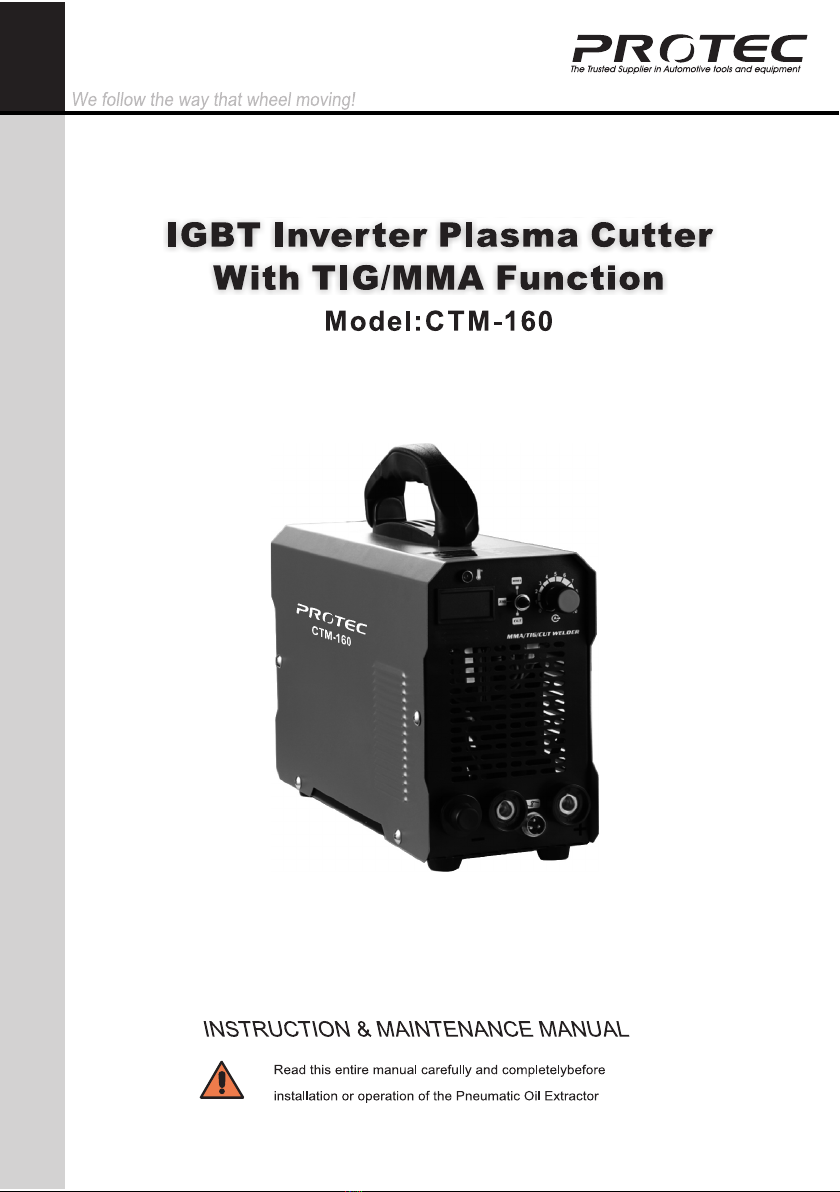

Pro-tec CTM-160 Instructions for use

- 1 -

Description: This machine is used to weld ferrous or nonferrous metals.

Disclaimer: The information, illustrations and instructions described in this manual

are based on the latest product information available at the time of publication. The

manufacturer and distributors reserve the right to make modifications at any time as

a result of product changes, and such modifications are not obligated to notify any

organization or individual. In addition, welder is a special type of work, and welding

equipment is special equipment. Welding work must be executed by qualified

workers after professional training. Therefore, the manufacturer and distributors are

only responsible for the quality of the product. They shall not be liable for direct or

indirect joint and several liability including loss of profit caused by omissions or

misdescriptions that may exist in this operation manual. This manual will contain as

much as possible the safety operation and preventive measures related to this

equipment, but cannot completely exclude the occurrence of accidents. The

manufacturer and distributors shall not be liable for any direct or indirect joint and

several liability, for any incidental or consequential damages caused by any accident,

that may occur outside of this manual. For more detailed health and safety

information, please contact the relevant professional agencies, welding materials or

welding flux manufacturers if necessary..

No warranty service is available in the following circumstances:

The consumables of the machine are not covered by the warranty, such as

welding wires, flux, fuse, protective tube, quick connector, wire feeder and

tension roller, etc..

Machine failures caused by incorrect input power voltage or fluctuating power

supply are not covered by the warranty.

Malfunction of the machine and parts damage caused by wrong connection or

incorrect operation.

The warranty will be invalid if the machine is disassembled or refitted without the

permission of the manufacturer, resulting in accidental work or unexpected

damage of the machine.

Accidental damage during transportation, storage, and transshipment.

Problems caused by man-made damage, natural disaster of force majeure and

accidental damage.

- 2 -

CONTENTS

Safety precautions................................................错误!未定义书签。

Warnings................................................................ 错误!未定义书签。

Package and transportation........................................................................... 8

Parameters..................................................................... 错误!未定义书签。

Product description..........................................................................................9

Working principle........................................................................................... 12

Installation and wiring................................................................................... 12

Brief instruction for welding operation........................................................15

Maintenance................................................................................................... 19

Common machine malfunctions and solutions.........................................19

- 3 -

Safety precautions

The equipment is designed for the qualified personnel who have passed professional

training. The operator shall have sufficient professional knowledge of welding, cutting

and circuit, and have obtained the qualification certificate of welder. Only operate the

machine after reading and fully understanding all the safety precautions and warnings

in the manual and of welding operations. Basic safety precautions should always be

followed when using tools, to reduce the risk of personal injury and damage to

equipment. The device is simple and reliable in selecting and performing all of its

functions. The operator must strictly follow the safety precautions below and execute

them as required. Improper use and maintenance will reduce the safety performance

of the machine.

1. The operator must have passed the systematic training and assessment of local

welder's relevant learning institution and obtained the qualified certificate before

operating the equipment.

2. The wire and cable connection of the equipment, as well as the installation, must

be operated by qualified professional and technical personnel.

3. The welding and cutting protective equipment used by the operator must be

provided by the manufacturer or distributor approved by the national safety

supervision department of the local country.

4. Welding and cutting is dangerous work, which may cause harm to you or others,

so sufficient protection should be done during welding and cutting. Please strictly

abide by the relevant safety precautions of the job operation. For more details, please

refer to the relevant safety guidelines for the operators to comply with the

manufacturer's regulations on accident prevention.

5. Please make sure that the welding/cutting machine is reliably grounded when

working. Please contact the professional electrician to solve the problems in time if

there is any doubt that the socket is not grounded or the grounding is not reliable.

6. Before welding/cutting , check whether the insulation layer of all wires and cables

of the machine is damaged or they are wrongly connected timely and fix them in a

timely manner if they are.

7. The faulty machine must be repaired by professional technicians. The machine

must be disconnected from the electricity supply before repair and maintenance.

- 4 -

8. Do not operate the welding/cutting machine in humid environment, otherwise it

may cause electric shock or short circuit accident.

9. It is strictly forbidden to re-modify the equipment or the attached equipment

related to the operation of the equipment without permission, to avoid accidents.

10.The disposal of the scrap equipment must comply with the relevant policies and

regulations of the local government.

Warnings

Welding and cutting is a special type of work, with a certain degree of danger.

Professional training, correct operation and necessary protective measures can

effectively avoid and reduce the damage and loss caused by machine accidents.

Personal and others’ safety protection

When welding and cutting equipment is working, it will generate

noise, strong light and high temperature sparks, which will cause

harm to human hearing, eyes and skin. Correct protective measures

and proper operation training are necessary to prevent injury

accidents.

1

Aprotective helmet with a shading filter must be worn to protect the face and

eyes during welding and cutting operations or when watching welding/cutting

operations.

2

Wear a helmet with the correct filter and cover plate to protect the eyes, face,

neck and ears from arcing sparks and bright light during welding operation or

observation. Warn bystanders not to look at the arc and not to expose their

skin in the area of strong light arc or high temperature spark

3

Wear flame retardant gloves, flame retardant welding/cutting overalls, flame

retardant shoes, and welding/cutting helmets or protective caps to protect

against arcing bright lights, high temperature sparks or hot metal particles. A

flame retardant apron is also available to protect against thermal radiation

and high temperature sparks.

4

Hot sparks or metal can get into rolled-up sleeves, trouser legs or pockets.

Before welding/cutting, sleeves and collars should be buttoned, and clothes

with front pockets should not be worn.

Table of contents

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual