Pro-Cut B17 User manual

WWW.PROCUTUSA.COM PG /1

QUICK START GUIDE

PG /6800.543.6618

Follow Steps and Scan QR Codes for Corresponding Videos.

B17 SET-UP FOR STANDARD PACKAGE

WWW.PROCUTUSA.COM PG /7

1. Remove packaging from wooden crate containing

50-4400 and remove all items from drawers.

2. Install the mobile cart handle on the right end of the cart.

3. Carefully remove the cart from the pallet

4. Remove wood top and sides of B17 lathe crate, plastic bag,

and extra cardboard.

PG /8800.543.6618

5. Remove 5 bolts holding lathe to pallet. Install 3 lifting eye bolts and attach the 49-4020 lifting chain.

The 2 short lengths attach to the top eye bolts, and the long chain secures to lower eye bolt to keep the

lathe level during lifting.

Insert Lift Eyes (5A / 5B). Add a

rag behind lift chain to pad ways.

5A 5B 5C

WWW.PROCUTUSA.COM PG /9

B17 49-4020 Lift Chain

6. Lift the B17, using a 2 ton engine hoist and 2 people. Before lifting be certain none

of the chains are arranged in a way that will cause damage to the lathe.

PG /10 800.543.6618

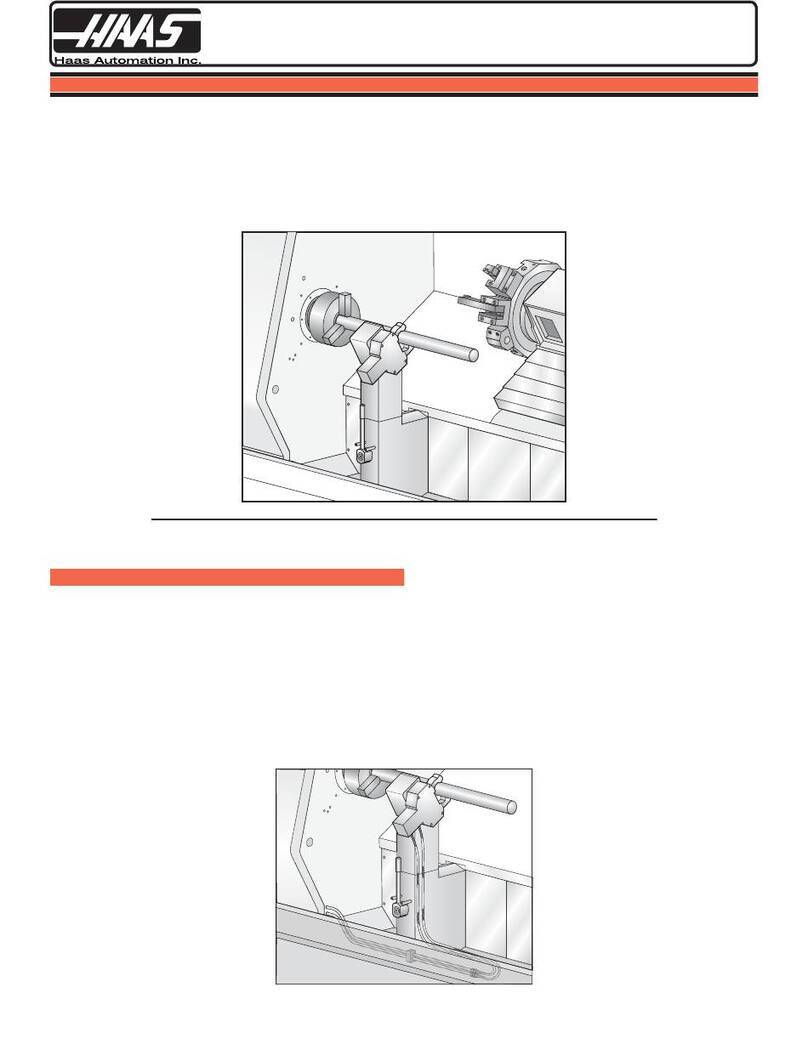

7. Roll the mobile cart under the lift-

ed B17 and line up the bolt holes

on the lathe to the top of the mobile

cart. Lower the lathe slowly until 1/4”

off cart top and start screws by hand.

Land the lathe and tighten screws se-

curely.

WWW.PROCUTUSA.COM PG /11

8. Remove the 3 screws w/washers already installed on the top center of the lathe body. Install command module with

the 3 screws. Find the 2 connectors for rear of command and carefully plug them into their corresponding port on the

back of the command module. Be certain to use foam gasket provided with multi-pin connector.

Installing 3 Screws Connecting Command Module

*WARNING: DO NOT PLUG IN COMMAND MODULE CONNECTORS WHEN AC POWER IS PLUGGED IN.

PG /12 800.543.6618

10. Remove 4 bolts that attach draw bar nut end cover (5mm hex)

9. Find and install the handles for the disc and drum axis cranks.

Installing Crank Handles (9) Removing 4 x 5mm Bolts (10)

WWW.PROCUTUSA.COM PG /13

11. Check both disc and drum axis ways for any looseness by trying to wiggle each of the gear boxes side to

side and up and down. Adjust gib ways as necessary to achieve a snug gib with smooth action when either

crank handle is turned.

Checking disk and drum axis for looseness Adjusting the Gib ways

PG /14 800.543.6618

11. (Continued) Oil the ways with 50-376 way oil provided.

Apply 50-376 Way Oil accordingly

WWW.PROCUTUSA.COM PG /15

12. Carefully remove arbor and drawbar from the packaging. Using a clean cloth, wipe the tapered end of

the arbor and the receiver hole on the lathe, and inspect for any burrs or shipping damage. Use Scotch-

Brite to clean the tapered end if needed.

13. Screw the drawbar into the end of the arbor until it is tight. Carefully send the drawbar

through the lathe until the threaded section of the drawbar protrudes through the other end of

the lathe and the tapered end is fully landed. If there is a match mark, be certain to reference

that point.

PG /16 800.543.6618

14. Use an open end wrench on the flats at the end of the spindle to hold the spindle from moving.

Then use a torque wrench and torque the 36-4005 drawbar nut to 30 lb-ft.

WWW.PROCUTUSA.COM PG /17

16. Once the arbor LRO is correct, reposition your dial indicator tip to the arbor base. Spin the

spindle on slow speed and observe reading. There should be .0005” or less at the arbor base. If

run-out is excessive, clean base face with Scotch-Brite or fine sandpaper until .0005” or less is

achieved. Contact Pro-Cut’s service dept if you are unable to reduce LRO to within specification:

1-800-543-6618 ext. 2

15. Use a roller tip dial indicator to measure the lateral motion of the arbor as close to threads of arbor as is

possible. The roller tip should be perpendicular to the arbor shaft and centered. If the lateral run-out (LRO)

is above .001”, loosen drawbar nut and change arbor position until desired run-out is achieved and re-torque

to 30 lb- ft.

15 16

PG /18 800.543.6618

17. Install the 50-4745 chip guard by first screwing in threaded insert into hole to the left of the command

module. Then screw plastic base piece down with bolt. Click the plastic joints together to mount the chip

guard to the base

WWW.PROCUTUSA.COM PG /19

18. Install chip tray brackets using 4 bolts provided and set chip tray in between the brackets.

PG /20 800.543.6618

20. Perform pre-test: Power up the lathe and check that all functions are working on the command module.

While doing that record DRO readings, and be certain the maintenance alert is set to the customer’s pref-

erence. Check that the arbor light is working properly when Quick-Pivot plate is switched between rotor and

drum modes.

19. Open the rest of the loose parts and arrange in drawers - accessories in top drawer, black adapters in

foam in middle drawer, and Quick-Chucks or other accessories in bottom drawer

Other manuals for B17

1