Procon 8404 User manual

Tel: +44 (0)1442 242 224

E-Mail: techical@procon.co.uk

www.procon.co.uk

Programmable Control Panel

03 Models

8404 / 8406 / 8408 / 8416

Instruction Manual

2

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Description

The panels are designed to be easily programmable allo ing control of equipment by RS232 commands and

InfraRed. The system can be expanded to control equipment by contact closure using our Relay unit. More

buttons can be added using our Slave Panels. The 8400s have t o IR or RS232 ports, t o dedicated

RS232 ports and one I/O port. Each button has LED feedback. Four, Six, Eight and Sixteen button panels

are available. The panels are programmed using ProCon soft are. This is found on our CD catalogue or

Website .procon.co.uk

Button Labelling for 8 Button Master and (Slave Panels)

Master Panel buttons are al ays numbered 1 to 8. Slave panels can be configured for (1 to 8), (9 to 16) or

(17 to 24).

The buttons are numbered as above for programming purposes. When using the Four button version buttons

2/3/6/7, (10/11/14/15), (18/19/22/23) only are used and hen using the Six-button panel only 1/2/4/5/6/8,

(9/10/12/13/14/16), (17,18,20,21,22,24) are used.

Button Labelling for 16 Button Master and Slave Panel

16 Button panels are al ays numbered as above.

A range of pre-labelled buttons are available or button can be custom labelled by printing on A4 acetate.

Button1/9/17 Button2/10/18 Button4/12/20 Button3/11/19

Button5/13/21 Button8/16/24 Button7/15/23 Button6/14/22

Button1 Button2 Button4 Button3

Button5 Button8 Button7 Button6

Button9

Button11

Button10

Button16

Button13

Button15

Button12

Button14

3

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

A template is available as a Word document on the CD catalogue under ‘Label8x.doc’. The document sho s

boxes ith popular button names and each can be edited as required. When printed cut out the labels along

the black outline.

To fit the labels pop the buttons out from underneath the panel noting the orientation. Remove the lens cap

and the lens and insert the label into the lens cap. Refit the lens and then carefully push the button back into

place.

Buttons can be factory Pre-labelled. Contact ProCon Sales for details.

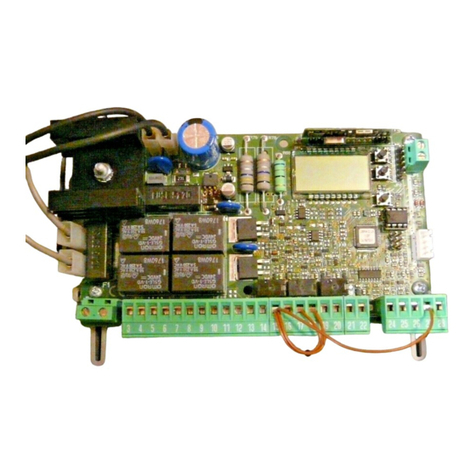

Installation

The panel is po ered from the supplied 12V po er pack, although any 12V non-regulated supply may be

used. Connect the hite strip lead to the 12V+ve scre terminal on the panel PCB and the Black lead to the

–ve. When the panel is po ered up or a program do nloaded, button 2 (and 10 on 16 button panel) ill

flash for 2 seconds then extinguish. This indicates the panel self test has passed.

All four ports may be used for general RS232 control but hen using the Procon expansion units the Xport

must be used exclusively. In this case the Xport RX must be connected to the Expansion unit TX.

DO NOT USE THE XPORT RX CONNECTION WITH ANY OTHER DEVICE.

Connect the TX and Gnd of the panel ports to the RS232 RX and Gnd of the Equipment to be controlled.

Ports 1 and 2 can be used for IR or RS232 control. Ports 3 and Xport are used for RS232 control but hen

using the Procon expansion units the Xport must be used exclusively. In this case the Xport RX must be

connected to the Expansion unit TX.

Typical 8400 installation

I/O Port

This can be configured to give a High or Lo TTL level (eg. For s itching a relay interface) or for detecting a

High to Lo or Lo to High state. (eg. For detecting an external s itch such as a PIR)

Output State Input State

I/O Gnd

I/O Gnd

Relay

Interface

PIR S itch

IR

IR

XPort

Port3

Port2

Port1

RX TX Gnd TX Gnd TX Gnd TX Gnd

VCR

DVD

ProCon 8300

PROJECTOR

RX

GND

RS232

RX

GND

TX

Max. cable length 25m/80ft.

(9600 Baud)

Max. cable length 25m/80ft.

4

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Slave Panels

Slave Panels can be daisy-chained as above. If other ProCon units are used then they should be connected

bet een the Master & Slave Panels. Use screened cable to link to units. The maximum cable length

bet een panels should not exceed 25m/80ft.

IR Transmitter

The IR transmitter heads are connected as follo s:

Program Download

To Do nload a program to the Panel connect the Programming cable to the Panel Program socket and the

Serial Port of the PC.

Programming Cable Pin Connections

RJ10 Plug

Front Vie

Pin 5 (Gnd)

Pin 3 (Tx)

Pin 2 (Rx)

Panel Port

Female D9 Connector

PC Serial Port

Black or Braid to Port GND

Blk\White or Signal ire to Port TX

Transmitter must be place directly in

front of the Device IR indo .

XPort

RX TX Gnd

Master Slave

To Master

RX TX Gnd TX RX Gnd

From Slave

Slave

To Master

RX TX Gnd TX RX Gnd

From Slave

GND

TX

RX

5

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Getting Started

The panels are programmed using the ProCon84X soft are.

For panels ith 01\02 suffix e recommend using version 3.92.

For panel ith 03 suffix e recommend using version 4.4 or later.

The soft are can be used directly from the CD or loaded onto a PC by running Set Up from the Soft are

folder.

The soft are allo s the panel to perform various functions such as RS232/IR control / Button Feedback /

Delay Time / Relay Control / Time Out if a button press is not detected after a certain time period. Run the

ProCon84X soft are and click on ‘Help’ click on ‘Getting Started’. This gives a brief description of the ho to

use the soft are. Close the indo then click on ‘Help’ then ‘HelpWindo On’. This gives a description of

the major items as the Cursor passes over them. Take time to familiarise yourself ith the items.

Programming Step by Step

Each button is programmed individually it can be made to action on Pressing or Releasing. It can be

programmed to Toggle for up to 4 Presses or it could be assigned to a Bank of buttons having the same

function but controlling different equipment. A Script is ritten for each button containing up to 24 events. A

script can be ritten for events to action hen the Panel is po ered up by selecting ‘Start Up’ from the

Program Button dropdo n list.

An Event could be an RS232 command, a button Feedback, a Delay Time etc..

When all the buttons have been programmed the information can be Do nloaded to the panel.

Start by running the Procon84X soft are.

Feedback

A button LED has 3 states. On / Off / Flash. It can be assigned to a group here only one LED of the group

may be on at any one time.

To add Feedback to a Button Script Example)

Select a button to program from the ‘Program Button’ dropdo n list.

Click on ‘Add Panel Feedback’. This ill open up the Feedback indo .

The chosen button LED ill be listed as the default although any button LED may be selected.

Select ‘On’ from the Action dropdo n list and click on ‘Add to Script’. The Event Script ill sho Event1 as

being the chosen button Feedback On. Chose another Feedback LED and click on ‘Flash’ add this to the

Script. The Event Script ill no sho Event2 as being the chosen LED Flash.

No Test the program by going to the ‘Do nload’ section.

When the panel has been loaded Press the programmed button. The chosen button for Event1 ill illuminate

and the button for Event2 ill flash. Try programming other buttons ith On / Off / Flash actions.

To Save any programs click on Save from the File menu and give them a title.

6

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

On / All Buttons Off

This function ill illuminate the chosen Feedback button and turn off any other on the panel.

On / Group Off

This allo s you to assign an LED to a group here only one of the group may be illuminated at a time. For

instance Play / Stop / Pause. An LED may be assigned to up to 8 groups.

To illustrate this, clear the program by selecting ‘Ne ’ from the File menu.

Select Button 1 to program and open the Feedback indo . From the Action list select ‘On/ Group Off’. Click

on ‘Group1’. Repeat for Buttons 2 to 4.

Select Button 5 to program, open the Feedback indo and select On/ Group Off, click on ‘Group2’. Repeat

for buttons 6 to 8.

Do nload the program to the Panel.

Press Button1, this ill illuminate. No press Button2, this ill illuminate and extinguish Button1. Only the

pressed button of 1 to 4 ill stay illuminated.

Like ise only the pressed button of 5 to 8 ill stay illuminated.

Delay Time

A delay time can be added in bet een events in a Script. This can be from 0.5 seconds up to 24hours. The

delay is absolute and no other Event or Button press ill be ackno ledged until the time period has elapsed.

Adding Delay Time to a Script. Example)

Select a Button to program and Add Feedback Button to Flash as Event1.

Click on ‘Add Time Delay’. This opens up the Delay time indo . Using the scroll bars you may set a time

period. For this example set the Time period for 5 seconds. Click on ‘Add to Script’. The Set delay no

appears as Event2.

Select the Feedback button action to On and add to script as Event3.

Do nload the program and press the programmed Button. This ill flash for 5 seconds then stay On.

RS232 Command

The Panel can be programmed to output an RS232 command on a Button action.

A command is contained ithin a Library.

Select ‘Ne ’ from the File menu to clear the program.

Click on ‘Add RS232 Function’ this ill display the RS232 indo . The indo ill tell you

the current library selected. The default is the Proconlib library containing the RS232 commands for ProCon

equipment set at address 0. If the Device to control is ithin another Library then click on ‘Change Library’

and select the library to display.

To add an RS232 command to an event, first select the device to control from the dropdo n menu then the

function. Next select the panel port the device is connected to. Finally select the action. This may be Send

Once, Send No. of Times or Send Continuous. Send Once ill send the command string one time only. Send

7

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

No. of times allo s you to send a command up to 50 times, selectable from a scroll bar. Also you may set a

delay time bet een strings, again selectable from a scroll bar. Send Continuous ill send continuous strings

hile a button is actioned. A delay time can be set bet een strings. This action is useful for Volume Up and

Do n commands ith ProCon equipment. Setting a delay time of 150mS bet een strings gives a steady

ramp up and do n.

When the RS232 parameters have been set click on ‘Add to Script’.

RS232 Libraries

To Add or Edit information to libraries first open the RS232 indo then click on ‘Vie RS232 Library’.

This ill display a ne page sho ing the currently selected Library Contents. To vie a functions’ Protocol

and string settings, Select the Device from the Dropdo n menu and its’ function. All the relevant information

ill be displayed. Protocol can be changed by selecting ne settings for Baud rate, Data bits and Stop bits.

Command strings can be edited by changing Byte values. All Byte values are entered in Hex, Ascii or

Decimal. Select the type from ‘Code Format ‘ in the menu bar. When an edit is complete click on ‘Save Edit’

to store ne values. To add a ne device to a Library click on ‘Add Ne Device’. Enter the Information then

‘Save’. The screen ill then prompt you a to name a Function. Type the Function name in the box then enter

the command string and Protocol. Click ‘Save Edit’ to store.

A ne function can be added to an existing Device by clicking on ‘Add Ne Function’.

To copy a list of functions from an existing device to a ne device first select the device to copy from

then click on ‘Copy Functions’. Type in ne device and description then save.

For easy finding of Functions it is recommended that groups of Libraries are made containing common

Devices. Ne Libraries can be created by clicking on Ne from the File Menu. Save the Library using a

relevant name, such as the equipment Brand name or Projector etc.. Devices and Functions can be added to

the Library as above.

As a confidence check hen editing or adding, a function can be tested by directly connecting the PC to the

Device RS232 port. Select the PC serial port you are using from the dropdo n list and press ‘Test’. The

Device should then respond to the command sent.

To connect to a Device a test cable can be made as follo s:

PC Serial Port (female D9 connector) Pin 3 to Device (RX) / Pin 5 to Device (Gnd)

Verifying RS232 Commands

To check a command from a Panel Port use the Verify Command screen.

First go to the RS232 Library screen and click on Verify Command from the Menu Bar, this ill bring up the

Verify Command screen.

A cable ill be required to connect the Panel port to the PC serial port. Connections are as follo s:

Port TX to female D9 Pin 2

Port Gnd D9 Pin 5

From the dropdo n list select the PC serial port the cable is connected to.

Set the Baud rate, Data Bits and Stop bits to match the command Protocol.

Click on ‘Capture Command’ then press the Panel button to transmit command.

The captured string ill appear in the Byte boxes. This should match the string in the Library.

8

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Infra Red Command

The Panel can be programmed to output an Infra Red function on a Button action.

A function is contained ithin a Library.

Select ‘Ne ’ from the File menu to clear the program.

Click on ‘Add IR Function’ this ill display the IR indo . The indo ill tell you the current library

selected. If the Device to control is ithin another Library then click on ‘Change Library’ and select the

library to display. To add an IR function to an event first select the device to control from the drop do n list

then the function. Next select Panel or the address of an 8300 unit from the address list then the panel port

the device transmitter head is connected to. Finally select the action. This may be Send IR Pulse, IR Pulse

number or Send Continuous. Send IR Pulse ill send the IR function one time only. IR Pulse No. allo s you

to send a function up to 120 times, selectable from a scroll bar. Send Continuous ill send continuous

pulses hile a button is actioned. This action is useful for Volume Up and Do n and Cursor functions. When

hard iring to a device the carrier may have to be turned off, refer to Manufacturers instructions, other ise

carrier must be left On.

When the IR parameters have been set click on ‘Add to Script’.

Infra Red Libraries

To Add information to libraries first open the IR indo then click on ‘Vie IR Library’.

This ill display a ne page sho ing the currently selected Library Contents. To vie a functions’ data,

Select the Device from the Dropdo n menu and its’ function. All the relevant information ill be displayed.

To add ne devices and functions a Procon 8300 or 8350 IR Learner unit ill be required.

Connect the 8300/8350 Program Port to a PC serial Port using the standard programming cable.

From the menu bar select the PC Serial Port the cable is connected to.

To add a ne device to a Library click on ‘Add Ne Device’. Enter the Information then ‘Save’.

Click on ‘Learn Ne Function’. Enter a name for the function then follo the on screen instructions.

Capture status ‘A’ led ill turn Red indicating Ready to Learn. When function has been learnt the led

ill turn Green. Status ‘B’ ill turn Red indicating a presence of InfraRed. This is a useful indication

that a handset is orking. When a function has been learnt the screen ill prompt to Test. If using an 8300

select the IR Port from the drop do n list the Transmitter head is connected to and place head in front of the

Device IR indo . If using an 8350 place the unit in front of the device. Click on ‘Test’.

The screen then prompts ‘Confirm’. If function operates click on ‘Yes’ other ise click on ‘No’ and follo the

on screen instructions. A library function can be re-learnt by clicking on ‘Re-Learn Function’ and follo ing the

above procedure.

For easy finding of Functions it is recommended that groups of Libraries are made containing common

Devices. Ne Libraries can be created by clicking on Ne from the File Menu. Save the Library using a

relevant name, such as the equipment Brand name or Projector etc.. Devices and Functions can be added to

the Library as above.

A function can be tested at any time by using an 8300 or 8350 and connecting to a PC.

Select a function and relevant IR Port and click on ‘Test’.

I/0 Ports

A panel has one I/O port the 8300 has t o.

An I/O port can be configured for ‘Input or Output’.

9

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Output means the port can be controlled to give a High state (+5v TTL) or a Lo state (0v). This useful for

s itching relays etc.

Input means that a script can be actioned hen a High to Lo or Lo to High state is detected on the Port.

This is useful for external detection of a s itch or PIR.

10

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

The default setting of all IR ports is Output. To change to Input click on ‘I/O setup’ from the Menu bar.

The I/O Ports gives a list of all possible I/O ports on a system. To change a Panel port to Input select ‘Panel

I/O Port’ from the top of the list. To change an 8300 I/O port select the address of the unit from the list and

the Port number. A maximum of 4 ports can be configured for Input. Once the Port settings have been

confirmed they cannot be reset ithin a program. If a mistake has been made select Ne from the file menu

and start again.

To add an Output function to a script click on ‘Add Output function’ this ill display the Output indo .

The Unit address displays all the possible Output ports on a system. From the list select the Port and the

state to change to and add to a button script. When the button is actioned the Port ill change to the

programmed state.

To rite a script for an Input port click on ‘Button’ from the Menu bar and select Input Port.

A list of the configured Input ports ill appear. Select the Port and the state change from the list and rite a

script as normal. When the programmed Port state is detected the script ill action. If the Panel is ‘busy’

hen the state change occurs the script ill action hen the Panel is ‘free’. To return to the button list select

Press from the Button menu.

Button Action

A button action can be changed by clicking on ‘Button’ from the menu bar. 4 options are available.

Press – script is programmed for a button press. Release – script is programmed hen a button is pressed

then released.

Toggle – up to four different scripts can be ritten for a button. Chose a button to program and select

‘Toggle’ from the Button menu. Click on ‘Enable’. Select the number of toggle presses required for the

button. Program the script as normal for the first button press. Next select 2

nd

button Press from the

dropdo n menu. Program the script for the second press. Continue for each required button press.

When the panel is programmed the button ill toggle on each button press then loop to 1st press.

Bank Assign – A button can be assigned to one of three Banks each bank can have up to four functions.

This is useful if you have a common set of buttons for Play/ Stop/Pause controlling different sets of

equipment. In this case three buttons can be assigned to a Bank. These three buttons could then control four

different sets of equipment.

Chose a button to program and Select ‘Bank Assign’ from the Button menu. Select Bank X.

Write a script for X1 Function then X2 etc..

Enable a Bank – This function orks alongside the Bank Assign. Enabling a Banks function ill

then allo another button or groups of buttons to perform the programmed script ritten for the Bank

Function.

Chose a button and set it to Toggle 4 times. For the 1

st

press Click on ‘Enable a Bank’ and select X2

Add this to the script. 2

nd

Press add X3. 3

rd

Press add X4 and 4

th

Press add X1.

When the panel is programmed the Bank Assigned button ill perform the X1 script hen it is pressed.

Pressing the Toggle ill the enable X2 and the Bank Assigned button ill then perform the X2 script etc..

On Panel po er up the default Bank Function is X1, Y1, Z1.

Example of Bank Assign to control a VHS player and DVD using common Play/Stop buttons.

Select Button 1 to program: Select Bank assign from Button menu: Click on BankX.

Using the Add IR Function chose a VHS play command and add this to the script.

Select X2 from the dropdo n list in the Assign to Bank indo .

Select a DVD play command from the Add IR Function and add to script.

11

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Select Button 2 to program. Repeat as above using VHS and DVD stop commands.

Select Button 3 to program. Click on Enable a Bank: Select X1 and add to script.

Select Button 4 to program: Click on Enable a Bank: Select X2 and add to script.

Do nload program to Panel.

When Button 3 is pressed Buttons 1 and 2 ill operate Play/Stop on the VHS.

When Button 4 is pressed Buttons 1 and 2 ill operate Play/Stop on the DVD.

Advance Toggle

This function ill allo a button to skip toggles, for example, a button is programmed to toggle

a Device on and off and the first press turns the Device on. If the Device is also turned off by a Time Out

function then pressing the button a 2

nd

time ill have no effect as the Device is already off.

By programming an Advance to Press 1 in the Time Out script the Toggle button ill then be set to s itch

the Device on again on the next press.

Click on ‘Advance Toggle’ to open the indo . Select the Toggle button and click on the Press number to

advance to.

Panel Lockout

Adding Panel Lockout to a script ill halt an event list at that point. This also means that any button press ill

be ignored. To unlock the Panel press buttons 2 and 6 simultaneously.

Copy and Paste

Click on the Copy button and the paste indo ill open displaying the current button script. The script can

be trimmed using the Select Event controls. Select the button to copy to from the dropdo n list and click on

Paste. The copied events ill be added to the ne button script. The paste indo can be used to copy

scripts to Ne and existing programs."

Time Out

A script can be ritten to action if a button press is not detected ithin a set time period, for example

s itching equipment off that may have been left running overnight. Three time periods can be set.

From the Program Button dropdo n list select ‘Time Out’. Set a time for Period1 and then rite a script.

When the panel is programmed and a button press is not detected ithin the time period then the script ill

action. A 2

nd

period can be set to occur after the 1

st

period has elapsed. Again if a button press has still not

occurred ithin that time then the 2

nd

period script ill action. A 3

rd

period can be set to occur after the 2

nd

period has elapsed. If a button press is detected at any time then the internal clock ill be reset back to

detect for a button press during the 1

st

period.

File Menu

The file menu gives the option to Save and Open program files.

To clear the program for riting ne programs click on ‘Ne ’

Clicking on ‘Print Script’ ill print out a hard copy of the Script.

12

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Run Mode

There are t o modes of operation one being the default Manual run and the second Auto-Run.

Manual Mode – normal programming mode.

Auto-Run – events in a script ill start running 5 seconds after s itch on. Up to 162 events can be

programmed in a script and can be continually looped.

From the Run Mode menu select ‘Auto-Run’ then ‘Continue’.

Write the script then click on ‘Loop’ if you ant the script to continually run.

DownLoad

When a program has been ritten it can then be do nloaded to the Panel.

Connect the Programming cable to the Panel program port and the PC Serial port.

If using with an 8300 the system must be programmed from the 8300 Program Port.

Click on ‘Do nload’ from the Program menu. The programming indo ill appear.

From the dropdo n list select the PC serial port the cable is connected to.

Click on ‘Program’. All the buttons on the Panel ill illuminate and the program ill do nload.

When the do nload has completed the buttons ill dim and a message ill appear ‘Do nload Complete'.

If an error occurs check the follo ing:

Cable is correctly connected

The correct serial port number has been selected.

Shut do n any other programs running on the PC.

If problem persists po er do n the Panel, hold in buttons 2 and 6 and re-po er. Buttons 1 to 8 ill

illuminate. Release buttons 2 and 6 and do nload program.

Downloading an Auto-running panel

To program a panel that is currently Auto-running the panel must be po ered do n and the program

Do nloaded ithin the first five seconds of po er up before the panel starts auto-running again.

Slave Panels

A system can be expanded by using 4/6/or 8 button slave panels. The panels can be configured for up to 24

programmable buttons. The slave panels must be connected to a Master Panel. The panels can be

configured to operate buttons 1 to 8 (ie. Duplicate the Master), 9 to 16 of 17 to 24.

The panel numbering is set by Dip s itches on the rear of the Panel. The buttons are programmed by

selecting the required number from the Program Button dropdo n list and riting a script as normal.

The 16 button slave panel can only be connected to the 16 button Master. This duplicates the operation of

the Master Panel.

Relay Unit 8200

Connect the relay unit to the panel referring to the INSTALLATION section.

13

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Click on ‘Add Relay’, the Relay indo ill open. First select the Relay unit address from the drop do n

menu then the relay to control. Next select the relay action type. On ill latch the relay on,

Off ill latch the relay off. Momentary ill hold a relay on for a set period of time from 0.5 seconds up to 1

minute. The time period is set by a scroll bar. When the parameters have been set click on ‘Add to Script’.

Relay Unit 8210

Connect the relay unit to the panel referring to the INSTALLATION section.

Click on ‘Add Relay’, the Relay indo ill open. First select the Relay unit address from the drop do n

menu then the relay to control. Use Relay1/ Relay2/ Po er Relay from menu. Next select the relay action

type. On ill latch the relay on, Off ill latch the relay off. Momentary ill hold a relay on for a set period of

time from 0.5 seconds up to 1 minute. The time period is set by a scroll bar. When the parameters have been

set click on ‘Add to Script’.

IR Learner / IR Transmitter / I/O Unit 8300

This unit has the ability to learn ne Infra Red codes to add to the Infra Red programming Library as ell as

regenerating Infra Red signals. The unit has 6 IR Ports for controlling various devices and 2

I/O Ports. The unit can be programmed and controlled from ProCon control panels or alternatively can be

used as a stand alone unit being controlled directly from RS232 commands.

When using ith a Procon Panel connect as follo s:

PANEL XPORT 8300 RS232 IN

TX RX

RX TX

GND GND

To program the System the program cable must be connected to the 8300 program Port and a PC.

To program ith a Panel see ‘INFRA RED COMMAND’.

When a button ith an IR function is actioned the programmed IR port ill transmit the function.

When using ith an 8300 unit the status ‘B’ and IR port led ill flicker RED hile the unit is transmitting.

The unit has a 12V output for connection to a Panel.

To Learn ne IR functions see ‘INFRA RED LIBRARIES’.

To use as stand alone RS232 to Infra Red Interface

Run soft are Procon83X. The IR indo ill appear.

Set the Unit address using the Hex s itch on the rear of the Unit. From the drop do n list select the Unit

address.

Select a Device and a Function from the drop do n lists. To find a Device in another Library click on ‘Change

Library’. Click on ‘Add to Command List’. The selected function ill appear in the Command Reference

Table. Beside the function ill be a reference number X.

When all the required functions have been added to the list the 8300 can be programmed.

Connect the programming cable to the 8300 program port and a PC serial port. Click on ‘Program and Load’

from the Menu bar. Select the PC Serial Port the cable is connected to and click on Program.

When finished a message Do nload Complete ill appear. The unit can no be controlled using RS232.

The program can be saved by selecting ‘Save’ from the file menu.

14

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

The required Baud rate and Command is displayed on the Program screen. Byte 3 is the X reference of the

Function, Byte 4 is the IR Port number to transmit from and Byte 5 is the number of pulses to transmit. This

can be any number from 1 to 120. All Bytes are in Hex. Connect the RS232 device to the RS232 IN

connection on the 8300. Additional 8300s can be linked by ‘daisy chaining’ to the RS232 Out connectors,

see INSTALLATION. The RS232 device TX must connect to the Unit RS232 RX In and the device Rx must

connect to the unit RS232 TX In. When a valid command is sent the unit ill transmit the X numbered

function from the (Byte4) IR Port, (Byte 5) number of times. The status ‘B’ led and the IR Port led ill flicker

Red hile the function is being transmitted. The unit must finish transmitting before a ne command ill be

accepted. When the unit has finished transmitting it ill return Byte 0h from the TX connector.

To use as stand alone RS232 to I/0 interface

The 8300 has t o I/O ports. These can be configured for ‘Input or Output’.

Output means the port can be controlled to give a High state (+5v TTL) or a Lo state (0v). This useful for

s itching relays etc.

Input means an RS232 command ill be sent hen a High to Lo or Lo to High state is detected on the

Port. This is useful for external detection of a s itch or PIR.

Run soft are Procon83X. Set the Unit address using the Hex s itch on the rear of the Unit. From the drop

do n list in the IR indo select the Unit address.

The default setting of all IR ports is Output. To change to Input click on ‘I/O setup’ from the Menu bar.

To change an I/O to Input Tick the Input box.

The I/O code indo displays the RS232 codes required for controlling the Ports. When a port is set as

Output an RS232 command is sent to the Unit to change the state.

When a port is set as Input an RS232 code is transmitted from the Unit. The code ill continue to be

transmitted at intervals until the Ackno ledge code has been returned.

15

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Panel Control using External RS232 Commands

It is possible to have any Master panel respond to external RS232 commands. T o commands need to be

sent to activate a button script. The First command activates the button script. When the Panel has

completed the script it ill return the Script Finished code. The Second command ill ackno ledge that it

has received the Panel Finished code. If the system is being used without any feedback then a delay

must be added between the first and second command until the Panel has completed the script. he

Panel will be disabled until it receives the second command.

CONNECTIONS

Master Panel

Master Panel Xport External RS232 controller

RX TX

TX RX (Only connect if feedback required)

GND GND

With Feedback

Without Feedback

COMMAND 1 Button

Activated

Delay until

Script finished COMMAND 2

Panel

RX

X-Port TX

Or Gnd

FROM

SLAVE

TX

External

RX Controller

Gnd

feedback

COMMAND 1 Button

Activated

Ackno ledge

EC(h) Sent

Script

Performed

Script Finished

F0 17 20 Sent COMMAND 2

16

Tel: +44 (0)1442 242 224

E-Mail: technica[email protected]

www.procon.co.uk

Slave Panels

Slave Panel (To Slave Port) External RS232 controller

RX TX

TX RX (Only connect if feedback required)

GND GND

PROTOCOL

Baud Rate – 9600

Data Bits – 8

Stop Bits – 1

No Parity

COMMANDS

Button No. 1

st

Command 2

nd

Command

1 F2h 09h 81h 10h 01h F2h 09h 81h 01h

2 F2h 09h 81h 11h 02h F2h 09h 81h 02h

3 F2h 09h 81h 12h 03h F2h 09h 81h 03h

4 F2h 09h 81h 13h 04h F2h 09h 81h 04h

5 F2h 09h 81h 14h 05h F2h 09h 81h 05h

6 F2h 09h 81h 15h 06h F2h 09h 81h 06h

7 F2h 09h 81h 16h 07h F2h 09h 81h 07h

8 F2h 09h 81h 17h 08h F2h 09h 81h 08h

9 F2h 09h 81h 20h 09h F2h 09h 81h 09h

10 F2h 09h 81h 21h 0Ah F2h 09h 81h 0Ah

11 F2h 09h 81h 22h 0Bh F2h 09h 81h 0Bh

12 F2h 09h 81h 23h 0Ch F2h 09h 81h 0Ch

13 F2h 09h 81h 24h 0Dh F2h 09h 81h 0Dh

14 F2h 09h 81h 25h 0Eh F2h 09h 81h 0Eh

15 F2h 09h 81h 26h 0Fh F2h 09h 81h 0Fh

16 F2h 09h 81h 27h 10h F2h 09h 81h 10h

17 F2h 09h 81h 40h 11h F2h 09h 81h 11h

18 F2h 09h 81h 41h 12h F2h 09h 81h 12h

19 F2h 09h 81h 42h 13h F2h 09h 81h 13h

20 F2h 09h 81h 43h 14h F2h 09h 81h 14h

21 F2h 09h 81h 44h 15h F2h 09h 81h 15h

22 F2h 09h 81h 45h 16h F2h 09h 81h 16h

23 F2h 09h 81h 46h 17h F2h 09h 81h 17h

24 F2h 09h 81h 47h 18h F2h 09h 81h 18h

FEEDBACK

Ensure the Panel TX connection is made to the RX of the RS232 controller.

When a Master Panel receives the First command it ill return an Ackno ledge code: ECh.

It ill then perform the programmed Button script. When it has completed the last event

of the script it ill return a script Finished code: F0h 17h 20h.

The Panel ill ait until it receives the second command.

If the system is being used without any feedback then a delay must be added between the first and

second command until the Panel has completed the script. he Panel will be disabled until it

receives the second command.

This manual suits for next models

3

Table of contents