Pro-Cut KSDS-12 User manual

DELI MEAT SLICER

OWNER´S MANUAL

OPERATION INSTRUCTIONS MODELS

KSDS-12

READ THIS MANUAL BEFORE USING THE EQUIPMENT FOR THE FIRST TIME. 507133-0

KSDS-12

INSTRUCTIONS FOR OPERATION, SERVICE AND MAINTENANCE OF THIS EQUIPMENT

1

CONTENTS: PAGE

I. INTRODUCTION 2

II. UNPACKING 3

III. INSTALLATION 4

IV. OPERATION 5

V. KEY ELEMENTS IN CUTTING QUALITY PRODUCT 6

VI. CLEANING 6

VII. MAINTENANCE 7

VIII. EQUIPMENT SPECIFICATIONS 9

IX. ELECTRICAL DIAGRAM 9

X. PARTS LIST KMS-13 10

DELI MEAT SLICER

2

DELI MEAT SLICER

I.INTRODUCTION:

CONGRATULATIONS! YOU HAVE ACQUIRED A PRO-CUT SLICER WHICH IS MADE OF HIGH QUALITY LONG LASTING

MATERIALS THAT SHOULD GIVE YOU YEARS OF TROUBLE-FREE OPERATION AND SERVICE. THIS SLICER IS MADE OF

ANODIZED ALUMINIUM PARTS, THAT MAXIMIZES THE APPEARENCE AND IT IS ALSO THE BEST FOR THE CONTACT

WITH FOOD PRODUCTS.

BEFORE YOU UNPACK YOUR NEW PRO-CUT SLICER, IT IS OF VITAL IMPORTANCE THAT YOU AND ANY PERSON THAT

WILL OPERATE THIS UNIT READ THOROUGHLY THIS MANUAL.

WARNING!:

THIS MACHINE IS DESIGNED TO CUT FOOD PRODUCTS AND IS BY NATURE

DANGEROUS IF IT IS NOT USED AND MAINTAINED PROPERLY AND CAUTIOUSLY

FOR SAFETY.

DO NOT ALLOW UNTRAINED OR UNQUALIFIED PERSONNEL OR CHILDREN TO OPERATE THIS

EQUIPMENT.

NEVER PERFORM SERVICE, CLEANING OR MAINTENANCE ON THIS UNIT WHILE IT IS CONNECTED TO

APOWER SOURCE.

NEVER USE HANDS OR FINGERS TO FEED PRODUCTS TO CUT; DO NOT PLACE FINGERS OR HANDS

WITHIN 4" (FOUR INCHES), OF THE BLADE, WHILE IN OPERATION.

THE MOST DANGEROUS COMPONENT OF THIS EQUIPMENT IS THE BLADE; ALWAYS EXERCISE

EXTREME CAUTION WHILE CLEANING OR SERVICING AND USE CUT RESISTANT STEEL OR PLASTIC

GLOVES FOR CLEANING OR SERVICING.

DO NOT LEAVE THE MACHINE UNATTENDED WHILE IN OPERATION.

THIS EQUIPMENT MUST BE CONNECTED TO A THERMALLY PROTECTED OUTLET.

KSDS-12

3

II.-UNPACKING:

*WHILE UNPACKING THE MACHINE TAKE SPECIAL CARE IN REMOVING THESE COMPONENTS AND MAKE SURE THAT

ALL THEM ARE ACCOUNTED FOR.

1 BASE UNIT (14) INCLUDING KNIFE(5), MOTOR(16), THICKNESS GAUGE PLATE(1), KNIFE GUARD(7)*.

1 SHARPENER BOX(6) AND CARRIAGE SUPPORT KNOB (11)*.

1. CARRIAGE ASSEMBLY INCLUDING CARRIAGE SUPPORT(12), CARRIAGE(2), CARRIAGE HANDLE(13) AND GRIP(3)*.

* NOTE: FOR NUMERIC REFERENCE SEE FIG. 4

A.-REMOVE THE CARTON CARD BOARD PROTECTORS.

B.-TAKE OUT THE CARRIAGE ASSEMBLY.

C.-DEFINE THE PLACE TO SET THE MACHINE.

D.-TAKE OUT THE MACHINE BY LIFTING FROM THE BASE(14), (EXERCISE PROPER LIFTING METHOD, PREFERABLY DO

THIS PROCEDURE WITH TWO PERSONS).

E.-ONCE THE UNIT IS FIRMLY ON THE INTENDED PLACE OF OPERATION, REMOVE THE FOAM PROTECTOR FROM THE

KNIFE SHARPENER BOX(6).

F.-REMOVE THE ORANGE (OR BLACK) KNIFE EDGE PROTECTOR; TO DO THIS:

ROTATE THE SLICE ADJUSTING KNOB(15) COUNTER CLOCKWISE UNTIL IT STOPS.

REMOVE THE KNIFE GUARD PLATE(7) BY LOOSING THE KNIFE GUARD KNOB (NOT SHOWN) ALL ITS TRAVEL.

EXERCISE EXTREME CAUTION TO REMOVE THE KNIFE EDGE PROTECTOR BY FINDING THE PROTECTOR JOINT AND

REMOVING THE PROTECTOR BY LIFTING IT FROM THE KNIFE. (ALWAYS WEAR HAND AND FINGER PROTECTION FOR

THIS OPERATION).

ONCE THE KNIFE EDGE PROTECTOR IS REMOVED, REPLACE THE KNIFE GUARD PLATE(7) AND ASSURE IT WITH THE

KNIFE GUARD KNOB (NOT SHOWED). CLOSE THE THICKNESS GAGE PLATE(1) BY ROTATING THE SLICE ADJUSTING

KNOB(15) CLOCKWISE FULLY.

DELI MEAT SLICER

WARNING!:

TAKE SPECIAL CARE WHEN YOU TAKE APART THE KNIFE PROTECTOR,

THE KNIFE IS ALREADY SHARP FROM THE FACTORY AND WITHOUT

PROTECTOR SERIOUS INJURY MAY HAPPEN.

KSDS-12

4

III.-INSTALLATION:

BEFORE CONNECTING TO THE POWER SOURCE FOLLOW THIS EASY ASSEMBLY AND PREPARATION

STEPS. (NEVER EXECUTE THESE PROCEDURES WITH THE CORD PLUGGED TO THE POWER SOURCE).

1.-SET THE SLICER ON A CLEAN AND LEVEL PLACE.

2.-USE THE SUPPORT FOOT RUBBERS (9) TO LEVEL THE SLICER. TURN THESE FEET TO DO THIS.

3.-ROTATE THE THICKNESS CONTROL KNOB (6) TO BE SURE THAT IT WORKS FREELY ALL THE WAY THROUGH AND

CHECK IF THE THICKNESS TABLE OPENS AND CLOSES SIMULTANEOUSLY.

NOTE: CHECK THE POWER REQUIREMENTS OF THE UNIT: 110 VOLTS, 60 HZ. AND GROUNDED. ANY PROBLEM,

PLEASE CONTACT YOUR PRO-CUT DEALER.

4.-CONNECT THE SLICER TO THE POWER SOURCE. THE POWER OUTLET SHOULD BE CLOSE ENOUGH TO THE

MACHINE TO PROVIDE EASE OF DISCONNECTION FOR CLEANING AND SERVICE.

DELI MEAT SLICER

WARNING!:

NEVER OPERATE THE MACHINE WITHOUT PROPER TRAINING

SERIOUS INJURY MAY HAPPEN.

KSDS-12

5

IV.-OPERATION:

IMPORTANT: FOR THE FIRST TIME USAGE, YOU MUST CLEAN THE MACHINE AND ALSO CUT A COUPLE OF SLICES OF

SCRAP PRODUCT (YOU CAN USE CARROTS, POTATOES ETC.) TO BE SURE THAT THE KNIFE IS CLEAN BEFORE

CUTTING EDIBLE PRODUCT.

NORMAL OPERATION OF THE SLICER:

1.-PLACE THE PRODUCT TO BE CUT ON THE CARRIAGE (2).

2.-UNLOCK THE GRIP(3) FROM UNDER THE CARRIAGE (2), MOVE IT TO THE TOP OF THE SLIDE ROD, DO NOT FORCE

THIS OPERATION, THEN ROTATE THE GRIP(3) COUNTER CLOCKWISE TO ITS POSITION OVER THE PRODUCT.

3.-PUSH THE GRIP(3) BY THE GRIP KNOB(4) ALL THE WAY DOWN ON THE PRODUCT. TO SLIDE THE CARRIAGE BACK

AND FORTH USE THE CARRIAGE HANDLE(13) OR THE GRIP KNOB(4).

4.- MOVE THE CARRIAGE ASSEMBLY ALL THE WAY BACK AND SELECT THE THICKNESS USING THE SLICE ADJUSTING

KNOB(15).

5.-TURN ON THE MACHINE USING THE ROCKER SWITCH (NOT SHOWN), THE PILOT SAFETY LIGHT SWITCH GIVES

WARNING THAT THE SLICER IS RUNNING.

6.-NOW YOU CAN START TO SLICE THE PRODUCT; THIS MACHINE HAS BEEN DESIGNED WITH A 45 ANGLE SO THAT

MINIMUM EFFORT IS REQUIRED TO PUSH THE PRODUCT THROUGH THE CUT; FOR BEST RESULTS, KEEP KNIFE(5)

SHARP.

7.-WHEN SLICER CUTS ARE FINISHED, ALWAYS TURN THE MACHINE OFF BY USING THE SWITCH(NOT SHOWN) AND

TURN THE SLICE ADJUSTING KNOB(15) CLOCKWISE AS FAR AS IT WILL GO (BE SURE THAT THE THICKNESS GAUGE

PLATE(1) COVERS THE EDGE OF THE KNIFE(5) TO PREVENT ANY POSSIBLE ACCIDENT).

8.-REPLACE THE GRIP(3) TO ITS STOWED POSITION UNDER THE CARRIAGE(2), FOLLOWING THE

REVERSE ORDER IN POINT 2.

NOTE: TO SLICE OTHER PRODUCT JUST FOLLOW ALL THE PREVIOUS STEPS

9.-IN CASE THAT THE USAGE OF THE SLICER IS MORE THAN 2 HOURS CONTINUOUSLY THE MOTOR CAN BE

PROTECTED BY ITSELF BECAUSE OF THERMAL PROTECTION, THEREFORE, LET THE MOTOR BE COLD (20 MIN

APROX.) AND START AGAIN THE SLICER PRESSING THE GREEN START BUTTON.

DELI MEAT SLICER

WARNING!:

NEVER LEAVE THE MACHINE UNATTENDED WHILE IN OPERATION

SERIOUS INJURY MAY HAPPEN.

KSDS-12

6

V.-KEY ELEMENTS IN SLICING QUALITY PRODUCT:

1.-DO NOT FORCE THE CUT AGAINST THE KNIFE(5).

2.-KEEP KNIFE(5) EDGE SHARP TO ASSURE EASE OF CUTTING AND ENHANCE PRODUCT APPEARANCE.

NOTE: THE RE-SHARPENING PROCEDURE STEPS ARE SHOWN IN SECTION VI MAINTENANCE.

3.-KEEP THE THICKNESS GAUGE PLATE(1), THE CARRIAGE (2), THE KNIFE(5) FREE OF SCRAPS AND DEBRIS.

NOTE: NEVER ATTEMPT ANY CLEANING WHILE THE MACHINE IS CONNECTED TO THE POWER SOURCE.

VI.-CLEANING:

NOTE: IT IS RECOMMENDED TO CLEAN THE MACHINE DAILY, WITH A SOFT DAMP CLOTH, AND A SOFT BRUSH WITH

APPROVED MILD DETERGENT AND WATER DO NOT CLEAN THE MACHINE WITH A WATER HOSE. DO NOT SUBMERGE

THE UNIT IN WATER OR OTHER LIQUIDS.

FOR DAILY CLEANING YOU MUST CLEAN ALL THE COMPONENTS MENTIONED ON POINT 3 SECTION IV. FOR A MORE

THOROUGH CLEANING FOLLOW THESE EASY STEPS.

1.- LEVEL THE THICKNESS GAUGE PLATE(1) WITH THE KNIFE(5) USING THE SLICE ADJUSTING KNOB(15).

2.-PLACE THE GRIP (3) IN ITS STOWED POSITION UNDER THE CARRIAGE (2).

3.-WITHDRAW THE CARRIAGE ASSEMBLY FROM ITS SUPPORT BY REMOVING THE CARRIAGE KNOB(11).

4.-REMOVE THE SHARPENER BOX(8) BY LOOSENING THE SHARPENER LOCK KNOB (C) AND PULL THE

ASSY UP.

NOTE: FOR CLEANING THE INSIDE OF THE SHARPENNER USE A SMALL SOFT BRUSH AND A SOFT DAMP CLOTH, DO

NOT USE WATER HOSE. (FIG. 1)

DELI MEAT SLICER

WARNING!:

ALWAYS UNPLUG OR DISCONNECT THE MACHINE FROM

THE POWER SOURCE BEFORE CLEANING OR SERVICING

KSDS-12

7

DELI MEAT SLICER

WARNING!:

ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE

BEFORE EXECUTING ANY SERVICING OR MAINTENANCE.

5.-YOU MAY ALSO REMOVE THE KNIFE GUARD PLATE(7) FOR DEEPER CLEANER BUT, BE EXTREMELY CAREFUL,

WHEN THE KNIFE EDGE IS PARTIALLY EXPOSED OR TOTALLY EXPOSED BECAUSE IT IS EXTREMELY DANGEROUS.

6.-AFTER THESE STEPS YOU CAN GIVE A DEEPER CLEANING TO ALL COMPONENTS; AFTER CLEANING

REASSEMBLE IN REVERSE ORDER.

VII.-MAINTENANCE:

1.-SLIDE RODS: YOU MUST LUBRICATE THE SLICER WITH LIGHT OIL AT LEAST EVERY 100 HOURS OR 30 DAYS OF

SERVICE. THE POINTS TO LUBRICATE ARE UPPER AND BOTTOM SIDES OF SLIDDING RODS (9).

2.-KNIFE: AFTER MANY HOURS YOU WILL NEED TO RE-SHARPEN THE KNIFE(5), THE STEPS AS ARE FOLLOWS:

A.-BE SURE THE MACHINE IS OFF.

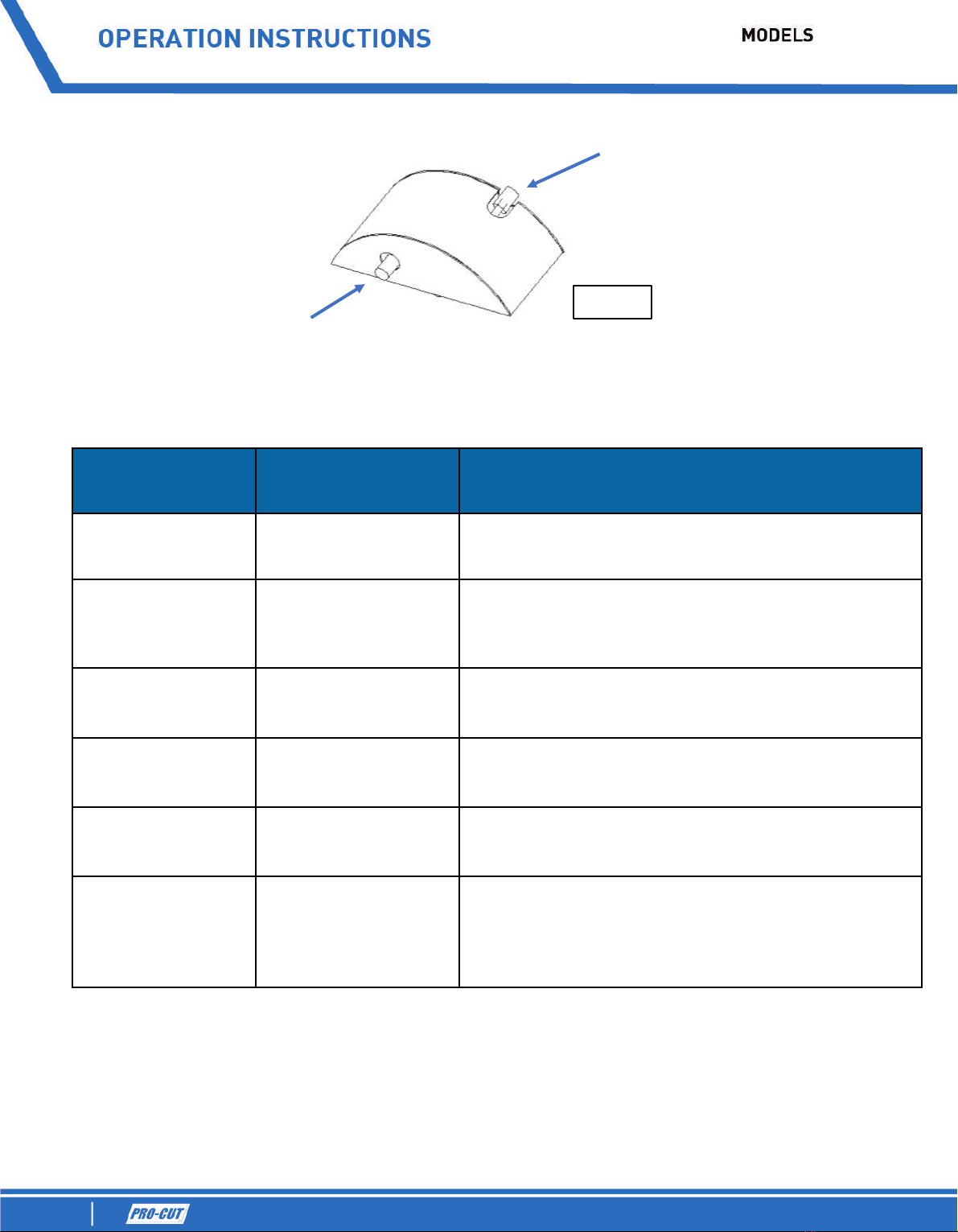

B.-LOOSEN THE SHARPENER LOCK KNOB (K; SEE FIG. 2) UNDER THE SHARPENING ASSEMBLY, UNTIL IT SPRINGS

UP.

C.-LIFT THE SHARPENER ASSEMBLY AND ROTATE IT 180, REASSEMBLE AND SECURE IT. VERIFY THAT THE STONES

ARE ON EACH SIDE OF THE KNIFE ( APROX. 1/4" UNDER THE EDGE ), THEN TIGHTEN THE KNOB(K; SEE FIG. 2)

AGAIN.

D.-TURN ON THE MACHINE, AND PUSH THE ROD " A " ON FIG 3, LET THE STONE GRIND THE UNDER SIDE OF THE

KNIFE FOR A FEW SECONDS. THIS WILL SHARPEN THE EDGE AND CREATE A SLIGHT BURR ON THE TOP SIDE OF

THE EDGE. WHEN YOU RELEASE THE ROD "A" IT WILL RETURN AUTOMATICALLY.

E.-THEN REMOVE THE BURR FROM THE TOP SIDE OF THE KNIFE BY PULLING DOWN ROD "B" FIG 3. ONLY A VERY

SLIGHT PRESSURE IS NEEDED TO HOME THE EDGE. TOO MUCH PRESSURE AND TIME CAN CREATE A REVERSE

ANGLE AND DESTROY KNIFE EDGE. ROD "B" WILL RETURN AUTOMATICALLY WHEN RELEASED.

F .- REPLACE THE SHARPENER ASSEMBLY BY FOLLOWING THE REVERSE ORDER.

IMPORTANT: THE TIME SPENT IN GRINDING AND TRUING THE KNIFE EDGE WILL ADD TO LONGEVITY OF THE KNIFE

AND PROVIDE OPTIMUM EFFICIENCY OF YOUR PRO-CUT SLICER. REPEAT STEPS “D” AND “E” IF IT IS NECESSARY.

KSDS-12

K

8

THIS SLICER HAS SOME PARTS THAT MAY WEAR DOWN. TAKE CARE OF CHECK (AND REPLACE IF NECESSARY)

THE FOLLOWING PARTS:

DELI MEAT SLICER KSDS-12

ROD “A”

ROD “B”

FIG. 3

PARTS CHEKING FREQUENCY

VERIFICATION

COMMENTS

BAND ONCE A MONTH

IF YOU SEE ANY PRODUCT TO YOUR SLICING BLADE STOPS.

TENSION TO GIVE THE BAND FOR A BETTER GRIP ROTATION

BETWEEN PULLEYS.

BEARING DAILY

DO DAILY CLEAN BEARING AREA TO PREVENT BUILDUP OF

FLUIDS AND WASTES.ALSO OIL (FOOD GRADE GREASE) THIS

AREA FOR THE PURPOSE OF EXTENDING THE LIFE OF

BEARING.

MEMBRANE (ON-OFF) DAILY

REQUIRED IMMEDIATELY CHANGE SWITCH MEMBRANE BREAK

IF FAILURE TO PREVENT POST ON OR OFF THE INTRODUCTION

OF MOISTURE OR OTHER WASTE.

MOVING

TRUCK (BARS

MEDIA)

ONCE A WEEK

KEEP FREE OF WASTE (POWDER, FOOD, ETC.) BARS ALSO

KEEP MOVING THIN OIL LUBRICATED, DO NOT USE OIL OR FAT

THICK AS IT AFFECTS THE MOVEMENT.

KNIFE ONCE A WEEK

SHARPENING BLADE HEAVY CUT IF YOU NOTICE, OR IF YOU

NOTICE WHEN EXCESS SCRAP SLICING. (CUT TO BE GENTLE,

EASY CLEAN).

SHARPENING

STONES

AND

SEATED

DAILY

IT IS RECOMMENDED THAT THE STONES ARE KEPT COVERED

OR PROTECTED FROM WASTE TO EXTEND THE LIFE OF

THESE. MAKE SURE BEFORE THE BLADE SHARPENING IS FREE

TO PREVENT WASTE

CLOGGED PORES OF STONES.

9

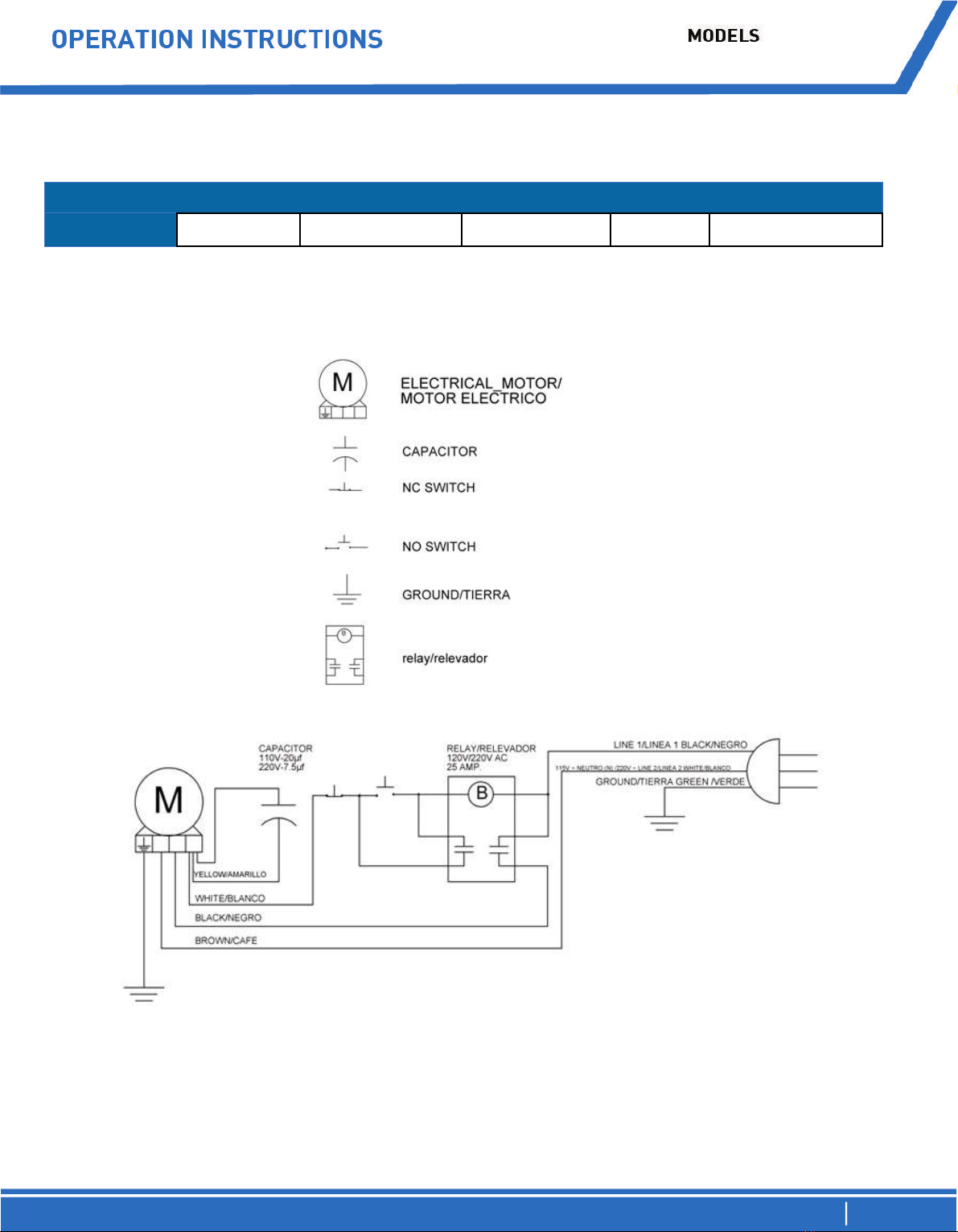

VIII.-ELECTRICAL SPECIFICATIONS KSDS-12:

DELI MEAT SLICER

MODEL VOLTAGE FRECUENCY CURRENT PHASES MOTOR POWER

KSDS-12 115 V~ 60 HZ 3,7 A 1 Ø248 W 1/3 (HP)

KSDS-12

IX.-ELECTRICAL DIAGRAM KSDS-12

*ELECTRICAL DIAGRAM VALID ONLY FOR KSDS-12 MODEL.

10

DELI MEAT SLICER

X.-PARTS LIST

KSDS-12

ITEM DESCIPCION CANTIDAD

1

THICKNESS GAGE PLATE

1

2

CARRIAGE

1

3

GRIP

1

4

GRIP KNOB

1

5

SLICER KNIFE

1

6

SHARPENER BOX

1

7

KNIFE GUARD PLATE

1

8

RUBBER FOOT

4

9

ROUND SLIDING ROD

1

10

CARRIAGE BEARING

1

11

CARRIAGE SUPPORT KNOB

1

12

CARRIAGE SUPPORT

1

13

CARRIAGE HANDLE

1

14

SLICER BASE FRAME

1

15

SLICE ADJUSTING KNOB

1

16

MOTOR 1/3HP SINGLE PHASE (NOT SHOWN)

1

17

HOOKS

2

4

THANKS FOR READING THIS MANUAL. IF YOU HAVE ANY DOUBT REGARDING

THE OPERATION OF THIS MEAT SAW, PLEASE CONTACT TO YOUR PRO CUT

AUTHORIZED DEALER.

Other manuals for KSDS-12

1

Table of contents

Other Pro-Cut Kitchen Appliance manuals