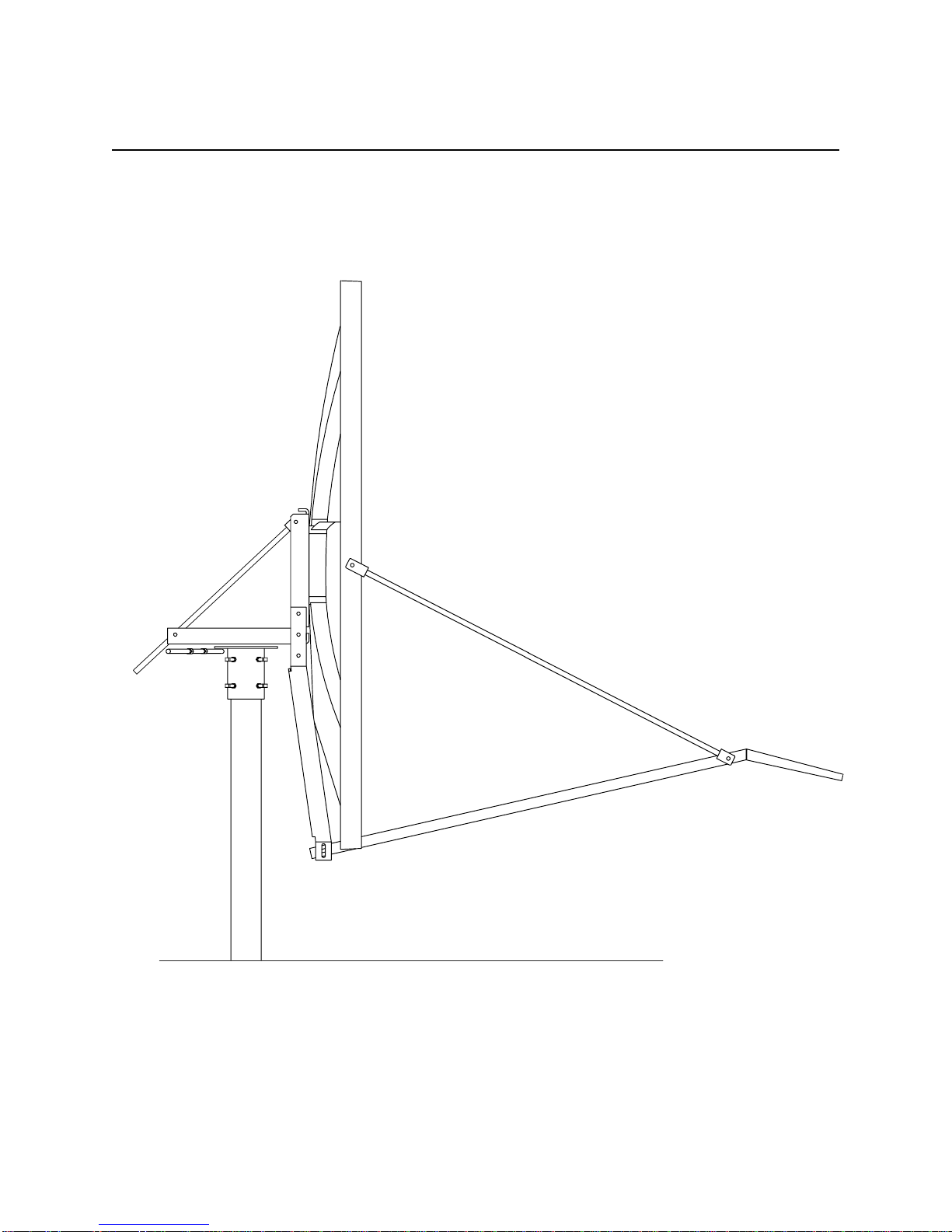

prodelin 1134 User manual

Table of contents

Other prodelin Antenna manuals

prodelin

prodelin 1135 Series User manual

prodelin

prodelin 1183 series User manual

prodelin

prodelin 3.8M User manual

prodelin

prodelin 1251 User manual

prodelin

prodelin 1381 User manual

prodelin

prodelin 1132 series User manual

prodelin

prodelin 1132 series User manual

prodelin

prodelin C-Band Rx/Tx User manual

prodelin

prodelin TIER II User manual

prodelin

prodelin 4096-247 User manual

Popular Antenna manuals by other brands

M2 Antenna Systems

M2 Antenna Systems 6M5XHP manual

Ubiquiti

Ubiquiti airMAX Omni AMO-2G10 Anchoring requirements and Instructions

Hypercable

Hypercable Z24A60T37301 installation instructions

Global Invacom

Global Invacom DB60L4 Quick user guide

Ubiquiti

Ubiquiti AP-5AC-90-HD Air Prism quick start guide

WiMo

WiMo ULTRABEAM troubleshooting guide

Meinberg

Meinberg GNSS Multiband Antenna manual

Intuicom

Intuicom RTK Bridge -M Hemisphere Outback A220 installation guide

Megasat

Megasat Caravanman 65 Premium V2 user manual

Channel Master

Channel Master 2016 installation instructions

CNET

CNET CDA-09O Specifications

Grundfos

Grundfos CIM 250-299 instructions