pro3dure medical CD-2 User manual

1

ENGLISH

Working Instructions

CD-2

Light polymerisation unit

2

ENGLISH

Technical specifications

External Dimensions (WxHxD) 405 x 210 x 430 mm

Polymerisation chamber (WxHxD) 167 x 115 x 105 mm

Voltage / frequency 220 V / 50 Hz

Light source UV LED panel

Wave length 365 nm – 405 nm

Power consumption 80 W

Pressure control valve max. 5 bar

Working pressure 1.8 bar

Network Wi-Fi

3

ENGLISH

Safety instructions

Attention: Read the following notes before connecting and putting the unit into service.

The operating service and the function of the unit can only be guaranteed, if the general

safety and accident prevention instructions of the legislation as well as safety and working

instructions are followed.

1. This unit must only be used according to the present working instructions. We cannot

be held liable for damages which have been caused by improper treatment.

2. The indicated voltage on the type plate has to meet the voltage of the power source.

3. The unit must only be connected with a socket with protective conductor. Never

touch the plug with wet hands.

4. Put the unit on a stable and even basis.

5. Do not intrude any objects into the unit outside of the polymerization chamber.

6. Only those appliances and square parts may be used which are released by the

manufacturer. Pro3dure are not responsible for damages caused by the user of

external parts.

7. Do not operate the unit if the lid is open.

8. The unit has to be examined before operation in the view of proper condition. If the

unit is not in proper condition, it must be used and has to be marked accordingly.

9. Before cleaning and maintenance of the unit or exchange of parts the plug has to be

disconnected.

10. The opening of the unit and repairs are only to be carried out by accordingly trained

experts.

11. Use only nitrogen as protective gas. In no case use flammable or toxic gases. Follow

the general safety and accident prevention instructions for the use with gas.

12. Only use permitted gas pressure tanks.

13. When connecting the gas pressure tank check the tightness of the supply pipe. Make

sure that the gas pressure tank will not tip over.

14. Never connect the gas tank without using the pressure reducer, the unit has to be

operated with maximum pressure of 5 bar (70PSI).

15. If the unit is not used, block the gas supply, do not operate the unit unattended.

16. Provide sufficient ventilation in the working area.

4

ENGLISH

Description of unit

CD-2 is a light polymerization unit for curing the light polymerization materials under

protective gas. The protective gas atmosphere prevents from the development of an

inhibition layer on the surfaces of the parts. CD-2 is very easy to use. Includes an electronic

timer which can be programmed individually for all production procedures down to the

exact one second.

Putting into service

Before putting into service make sure that no transport damages occurred. Check for

external damages to the housing and IPAN. Further ensure that the indicated voltage on the

type plate meets the voltage of the power source. Put the cable into the socket of the unit

and create a connection with the enclosed connector cable. Safely fix the protective gas

supply pipe at the hose nozzle of the pressure reducer of the gas pressure tank with the help

of the hose clamp. Create a connection to the unit with a quick coupler. The pressure must

not exceed 3 bar (42 PSI).

Information on using protective gas

By using protective gas, it is possible to do the polymerization in an oxygen-free

atmosphere. The protective gas replaces the air in the polymerization chamber and

thus reduces the oxygen content in the polymerization chamber of the CD-2 leading

to a curing of the parts without inhibition layers. For checking the gas consumption,

a flowmeter has to be used.

The operator is responsible for the warranty of the operating safety of the CD-2.

Review the national safety instructions when using gases for technical purposes.

Operators using the CD-2 have to be instructed about the dangers of protective

gases. The use of protective gas reduces the oxygen content in the working areas.

If the CD-2 is adjusted correctly there is no risk of danger for operators.

Setting protective gas

The pressure reducer at the pressure tank should be set to approx. 2.5 - 4.5 bar

For the connection to the CD-2 a 6mm tube is required.

Please take care to use a proper connector to the pressure reducer

5

ENGLISH

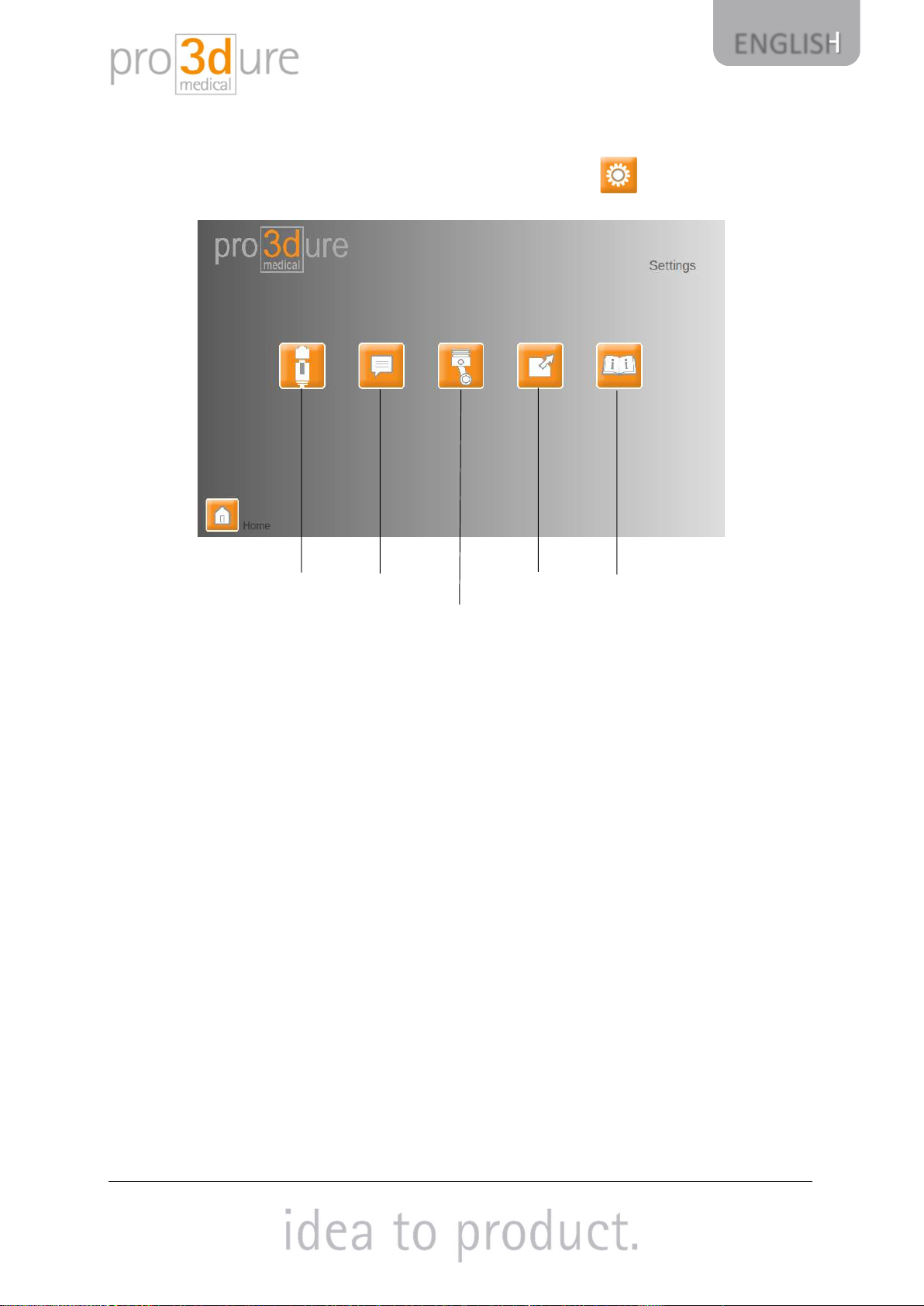

Controls

Operation of CD-2

Before using the CD-2 check the power supply and connect the gas. Then turn on the main

switch at the right back of the unit. To turn on the curing unit, press the power button at the

right side of the unit. The software will be starting and the display shows the pro3dure Logo

during the initialization. When the software has started check on the start screen if every

status lamp is green. The CD-2 is ready to use. To control the curing device, the display must

be used. The menu items are further described below.

Info: Before the initialization of the CD-2 is ready, the pro3dure logo disappears for some

seconds and the screen will be black. This is normal during the initialization and no defect of

the curing device.

status lamps

open program

saved programs

settings

6

ENGLISH

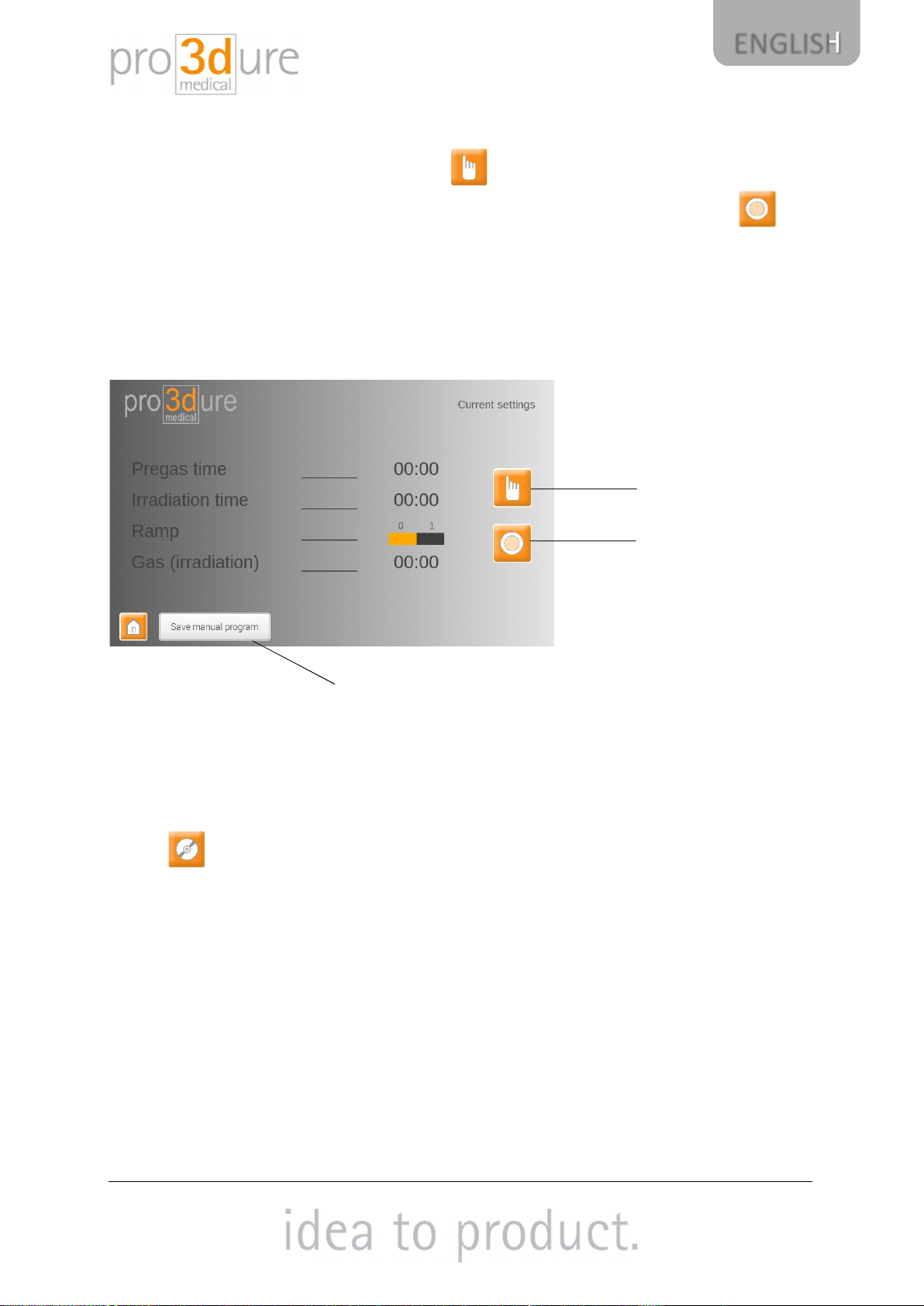

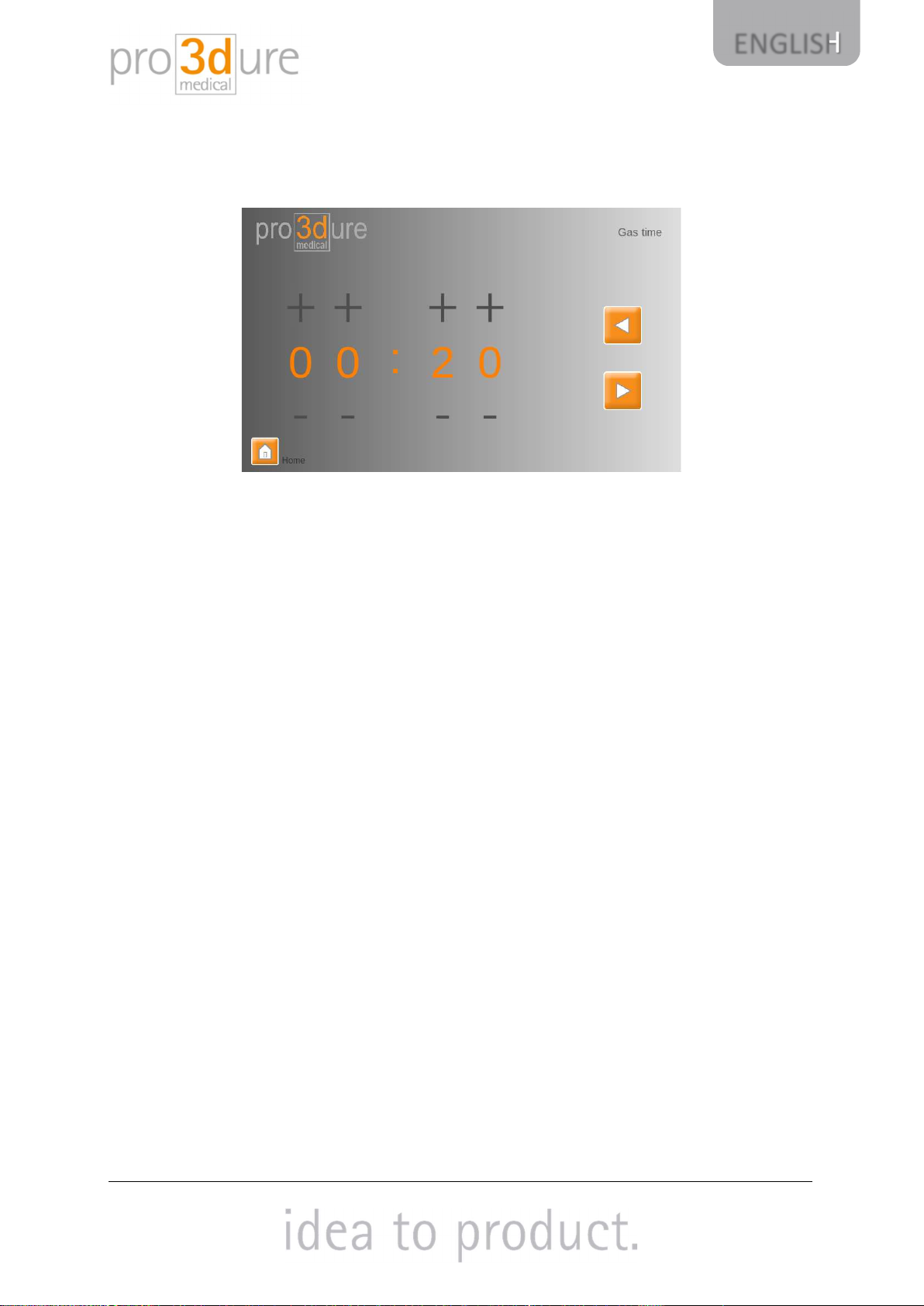

Start irradiation

To start the irradiation push open program. The current program will open and the

display shows the parameters of this program. Push the start button to irradiate.

Info: The lid must be closed and the gas must be turned on.

Saving a program

Press the Save manual program button to save the current setting. It is possible to store

different programs and name them manually. To access saved programs, press the programs

button in the main menu.

edit program

start irradiation

save current settings

7

ENGLISH

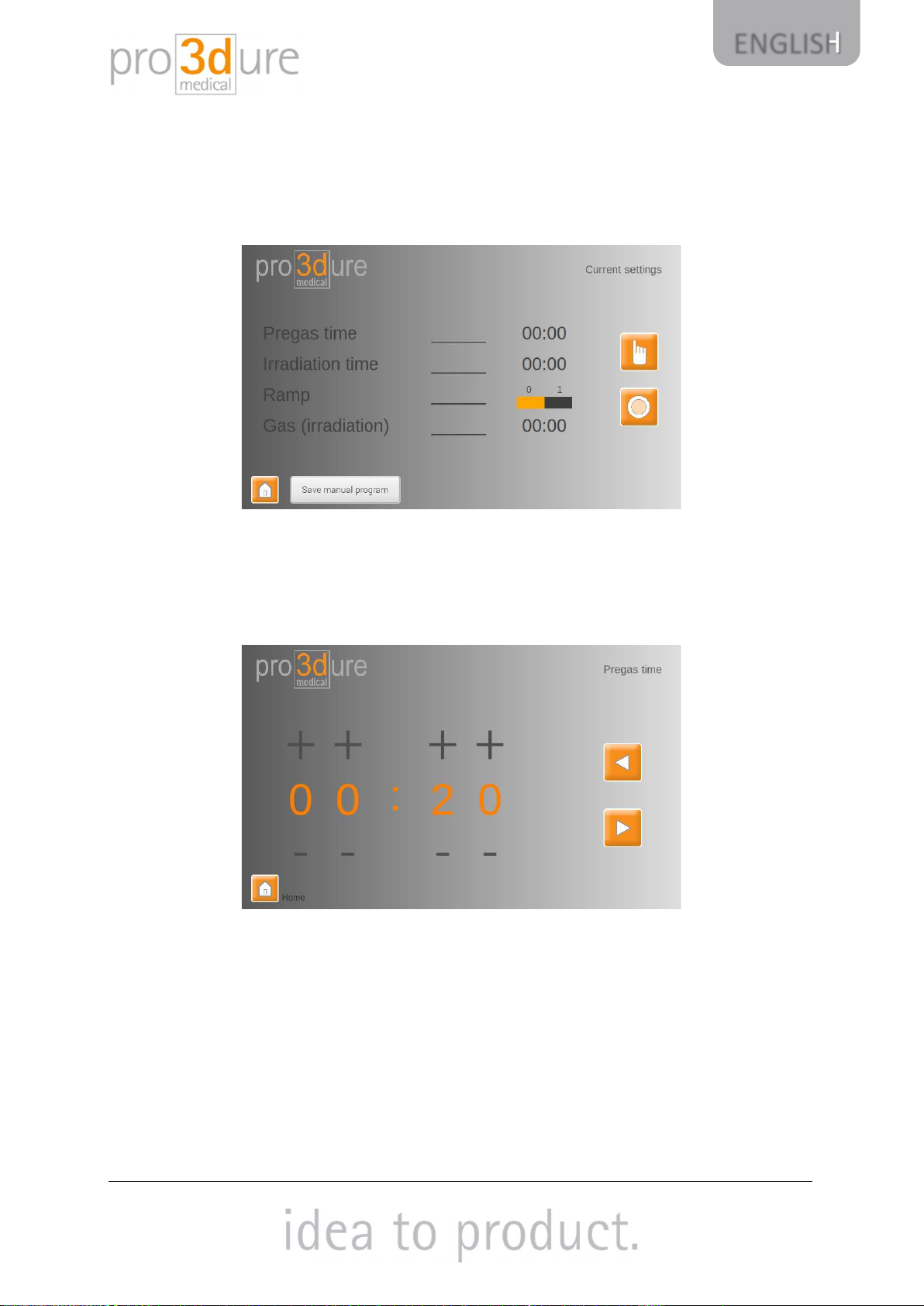

Editing a program

For generating a program or editing a program push the program button. A new screen

opens and program 1 to 24 can be chosen. Click on the program which should be programed

or edited. Then click on edit program.

At first the pregas time can be set. This is necessary to replace oxygen with nitrogen gas. A

pregas time from 00:00 minutes to 59:59 minutes can be set. Use plus and minus to extend

or reduce the time. The CD-2 will not exposure during this timer. To proceed push forward.

Recommendation: 00:20 minutes

8

ENGLISH

The next step is to set the irradiation time. An irradiation time from 00:00 minutes to 59:59

minutes can be set. Use plus and minus to extend or reduce the time and move then

forward.

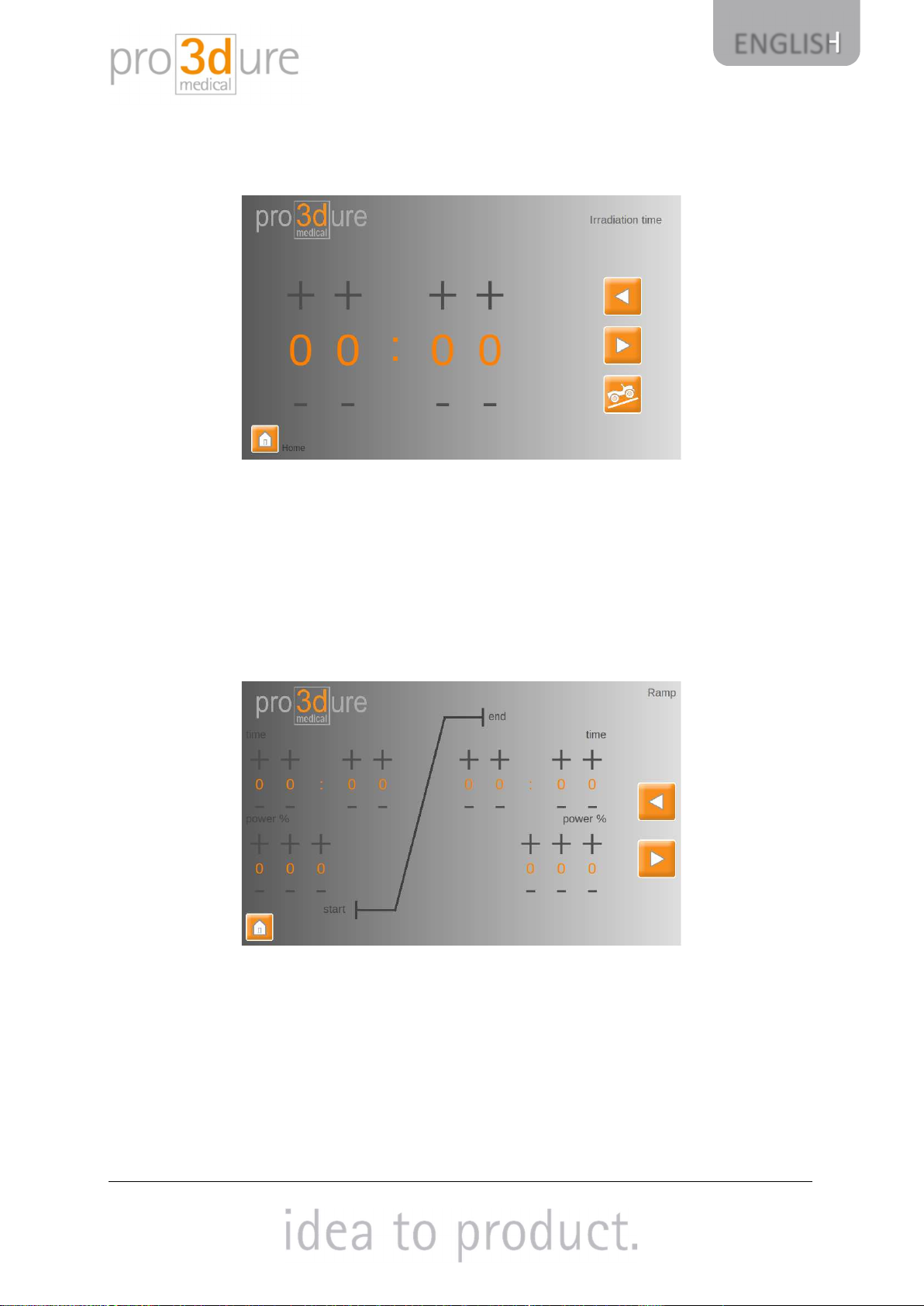

In the next step a ramp can be configured. Set a start time when the CD-2 should increase

the LED power. By power the LED power can be configured. Up to the start time the CD-2

will exposure with the set power. Then it starts to increase the LED power step by step to the

end LED power and end time. Off the end time the CD-2 exposures with the set end LED

power for the rest of the irradiation time. When the program is configured completely the

overview of the program shows an activated ramp. The register shows position 1. When no

ramp is configured the register is on position 0 and the LED power is set for the hole

exposure time on 100%.

9

ENGLISH

At last the gas during the irradiation time can be configured. Push forward to rename the

program.

Recommendation: 00:20 minutes

If it is desired a name for this generated program can be set. Push on the program name and

a virtual keyboard will open. An individual name can be set now. When this is finished push

forward to finish the generation of this program. An overview of the settings will be shown

and the irradiation can be started.

10

ENGLISH

status update

Settings

To open the settings menu of the CD-2 press the settings button in the main menu. A

new menu will open

Network: The CD-2 is network compatible. When a network cable is connected you can

configure the local IP address, the mask and your gateway.

Info: For normal use the access to the internet is not necessary. It is only needed to update

the curing device if updates are available.

Language: For changing the language push the language button. By pushing on “English” or

“German” the language can be selected. The language will change immediately. No restart is

necessary.

Machine information: In this menu you will find the machine information shown.

Updates: In the updates menu is the current version shown. If the CD-2 is connected to the

internet there will be also shown if an update is available and the version number of the new

version. The update can be started by pushing the play button.

Working instructions: Under working instructions the manual of the CD-2 will be shown.

machine information

Language

network

11

ENGLISH

Care and maintenance

Disconnect the unit mains supply before executing care and maintenance. Cleaning is

effected with a mild cleaning liquid. Clean it regularly with a humid piece of cloth. Cleaning

liquids must not get into the unit.

General notes

Repairs on the CD-2 are only to be executed by experts. Disconnect the unit from main

supply at any rate. Pro3dure is only responsible for safety, reliability and performance of the

unit, if the unit is exclusively used for the corresponding application, operation is only to be

carried out by trained personal.

-the unit is used in accordance with these working instructions

-extensions, new adjustment, changes or repairs are executed by persons authorized by the

company.

As we permanently develop our products, we reserve the right for technical changes.

Table of contents

Popular 3D Printer manuals by other brands

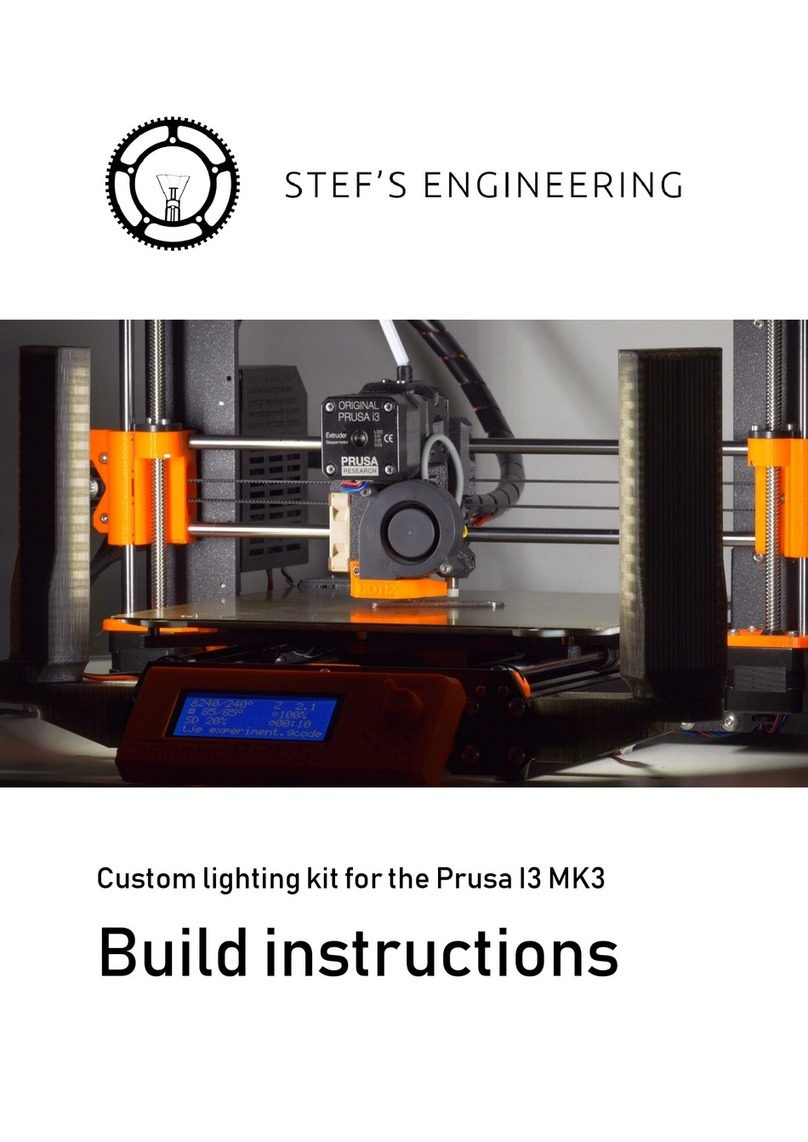

Stef's Engineering

Stef's Engineering Prusa I3 MK3 Build instructions

TierTime

TierTime UP BOX user manual

Creality

Creality CR-30 user guide

Geeetech

Geeetech Duplicator 5 Assembly manual

Phrozen

Phrozen SONIC MIGHTY 8K manual

TRAK

TRAK Airwolf EVO-T Installation, Printing, Maintenance & Troubleshooting Manual