4096-630

PRODELIN CORPORATION 1.2M Ku-BAND Rx/Tx SERIES 1132

12

SECTION III ANTENNA POINTING

3.0 ANTENNA POINTING

The 1.2 meter reflector contains a 17.3° elevation offset look angle. Therefore,

when the reflector aperture is perpendicular to the ground, the antenna is actually

looking 17.3° in elevation. Refer to Figure 2.

Note: The following alignment procedure is intended only as a general reference

guide for this antenna. For proper antenna performance, accurate

alignment is critical. Therefore, it is recommended that your own detailed

procedure be used or contact Prodelin’s Technical Support Department for

additional recommendations.

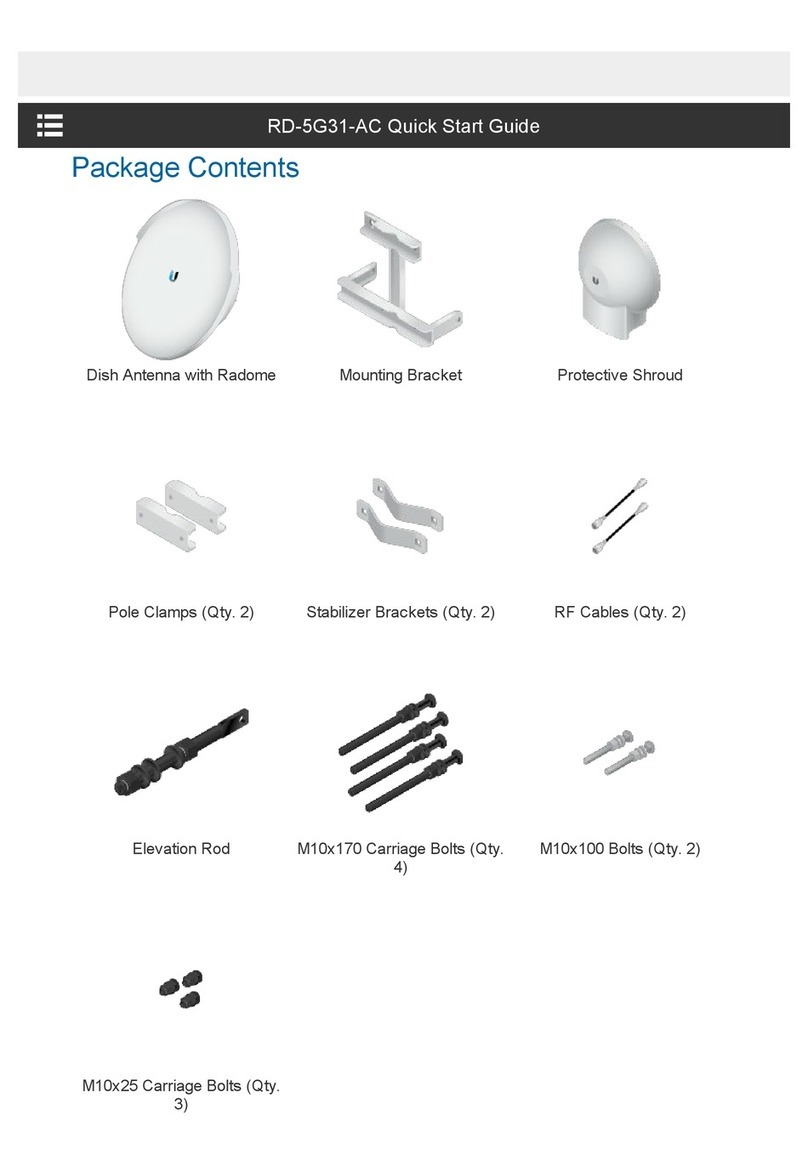

STEP 1: BEFORE ADJUSTING ELEVATION LOOSEN THE HARDWARE ON

BOTH SIDES OF THE POSITIONER, REFER TO FIGURE 2 FOR

LOCATION. Adjust the reflector up or down in elevation by turning the

5/16” Bolt at the az/el positioner until the desired elevation is read on the

‘B side’ of the positioner. This scale is used for nominal readings and is

accurate to ±2 degrees. Note: Elevation rod is for adjustment only, it

is not intended to be part of the structural integrity of the assembly,

tightening the elevation rod is not necessary. Snug the hardware at

the side of the positioner.

STEP 2: Azimuth Adjustment: With the electronics set to acquire the satellite,

rotate the antenna in azimuth until the satellite is found. Tighten the

canister hardware at this time.

STEP 3: Fine azimuth adjustment is achieved by loosening the three hex nuts

inside the Az/el positioner and turning the single hex bolt at the back of

the positioner in either direction. Note: Azimuth rod is for adjustment

only, it is not intended to be part of the structural integrity of the

assembly, tightening the azimuth rod is not necessary.

STEP 4: Peak the antenna signal by fine adjustments made in both azimuth and

elevation until the optimum signal is achieved.

STEP 5: Tighten all hardware used for adjustment.