Procon LD160 Series User manual

Single Channel Loop Detector

The LD160 is a single channel inductive loop detector designed for traffic

control applications.

The detector is connected to an inductive loop mounted in the road surface.

When vehicles pass over the loop the detector switches on an output.

The use of microprocessor and surface mount technology enables a large

number of functions to be incorporated into a small package. The LD160 is

compatible with most single channel detectors on the market and is easy to

set-up and install.

Typical applications in the traffic environment are traffic control (traffic lights), toll systems and vehicle counting.

Reset Switch. Pressing the reset switch enables the detector to be manually reset during commissioning and

testing. This results in the detector re-tuning the sensing loop and becoming ready for vehicle detection.

Switch selectable Sensitivity. The detect sensitivity is the minimum change in inductance required to produce a

detect output. (%∆L/L). Eight sensitivity settings are available on the switches to allow flexibility in configuration.

Switch selectable Frequency. Two frequency settings are available to prevent cross-talk between adjacent

loops.

Fault Relay feature. The Fault relay is activated when a fault has occurred on the loop.

Indicators

Features

App

lications

Model - LD160 Series

Power Indicator. This LED Indicator illuminates when power is present.

Detect Indicator. This LED Indicator is illuminated when there is a vehicle over the loop or the loop is faulty. This

LED can also be used to determine the loop frequency. On reset, count the number of times the LED flashes.

Multiply this number by 10KHz.For example: if the LED flashes 6 times, then the loop frequency is between

60KHz and 70KHz.

Loop Fault Indicator. This LED Indicator is illuminated when the loop is either open circuit or short circuit and is

used to give a visual indication of a faulty loop.

1

Technical S

p

ecifications

Power supply LD160 200 - 260VAC 50Hz 1.5VA

LD161 100 - 120VAC 60Hz 1.5VA

LD162 11 - 26VAC/DC 50/60Hz 95mA max.

Presence Relay 0.5A/220VAC . (Fail Safe - The channel output will go into detect if a

loop fault is detected or the power fails.)

Fault Relay 0.5A/220VAC (The fault output will indicate a fault during a loop fault or

power fail.)

Response time Approximately 50ms after vehicle enters loop.

Indicators LED indicators show: Power, Detect state and Loop Fault.

Detector tuning range 15 - 1500uH

Loop Frequency Approx. 23 – 130KHz

Power Fail Memory 20 Seconds

Environmental tracking Automatic Compensation

Protection Loop isolation transformer with zener diodes and gas discharge tube.

Connecto

r

11 Pin Connector on rear of unit.

Dimensions 80mm (height) X 40mm (width) X 79mm (Depth excl. connector).

Operating Temperature -40°C to +80°C

Storage Temperature -40°C to +85°C

2

LD160 Switch Settings

Switch No. Function

ON OFF

2,3,4 Sensitivity 0.02% - S2/S3/S4

2,3,4 Sensitivity 0.01% S4 S2/S3

2,3,4 Sensitivity 0.05% S3 S2/S4

2,3,4 Sensitivity 0.1% S3/S4 S2

2,3,4 Sensitivity 0.2% S2 S3/S4

2,3,4 Sensitivity 0.5% S2/S4 S3

2,3,4 Sensitivity 1% S2/S3 S4

2,3,4 Sensitivity 2% S2/S3/S4 -

1 Frequency Low High

Rela

y

Functionalit

y

Switch Settin

g

s

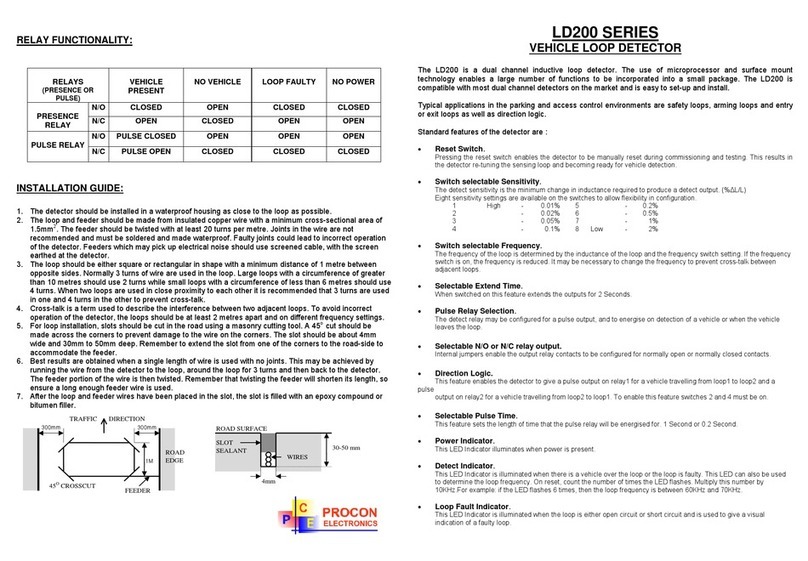

RELAYS VEHICLE

PRESENT NO

VEHICLE LOOP

FAULTY

NO

POWER

PRESENCE

RELAY

N/O CLOSED OPEN CLOSED CLOSED

N/C OPEN CLOSED OPEN OPEN

PULSE

RELAY

N/O PULSE CLOSED OPEN OPEN OPEN

N/C PULSE OPEN CLOSED CLOSED CLOSED

3

4

SYMPTOM POSSIBLE CAUSE SOLUTION

The POWER LED is not

on.

No power supply voltage on

the input.

Check that the power supply is

correctly wired to the detector.

(PINS 1 and 2)

The DETECT LED flashes

erratically.

There may be a poor

connection in the loop or

loop feeder.

The detector may be

experiencing crosstalk with

the loop of an adjacent

detector.

Check all wiring. Tighten screw

terminals. Check for broken wires.

Try changing frequencies using the

frequency switch. Put the detector

with the larger loop onto low

frequency and the detector with the

smaller loop onto high frequency.

The DETECT LED

randomly stays on.

Faulty loop or loop feeder

wiring.

Movement of the loop in the

ground.

Check the wiring. Tighten screw

terminals. Check for pinched or bent

wires. Is the feeder wire twisted?

Check for cracks in the road surface

near the loop.

The LOOP FAULT LED is

flashing.

The loop inductance is to

small or the loop is short

circuit.

Check that there is no short circuit

on the loop feeder wiring or the loop.

If there is no short circuit then the

inductance is to small and more

turns of wire should be added to the

loop.

The LOOP FAULT LED is

permanently illuminated.

The loop inductance is too

large or the loop is open

circuit.

Check that there is electrical

continuity on the loop. This can be

done using a multimeter on the

ohms range (< 5 Ω). If the loop

inductance is too large then try

reducing the number of turns.

Wirin

g

Dia

g

ram

Dia

g

nostics

7

LOOP INPUT

8

1

2 POWER INPUT

9

LD160 220VAC / LD161 110VAC

LD162 12-24VAC/DC

EARTH

LOOP TWISTED

5 3

10 PRESENCE RELAY 11 FAULT RELAY

OUTPUT OUTPUT

6 4

5

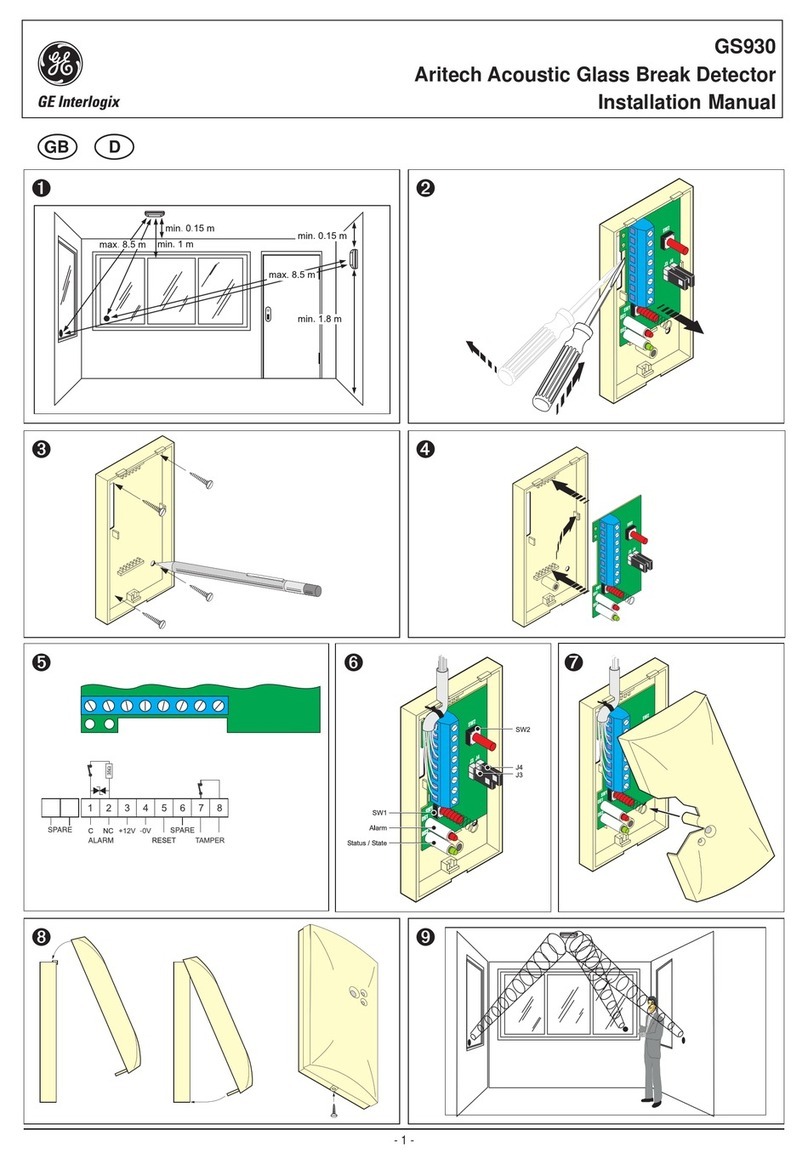

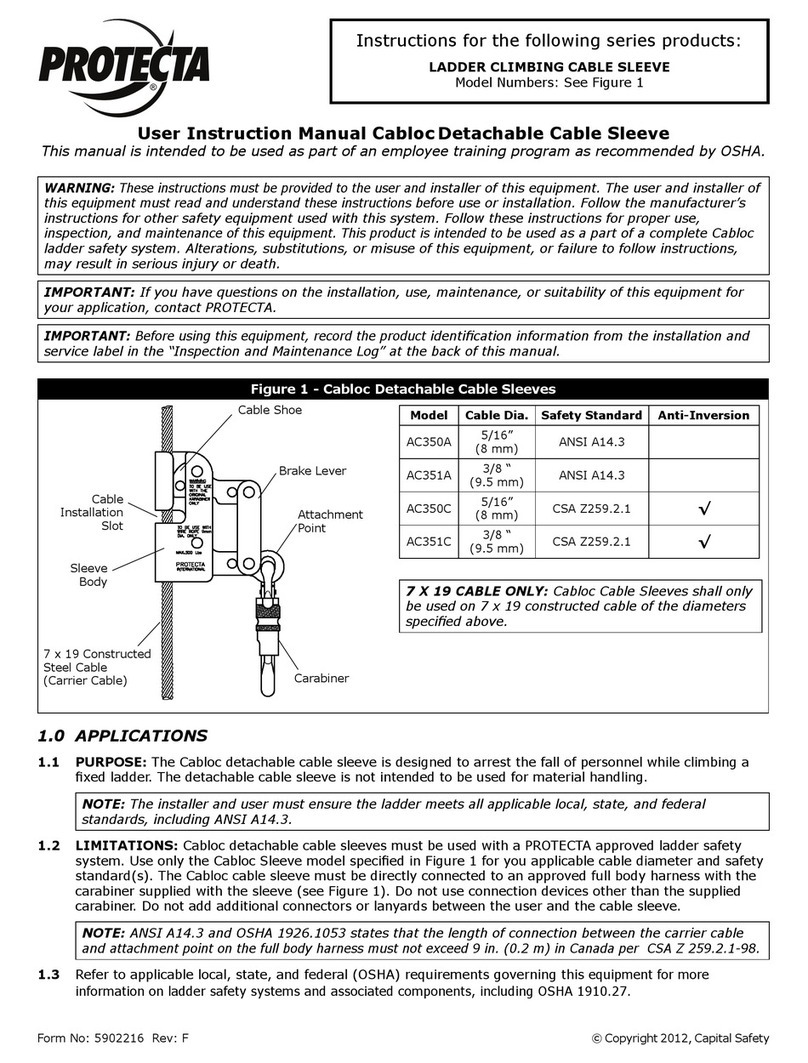

1. The detector should be installed in a waterproof housing as close to the loop as possible.

2. The loop and feeder should be made from insulated copper wire with a minimum cross-sectional area of

1.5mm2. The feeder should be twisted with at least 20 turns per metre. Joints in the wire are not

recommended and must be soldered and made waterproof. Faulty joints could lead to incorrect operation of

the detector. Feeders which may pick up electrical noise should use screened cable, with the screen earthed

at the detector.

3. The loop should be either square or rectangular in shape with a minimum distance of 1 metre between

opposite sides. Normally 3 turns of wire are used in the loop. Large loops with a circumference of greater than

10 metres should use 2 turns while small loops with a circumference of less than 6 metres should use 4 turns.

When two loops are used in close proximity to each other it is recommended that 3 turns are used in one and

4 turns in the other to prevent cross-talk.

4. Cross-talk is a term used to describe the interference between two adjacent loops. To avoid incorrect

operation of the detector, the loops should be at least 2 metres apart and on different frequency settings.

5. For loop installation, slots should be cut in the road using a masonry cutting tool. A 45o cut should be made

across the corners to prevent damage to the wire on the corners. The slot should be about 4mm wide and

30mm to 50mm deep. Remember to extend the slot from one of the corners to the road-side to accommodate

the feeder.

6. Best results are obtained when a single length of wire is used with no joints. This may be achieved by running

the wire from the detector to the loop, around the loop for 3 turns and then back to the detector. The feeder

portion of the wire is then twisted. Remember that twisting the feeder will shorten its length, so ensure a long

enough feeder wire is used.

7. After the loop and feeder wires have been placed in the slot, the slot is filled with epoxy compound or bitumen

filler.

1. Connect the wiring according to the pin-out on the side label of the detector.

1.1 Connect the power supply to the terminals 1 & 2.

1.2 Connect the loop to the terminals 7 & 8.

1.3 Connect the relay outputs as required. The relays are fail safe and the normally open/normally closed

contacts are indicated with the detector switched on and tuned to the loop, with no vehicle on the loop.

2. The next step is setting the 4 way switch on the front of the unit.

2.1 Set up the desired sensitivity on switches 2, 3 and 4. The settings can be seen on the side label. For

normal operation of 0.02% switch off switches 2, 3 and 4.

2.2 The frequency switch 1 is used to change the loop frequency. If the loop detector is experiencing

interference from an adjacent detector ( crosstalk) or from another source, the problem can be

eliminated by switching this switch on. For normal operation this switch can be off.

To conclude the switch setting, all the switches can normally be left in the off position. ie: all of the switches are

toward the outside edge of the detector.

LD160 Confi

g

uration

Loo

p

Installation Guide

300mm 300mm

1M

ROAD

EDGE

45

O

CROSSCUT

FEEDER

TRAFFIC DIRECTION

4mm

ROAD SURFACE

30-50 mm

SLOT

SEALANT WIRES

1. Switch on the power and observe the lights on the front of the detector.

2. The top light is an indication of power. This light must always be on.

3. The middle light indicates if there is a vehicle present on the loop. When the power is first applied to the

detector this light flashes a couple of times indicating that the detector has tuned to the loop. The

number of flashes indicates the frequency of the oscillator multiplied by 10 KHz (Kilohertz). For example,

7 flashes indicates that the loop frequency is between 70 and 80 KHz. If this light does not flash and

stays on there is a problem with the loop or wiring.

4. The bottom light comes on if there is a problem with the loop. Some of the common problems are:

a. The loop wires have a short circuit. Check the wiring.

b. The loop inductance is too small. More turns must be added to the loop. For a 2m by 1m loop 3

turns is suitable. A wire size of 1.5mm2 cross sectional area is recommended.

c. The loop inductance is too big. This is very seldom a problem as most loops have an

inductance of less than 500uH. A solution is to reduce the number of turns on the loop.

d. The loop is open circuit. Check the wiring.

If the fault light is on it is easy to identify that there is a fault with the loop or wiring and this can easily be

repaired. If the detector is erratic the problem may be more difficult to find. The first step is to check the loop

wiring. Many intermittent problems can be attributed to poor wiring connections and even movement in the loop.

The next step is to switch on the frequency switch to change the loop frequency, and finally it may be necessary

reduce the loop sensitivity by switching on switch 2 or 3.

Care must be given to the placement of the loop. The loop should not be put below reinforcing mesh, should be

kept away from any metal objects such as a manhole and should also not be too close to sliding gates, etc.

Contact Details

Powerin

g

u

p

and testin

g

the LD160

Refer to our web site for distributor details.

Web: www.proconel.com

6

This manual suits for next models

3

Table of contents

Other Procon Security Sensor manuals