prodelin 1183 series User manual

4096-291

REVISION E

August 3, 1998

ASSEMBLY MANUAL

1.8 METER SERIES 1183

Rx/O Az/El MOUNT ANTENNA SYSTEM

PRODELIN CORPORATION

1700 NE CABLE DRIVE

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

2

CONOVER, NC 28613-0368

1.8 METER SERIES 1183

Rx/O Az/El MOUNT ANTENNA SYSTEM

E Updated Manual 08/03/98 PGW

DRevised Canister assembly per ECN 1837 7/14/98 PGW

CRevised antenna asm parts list, It. 8&9 were qty

of 2, Updated manual 06/10/97 P.G.W.

B Added revision page & changed P/N

for item #7 03/31/95 R.F.

~ Original Release 11/20/92 R.F.

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

3

REV. DESCRIPTION DATE APPROVED

1.8M SERIES 1183 ANTENNA SYSTEM

TABLE OF CONTENTS

SECTION TITLE

I GENERAL INFORMATION

1.0 Introduction

1.1 Unpacking And Inspection

1.2 Freight Damage

1.3 Missing Or Damaged Material

1.4 Suggested Tool List

1.5 Mechanical Alignment Tools

1.6 Site Selection

1.7 Suggested Mast & Foundation

II ANTENNA SYSTEM

2.0 Antenna Assembly

III FEED SUPPORT

3.0 Feed Support Assembly

IV ANTENNA POINTING

4.0 Alignment To Satellite

V MAINTENANCE

5.0 Maintenance Overview

5.1 Periodic Inspection

5.2 Reflector

5.3 Mount And Reflector Support

5.4 Feed System

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

4

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

5

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

6

SECTION I GENERAL INFORMATION

1.0 INTRODUCTION

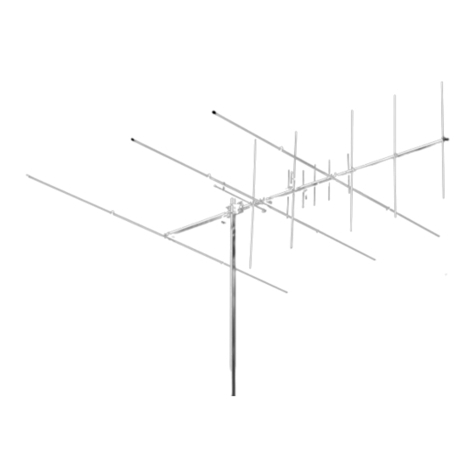

This manual describes the assembly and installation of Prodelin's 1.8M Rx/O

antenna system with an Az/El mount (series number 1183). The Prodelin 1.8M

is a rugged, reliable antenna system, which will operate with high efficiency and

at the same time successfully withstand the effects of the environment. The

basic 1.8 meter Rx/O antenna consists of an offset reflector, reflector support,

feed support structure and Az/El positioner.

These instructions are listed by sections that cover all areas of assembly and

installation. Additional sections are included in the manual to provide information

on antenna alignment to the satellite and maintenance.

1.1 UNPACKING AND INSPECTION

The antenna containers should be unpacked and inspected at the earliest date

to ensure that all material has been received and is in good condition. A

complete packing list for each major component is supplied.

1.2 FRIEGHT DAMAGE

Any damage to materials while in transit should be immediately directed to the

freight carrier. He will instruct you on matters regarding any freight damage

claims.

1.3 MATERIAL - MISSING OR DAMAGED

Any questions regarding missing or damaged materials that is not due to the

freight carrier should be directed to Prodelin's Customer Service Department at:

PRODELIN CORPORATION

1700 NE CABLE DRIVE

P.O. BOX 368

CONOVER, NORTH CAROLINA USA 28613

USA

(828) 464-4141

1.4 SUGGESTED TOOL LIST

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

7

The following tools are suggested for the antenna installation.

HARDWARE SIZE SAE WRENCH

SIZE METRIC WRENCH

SIZE MAXIMUM REC.

TORQUE

1/4" BOLT 7/16" 11mm 49 in-lbs

5/16" BOLT 1/2" 13 mm 12 ft-lbs

3/8” BOLT 9/16” 14 mm 20 ft-lbs

1/2" BOLT 3/4" 20 mm 45 ft-lbs

5/8" NUT 15/16" 24 mm 70 ft-lbs

1" BOLT 1-1/2" 38 mm 220 ft-lbs

1.5 MECHANICAL ALIGNMENT TOOLS

The following tools are suggested for the initial alignment to the satellite.

1) COMPASS

2) INCLINOMETER

3) 10"CRESCENT WRENCH

4) SCREWDRIVER, STANDARD BLADE

1.6 SITE SELECTION

In order to achieve maximum performance of your antenna system, it is

important to select the correct location for the antenna. The following guidelines

should be observed when selecting a site for the installation.

1. The line of site to the satellite should be clear of any obstructions, such as

trees or buildings.

2. The site should be relatively flat and level for ease of installation and

access to the antenna.

3. The site should be checked for underground obstruction, such as buried

cables or pipes.

4. All local building codes should be adhered to (i.e. grounding, foundation

requirements, zoning rules, setbacks, etc.).

1.7 SUGGESTED MAST & FOUNDATION

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

8

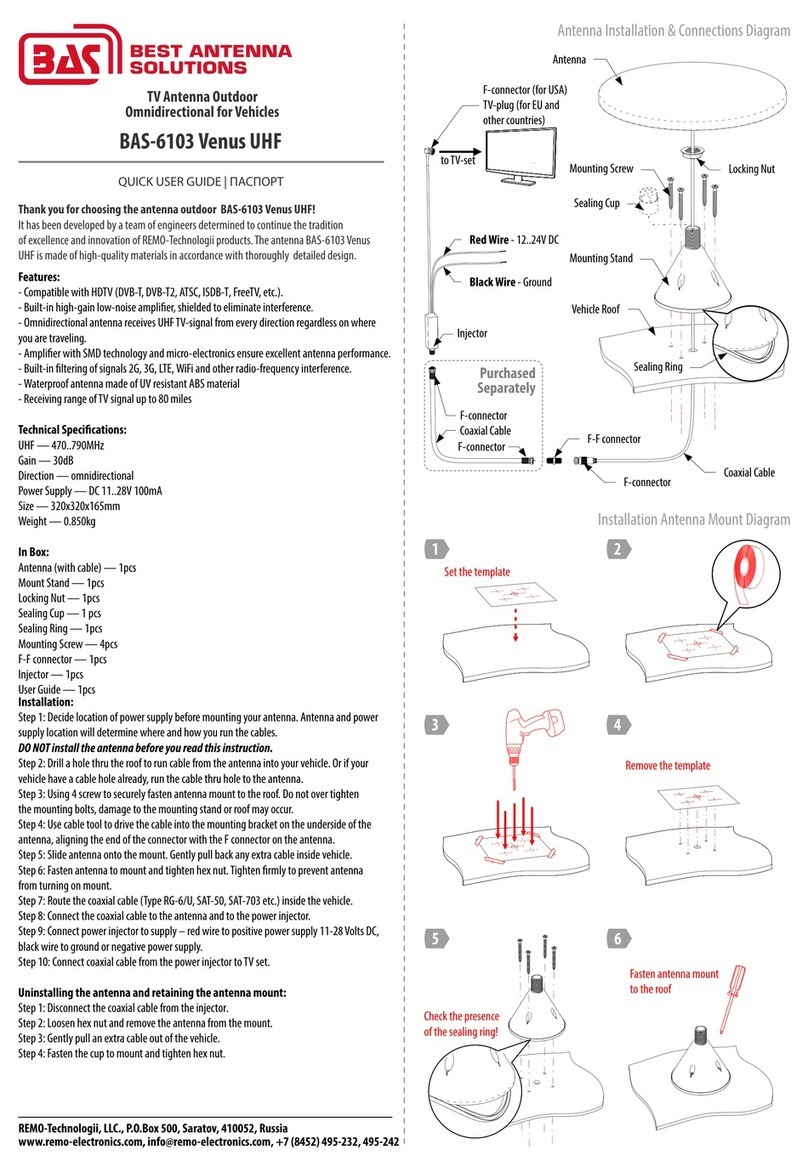

The required interface from the foundation to the mount is 3.5”schedule 40 pipe

(4.0”or 10.16 cm O.D.). A suggested in-ground foundation is shown in Figure 1.

FIGURE 1.

NOTES:

1. 2 x 2 x 1/4 HRS Angle and schedule 40 pipe should conform with ASTM A36 and ASTM A53

Type E and S Grade B.

2. All concrete should conform to building code standards and have a

minimum compressive strength of 3000 PSI at 28 days. (Per ACI-318-77)

3. Soil bearing capacity should be no less than 2000 PSF.

4-. Concrete should be poured against undisturbed soil.

5. Allow concrete 24 hours set time before installation of antenna.

6. The antenna should be properly grounded to meet applicable local codes.

7. Minimum depth as shown or extend to local frost line.

(PRODELIN CORPORATION DOES NOT REPRESENT OR WARRANT THAT ANY PARTICULAR

DESIGN OR SIZE OF FOUNDATION IS APPROPRIATE FOR ANY LOCALITY OR EARTH STATION

INSTALLATION.)

SECTION II ANTENNA ASSEMBLY

A

3.50”(8.89cm) SCH 40 PIPE

4.00”OD (10.16cm OD)

24.0”

(70cm)

2-5 TYP 2 42.0”

(107 cm)

42.0”

(107 cm)

See Note #7

A

12.0”

(30.5cm)

SECTION A-A

2”x 2”x 1 / 4”HRS Angle

12”Long (TYP 2 PLACES)

5cm x 5cm x .65 cm Angle

30.5 cm Long (TYP 2 PLACES)

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

9

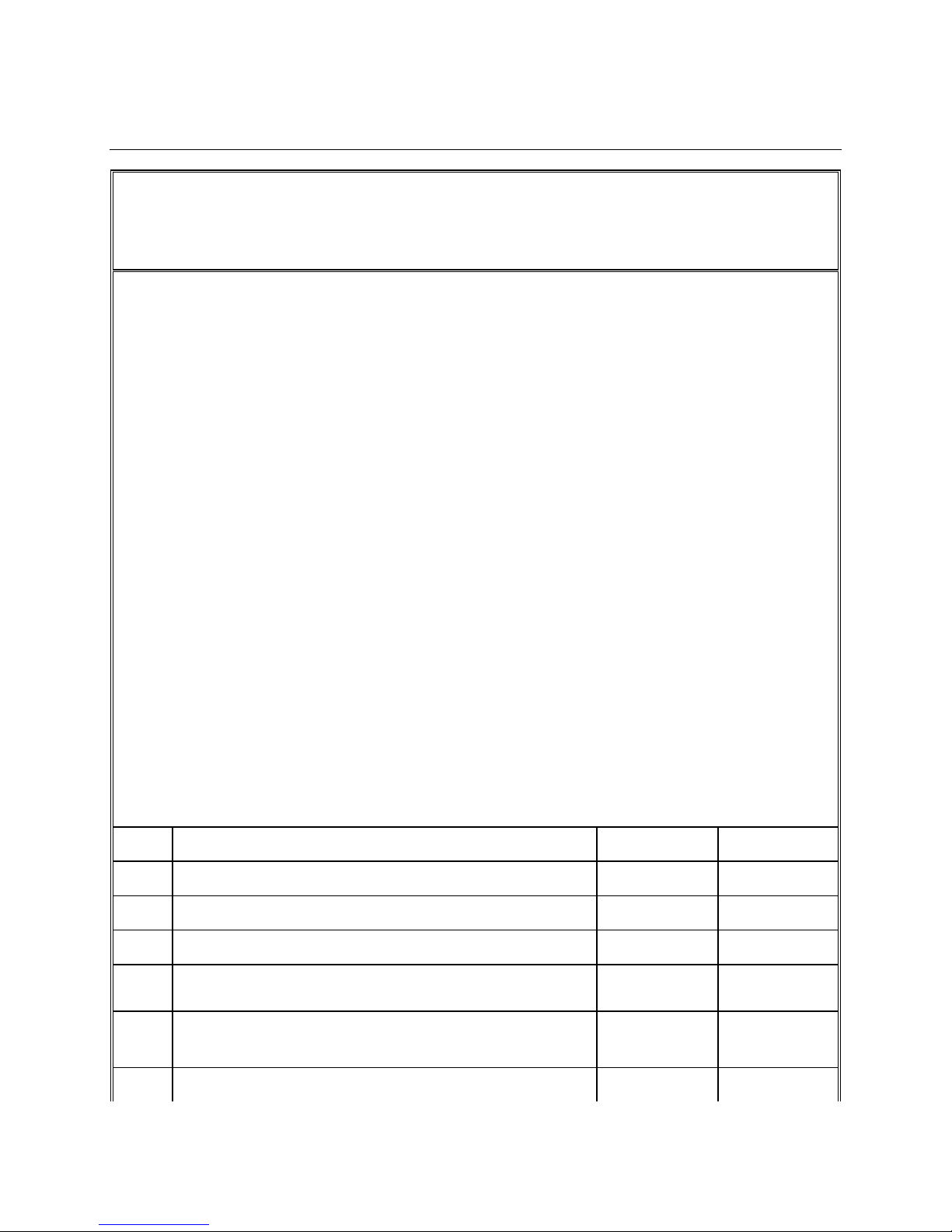

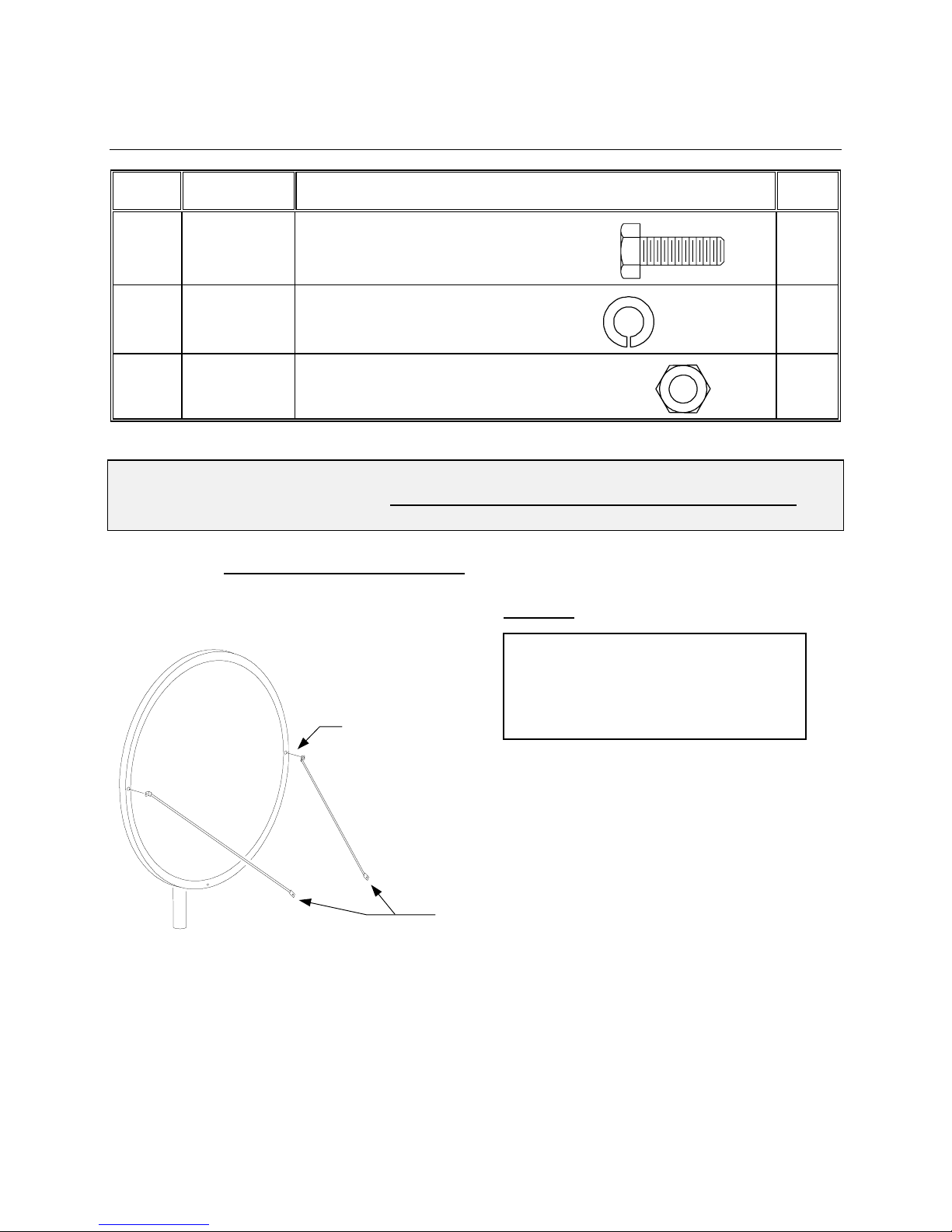

PARTS LIST - 1.8M ANTENNA ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 0179-191 1.8M REFLECTOR 1

2 0181-452 CANISTER & POSITIONER ASSEMBLY 1

3 0211-417 REFLECTOR CROSS ARMS 2

4 8043-014

4

5 8104-007

4

6 8202-043

4

7 8201-043

4

PARTS LIST - CONTINUED

1 / 2”x 1.50”CARRIAGE BOLT

1 / 2”HEX NUT

1 / 2”LOCK WASHER

1 / 2”WASHER

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

10

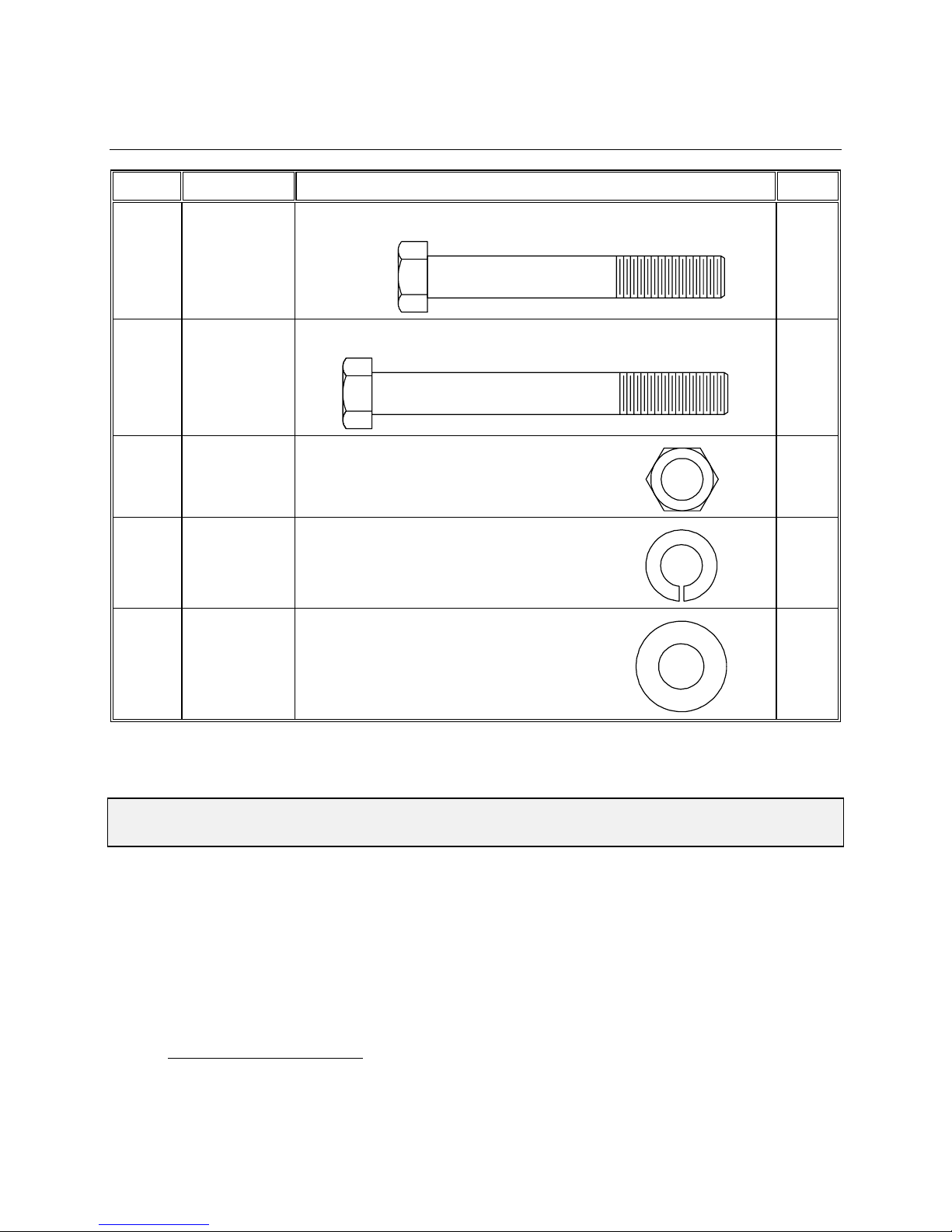

ITEM PART NO. DESCRIPTION QTY

8 8032-036

4

9 8032-040

4

10 8102-007

8

11 8202-042

8

12 8201-042

16

CAUTION: During the assembly procedure, the sequence of instructions must be

followed. DO NOT TIGHTEN ANY HARDWARE UNTIL INSTRUCTED.

2.0 ANTENNA ASSEMBLY

3 / 8”x4.5” HEX BOLT

3 / 8”x5.0” HEX BOLT

3 / 8”HEX NUT

3 / 8”LOCK WASHER

3 / 8”WASHER

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

11

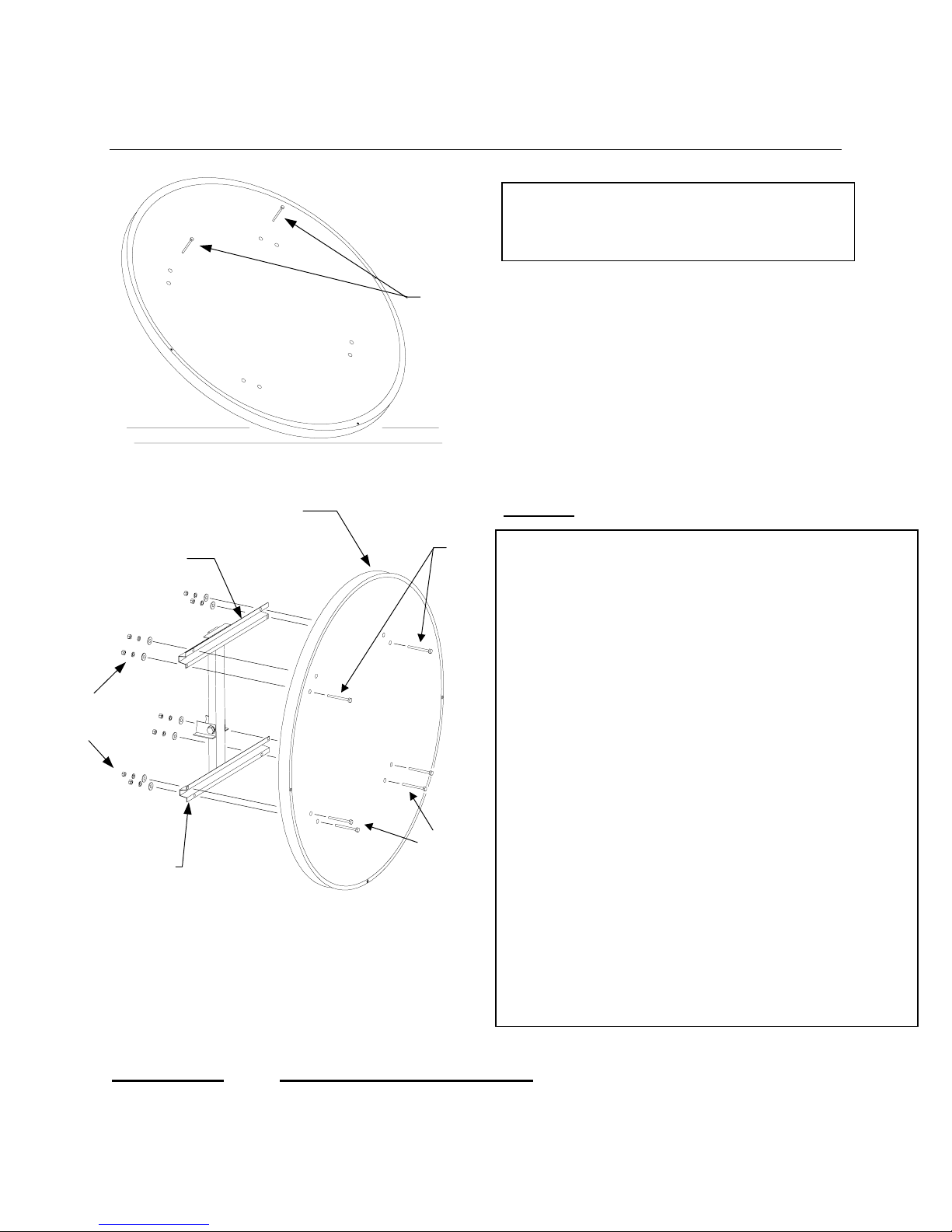

STEP 1:

STEP 2:

STEP 3:

Loosen the six 1/2 set screws on the

canister (item 2) and slip the canister

/positioner assembly onto the mast

pipe, orient toward the satellite, and

snug the set screws.

Mast

Top of Reflector

1/2"Set Screws

Canister/Positioner Assembly

Attach reflector cross arms ( item 3) to

the reflector support tube with 1 / 2”

hardware ( items: 4,5,6,7).

Note the orientation of reflector

mounting holes, the inner most holes

on the cross arm flanges will be to

the top and the bottom of the reflector.

Cross Arm

[ 4 ] 4 places

Reflector Support Tube

Cross Arm

[ 5, 6, 7 ]

4 places

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

12

STEP 4:

SECTION III FEED SUPPORT ASSEMBLY

Locate the top of the reflector and insert

(2) 5”bolts ( item 9 ) thru top two inner

most holes on face of reflector as shown.

[ 5 ]

A). With a person on each side of the reflector,

lift the reflector up.

B). Position the reflector so that the (2) bolts

(step 3) pass thru the two inner holes

in the top cross arm.

C). Loosely attach 3/8"”hardware

(items,10,11,12). Note: the reflector is

fully supported at this time.

D). Insert the (2) remaining 5”bolts (item 9)

thru the remaining two holes on top of

reflector.

E). Insert the (4) 4.5”bolts (item 8) thru the

four bottom holes in reflector.

F). Secure with (items 10, 11, 12).

G). Using the torque specifications on page 6,

tighten all reflector and mount hardware.

Top of Reflector

Cross Arm

( TOP )

Cross Arm

( BOTTOM )

[ 10,11,12 ]

8

p

laces

[

8

]

[ 9 ]

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

13

These instructions are intended as a general reference for feed support

assembly. If your antenna system has specific feed or feed support

installation instructions, please refer to them at this time.

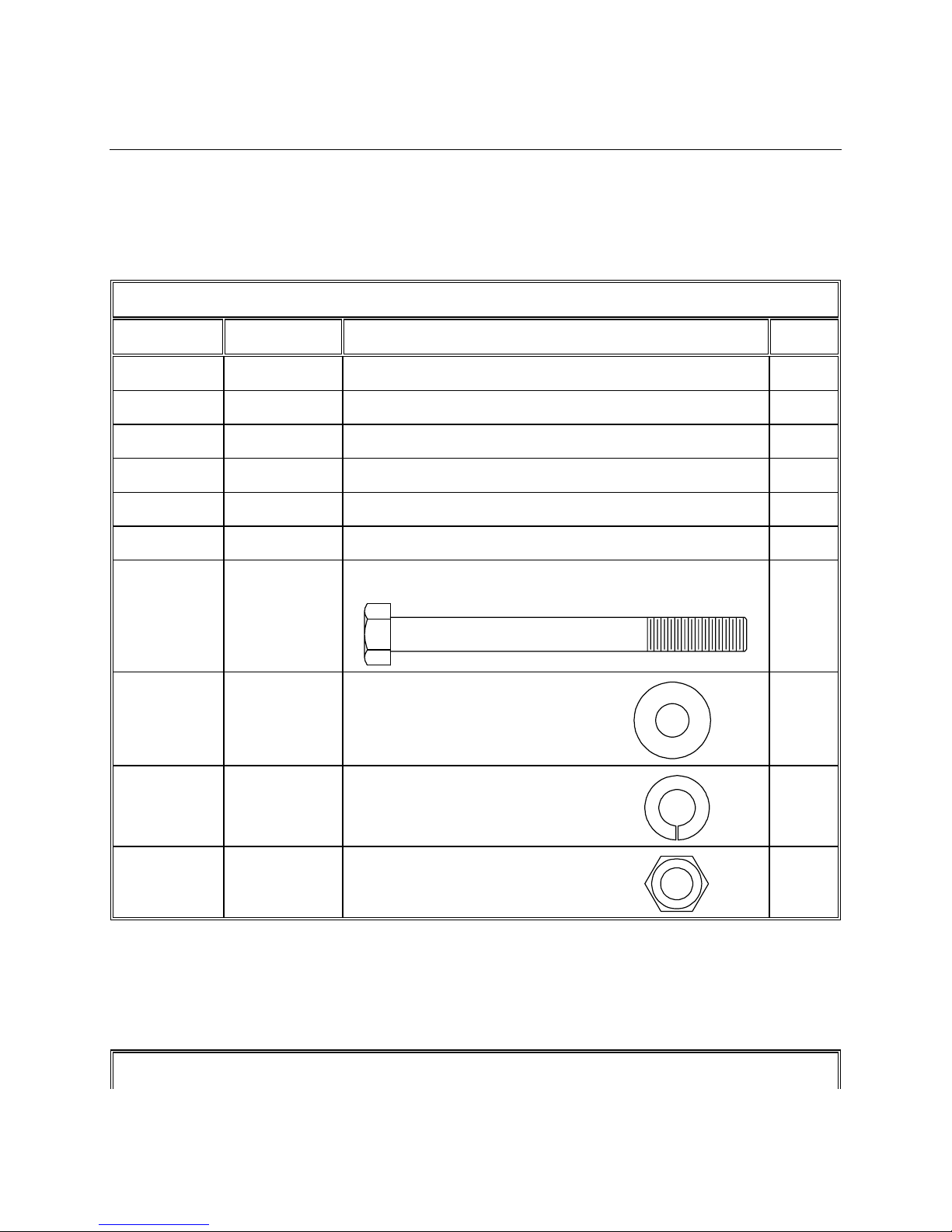

PARTS LIST - 1.8M FEED SUPPORT

ITEM NO. PART NO. DESCRIPTION QTY

1 0176-169 Feed Rod - Right Hand 1

2 0176-170 Feed Rod - Left Hand 1

3 0176-171 Feed Rod - Bottom 1

4 4080-059 Feed Bracket 1

5 4080-060 Feed Clamp 1

6 VARIES 50 Degree Feed Horn 1

7 8031-030 3

8 8201-041 6

9 8202-041 3

10 8101-009 3

PARTS LIST - CONTINUED

5 / 16”x3.75”Bolt

5 / 16”Flatwasher

5 / 16”Lock Washer

5 / 16”HexNut

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

14

ITEM PART NO. DESCRIPTION QTY

11 8030-006

5

12 8202-040

5

13 8102-007

5

CAUTION: During the assembly procedure, the sequence of instructions must

be followed. Do Not Tighten Any Hardware Until Instructed.

Refer to the feed support parts list and the steps shown below.

3.0 FEED SUPORT ASSEMBLY

STEP 1:

Attach right and left feed rods to

the reflector with (items 7, 9,10 )

and with (2) of ( item 8 ). Do not

tighten See Figure 2 and Detail A.

Feed Rods

See Detail A

1/4”x .75” Hex Bolt

1/4"Hex Nut

1/4”Lockwasher

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

15

STEP 2:

STEP 3:

Feed Bracket

Feed Rod

(Bottom) [ 12, 13 ]

3 Places

Attach the bottom feed rod (item 3) to the

bottom of the reflector with (items 7,9,10).

and with (2) of (item 8). Do not tighten.

See Detail B.

Bottom Feed Rod

See Detail B

Attach the feed bracket (item 4) to the

ends of the three feed rods using 1/4"

hardware (items 11, 12, 13). Note that

the bolts should be inserted from inside

the feed bracket, then through the feed

rod ends. Securely tighten the six feed

rod bolts at this time.

[ 11 ]

3 Places

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

16

STEP 4:

A) Assemble the feed horn (item 6) to the

LNB (single pole) using the screws

provided with the LNB or to the OMT

(dual pole) using the o-ring and screws

provided by Prodelin.

B) Place the feed assembly into the saddle

of the feed bracket (item 4) as shown,

making sure that the shoulder of the

feed horn in against the face of the

bracket.

C) Secure all in place with the feed clamp

(item 5) and 1/4"hardware (items

11,12,13). Tighten securely.

Reflector ( FACING )

Left Hand

Feed Rod

Right Hand

Feed Rod

FIGURE 2

[ 11 ]

Feed Clamp

Feed Horn

Feed Bracket

[ 12, 13 ]

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

17

SECTION IV ANTENNA POINTING

[

7, 8

]

[ 8, 9, 10 ] Reflector

Feed

DETAIL A

[ 8, 9, 10 ]

Feed Rod- Bottom

[ 7, 8 ]

DETAIL B

Bottom of

Reflector

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

18

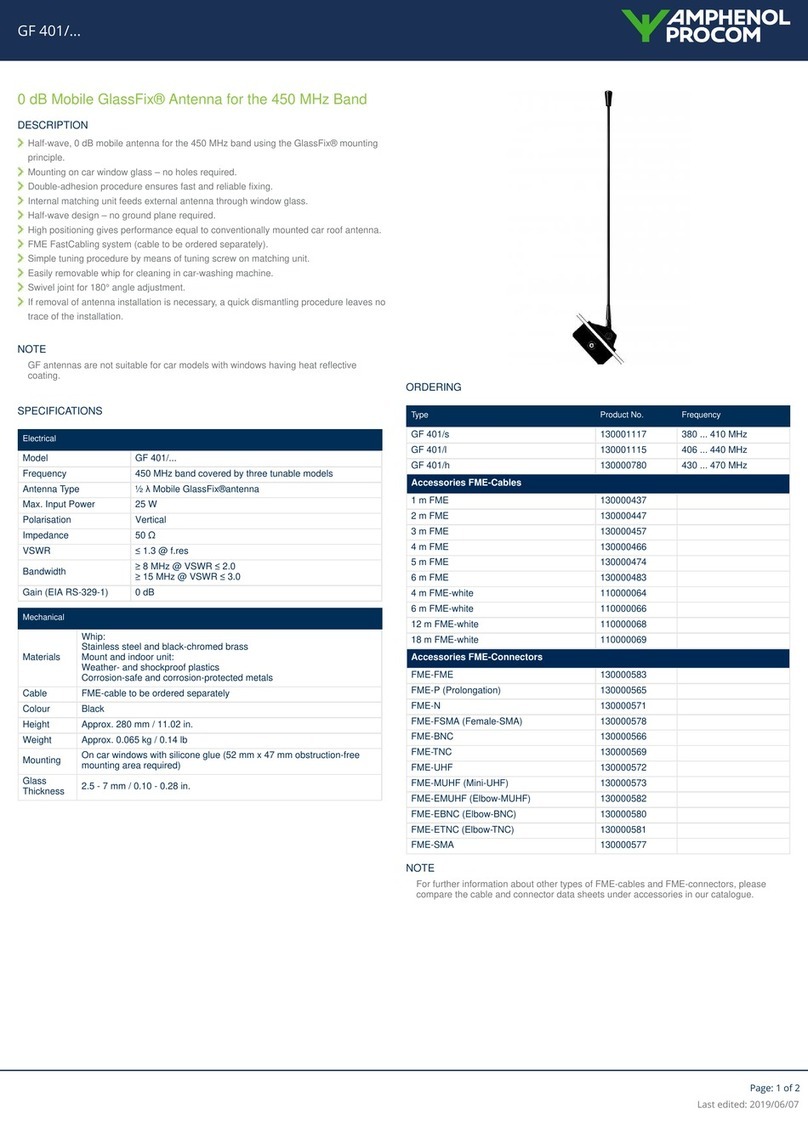

4.0 ALIGNMENT TO SATELLITE

The 1.8 meter offset reflector contains a 22.3oelevation offset look angle.

Therefore, when the reflector aperture is perpendicular to the ground, the

antenna is actually looking 22.3oin elevation. The lower back rib on the reflector

is a Sight Reference Rib and can be used to read the correct elevation look

angle.

1) Aligning to primary satellite: Place the inclinometer on the sight reference

rib as shown in figure 3. This surface compensates for the 22.3ooffset in

the reflector, therefore a direct reading can be taken.

2) Raise or lower the antenna to find the desired elevation by turning the 5/8"

nuts located on the elevation channel. Position the top nut so that it will

not interfere with adjustment. Turn the bottom nut clockwise to increase

elevation and counterclockwise to decrease elevation.

3) After the correct elevation angle is set, rotate the antenna in azimuth by

loosening the six 1/2" set screws located on the canister and rotating the

reflector assembly about the mast pipe until the correct signal is found.

4) Peak the antenna signal by fine adjustments made in both azimuth and

elevation.

5) Tighten the four (6) 1/2" set screws in the canister.

6) Tighten all 5/8"hardware on the elevation adjustment rod and the reflector

support tube.

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

19

Inclinometer

Elevation

Adjustment

FIGURE 3

4096-291

PRODELIN CORPORATION 1.8M SERIES 1183

20

SECTION V MAINTENANCE

5.0 MAINTANANCE OVERVIEW

After installation, the antenna requires only periodic inspection. It is anticipated

that maintenance, if required, will be minimal and easily handled by a local or in-

house maintenance staff. The materials used in the construction of this Earth

Station Antenna virtually eliminate any maintenance repairs.

5.1 PERIODIC INSPECTION

It is suggested that a periodic inspection be performed at least every six months.

NOTE: After any very severe weather conditions, inspection of the antenna

should be performed to determine if foreign objects have caused damage or if

survival specifications have been exceeded.

This inspection should include the following:

1) Check all bolting locations - all bolts should be tight.

2) Check all structural members - repair or replace if damaged.

3) Check the foundation anchor bolts - they must be secure and with no

failure signs in foundation.

4) Check for corrosion - on the reflector structure and mount.

5.2 REFLECTOR

Prodelin's reflector does not require any maintenance. The composite

construction of the reflector is virtually impervious to any damages that could be

caused by weather or other atmospheric conditions.

It is only necessary to inspect for any physical damage done by vandalism or

very severe weather conditions.

Should any damage be detected to a portion of the reflector, contact the

Customer Service Department at Prodelin for recommendations involving

reflector repair.

5.3 MOUNT AND REFLECTOR SUPPORT STRUCTURE

Table of contents

Other prodelin Antenna manuals

prodelin

prodelin 3.8M User manual

prodelin

prodelin 1132 series User manual

prodelin

prodelin TIER II User manual

prodelin

prodelin 1135 Series User manual

prodelin

prodelin 1381 User manual

prodelin

prodelin 4096-247 User manual

prodelin

prodelin 1134 User manual

prodelin

prodelin 1251 User manual

prodelin

prodelin C-Band Rx/Tx User manual

prodelin

prodelin 1132 series User manual

Popular Antenna manuals by other brands

Diamond Antenna

Diamond Antenna CP6 Assembly instructions

MOBILE SIGNAL BOOSTERS

MOBILE SIGNAL BOOSTERS LPD-9 installation guide

BrasilSat

BrasilSat SCB37-160 user manual

BAS

BAS BAS-6103 Venus UHF Quick user guide

SteppIR

SteppIR CrankIR Assembly & instruction manual

Amphenol Procom

Amphenol Procom GF 401/ Series quick start guide