ES0381 rev P 01/08 2

OPERATION

Use the steady rest manufacturer’s operation manual for additional steady rest alignment instructions.

Notes for proper operation:

Do not exceed the recommended maximum pressure for the steady rest.

Check all bolts that secure the steady rest to the platform. Ensure they are torqued properly.

1/2 -13 110 ft-lb. 5/8-11 180 ft-lb.

Keep your hands, loose clothing, tools, etc. away from the steady rest as it closes.

The workpiece must have a smooth, concentric diameter in order to clamp it properly. Do not put rough

material in the steady rest jaws.

Warning

If using the tailstock be aware of the current position of the steady rest

platform, a collision could occur.

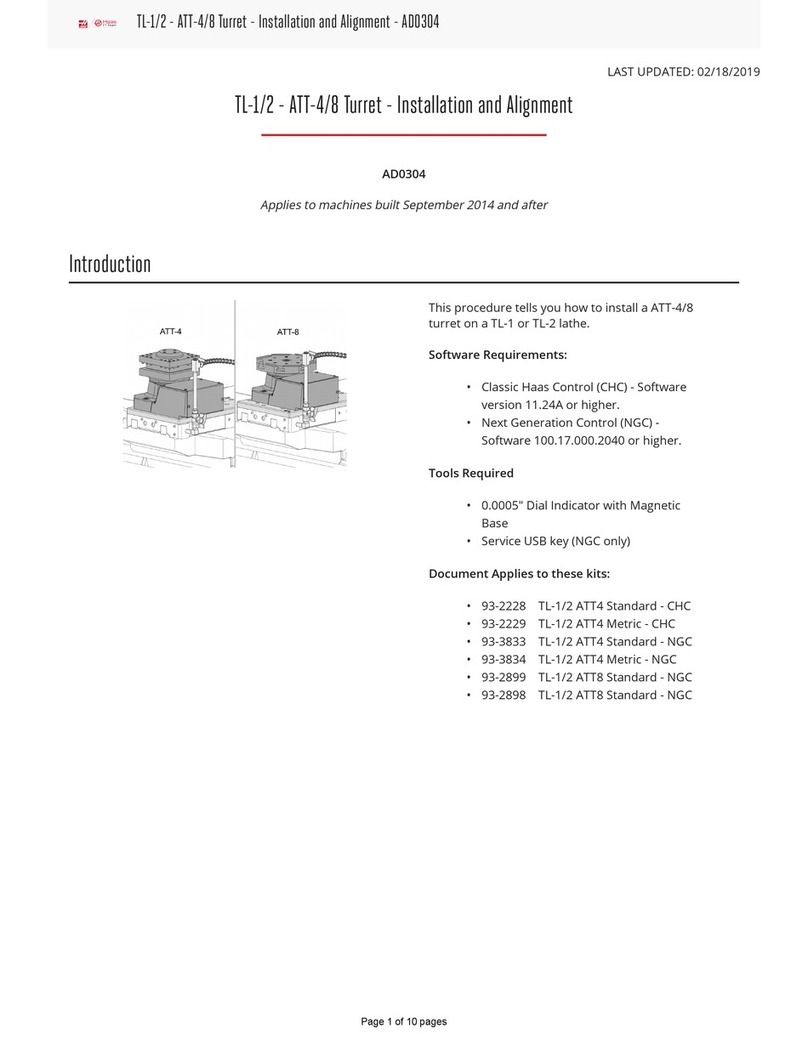

Types of Rollers

Different rollers can be used in the steady rest unit. There are two types of rollers, crowned and straight.

Straight rollers are used on standard cylindrical parts and crowned rollers are used on tapered work pieces.

SETTING UPTHE STEADY REST WITHOUT ATAILSTOCK

Mount the steady rest on the platform and snug the mounting bolts. Clamp the workpiece in the chuck and the

steady rest.

NOTE: The hydraulic pressure to the steady rest is adjusted using the pressure regulator

on the left side of the lathe.

Place a dial indicator on the turret and position the tip on the diameter of the part. Rotate the work piece by

hand and check for deflection of the part, deflection should not exceed .001”.

NOTE: Check the pressure to the steady rest. Incorrect pressure routed to the head can

cause deflection in the part.

Correct any deflection and tighten the steady rest mounting bolts.

Open and close the steady rest and check for deflection again.

NOTE: If the pressure to the steady rest unit is changed, the previous steps should be

repeated to verify the part is turning true.

Part accuracy will suffer if the steady rest head is not aligned properly. The misalignment will cause the mate-

rial to not turn true and can lead to the part being thrown from the chuck.

PROGRAMMING

M Codes

M Codes are used to automatically open and close the steady rest.

M59 P1155 to clamp

M69 P1155 to unclamp

NOTE: If the M code commanded is the reverse of what is described, the hydraulic lines

are installed incorrectly. Swap the positions of the hydraulic hoses at the steady

rest head.