sewerin Ex-Tec OD 4 User manual

Operating

Instructions

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 HOERDT CEDEX, France

Tél. :+33 3 88 68 15 15

Fax :+33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

SEWERIN IBERIA S.L.

Centro de Negocios “Eisenhower”

Avenida Sur del Aeropuerto

de Barajas 28, Of. 2.1 y 2.2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Faks: +48 22 486 93 44

Tel. kom. +48 501 879 444

www.sewerin.pl

info@sewerin.pl

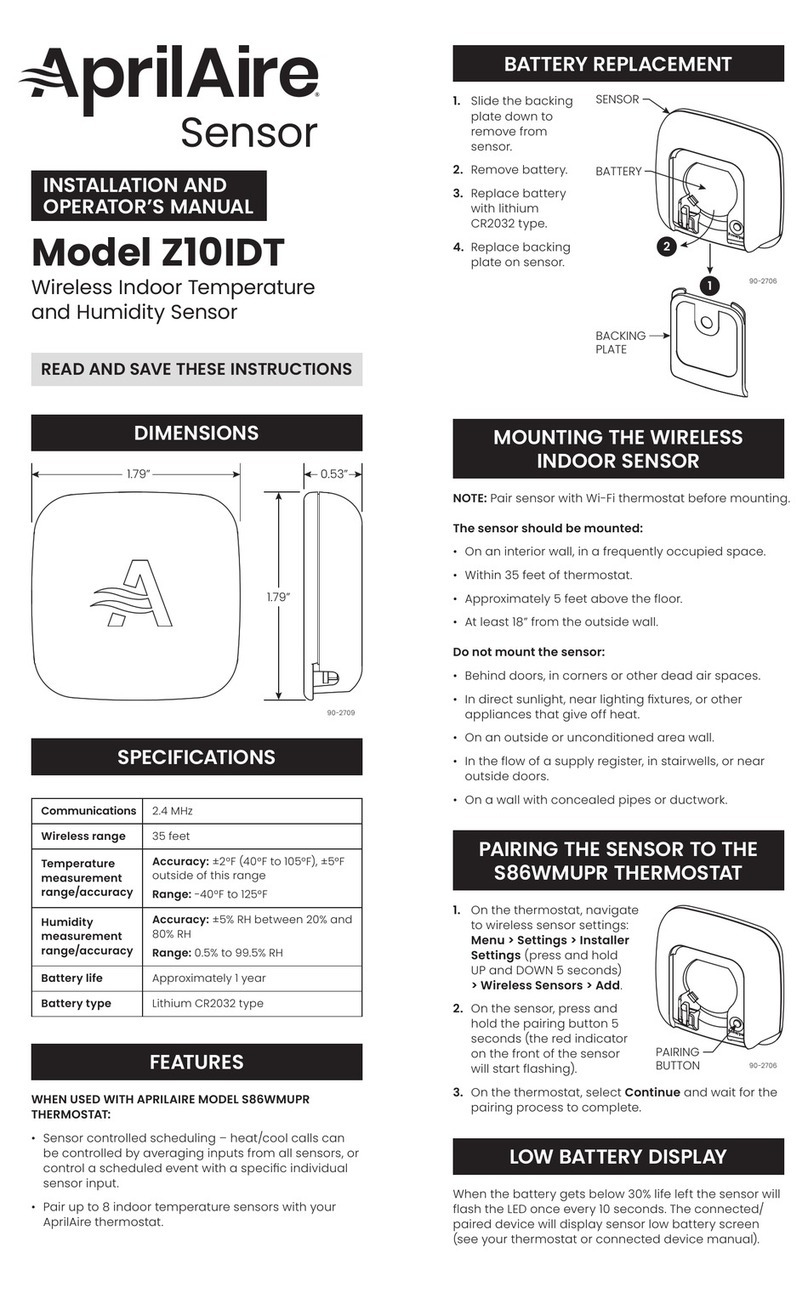

Illustration EX-TEC OD 4

EX-TEC OD 4

®

0.0

THT

mg

m3

Sensor head

Attachment

Alarm lamp

LCD

Buzzer

Keypad

Charging contacts

Illustration EX-TEC GM 4

EX-TEC GM 4

®

H2

PPM

1500

Sensor head

Attachment

Alarm lamp

LCD

Buzzer

Keypad

Charging contacts

H2

PPM

1500

Activation

Alarm thresholds Type of gas

Trend bar

Unit

Gas concentration

Battery state

Operating Instructions

20.04.2016 a – V1.XXX – 103955 – en

EX-TEC® OD 4/GM 4

For your safety

This product may only be operated by appropriately-trained persons who

are familiar with the relevant operating manual.

It may only be used for its designated purpose, i.e. for industrial and com-

mercial use.

Repair work may only be carried out by specialists or by persons who have

undergone appropriate training.

Any alterations or modications to the product require the prior approval of

Hermann Sewerin GmbH. In the event of unauthorised alterations to the

product the manufacturer accepts no liability for damage.

Only Hermann Sewerin GmbH accessories may be used with the pro-

duct.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH accepts no liability for damage resulting from

non-compliance with the foregoing. The guarantee and liability provisions

in the Hermann Sewerin GmbH terms of sale and supply are not extended

by the foregoing.

We reserve the right to make changes in the context of continued techni-

cal development.

In addition to these instructions, please comply with generally applicable

safety and accident-prevention regulations.

Symbols used:

CAUTION:

This symbol warns of dangers that may threaten

the safety of the user or maty damage or destroy

the product.

Note:

This symbol ags information and hints extending

beyond the actual operation of the product .

I

Contents Page

1 EX-TEC OD 4/EX-TEC GM 4 system ......................................1

1.1 The EX-TEC OD 4 system ........................................................1

1.1.1 Before starting work ...............................................................1

1.1.2 The need for gas odorisation .................................................1

1.1.3 Measurement principle...........................................................1

1.1.4 Boundary conditions for measurement and sampling ..............2

1.1.5 EX-TEC OD 4............................................................................3

1.1.6 Test certicates ......................................................................4

1.2 EX-TEC GM 4 system...............................................................5

1.2.1 Test certicates ......................................................................5

2 Safety .......................................................................................6

2.1 Safety instructions.....................................................................6

3 Measuring operation...............................................................8

3.1 Switching on..............................................................................8

3.2 Operating modes..................................................................... 11

3.3 Alarms .....................................................................................16

3.4 Illumination and operating-hours display.................................18

3.5 Battery alarm...........................................................................18

3.6 Switching off............................................................................19

4 Charging and battery operation...........................................20

4.1 Charging and charge maintenance when using NiMH batteries ... 20

4.2 Self-dischargeand battery care ...............................................22

4.3 Battery operation.....................................................................23

4.4 Instruments showing serial number 062 00 ............................24

5 Testing the instrument..........................................................25

5.1 Testing/upkeep ........................................................................25

5.2 Test set....................................................................................27

5.2.1 EX-TEC GM 4 ......................................................................27

5.2.2 EX-TEC OD 4.......................................................................28

5.3 Test gases ...............................................................................29

5.4 Testing the pump, zero point and display accuracy ................30

II

Contents Page

6 Info menu ...............................................................................33

6.1 Menu structure ........................................................................33

6.2 Overview .................................................................................34

7 Adjustment menu..................................................................36

7.1 Menu structure ........................................................................36

7.2 Sensor adjustment ..................................................................36

7.2.1 Setting the H2-sensor ...........................................................36

7.2.2 Setting the O2sensor ...........................................................37

7.3 Setting the test gas concentration...........................................38

7.4 Inspection conrmation ...........................................................40

7.5 Leaving the adjustment menu .................................................40

8 System menu.........................................................................41

8.1 Menu structure ........................................................................41

8.2 Setting the date and time ........................................................42

8.3 Setting the inspection intervall ................................................43

8.4 Setting the inspection block ....................................................46

8.5 Setting the PIN ........................................................................47

8.6 Setting the alarm thresholds ...................................................48

8.7 Setting the user name .............................................................51

8.8 Setting the language ...............................................................53

8.9 Leaving the system menu .......................................................53

9 Hardware menu .....................................................................54

9.1 Menu structure ........................................................................54

9.1.1 EX-TEC GM 4 ......................................................................54

9.1.2 EX-TEC OD 4.......................................................................55

9.2 Setting the battery type ...........................................................56

9.3 Setting the illumination time and contrast ...............................57

9.4 Autostart..................................................................................58

9.5 Range .....................................................................................59

9.6 Changing the sensor ...............................................................59

9.6.1 Gas.......................................................................................60

9.6.2 Sensor installation................................................................60

9.7 Setting pump operation ...........................................................61

9.8 Carrying out an LCD test.........................................................61

III

Contents Page

9.9 Restoring the factory settings..................................................62

9.10 Leaving the hardware menu....................................................63

10 Memory menu........................................................................64

10.1 Menu structure ........................................................................64

10.2 Clearing memory.....................................................................64

10.3 Setting the memory interval ....................................................65

10.4 Leaving the memory menu......................................................65

11 Technical aspects..................................................................66

11.1 Technical notes .......................................................................66

11.2 Technical data .........................................................................68

11.3 Error messages.......................................................................79

11.4 Consumables ..........................................................................80

11.5 Hints on Disposal ....................................................................81

12 Delivery variants and accessories ......................................82

12.1 Delivery variants......................................................................82

12.2 Accessories.............................................................................84

13 Appendix................................................................................90

13.1 EU-declaration of conformity...................................................90

13.2 Inspection protocol ..................................................................91

13.3 EX-TEC OD 4/GM 4 operating instructions in brief.................92

1

1 EX-TEC OD 4/EX-TEC GM 4 system

The EX-TEC OD 4 is a combined warning and measuring instru-

ment for determining odorant concentration. It is available with

either a THT or a TBM sensor.

The EX-TEC GM 4 is a warning and measuring instrument that

detects oxygen and various toxic gases.

1.1 The EX-TEC OD 4 system

1.1.1 Before starting work

Adequate gas odorisation is an important criterion for safe network

operation. Please take careful note of the following information.

1.1.2 The need for gas odorisation

Natural gas is odourless. So that even the smallest leaks in indoor

installations or elsewhere in a gas-distribution network can be

immediately detected, the gas is odorised: a strong-smelling sub-

stance is added to it. The substances used are organic sulphur

compounds and acrylates. The most widespread currently being

tetrahydrothiophene (THT) and tertiary butyl mercaptan (TBM).

DVGW worksheet G 280 sets the minimum values for odorant

concentration at 10 mg of THT / m3 and 3.8 mg of TBM / m3. This

worksheet also requires the operator of a distribution network to

check and document the odorant concentration at least once a

year.

1.1.3 Measurement principle

The EX-TEC OD 4 contains an electrochemical sensor that reacts

to the smallest traces of sulphur compounds. This produces elec-

trical signals, which are then processed by the integral electronic

system. The intensity of the signal varies directly with the strength

of the concentration.

1 EX-TEC OD 4/EX-TEC GM 4 system

2

1 EX-TEC OD 4/EX-TEC GM 4 system

The sensor is lled with a liquid (electrolyte), which makes it very

sensitive to high temperatures. The maximum storage tempera-

ture of 40 °C must therefore not be exceeded. Electrochemical

processes constantly take place inside the measurement cell,

requiring the EX-TEC OD 4 to be permanently supplied with bat-

tery power at an adequate voltage. For this reason the integral

batteries must not be permitted to reach a state of deep discharge.

When the instrument is not in use it should therefore be stored

in charge-maintenance operation (see section 4.1: Charging and

charge maintenance when using NiMH batteries).

1.1.4 Boundary conditions for measurement and sampling

As well as all sulphur compounds, the electrochemical measure-

ment cell also reacts very strongly to moisture. Even though this

is rarely important when carrying out measurements in a gas-

distribution network, operators should not blow through sampling

hoses to clear them.

When sampling it is essential to ensure that there are no connect-

ing pieces made of rubber or synthetic substances between the

EX-TEC OD 4 and the connection to the gas main unless these

consist of inert materials (e.g. Viton or nylon).

A further factor that affects the measurement of sulphur com-

pounds with the EX-TEC OD 4 is the ow rate through the mea-

surement chamber, which must always exceed 20 l/h. Only the

connection hoses supplied with the instrument should therefore

be used for sampling.

3

1 EX-TEC OD 4/EX-TEC GM 4 system

1.1.5 EX-TEC OD 4

The EX-TEC OD 4 is a hand-held

instrument for the measurement

of tetrahydrothiophene (THT) or

tertiary butyl mercaptan (TBM). It

is available in pump and diffusion

versions.

The following sensors are available:

Sensor range principle

THT 0 –100 mg/m3electrochemical

TBM 0 –100 mg/m3electrochemical

4

1 EX-TEC OD 4/EX-TEC GM 4 system

1.1.6 Testcerticates

Passive explosion protection

The EX-TEC OD 4 has been tested for explosion protection in

accordance with European norms (CENELEC):

EC prototype test certicate: TÜV 01 ATEX 1657

Identication: II2G Ex e ib IIB T4 Gb

Testing institution: TÜV NORD CERT GmbH,

Hannover

5

1 EX-TEC OD 4/EX-TEC GM 4 system

1.2 EX-TEC GM 4 system

The EX-TEC GM 4 is a gas-measurement and warning instru-

ment. It is available in pump and diffusion versions. A different

sensor is used for each gas.

The following electrochemical sensors are available:

Sensor range

Carbon monoxide CO 0 – 500 ppm

Hydrogen H2 0 – 1.0 vol.%

Hydrogen sulphide H2S 0 – 100 ppm

Hydrogen sulphide H2S 0 – 2000 ppm

Ammonia NH3 0 – 100 ppm

Oxygen O2 0 – 25 vol.%

Hydrogen chloride HCI 0 – 30 ppm

1.2.1 Testcerticates

Passive explosion protection

The EX-TEC GM 4 has been tested for explosion protection in

accordance with European norms (CENELEC):

EC prototype test certicate: TÜV 01 ATEX 1657

Identication 1: II2G Ex e ib IIB T4 Gb

basic instrument without

leather case for all gases

except hydrogen H2

Identication 2: II2G Ex e ib IIC T4 Gb

basic instrument with leather

case for all gases including

hydrogen H2

Testing institution: TÜV NORD CERT GmbH,

Hannover

6

2 Safety

2 Safety

2.1 Safety instructions

CAUTION!

Always use original SEWERIN accessories with the

EX-TEC OD 4/GM 4!

CAUTION!

Observe the permissible operating temperature

range of minus 10 °C to plus 40 °C!

(with some sensors the temperature range may be

wider - see section 11.2: Technical data)!

CAUTION!

The EX-TEC OD 4/GM 4 must not be recharged or

its battery compartment opened in areas exposed

to the danger of explosion!

CAUTION!

Test gases may only be used in well-ventilated

spaces!

CAUTION!

The EX-TEC OD 4/GM 4 satises the limits of the

EMV regulation. When using it near (mobile) radio

equipment please also observe the instructions in

the manuals for that equipment!

7

2 Safety

CAUTION!

Please note that when the EX-TEC OD 4/GM 4 is

in measuring operation the gas sample is released

into the ambient air through its outlet.

Special care must be taken to ensure that this does

not produce an explosive or toxic gas mixture, espe-

cially during use in conned spaces. It may therefore

be necessary to use a gas-warning device to monitor

the ambient air.

CAUTION!

The EX-TEC GM 4 with the hydrogen sulphide H2S

sensor (0 – 2000 ppm) is a pure measuring instru-

ment: the „warning“ operating mode is not available.

Please note that the human sense of smell fails at

concentrations of 100 ppm of H2S and above. Con-

centrations of over 500 ppm of H2S lead to very seri-

ous damage to health, uncoordinated movements,

unconsciousness, respiratory failure and death. It is

thus essential to ensure that the lower toxic limit of

10 ppm in the ambient air is not exceeded!

CAUTION!

When using the H2sensor the HG4 must be in its

leather case (to provide explosion protection)!

8

3 Measuring operation

3 Measuring operation

3.1 Switching on

Note:

This operating manual describes the functions

of software version 1.XXX. Other versions may

involve changes.In this event please consult any

page insertions.

zalways switch the instrument

on in „fresh air“

zhold the on/off key down for

about 3 seconds

zthe optical and acoustic control

signals (items 1 and 7) operate

for about 3 seconds

zthe LC display illumination

automatically switches on

zpump instruments: the inte-

gral pump runs at constant

power

Opening screen

zdisplay of:

- version number (V1.001)

- instrument type (GM 4)

- sensor type (H2)

27.11.2000

12:37

Stadtwerke GT

Heinz Muster

Abt. TDLL 24.4

V1.001

EX-TEC GM4

H2

Date/time

zdisplay of:

- date (27.11.2000)

- time (12:37)

- user name

zproperly-set values are impor-

tant for the documentation of

your readings

9

3 Measuring operation

zyou can correct any variances

(cf. section 8.2: Setting the

date/time)

Instrument settings

The EX-TEC OD 4/GM 4 defaults

to a set operating mode at switch-

on, which you can change (cf.

section 9.4: Autostart). The

operating mode is factory-set to

„Measurement“:

zdisplay of:

- battery-charge level

- gas (here: H2)

- operating mode

(here: measurement)

- range

(here: 0 – 1.00 vol.%)

Other possible settings can be

found in section 9.4: Autostart.

zdisplay of the day the sensor

was tted

zdisplay of expected sensor

life

Symbols

zavailable operating hours are

displayed (5 hours = 5 bars)

symbol: battery

zmeasurement is under way

(symbol eggtimer)

zall alarm thresholds are acti-

vated

symbol: alarm threshold

Sensor install.

12.06.2002

durability

24 Monate

H2

0...1,00 Vol%

10

3 Measuring operation

Next scheduled inspection

(display optional)

zif you have set an inspec-

tion interval, the next sched-

uled inspection date (e.g.

11.03.2004) is displayed for

about 3 seconds (cf. section

8.3: Setting the inspection

interval))

zdepending on the current and

inspection dates, the intermit-

tent or continuous alarm may

also be triggered (items 1

and 7)

zclearing the alarm with the

on/off key or waiting for 15

seconds switches to mea-

suring operation

Note:

If the EX-TEC OD 4/GM 4 now automatically

switches off, the inspection date has passed with

the inspection block switched on (cf. section 8.0:

System menu).

The instrument does not revert to measuring opera-

tion until an inspection has been carried out and

conrmed.

11

3 Measuring operation

3.2 Operating modes

WARNING

zWarning of high gas concentration in buildings and the work-

ing environment

zTesting enclosed spaces

zall alarm thresholds are acti-

vated

NB:

zthe current gas concentration

is displayed:

- as a gure

(e.g.: 1500 PPM H2)

- as a trend bar

zevery 5 seconds an operating

signal - both acoustic (item 7)

and optical (item 1) - is emitted

to conrm that the instrument

in functioning in the warning

operating mode. If this ope-

rating signal is not emitted,

you cannot be sure that the

gas concentration is being

properly monitored and must

leave the endangered area

without delay.

H2

PPM

1500

This manual suits for next models

1

Table of contents

Other sewerin Security Sensor manuals

sewerin

sewerin Duophon User manual

sewerin

sewerin rmld User manual

sewerin

sewerin UtiliTrac User manual

sewerin

sewerin Stethophon 04 User manual

sewerin

sewerin FerroTec FT 10 User manual

sewerin

sewerin SeCorrPhon AC 06 User manual

sewerin

sewerin Aquaphon A 100 User manual

sewerin

sewerin UtiliTrac User manual

Popular Security Sensor manuals by other brands

SICK

SICK GTB6L Operating instruction

Endress+Hauser

Endress+Hauser Liquiphant S FTL70 operating instructions

Prime Controls

Prime Controls SD220 operating instructions

jablotron

jablotron JA-159P quick guide

Synergys

Synergys LEAKSHOOTER LKS1000 V3+PRO user guide

GREEN INSTRUMENTS

GREEN INSTRUMENTS G26 manual