Page 2

Pro2V080

Drivecon reserves the right to alter or amend the above information without notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

CONTENTS

1GENERAL.......................................................................................................................4

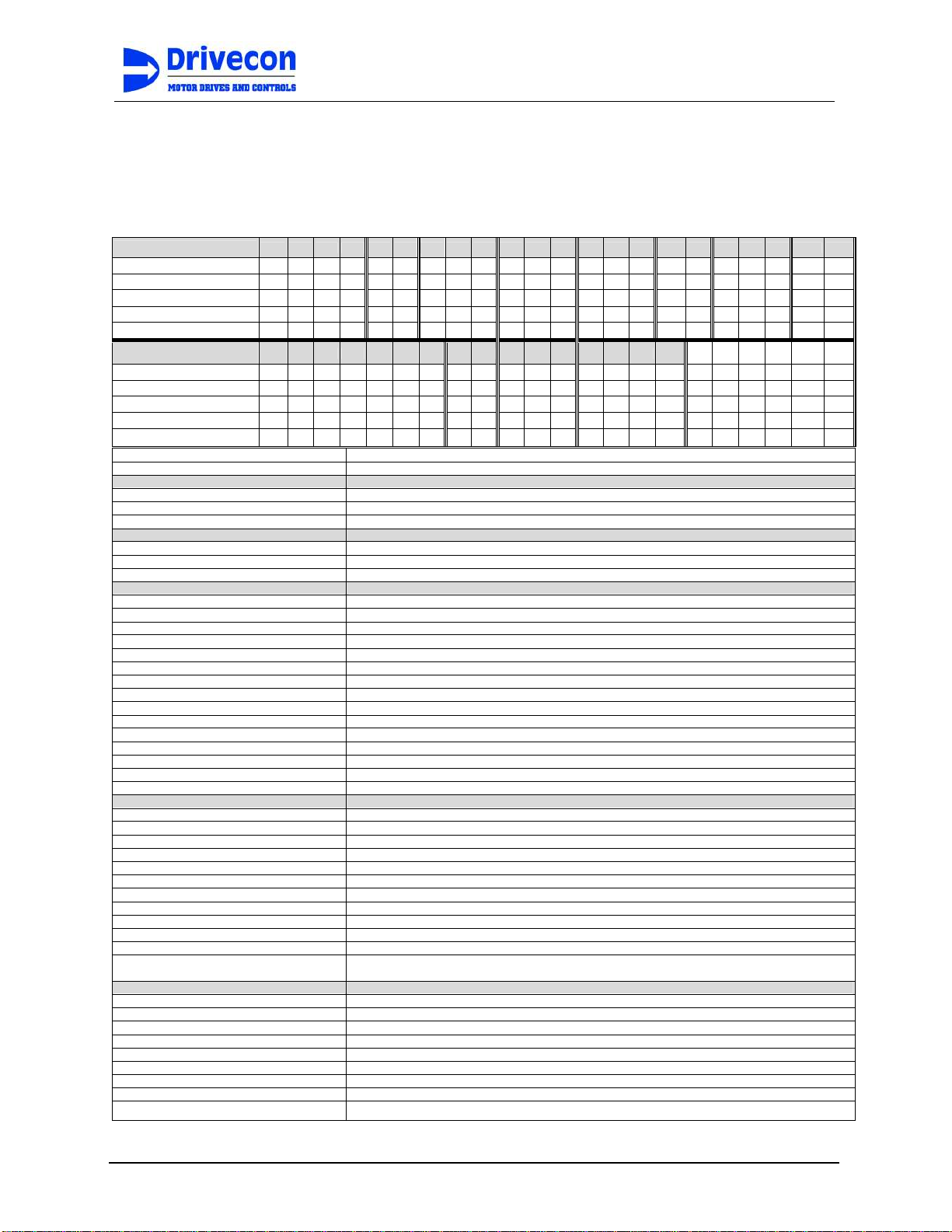

1.1 Technical data ......................................................................................................4

1.2 Type mark coding..................................................................................................5

1.3 Basic description...................................................................................................6

1.4 Functional description............................................................................................7

1.5 Control methods....................................................................................................8

1.6 Mechanical brake control.....................................................................................10

1.7 Motor control modes............................................................................................10

1.8 EMC................................................................................................................... 11

1.8.1 Fulfilled EMC-standards............................................................................ 12

2INSTALLATION.............................................................................................................13

2.1 Cooling............................................................................................................... 13

2.2 Power cabling ..................................................................................................... 13

2.3 Control wiring...................................................................................................... 15

2.4 EMC compatible grounding ..................................................................................16

3START-UP PROCEDURE .............................................................................................. 17

3.1 Visual checks...................................................................................................... 17

3.2 Checks before the first test run ............................................................................17

3.3 Test run without load...........................................................................................18

3.4 Test run with load................................................................................................18

3.5 After the test run and autotuning ..........................................................................18

4PARAMETER ADJUSTMENTS .......................................................................................19

4.1 Control keypad operation.....................................................................................19

4.1.1 Navigation on the control keypad............................................................... 20

4.1.2 Value line editing...................................................................................... 20

4.1.3 Passwords................................................................................................21

4.1.4 Special button functions and shortcuts.......................................................21

4.1.5 Monitoring................................................................................................ 22

4.2 Input selections................................................................................................... 23

4.3 Speed supervision settings .................................................................................. 24

4.3.1 Functional test run for SSU .......................................................................26

4.4 Open Loop motor parameter adjustments.............................................................. 27

4.4.1 Open Loop speed control for hoisting......................................................... 27

4.4.2 Open Loop motor parameters for traveling ................................................. 27

4.4.3 Open Loop autotuning for traveling, frequency control................................. 28

4.4.4 Open Loop manual tuning for traveling....................................................... 28

4.4.5 Open Loop manual tuning for traveling, frequency control ........................... 29

4.4.6 Open Loop manual tuning for traveling, current control ............................... 29

4.5 Closed Loop motor parameter adjustments............................................................ 30

4.5.1 Closed Loop rated motor parameters ......................................................... 30

4.5.2 Closed Loop autotuning, speed control....................................................... 31

4.5.3 Closed Loop manual tuning for hoisting, speed control ................................ 34

4.6 Brake Slip Feature……………………………………………………………………………….37

4.6.1 Description of brake slip feature………………………………………...…………..37

4.6.2 Activation of brake slip feature……………………………..……………..………..38

4.6.3 Brake Slip Feature Field Testing Procedure…………………………..……….….38

4.6.4 What to do in case of brake slip……………………………………………………..39

4.6.5 Service on hoist motor/encoder/brake with Brake Slip feature active………...40

5PARAMETER DESCRIPTIONS....................................................................................... 41