PROCESSTEC ViscoTwin 130 G8 Manual

Address: 345 E. Tulare Avenue Unit E | Visalia, CA 93277 | Phone: +1 (559) 429-4227

ViscoTwin 130 G8

Operation & Maintenance Manual

Published February 23rd, 2023

TABLE OF CONTENTS

PROCESSTEC INC. 2022Page ii

TABLE OF CONTENTS

PROCESSTEC INC. 2022 Page iii

1. ABOUT VISCOTWIN SCREW PUMPS .............................. . 1

1.1 Safety Notes .............................................................. 1

1.2 Working Principle .......................................................... 3

1.3 General Overview .......................................................... 4

1.4 Opons .................................................................. 5

1.4.1 Opons for 3A or EHEDG .............................................. 5

1.4.2 Pump Face Opons................................................... 6

1.4.3 Pump Housing Opons................................................ 8

1.4.4 Elastomer Opons ................................................... 10

1.4.5 Spindle Opons...................................................... 11

1.4.6 Mechanical Seal Opons .............................................. 12

1.4.7 Bearing Housing Opons .............................................. 14

1.4.8 Motor Opons ...................................................... 17

1.4.9 Frame Opons ...................................................... 18

1.5 Performance Tables ........................................................ 19

1.5.1 Sizing Chart ......................................................... 19

1.5.2 Water Curves........................................................ 21

2. INSTALLATION............................................... 23

2.1 Unpacking ................................................................ 23

2.2 Inspecon / Technical Documentaon ......................................... 23

2.3 Hoisng and Transportaon.................................................. 24

2.4 Installaon................................................................ 26

2.5 Piping Before and Aer the Pump............................................. 27

2.5.1 Upstream Piping ..................................................... 27

2.5.2 Downstream Piping .................................................. 28

2.5.3 Piping Before and Aer the Pump....................................... 28

2.6 Mechanical Seal Connecon ................................................. 29

2.7 Pre-Installaon of Seal Water for Dual Acng Mechanical Seal ..................... 30

2.8 Electrical Installaon........................................................ 31

3. OPERATION................................................. 33

3.1 Pump Startup ............................................................. 33

3.2 So Starng the Pump ...................................................... 33

3.3 Avoiding Pump Cavitaon ................................................... 34

3.4 Pumping Sensive Products.................................................. 34

3.5 Material Selecon for Sealing Surfaces......................................... 35

3.6 Pumping Product with Large Parculates ....................................... 35

TABLE OF CONTENTS

PROCESSTEC INC. 2022Page iv

3.7 High Pressure Systems ...................................................... 35

3.8 CIP / COP Soluon.......................................................... 36

3.9 Visual Inspecon ........................................................... 37

3.10 Available Elastomer Opons ................................................ 37

3.11 Leakage ................................................................. 38

3.12 Scratches in the Pump Housing .............................................. 39

4. MAINTENANCE.............................................. 41

4.1 Maintenance Preparaon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.1 General Movie: HOW THE PUMP WORKS................................. 41

4.1.2 Introducon to Web Page ............................................. 41

4.1.3 Risk Assessment for Pump Maintenance ................................. 42

4.1.4 Safety Measures ..................................................... 42

4.2 Explaining Maintenance Levels ............................................... 43

4.2.1 Maintenance Level 1 (ML-1) ........................................... 43

4.2.2 Maintenance Level 2 (ML-2) ........................................... 44

4.2.3 Maintenance Level 3 (ML-3) ........................................... 45

4.3 Material at hand, Required Parts & Tools ...................................... 46

4.3.1 Recommended Spare Parts ............................................ 46

4.3.2 Recommended Tools ................................................. 47

4.3.3 Recommended Oils, Grease............................................ 47

4.4 Maintenance Instrucons for ML-2............................................ 48

4.4.1 Removing the Pump Housing .......................................... 48

4.4.2 Complete Pump Disassembly .......................................... 51

4.4.3 Complete Pump Assembly ............................................. 57

4.5 Preventave Maintenance Program ........................................... 65

4.5.1 First Oil Change ...................................................... 65

4.5.2 Oil Change Intervals .................................................. 65

4.5.3 Checking Levels on Motor Gearbox Oil................................... 65

4.5.4 Greasing Motor Bearings .............................................. 65

4.5.5 Check Condion of O-rings ............................................ 66

4.5.6 Check the Exterior Lip Seals and O-rings on the Mechanical Seals ............ 66

4.5.7 Check Oil Sha Sealing Rings ........................................... 67

4.5.8 Proper Gapping of Pump .............................................. 68

4.5.9 Changing Product Flow Direcon ....................................... 72

4.6 Failures................................................................... 73

4.6.1 Foreign Material enters Pump Housing .................................. 73

TABLE OF CONTENTS

PROCESSTEC INC. 2022 Page v

5. TOOL-BOX .................................................. 75

5.1 Tools ..................................................................... 75

5.1.1 ViscoTwin Tools...................................................... 75

5.1.2 General Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2 Spare Parts................................................................ 81

5.2.1 Spare Parts for Pump Housing.......................................... 81

5.2.2 Spare Parts for Seal Housing ........................................... 85

5.2.3 Spare Parts for Bearing Housing ........................................ 87

5.2.4 Spare Parts for Gear Housing........................................... 88

5.2.5 Spare Parts for Drive Train ............................................. 90

5.3 Explosion Drawings......................................................... 92

5.4 Torque Tables ............................................................. 93

5.5 Pump Housing Conguraon ................................................. 94

5.6 Oils, Grease & Lubricaon Recommended ...................................... 102

5.7 Oil Tesng Kit (with Form) ................................................... 104

6. GEEK‘S CORNER ............................................. 105

6.1 Oil Cooler with Oil Filter ..................................................... 105

6.2 Vibraon Sensor with Oil Temperature Sensors.................................. 106

6.3 Quench Design for Recirculang Fluids in Mechanical Seals........................ 107

6.4 Maximizing Bearing Lifespan ................................................. 108

6.5 Equipment Commissioning Protocol ........................................... 118

7. APPENDIX .................................................. 119

7.1 Maintenance Movies ....................................................... 119

TABLE OF CONTENTS

PROCESSTEC INC. 2022Page vi

This page intenonally le blank.

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 1

1. ABOUT VISCOTWIN SCREW PUMPS

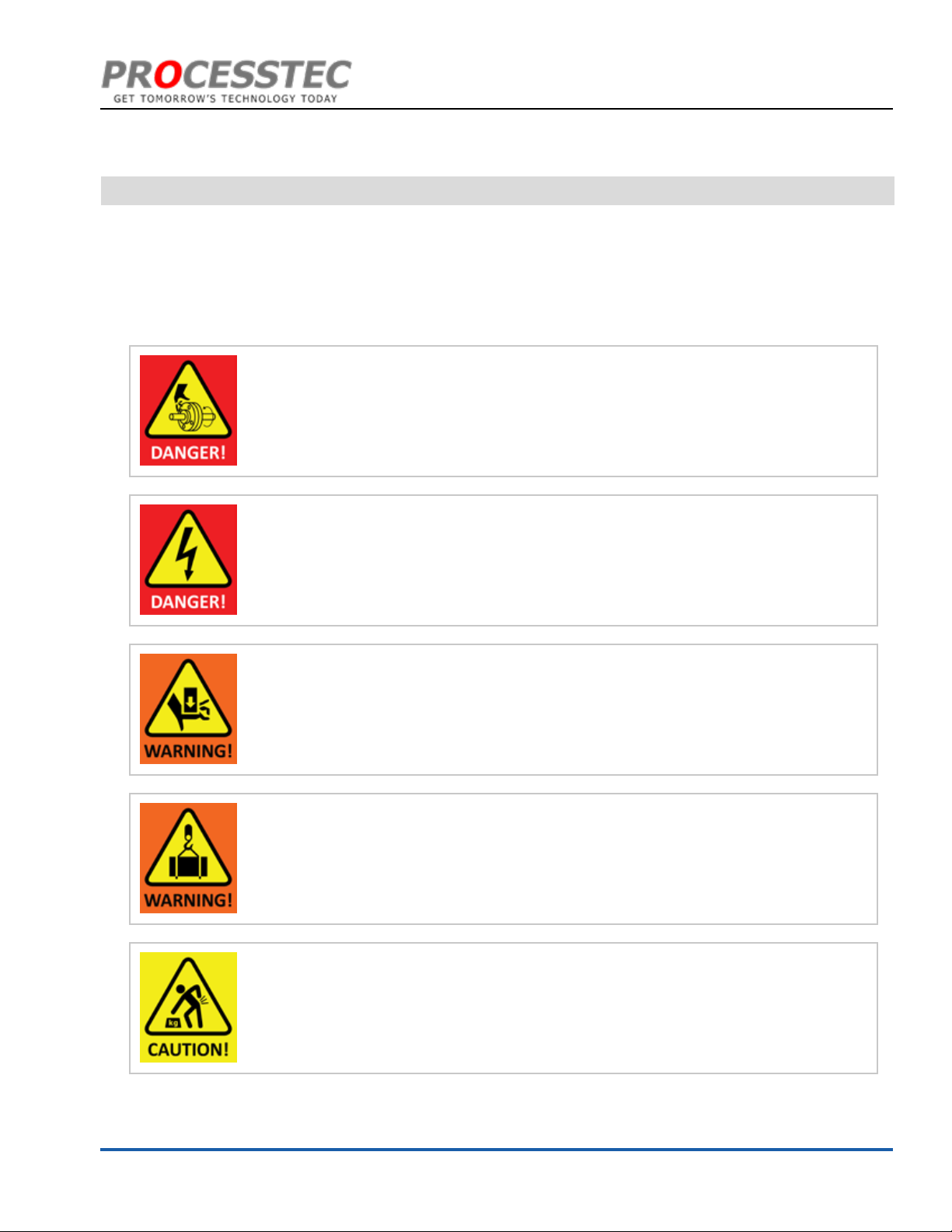

1.1 Safety Notes

This manual contains instrucons which should be heeded to ensure personal safety and prevent damage

to property. These instrucons are highlighted by a warning triangle and a color to indicate the degree of

the hazard. The following warnings should be observed throughout the life cycle of the pump:

ROTATING PARTS

Indicates rotang parts that can cause injury. Only perform work on or near these parts

when it is locked to prevent rotaon. It is advised to have a protecve barrier surrounding

the rotang part to prevent injury or property damage during operaon.

HIGH VOLTAGE

Indicates high voltage and risk of shock or severe burns. No work should be performed

around high voltage parts unless they have been disconnected from the main power

supply. Any work on high voltage parts must only be performed by an electrician licensed

in the state where operaons and maintenance is being performed.

CRUSHING PARTS

Indicates moving parts that can crush and cut. Perform work with awareness of how

parts move and where these crushing parts can be encountered.

SUSPENDED LOAD

Indicates a suspended or overhung load, where parts can fall, slip, or p over if not

properly secured. Do no work on any part that is suspended and avoid being directly

under or near a suspended load. Do not stand between a staonary object and a

suspended load.

LIFTING OBJECTS

Indicates heavy objects that can cause muscle strain or back injury. Liing aids and

proper liing techniques should be used to prevent injury.

1. ABOUT VISCOTWIN SCREW PUMPS

Page 2 PROCESSTEC INC. 2022

Commissioning and operang the ViscoTwin 130 G8 may only be performed by qualied personnel.

Qualied personnel in terms of the safety instrucons in this operang and safety manual are persons

who have completely read this manual.

Furthermore, maintenance can only be performed by qualied maintenance technicians. Qualied

maintenance technicians in terms of the maintenance instrucons in this operang and safety manual are

persons who have read Chapter 4 “Maintenance” and have been trained by Processtec in the use and

maintenance of this pump. In lieu of in-person training by Processtec personnel, a qualied maintenance

technician may also review the online maintenance movies available at hp://processtec.com. WARNING:

ANY MAINTENANCE LEVEL 2 PERFORMED ON THIS PUMP BY UNTRAINED PERSONNEL WITHOUT THE

EXPRESS WRITTEN CONSENT OF PROCESSTEC WILL RELEASE PROCESSTEC OF ANY LIABILITY AND VOID

ANY WARRANTY CLAIMS ON THE PUMP..

In addion to this operang manual, general on-site regulaons as well as city, state, and federal regulaons

applicable to accident prevenon must be made available and followed.

The ViscoTwin 130 G8 may only be used in the applicaons as specied in Chapter 3 "Operaon" on page

33, and only in connecon with the spare parts recommended by Processtec, Inc.

LEAKAGES

Indicates that leaks are possible. Leaked uid can cause slip-and-fall hazards and should

be cleaned up and disposed of immediately.

HOT SURFACE

Indicates a surface is hot to the touch and can cause burn injury. Do not maintain or

touch a hot surface unl the pump is turned o and allowed to cool. If immediate repair

is necessary, it is advised to wear protecve gloves while handling a hot part.

CAUTION

When operang the ViscoTwin 130 G8, it is essenal to wear appropriate protecve

equipment.

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 3

1.2 Working Principle

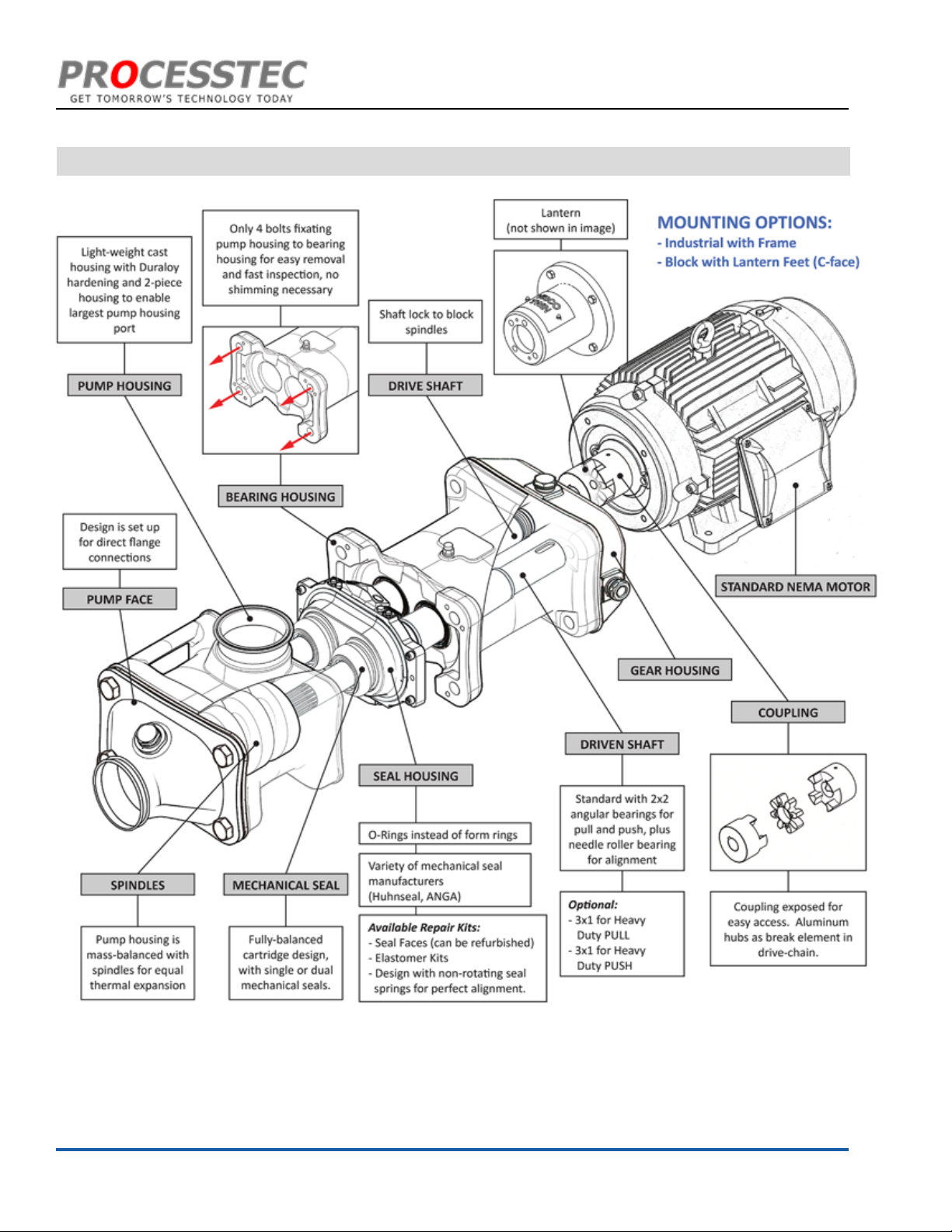

Screw pumps are rotary posive displacement pumps for conveying low to high viscosity media. The

ViscoTwin G8 is a posive displacement pump characterized by a double screw, or spindle, design. The

pump ulizes very close tolerances to create a series of “sealed” chambers between spindle windings.

This allows the pump to more eciently transport highly viscous product with minimal slippage and

precision owrate control as well as gentle handling of solid parculates already mixed into the product.

The precision crasmanship of the ViscoTwin G8 means it can generate a very high pressure dierenal,

even with a low inlet pressure.

The pump is also highly customizable, with several sizes and inlet/outlet variaons to suit the needs of

the product and the space available. Addionally, the pump is maintenance friendly and fully CIP-able, to

ensure ease of use.

ViscoTwin G8 pumps used in the food and beverage industry are designed to meet the most stringent

sanitary design criteria (3A, EHEDG), and are built with corrosion-resistant materials in accordance with

recommendaons from US Food and Drug Administraon (FDA) and other internaonal food safety

governing bodies. Pumps are delivered with a motor, lantern, and framing as standard for easy installaon.

1. ABOUT VISCOTWIN SCREW PUMPS

Page 4 PROCESSTEC INC. 2022

1.3 General Overview

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 5

1.4 Opons

1.4.1 Opons for 3A or EHEDG

All ViscoTwin pump models including all associated

opons as listed throughout this Secon 1.4 are designed

according 3A and EHEDG guidelines. General design and

detail design consideraons like radii, O-ring grooves,

surface treatment, material, and elastomer selecon

fulll both norms.

Only pumps for the US dairy industry require the 3A symbol aached to it. The only dierence is a slight

improvement on the spindle polish. In case the spindles are hardened with the kolsterizaon process, the

spindels show a mae surface, because the spindle polishing took place before the kolsterizaon process.

All ViscoTwin Pump Housings are hardened with a

DURALOY treatment. The inside surface of the pump

housing is always mae.

The general build of all ViscoTwin pumps also fulll

OSHA guidelines.

1. ABOUT VISCOTWIN SCREW PUMPS

Page 6 PROCESSTEC INC. 2022

1.4.2 Pump Face Opons

Processtec is always on the lookout for new ways to innovate pro-

ducts in our Industry, and so we are proud to announce the NPSH

Opmized Pump Face. It was designed to transion pumped product

more eciently and gently between the pump face and the pump

housing. This design helps in many ways: it keeps the product whole

and intact, it eliminates cavitaon, and gives the customer more op-

ons for piping conguraons.

The NPSH Opmized Pump Face is designed to increase the eciency of the pump face during either

sucon or discharge. During sucon, the product has to transion from the cross-seconal area of a 4”

OD tube (or smaller) to a cross-seconal area of the pump housing. By the mass ow rate equaon and

Bernoulli’s equaon, respecvely:

The above equaons imply that:

That is, that as the product goes from the smaller inlet to the larger pump housing, the velocity decreases

thus the pressure increases. This increased pressure results in a higher NPSHa, thus increasing the pump’s

capabilies. The NPSH Opmized Pump Face also comes with a G1” sanitary port to add a pressure sensor

to see the process in acon.

Another factor considered in the NPSH design is smooth ow transion. Sudden changes in diameter

rapidly increase the Reynolds number of the ow, which can create turbulent ow that will both decrease

the pump eciency and could damage sensive product. The NPSH pump face addresses these concerns

by using a diverging nozzle to expand the ow evenly, avoiding sharp corners and sudden changes to the

ow characteriscs.

The Dual Port Pump Face uses the same principle as the NPSH

pump face. This conguraon allows for two lines to conjoin at the

pump which reduces piping system complexity, while maintaining

the eciency of the NPSH standard pump face.

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 7

There is also an Eco Pump Face. This is an economic opon pum-

ping less viscous or more robust product that can withstand the ra-

pid pressure changes and turbulent ows addressed in the NPSH

pump face.

Both the NPSH Opmized and Dual Port Pump Faces are

standardized on 4”OD and a Tri-Clamp connecon. Several other

size opons and process connecon opons exist but will require longer delivery mes. These available

opons are outlined in the tables below.

PORT SIZE OPTIONS

OD3" OD4" (Std.) OD5" OD6" DN80 DN100 DN125

PROCESS CONNECTION OPTIONS

Tri Clamp

(Standard) DIN 11851

DIN 11864-1

(Screwed Union)

DIN 11864-2

(Flange Union)

DIN 11864-3

(Clamp Union,

Feral Collar Side) Varivent Flange Bu Weld Short Pipe

NOTE: Processtec supplies the Non O-ring / Collar side; the mated O-ring Groove side & clamps are not

included with the ViscoTwin Pump.

1. ABOUT VISCOTWIN SCREW PUMPS

Page 8 PROCESSTEC INC. 2022

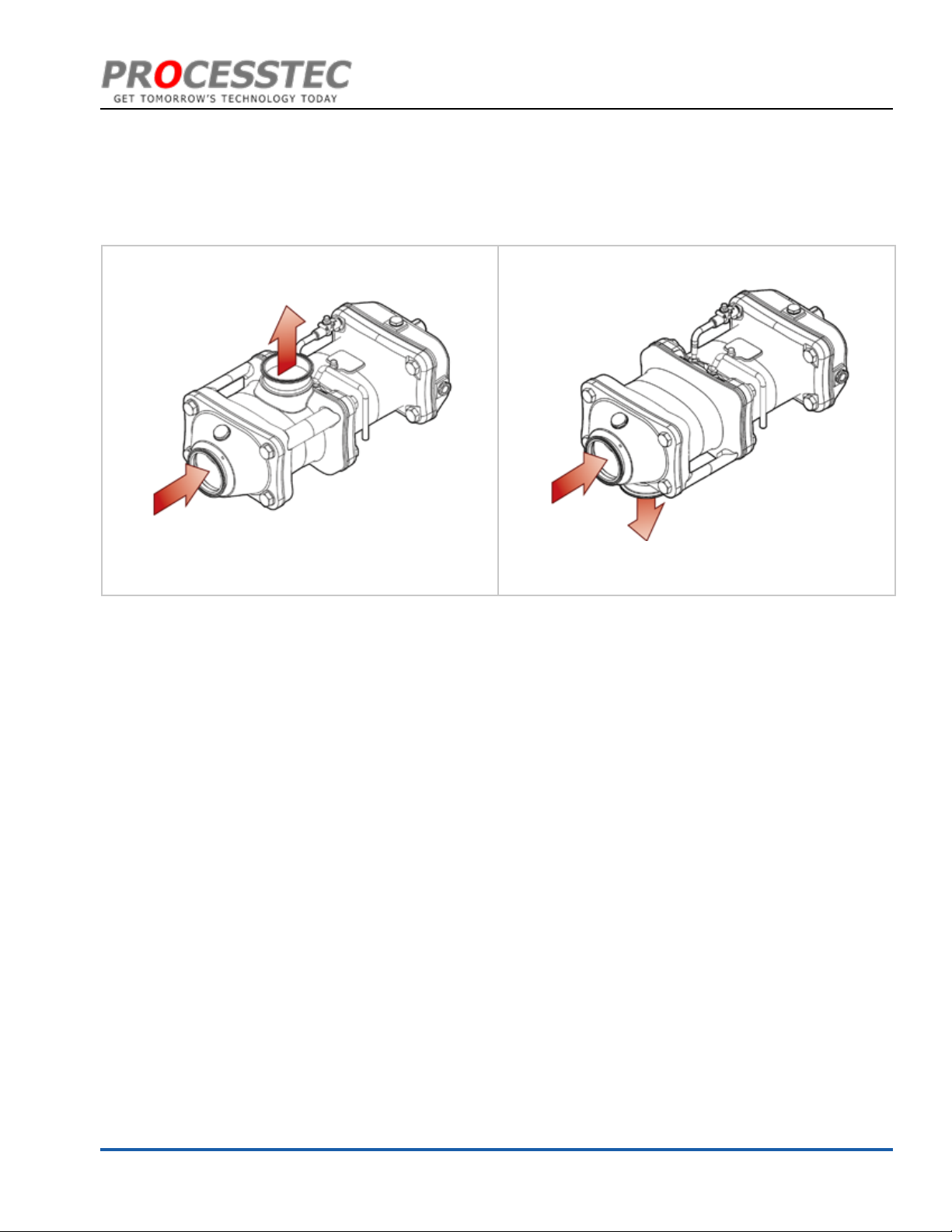

1.4.3 Pump Housing Opons

Flow Direcon

The ViscoTwin G8 has two general ow direcons: Face in -> Housing out (FH) and Housing in -> Face

out (HF)

It is preferred to drag the product along the boom of the housing which requires the shas to spin

“outwards”.

Spindle arrangement for shas turning “Outwards”:

Housing arrangement “FH” -> Spindle arrangement “V”

Housing arrangement “HF” -> Spindle arrangement “A”

Outwards turning shas require the PIN arrangement “3”

Spindle arrangement for shas turning “Inwards”:

Housing arrangement “FH” -> Spindle arrangement “A”

Housing arrangement “HF” -> Spindle arrangement “V”

Inwards turning shas require the PIN arrangement “1”

The most common arrangement for ViscoTwin pumps is arrangement FHO3V (see page 96).

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 9

Port Direcon

The ViscoTwin G8 also has two general port direcons: Discharge to Top, and Discharge to Boom.

Discharge to Top Discharge to Bottom

1. ABOUT VISCOTWIN SCREW PUMPS

Page 10 PROCESSTEC INC. 2022

1.4.4 Elastomer Opons

Elastomer Selecon Table

MAX. TEMP MAX. FAT TEMP / STRESS

EPDM 140° C 10% 28 bar

FKM 120° C 100% 28 bar

V70SW 200° C 100% 40 bar

PERLAST 200° C 100% 50 bar

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 11

1.4.5 Spindle Opons

Three dierent spindle pitches are available for each ViscoTwin pump size. Each individual spindle pitch

itself has the following opons:

• Standard EHEDG polish

• Standard 3A polish

• Hardened EHEDG polish

• Hardened 3A polish

• Hardened tapered EHEDG polish

• Hardened tapered 3A polish

Smaller spindle pitches are used to create high discharge pressures, especially with product at viscosies

below 2000 cps, at the cost of liming the ow rate. Larger spindle pitches can be used for high viscous

product at medium discharge pressure, and/or high owrates of low viscous media like CIP at lower

dierenal pressures.

For product with specic parculate sizes, the spindle pitch will determine the minimum pump size. For

example, if the parculate requires a cross secon of 1", then the pump would need to be a Model 104.53

or Model 130.65.

33mm 44mm 65mm

Volume per Revoluon

SIZE SCREW PITCH VOLUME PER REVOLUTION

METRIC US STANDARD

PARTICULATE SIZE

METRIC US STANDARD

ViscoTwin

130 G8

33 mm 0.317 Liter 0.084 Gal 16.5 mm 2/3"

44 mm 0.423 Liter 0.112 Gal 22.0 mm 6/7"

65 mm 0.623 Liter 0.165 Gal 32.5 mm 1-2/7"

Max Pump Head RPM: 3000 rpm.

1. ABOUT VISCOTWIN SCREW PUMPS

Page 12 PROCESSTEC INC. 2022

1.4.6 Mechanical Seal Opons

Dierent mechanical sealing surfaces and elastomers are available for the ViscoTwin G8 pumps. Material

and design are selected based on applicaon.

For easy handling, the ViscoTwin 130 G8 is designed to use a fully pre-assembled cartridge seal to prevent

assembly errors and damages to the sealing surfaces.

For a long service life, please follow the operang condions the mechanical seals are designed for.

Processtec has mechanical seals for various pressure and temperature requirements available.

Design Opons

Mechanical seals for the ViscoTwin are categorized as follows:

• Single Acng Mechanical Seals (SAMS)

• Double Acng Mechanical Seals (DAMS)

Available sealing surfaces in the product area:

• Silicon Carbide (SIC)

• Tungsten Carbide knife edge (TC)

Available Elastomers in the product area:

• FKM (standard)

• EPDM for high temperature without fat content

• FFKM (special applicaons for high temperature, fat content, and stress)

The mechanical seals are designed to withstand a product area pressure of up to 400 psi. High pressure

seals can be used when the product area pressure can reach up to 630 psi, however, these seals can

only be used in a specially designed HPHT (High Pressure, High Temperature) ViscoTwin. Please contact

Processtec for more informaon on our High-Pressure pumps.

1. ABOUT VISCOTWIN SCREW PUMPS

PROCESSTEC INC. 2022 Page 13

Single Acng Mechanical Seals (SAMS)

ViscoTwin G8 Pumps with single acng mechanical seals CANNOT run dry.

Due to the self draining capability of ViscoTwin G8 pumps, Processtec

does not recommend using single acng mechanical seals for standard

applicaons.

Double Acng Mechanical Seals (DAMS)

ViscoTwin G8 pumps with double acng mechanical seals can run dry as long

as the quench media ows through the seal. The quench media lubricates

and cools the sealing surfaces whether there is product in the pump or not.

The quench area is located between the inboard sealing surfaces (product

area) and the outboard sealing surfaces (atmosphere). The quench media

reduces fricon between the rotang sealing surface and the stac sealing

surface. The quench media, in most cases, is city water, single pass. It can be

glycerine or vegetable oil recirculated from a quench tank.

Sealing Surface:

Silicon Carbide (SIC)

Sealing Surface:

Tungsten Carbide knife edge (TC)

1. ABOUT VISCOTWIN SCREW PUMPS

Page 14 PROCESSTEC INC. 2022

1.4.7 Bearing Housing Opons

Housing Opons:

There are two housing opons available for the ViscoTwin Bearing Housing and Gear Housing. Both have

disnct advantages.

Stainless Steel

The Stainless Steel bearing housing is our standard opon.

The Stainless Steel bearing housing will not show external

wear even aer many years in operaon, and fullls the

highest sanitary standards.

The Stainless Steel bearing housing includes:

1) The Gear Housing Inspecon Port, which allows for:

• A mounng space for a vibraon sensor & oil temperature

sensor to connuously monitor pump performance.

• Easy oil sampling for gear oil quality tesng.*

• Spindle gapping without needing to remove and replace

the gear oil.

2) A second Oil Sight Gauge, which allows for:

• Oil level inspecon from either side of the pump.

• Easier gear oil visual inspecon (parculates in the oil,

discoloraon, etc.)

*oil sample tesng kits can be ordered at: info@processtec.com.

Powder Coated

The Powder Coated bearing housing is an economic soluon

made from cast iron. The powder coang is resilient to external

weathering, however some wear can show over me.

Table of contents

Other PROCESSTEC Water Pump manuals

Popular Water Pump manuals by other brands

Graco

Graco SaniForce 3250 Operation

Hydor

Hydor Koralia 900/240 user guide

Veneto

Veneto Bombas MN Instructions for use and maintenance

GORMAN-RUPP

GORMAN-RUPP VGH Series Installation, operation and maintenance manual

Sera

Sera 409.2 ML Series operating instructions

Watson-Marlow

Watson-Marlow 530 Bp Installation, operating and maintenance manual

Graco

Graco Husky 15120 repair parts

jtc

jtc PCF 200 INSTALLATION - EXERCISE AND MAINTENANCE INSTRUCTIONS

InoTec

InoTec Inomat M8 Operation and maintenance instructions

Hospira

Hospira GEMSTAR 13088-04-01 System Operating Manual

Royal Exclusiv

Royal Exclusiv Red Dragon 6 Operating and maintenance manual

Binks

Binks Maple 30/3 Service manual