MNX10010 / Rev B

4/11/2008 2

Introduction

The PRO Model PS03 Power Supply unit is a battery operated 3-channel,

portable power unit designed to operate Integrated electronics, piezo electric

(IEPE) sensors.

NOTE: SENSORS may refer to accelerometers, pressure sensors, hammers

and force transducers, etc. The words SENSOR and TRANSDUCER are

used interchangeably in this guide.

Sensors require a source of constant current, usually in the range of 2 to 20 mA

at a supply (compliance) voltage range of +18 to +30 VDC.

Model PS03 supplies fixed constant current (called sensor drive current) to up to

three sensors, of 2 mA at a +18 Volt compliance voltage level.

Power to operate the sensors is supplied by two 9 Volt transistor radio type dry

cell batteries, operating in series, to produce +18 Volts DC.

A low current voltmeter located on the front panel of the PS03 constantly

monitors the voltage appearing at the ‘Sensor’ jack of any of the three sensors

selected for monitoring by a front panel rotary switch. This DC voltage is the

quiescent bias voltage of the sensor and measuring this voltage is very useful in

testing for faulty operation of cables and sensors.

A momentary pushbutton switch located just below the meter checks the battery

voltage without disturbing the test in progress.

Both ‘Sensor’ and ‘Output’ jacks are BNC.

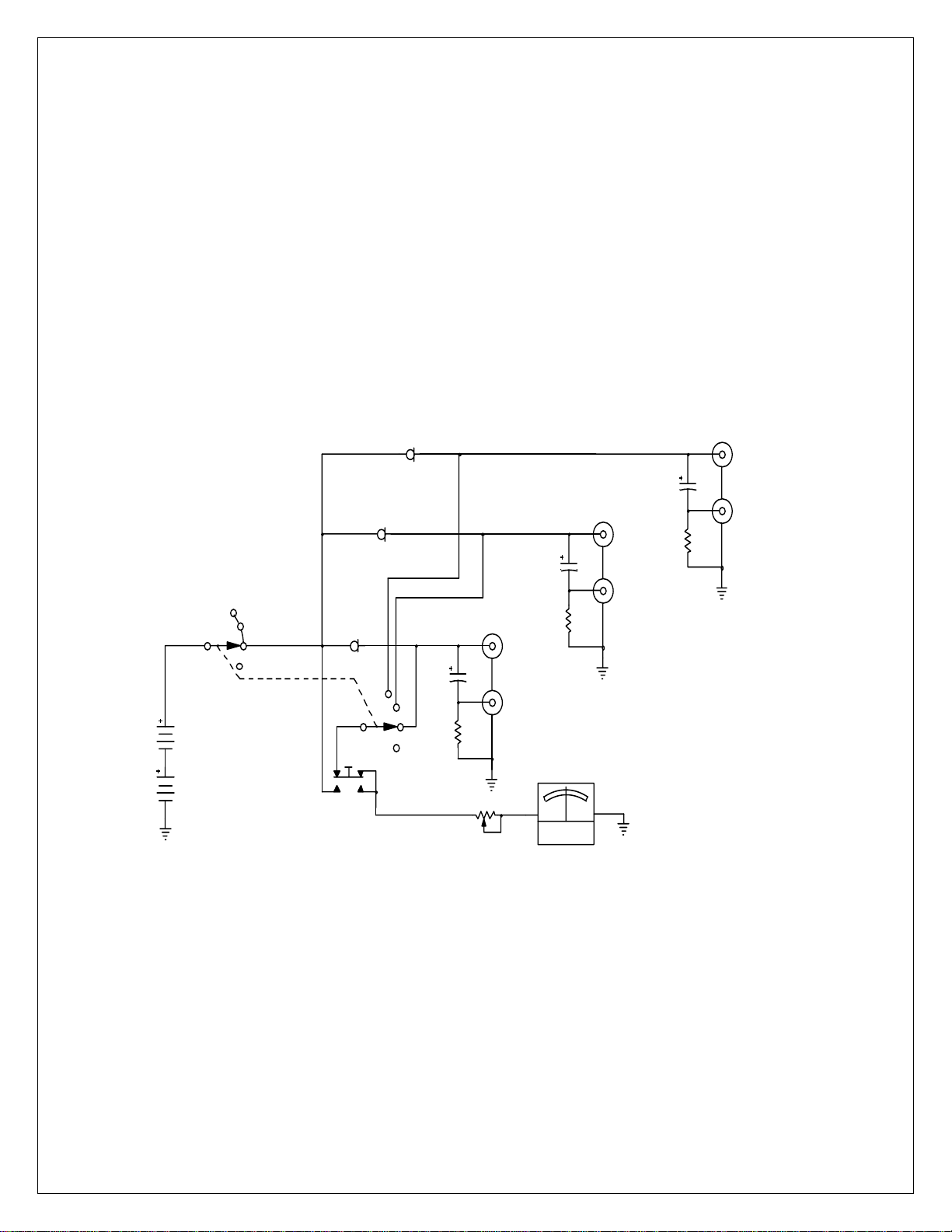

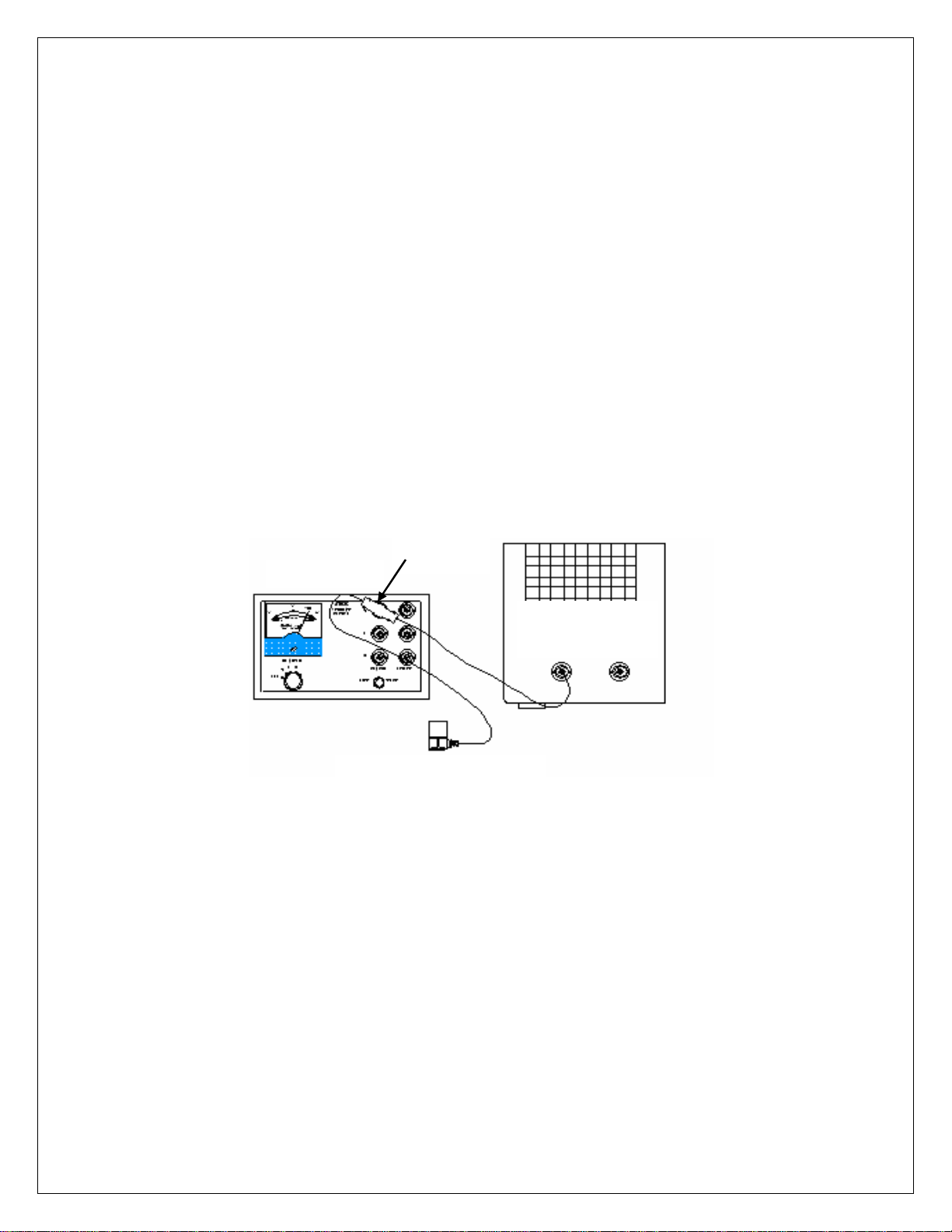

Description (Figure 1)

Model PS03 utilizes three 2 mA current regulating JFET diodes to supply the

sensor drive current to up to 3 sensors. The metering circuit draws only 25µA at

mid-scale (its normal operating level). With this low current drain, the battery life,

starting out with a fresh pair of alkaline batteries, will be about 80 hours. Figure 1

is a schematic diagram of one channel of Model PS03. The voltmeter normally

monitors the sensor bias voltage which is nominally about +10 Volts DC. Consult

the specification sheet for your particular sensor to verify the actual bias voltages

since some sensors have various other bias voltages.

Section I

Overview