©Copyright 2012

1.2 Safety Caution Symbol

Safety Caution Symbol locations shown in Fig 1-5:

Fig 1-5

Notice: The sign of shows the belt is rotating, keep hands away.

The sign of shows there is motor and electric box, operate the

machine carefully.

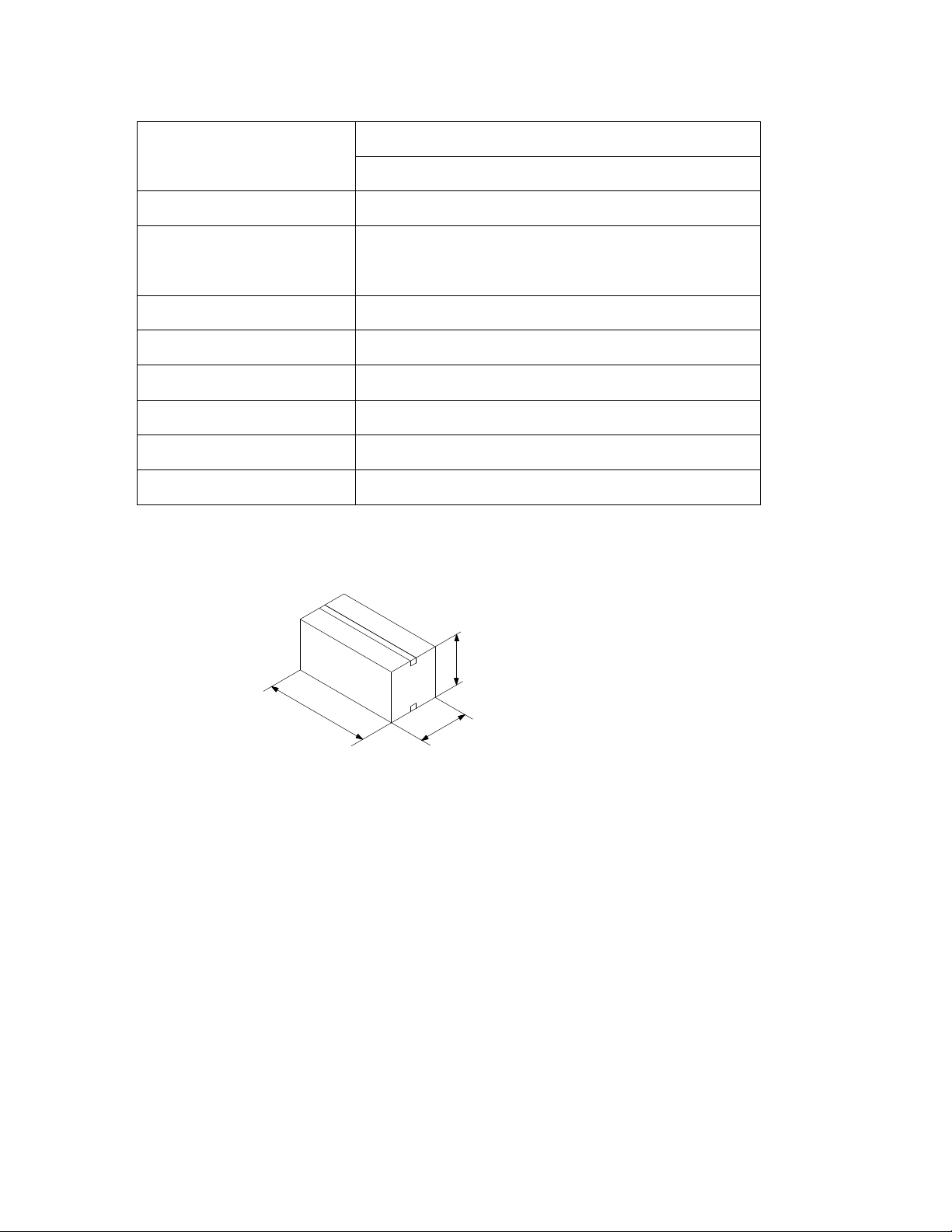

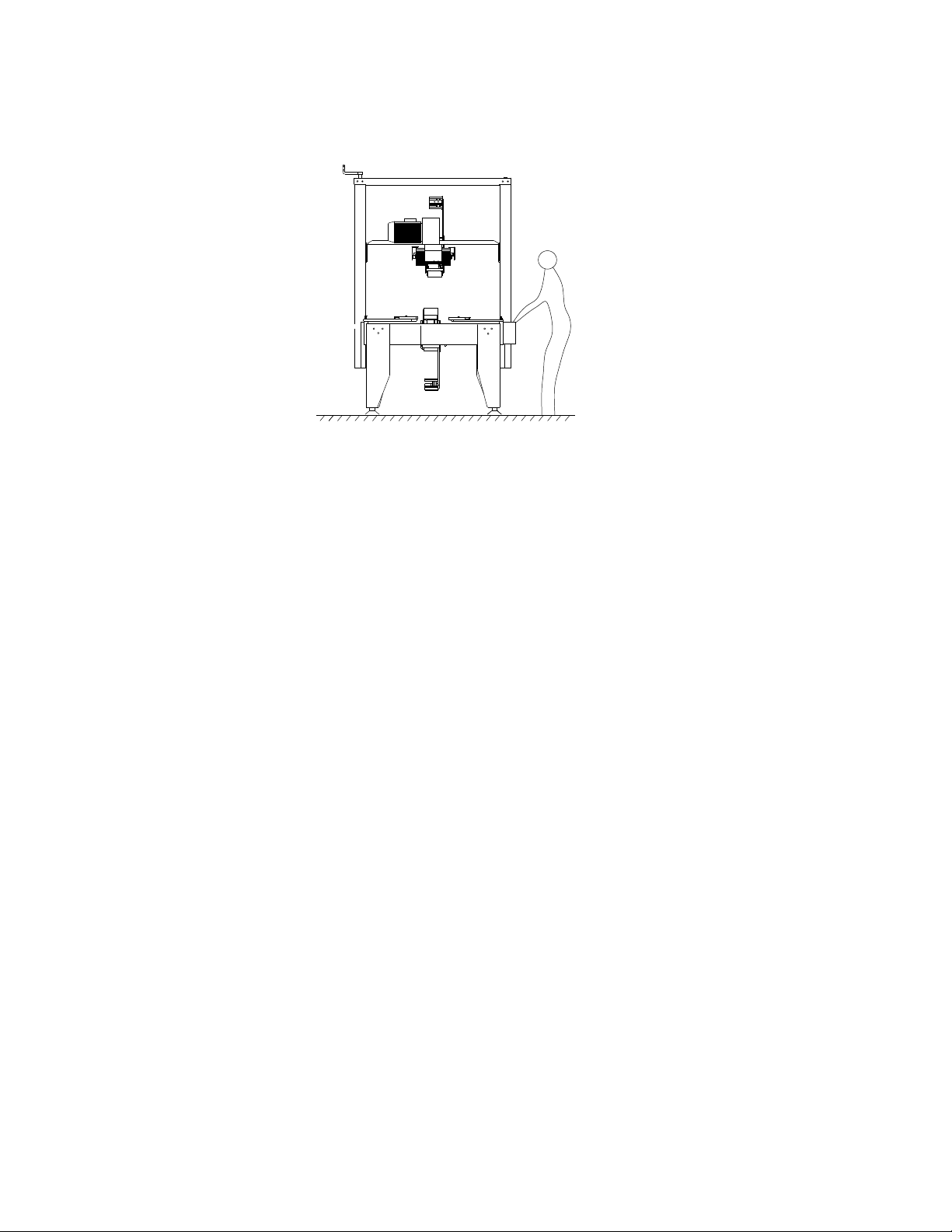

1.3 Outline and Application Field

This is an automatic case sealing machine using pressure-sensitive tape such as

PVC and BOPP. It can be set to conform to the shape of the carton and seal boxes

for packaging. This machine has a wide range of applications including the

following fields: chemical fiber field, tobacco leaf drying, pharmaceutical,

publication, refrigeration and air-conditioning, household appliances, ceramics,

etc.

ELECTRIC SHOCK

operate carefully

DANGER

CUT

keep hands away

DANGER

ROLLING

keep hands away

DANGER

DANGER

operate carefully

ELECTRIC SHOCK

DANGER

keep hands away

ROLLING

ROLLING

keep hands away

DANGER

ROLLING

keep hands away

DANGER

DANGER

keep hands away

CUT