prodelin 1135 Series User manual

Table of contents

Other prodelin Antenna manuals

prodelin

prodelin 1183 series User manual

prodelin

prodelin TIER II User manual

prodelin

prodelin 4096-247 User manual

prodelin

prodelin 1132 series User manual

prodelin

prodelin 1381 User manual

prodelin

prodelin 1134 User manual

prodelin

prodelin 1132 series User manual

prodelin

prodelin 3.8M User manual

prodelin

prodelin 1251 User manual

prodelin

prodelin C-Band Rx/Tx User manual

Popular Antenna manuals by other brands

Camos

Camos CSA-2300M instruction manual

Dish Network

Dish Network DishPro installation quick reference guide

SilentWind

SilentWind WEB-Catcher SW8WL User's manual & installation instructions

Maxview

Maxview 5G/4G 4X4 MIMO installation instructions

BLIP

BLIP Node L2i user guide

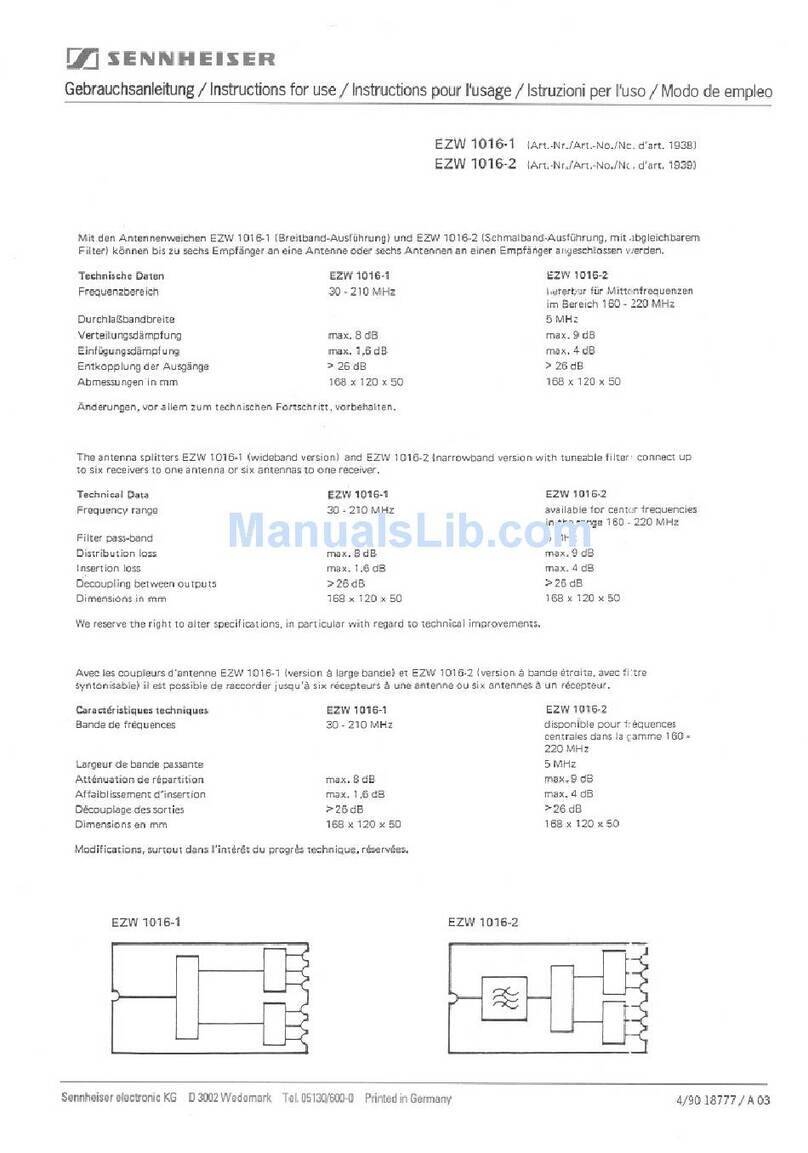

Sennheiser

Sennheiser EZW 1016-1 manual

Diamond Antenna

Diamond Antenna CP-5HS Operation instructions

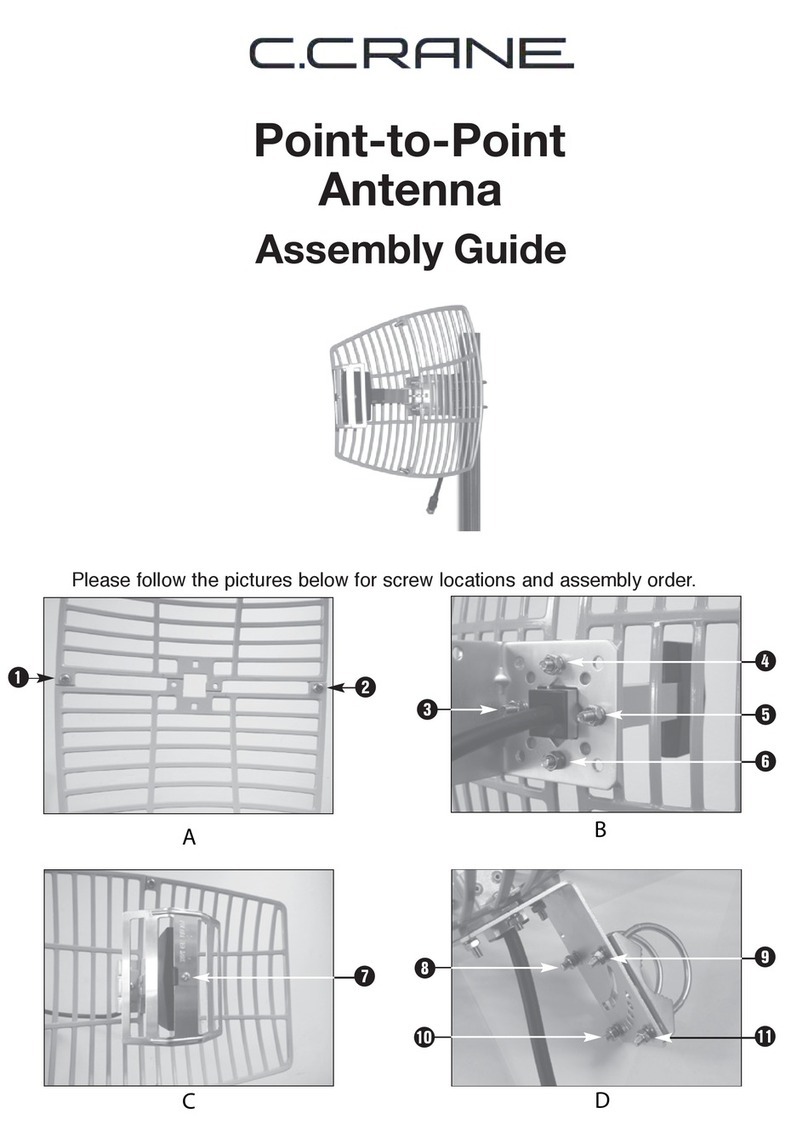

C. Crane

C. Crane Point-to-Point Assembly guide

Winegard

Winegard Carryout quick start guide

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

MobilSat

MobilSat MSP-S Mounting instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction