ProCo 240 Instruction manual

Installation, Operation &

Maintenance Manual

Style 240/242

2431 North Wigwam Dr.

Stockton, CA 95205

Phone: 800-344-3246

Fax: 209-943-0242

Proco Products, Inc. Page 1 2013 IOM 240/242

Table of Contents

1.0 Introduction: 2

2.0 Storage and Handling: 2

2.1 Storage: 2

2.2 Large Joint Handling: 3

3.0 Prior to Installation: 3

3.1 Verify System Parameters: 3

3.2 Pipe Anchoring/Supports: 3

3.3 Pipe Alignment: 4

3.4 Concurrent Movement Calculation: 5

3.5 Unpack/Inspect Expansion Joint: 5

4.0 Expansion Joint Installation: 6

4.1 Installation Precautions: 6

4.2 Control Unit Installation Configurations: 7

4.3 Installation Procedures: 9

5.0 System Testing: 14

6.0 Operation and Maintenance Procedures: 14

7.0 Trouble Shooting: 15

Appendix A: Torque Data: 16

Appendix B: Installation Record Sheet: 18

Proco Products, Inc. Page 2 2013 IOM 240/242

1.0 Introduction:

Proco Products, Inc. (Proco) rubber expansion joints are flexible connectors fabricated of natural or synthetic

elastomers and fabrics and if necessary metallic reinforcements, to provide stress relief in piping systems due to

thermal expansion/contraction, mechanical vibration and/or system movements. This installation, operation and

maintenance manual will cover the general practices for the proper installation, operation and maintenance of the

Proco molded spherical type rubber expansion joints. The Proco style of rubber expansion joints covered in this

guide include the style 240 and style 242, molded rubber expansion joints incorporating floating flanges.

Figure 1: Style 240 & 242

Note: The style 242 comes with a reinforcing ring in-between the 2 arches and depending on the size the reinforcing

ring is either embedded in the carcass or exposed.

2.0 Storage and Handling

2.1 Storage

2.1.1Inside:

The ideal storage location for an expansion joint is in a warehouse setting with a relatively dry

and cool location. Store the expansion joint face down on a pallet or wooden platform. Do not

lay other boxes on top of the expansion joint or expansion joint box.

2.1.2 Outside

If the expansion joint is to be stored outside, keep the expansion joint protected in a waterproof

protected crate until ready for installation. Also keep the expansion joint protected from any

external elements such as direct UV exposure and/or animals. Do not lay other boxes on top of

the expansion joint or expansion joint box.

Proco Products, Inc. Page 3 2013 IOM 240/242

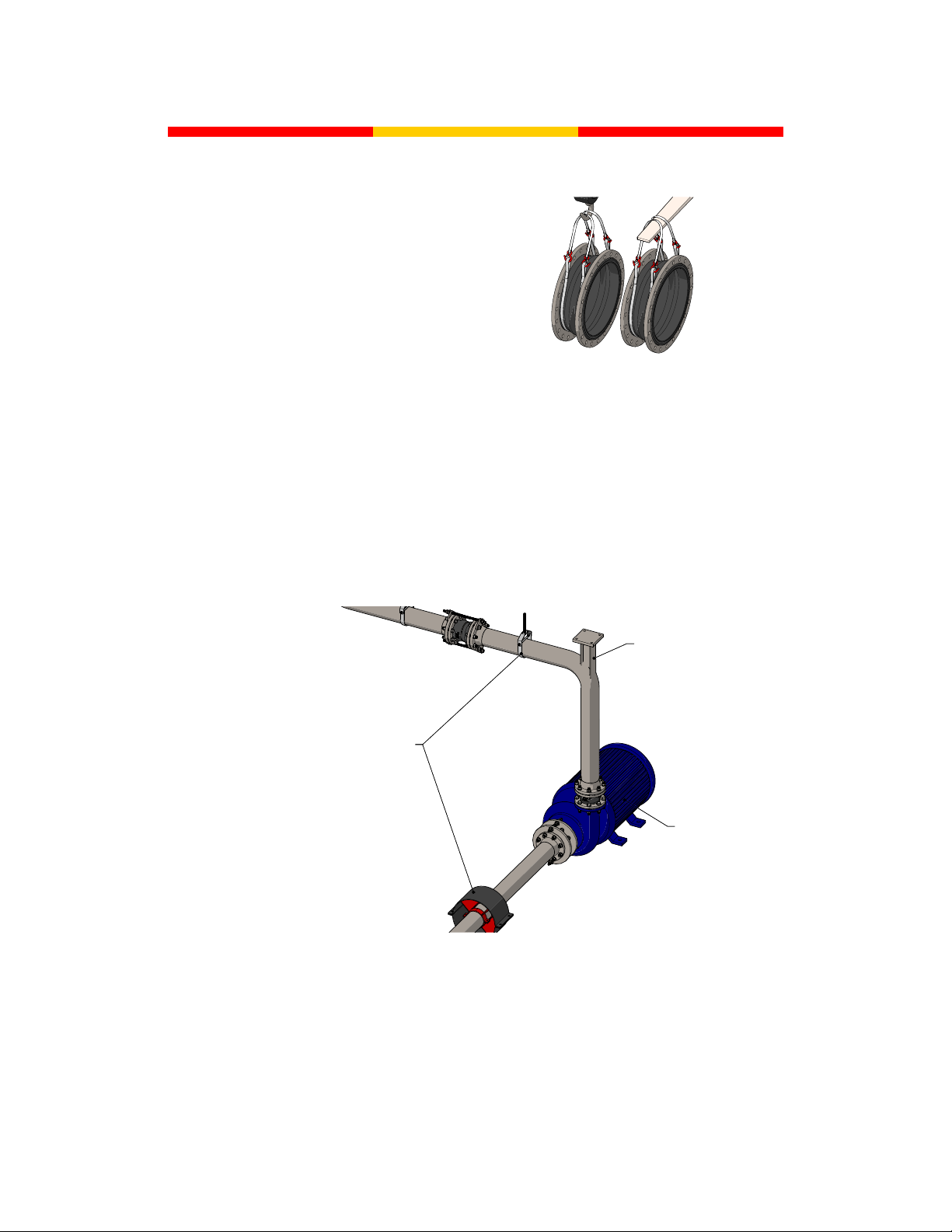

2.2 Large Expansion Joint Handling:

In the case of large size expansion joints,

special care should be taken in loading, hoisting

and lowering, being careful not to hit against

adjacent equipment, forklift tines, crane cables,

etc. Lift utilizing nylon slings around the exterior

of the expansion joint as shown in Figure 2.

Position the slings to each side of the arch; this

will help prevent any damage to the arch as well

as to ensure that the weight is evenly distributed

during installation.

3.0 Prior to Installation:

3.1 Verify System Parameters

Check the system design parameters for the point of installation to ensure that the supplied expansion

joint meets the system requirements and that the system requirements do not exceed the rated

capabilities of the supplied expansion joint. (Pressure, Temperature, Material Compatibility, System

Movements)

3.2 Pipe Anchoring/Supports

Figure 3: Properly Anchored and Supported/Guided System

3.2.1 Anchoring:

Solid anchoring is required wherever the pipeline changes direction and expansion joints should

be located as close as possible to anchor points. If proper anchor points are not used, the

pressure thrust may cause excessive movements in the expansion joint and cause damage.

PROPERLY SUPPORTED

AND GUIDED PIPE SYSTEM

ANCHORED PUMP

PROPERLY ANCHORED

PIPE SYSTEM

PROPERLY SUPPORTED

AND GUIDED PIPE SYSTEM

ANCHORED PUMP

PROPERLY ANCHORED

PIPE SYSTEM

Figure 2: Large Joint Handling

Proco Products, Inc. Page 4 2013 IOM 240/242

3.2.2 Supports:

Check the piping supports where the rubber expansion joint will be installed. Piping to and from

the location of installation for the expansion joint must be properly supported and guided to

ensure that the weight of the piping is not transferred to the expansion joint.

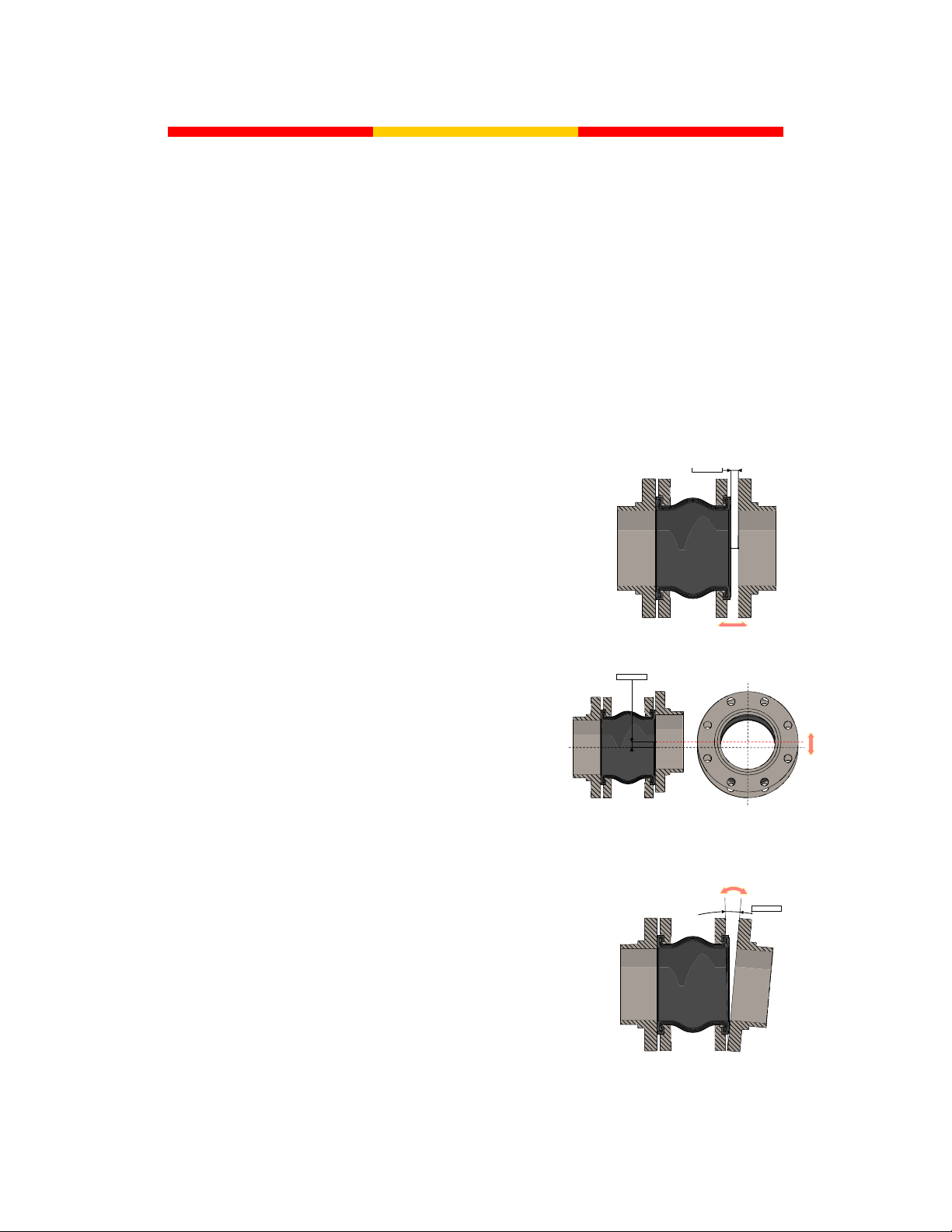

3.3 Pipe Alignment

Inspect the system for proper alignment as stated in the procedures listed below for axial, lateral, angular

and torsional alignment. Piping misalignment in the system should not exceed a maximum of ±1/8” per the

Fluid Sealing Association (FSA). If the maximum allowable misalignment is exceeded, the piping should

be corrected before installation of the expansion joint. The piping must be prepared to receive the rubber

expansion joint, never the contrary, as this would result in compressing, extending, laterally deflecting or

angularly bending the expansion joint until it fits into the available clearance for installation. This will result

in additional movements for the expansion joint, thereby decreasing its movement capabilities during

operation and lead to a possible failure.

3.3.1Axial Misalignment

To measure for axial misalignment, measure the

perpendicular distance from the inside of one

mating flange to the inside of the other, the area in

which the expansion joint is to be installed. This

measured dimension should correspond to the

ordered expansion joint’s face-to-face or overall

length dimension otherwise an axial misalignment

is indicated.

3.3.2 Lateral Misalignment

To measure for lateral misalignment, place a

level on the outside edge of the mating flanges

and measure the distance across. Repeat the

measurement at least 3 times to obtain a total of

4 measurements evenly distributed around the

circumference of the mating flanges (6-8 total

measurements for large ID expansion joints). Any

variation in the measured dimensions and an

inconsistency in the level, indicates a lateral

misalignment.

3.3.3Angular Misalignment

To measure for angular misalignment between

mating flanges, the distance from one mating flange

to the other will need to me measured. Measure the

perpendicular distance from the inside of one

mating flange to the inside surface of the other

mating flange. Take several of these measurements

in various positions around the mating flanges. Any

variation in the measured dimensions indicates that

the mating flanges are not parallel and are angularly

misaligned.

AXIAL

OFFSETAXIAL

OFFSET

Figure 4: Axial Misalignment

LATERAL OFFSETLATERAL OFFSET

Figure 5: Lateral Misalignment

ANGULAR OFFSET

Figure 6: Angular Misalignment

This manual suits for next models

1

Table of contents