E-DC Drive

Quick Reference Guide

Motor Performance S

Input/Output Specification

Compumotor Division

Parker Hannifin Corporation

p/n 88-020592-01 A (effective May 22, 2002)

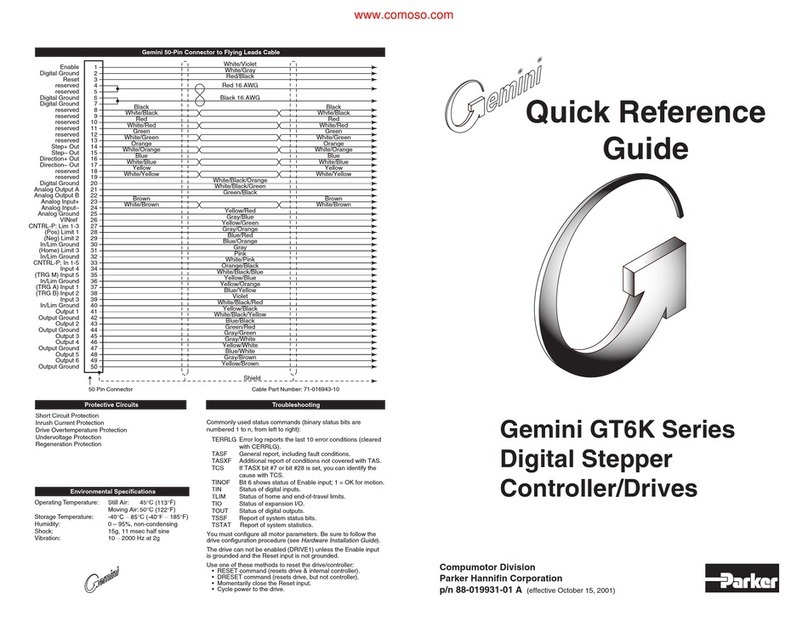

INP

s

maximum input frequency: 2MHz

minimum turn on current: 6.5mA

DIRECTION:

minimum setup time: 200 microseconds

minimum turn on current: 8mA

REMOTE:

minimum turn on current: 3.5mA

When in

ut is activated, drive reduces motor current

by ratio set by Rremote

a resistor connected between

REMOTE and CURRENT, as follows:

Rremote = 13,300 (3750 + Rc)/(Rc- Rs), where

Rc= resistor asociated with operating current

Rs= resistor asociated with desired standby current

NOTE: for zero current

GEAR SHIFT:

minimum turn on current: 3.5mA

When in

ut is activated, the drive multi

lies each

step pulse it receives by a factor of 8.

FAULT OUTPUT

Opticall

isolated; open collector/emitter output

active (output turns off on a fault condition)

To clear fault: cycle power.

maximum collector current: 10mA

Accurac

ht:

SERIES

Hardware Installation Guide

available at: www.compumotor.com

E-DC Hardware Installation Guide

is available online in PDF format:

http://www.compumotor.com

(part number 88-020714-01)

3.555 (90.30)

3.315 (84.20)

5.000 (127.00)

4.650 (118.11) 0.175 (4.45)

1.000 (25.40)

7.000 (177.80)

Mounting Clearance

2x 0.177

Clearance for #8

(M4) Mountin

1.000 (25.40)

Compumotor

5500 Business Park Dr.

Rohnert Park, CA 94928

Exposed aluminum for

electrical grounding

This surface must be thermall

REMOTE

REF

CURRENT

DUMP

VDC+

VDC-

A+

A-

B+

B-

PWR/FLT

!

SERIES

K

4.49 825 1.33 2.80 K

4.43 1.02 K 1.27 3.57 K

4.37 1.27 K 1.20 4.53 K

4.30 1.54 K 1.14 5.49 K

4.24 1.78 K 1.08 6.49 K

4.18 2.05 K 1.01 7.68 K

4.11 2.26 K 0.95 8.87 K

4.05 2.55 K 0.89 10.5 K

3.99 2.80 K 0.82 12.1 K

3.92 3.09 K 0.76 13.7 K

3.86 3.32 K 0.70 15.8 K

3.80 3.57 K 0.63 18.2 K

3.73 3.92 K 0.57 20.5 K

3.67 4.22 K 0.51 22.6 K

3.61 4.53 K

3.54 4.87 K

3.48 5.11 K

3.42 5.49 K

3.35 5.76 K SW3-#7 Off/#8 On

3.29 6.19 K Current Resistor

3.23 6.49 K (amps*) (ohms)

3.17 6.81 K 1.27 0

3.10 7.32 K 1.20 787

3.04 7.68 K 1.14 1.62 K

2.98 8.06 K 1.08 2.49 K

2.91 8.45 K 1.01 3.57 K

2.85 8.87 K 0.95 4.64 K

2.79 9.53 K 0.89 5.90 K

2.72 10.0 K 0.82 7.32 K

2.66 10.5 K 0.76 8.87 K

2.60 11.0 K 0.70 10.7 K

2.53 11.5 K 0.63 13.0 K

2.47 12.1 K 0.57 15.4 K

2.41 12.7 K 0.51 18.2 K

2.34 13.3 K 0.44 21.5 K

2.28 13.7 K

2.22 14.3 K

2.15 15.0 K

2.09 15.8 K SW3-#7 On/#8 On

2.03 16.5 K Current Resistor

1.96 17.4 K (amps*) (ohms)

1.90 18.2 K 0.50 0

1.84 19.1 K 0.38 2.21 K

1.77 20.0 K 0.32 5.36 K

1.71 20.5 K 0.25 10.0 K

1.65 21.5 K 0.19 16.2 K

1.58 22.6 K 0.13 27.4 K

SW3-#7 Off/#8 Off

(amps*) (ohms) Motor

3.0 S** 7.68 K OS2HA

4.8 S** 0 OS21A, 22A

VS12B