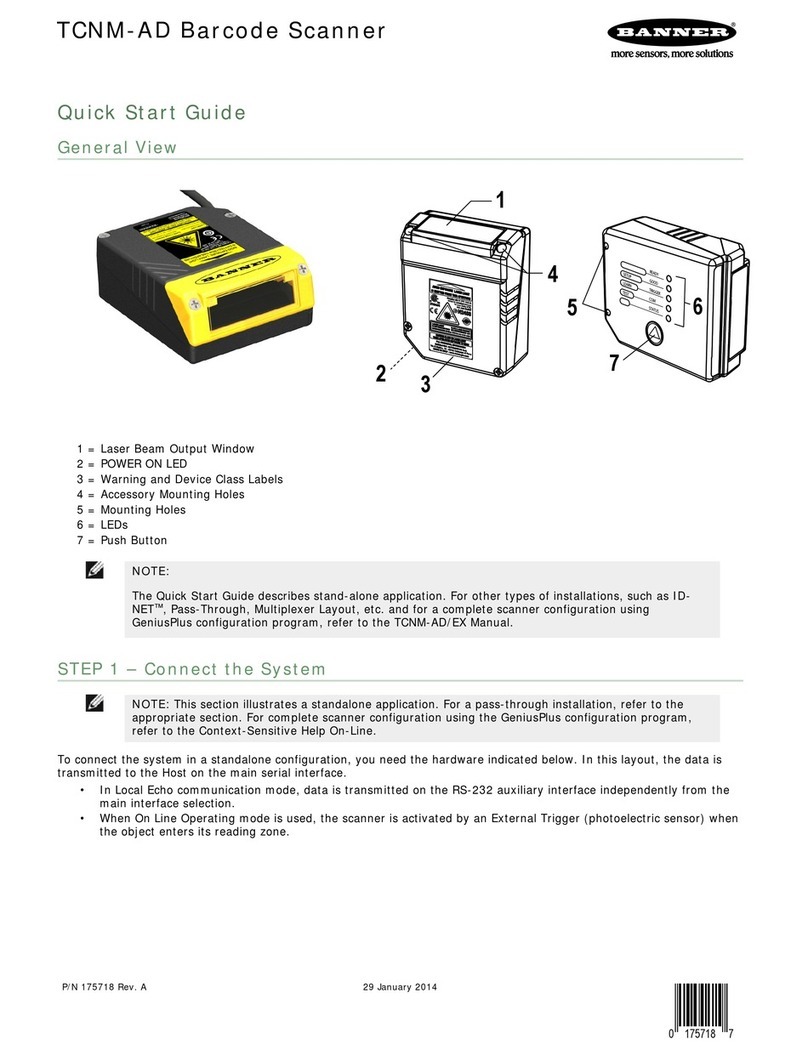

Figure 1. Safety Warnings

Note: This is the

laser exit window.

Chapter 1

16

Installation and Removal

This section describes how to install the validator. To remove the validator, reverse the

steps of this procedure.

Prepare the Printer

1. Set the printer power switch to O (Off).

WARNING Always unplug the printer power cord from the printer or power outlet before

doing any installation procedure. Failure to remove power could result in injury

to you and damage the equipment. You will be instructed when to apply power.

2. Unplug the printer power cord from the printer or the AC power source.

Factory Installation

If your printer has a factory installed validator, the ferrite, cable, wire saddle, grommet,

and extended media width guide have already been installed. Go to “Install the

Validator” on page 27

If you are doing a field installation, you must install the ferrite, cable, wire saddle,

grommet, and extended media width guide. Go to “Install the Ferrite” on page 17.

17

Install the Ferrite

1. Loosen the two captive screws securing the top of the frame side cover. (Figure 2.)

2. Tilt the frame side cover back from the top and lift it until the tabs along the lower

edge disengage from the slots in the printer frame.

Figure 2. Removing the Frame Side Cover

Captive Screw (2)

Frame Side Cover

Chapter 1

18

Figure 3. Locating the Ferrite Position on the Power/Data Cable

3. Stretch the Power/Data cable out straight on a flat surface.

4. Measure back 20.0 ± 0.5 inches from the DB15 connector and mark the cable with a

pencil line. (Figure 3.)

DB15 Connector

19

Figure 4. Routing the Power/Data Cable

CAUTION To prevent electrostatic damage to electronic components, always wear a

properly grounded static wrist strap when you handle circuit boards.

5. Put on a static wrist strap and ground it to an unpainted part of the printer frame.

Touch the frame with the hand wearing the wrist strap.

6. Raise the media cover and remove the plastic plug from the frame opening.

7. Gently press the small wires of the P10 connector end of the power/data cable

against the connector and route the connector through the frame opening. (Figure

4.)

P10 Connector

Frame Opening

Plastic Plug

Chapter 1

20

Figure 5. Wrapping the Power/Data Cable Around the Ferrite

8. Using the P10 connector end of the power/data cable, insert the cable through the

ferrite. (Figure 5.)

9. Wrap the power/data cable around the ferrite twice.

10. Adjust the position of the ferrite so that the length from the ferrite to the DB15

connector is 20 ± 0.5 inches.

Ferrite

Pencil Line

P10 Connector

(to controller board)

Other manuals for SL5000r MP

4

This manual suits for next models

1

Table of contents

Other Printronix Barcode Reader manuals