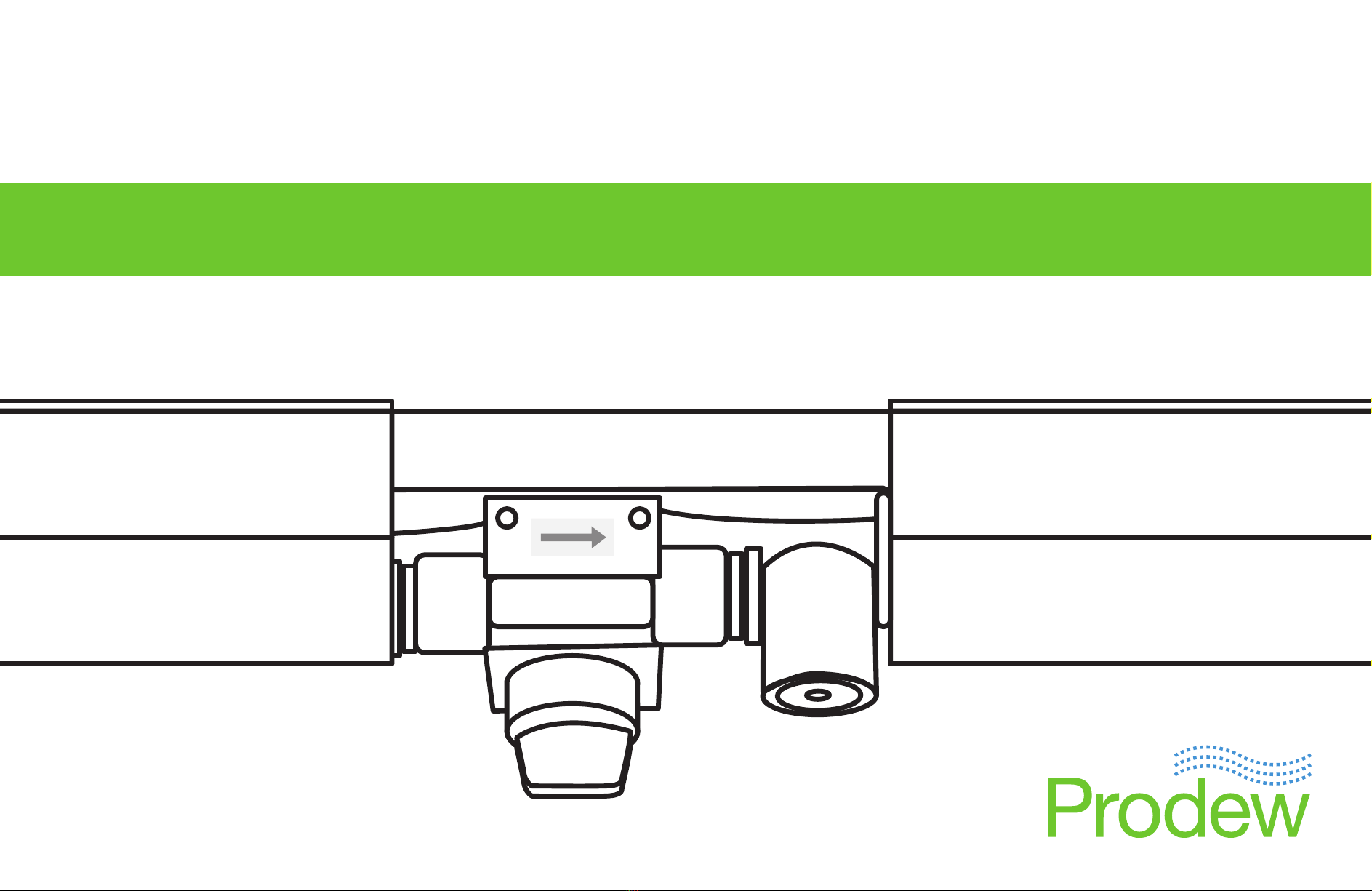

Prodew FogMist Track User manual

FogMist™ Track

Installation Manual for Produce Canopy

rev June 2017

www.facebook.com/Prodew.Inc

Table of Contents

Package Contents 5

Utility Requirements 6

System Layout 7

Air Compressor Kit Diagram 8-9

FogMist™ Track Breakdown 10

System Installation 11 - 15

Start-Up Procedures 16 - 19

Timer Settings 20

System Warranty 21

Having trouble understanding our instructions?

Contact our customer service

department with your questions.

sales@prodew.com

4

Quick Connect Fitting Assembly

5

Package Contents

Solenoid Box

(FMSOLBX-PRM38)

Timer Box

(HTIM001-110-CLDUL)

Phosphate Filter (5mic)

(2FIL-EC-S10-2038-P)

FogMist™ Clamp Lock

(3CLP388B)

Stainless

Steel Screws

(3FAS002)

Air Compressor Kit

(HCOM001-2HD-FOG)

FogMist™ Track

(FMTRC38-―-1B)

8in Zip-Ties

(3TIE7)

FogMist™ Track Cover

(3CLPCOVO―-B)

3/8in Clips

(3CLPCAB-38)

3/8” Tubing

(2TUB12O-38I-B)

1/2” x 6” Protective

Corrugated Tubing

(2TUB-COR-12ID-B-SLT)

3/8” x 1/4”

Splitter

Connection

(need part number)

Male Connector,

3/8” QC x 1/2”

MPT

(2PMCQ38M12)

3/4” Tubing

(2TUB340-58ID-B)

Stainless

Steel Screws

(FAS001)

6

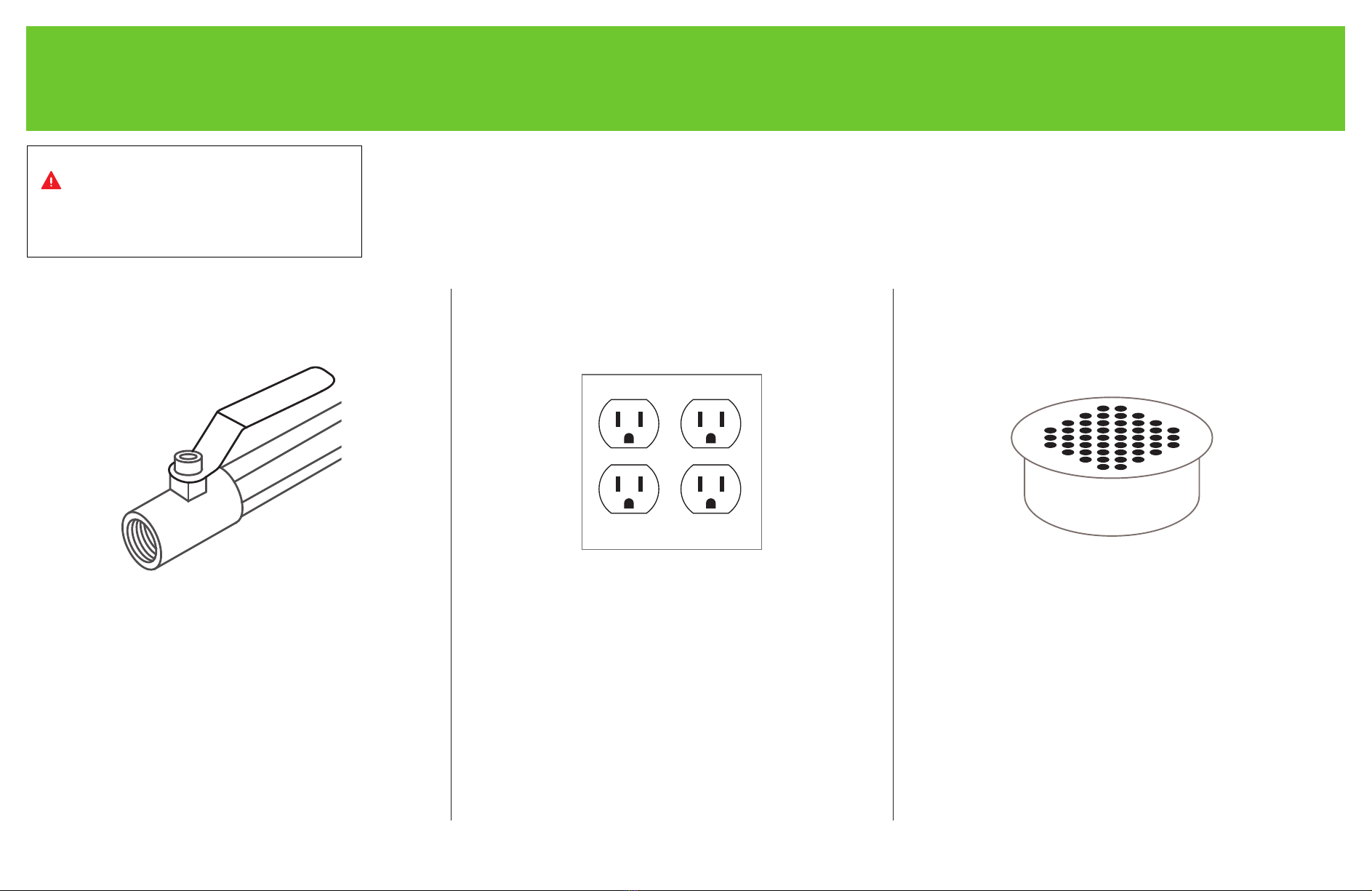

Utility Requirements

• 1/2in female NPT

adapter with ball valve

• Minimum inlet pressure

of 30 PSI

• Easily accessible under

the display case

Water Supply

• 110/220VAC

60/50Hz

20Amp

• Easily accessible under

the display case

4-Plug Power Outlet

• Minimum 3/4in for

waste water or a 1/2in

drain pipe

• Easily accessible under

the display case

Floor Drain

IMPORTANT

These utility requirements must be in

place before installation can take place.

7

System Layout

8

Air Compressor Kit Diagram

HCOM001-2HD-FOG (Small Systems)

4

3

2

1

57

8

6

9

# PART NUMBER DESCRIPTION QTTY

1 2GAU007 Gauge 1.5'' 1/4NPT, 0-150 1

2

3

2PMCQ38M14 M Con, 3/8 inch QC x 1/4 inch MPT 1

4

2AFIL-INL14-5MIC Air Filter 1/4 inch FNPT 5mic 1

2MSTF14F14M14 Straight Tee 1/4 inch, MTL 1

5

6

1CON119 #10 Blue Nylon Ring Terminal

7

2FCVAL-M14 Air Flow Control Valve 1/4 inch NPT 1

8

3CLPHUM003 Suction Cup, w/ 8-32 MS Insert 4

9

1WIR050 Wire, 16/3 Extension Cord 1

5 1COM006 Air Compressor, Dbl Hd, 110VAC 1

# PART NUMBER DESCRIPTION QTTY # PART NUMBER DESCRIPTION QTTY# PART NUMBER DESCRIPTION QTTY

1CON111 Wire, Butt Connector 18-22 GA 2

9

FogMist™ Track for Produce Breakdown

ITEM #

PART # DESCRIPTION

1

2PURQ38Q14

Poly, Union Red 3/8Qx1/4Q

2

2P2WDIVQ6-2XQ6-C

2 Way Divider, 6mmQ-2 x 6mmQA2

3

2VALQ6 Straight Valve 6mm x6mm

4

4SPRFM-4W6A-BL38T Spry, Fog Mist 4mm x 6mm Stem

ITEM #

PART # DESCRIPTION

6

3CLPCOV03-B C Clamp Cover 9.75"

7

2PSP6-C

Red Stem Plug

8

2TUB6O-4I-B

Tub, 6mm OD Poly BK

5

3CLP388B Clamp, 388 BK

12

3 4

5

7

6

8

10

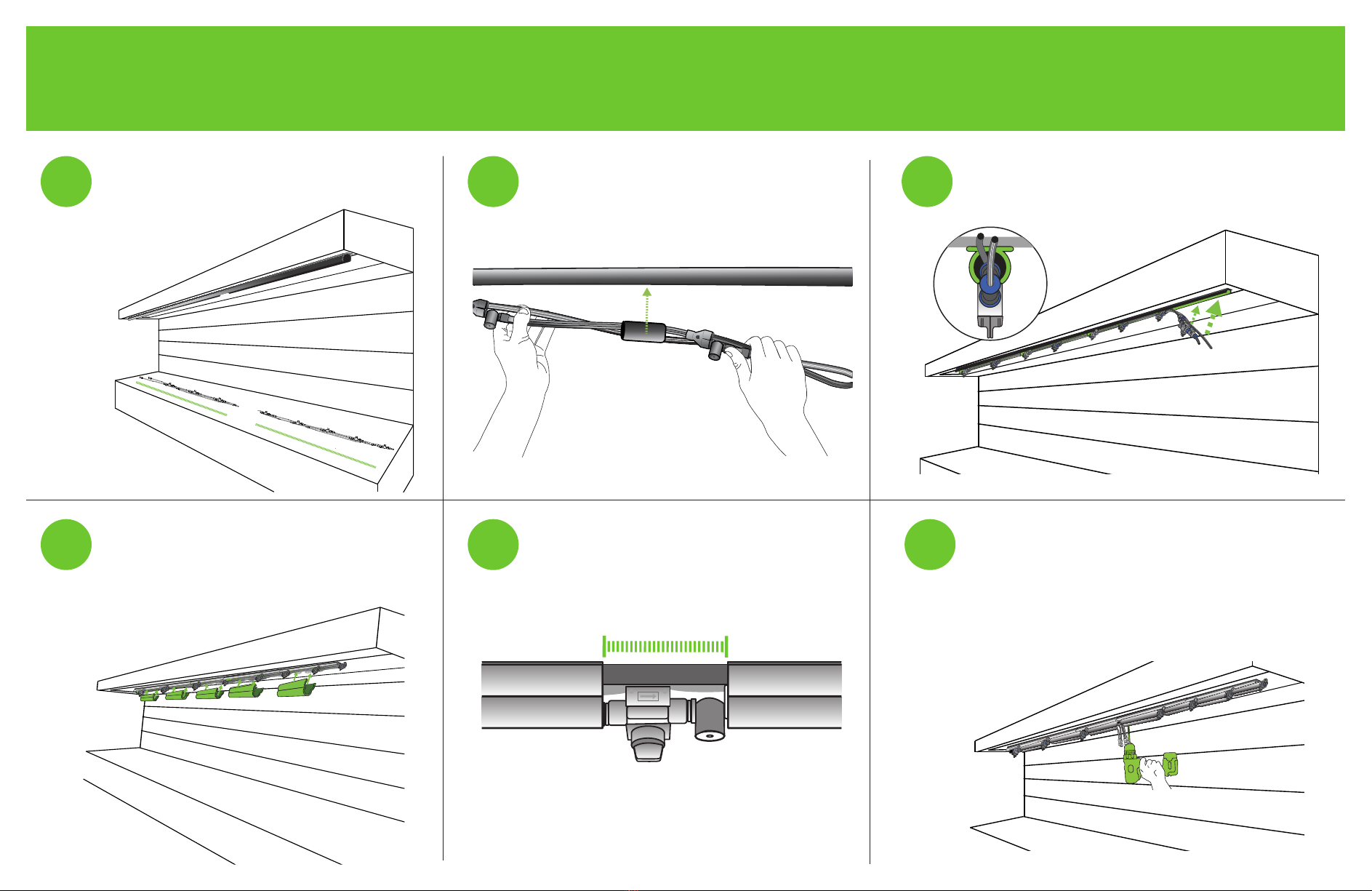

System Installation

4

2

IMPORTANT

Make sure to place the control box

near a power and water source.

FLUSH THE CITY WATER LINE FOR

3-4 MINUTES BEFORE CONNECTING

TO OUR WATER LINE.

Tools Required

Material Required

Tube Cutter

Drill

TeonTape

Misc Drill Bits

& Drivers

Adjustable

Wrenches

Chanel Lock

Pliers

Screw Drivers

1

3

Mount the mist control, air compressor and

timer box at the center of the area being

misted on top of the case.

(Other mounting locations can be used.)

OR

Air Curtain

Notch the clamp lock near the middle of the case where

the hole will be drilled to connect water and air lines.

Mount the clamp lock into the case ceiling in

the area to be fogged with the provided screws.

Decide where to mount the clamp lock onto the

case ceiling in the area to be fogged - preferably

inside the air curtain (can

also be placed outside of air

curtain).

11

System Installation

765

8910 Drill a hole for the feed lines in the case ceiling

behind the track (approximately 6in).

The hole should be drilled in the middle of the

case where the two lines of track meet.

Ensure that no water, air, electrical or

refrigerated lines are in the way.

When placing the covers, do not place

over the nozzles and shut-off valve. Make

sure to leave a gap as to not obstruct

valve and mist.

Snap the covers over the lines onto the

mounting clamp. The covers will t between

the nozzle and shutoff valves on the

exposed tubing (some trimming may be

needed for proper t).

Using 3/4in tubing on the track line, insert

the lines into the clamp. (Try not to twist the

lines as you install.)

Spread the lines across the area to be

fogged, starting from the center point and

going in each direction.

Once the lines are in place, ensure that all

tubing ts into the clamp.

1212

System Installation

131211

14 15 Connect the Y-divider ttings to the tubing from

couplers.

1/4”

WATER

1/4”

AIR

CASE CEILING

16

Insert a piece of corrugated tubing into

the hole to protect the lines.

Remove the couplers from the ends of the

track liners to be able to guide lines through

the corrugated tubing.

CASE CEILING

Once the corrugated tubing is set into place

it’s time to connect track lines to the controls.

Run the 6mm air and water lines through the

corrugated tubing. Cut to length if needed.

Re-attach couplers. Insert a 1/2in piece of

3/8in tubing into each coupler to connect to

the Y-divider tting. Be sure that both

air lines are going

to one Y, and

both water lines

are going to the

other Y.

13

System Installation

19

20

Run 3/8in air tubing from the air compressor

to air Y-divider.

Cut to length.

21

3/8”

WATER

3/8”

AIR

1/4”

WATER

1/4”

AIR

CASE CEILINGCASE CEILING

Connect the 3/8in air tubing from the

air compressor to the Y-divider with the

6mm air lines.

Connect the 3/8in water tubing from the mist

control box to the Y-divider with the 6mm

water lines.

Attach the 3/8in water tubing to the port

labeled “NOZZLE” on the mist control box.

Run 3/8in water tubing to water

Y-divider.

Cut to length.

17 18

Your lines should look like this after they’re

runt, cut to length, and connected.

3/8”

WATER

3/8”

AIR

1/4”

WATER

1/4”

AIR

CASE CEILINGCASE CEILING

22

14

Connect the 3/8in black tubing from the

water supply to the inline lter at the ball

valve. Cut to length.

Flush the lter into the drain for 2 minutes.

FLUSH THE CITY WATER LINE FOR

3-4 MINUTES BEFORE CONNECTING

TO OUR WATER LINE.

Thread black tubing

(water inlet and drain kit)

Run the drain line to the oor drain. Cut to

length.

Strap the 3/8in black tubing to the existing

drain lines using zip ties.

Leave 1in air gap between the 3/8in black

tubing and the drain to avoid contamination.

Connect 3/8in black tubing to the mist

control box port labeled “DRAIN”.

Connect the inline lter to the mist control

box port labeled “WATER INLET”.

System Installation

23 24 25

22

2726

Fill all voids around the corrugated tubing

with silicone to avoid leaks.

15

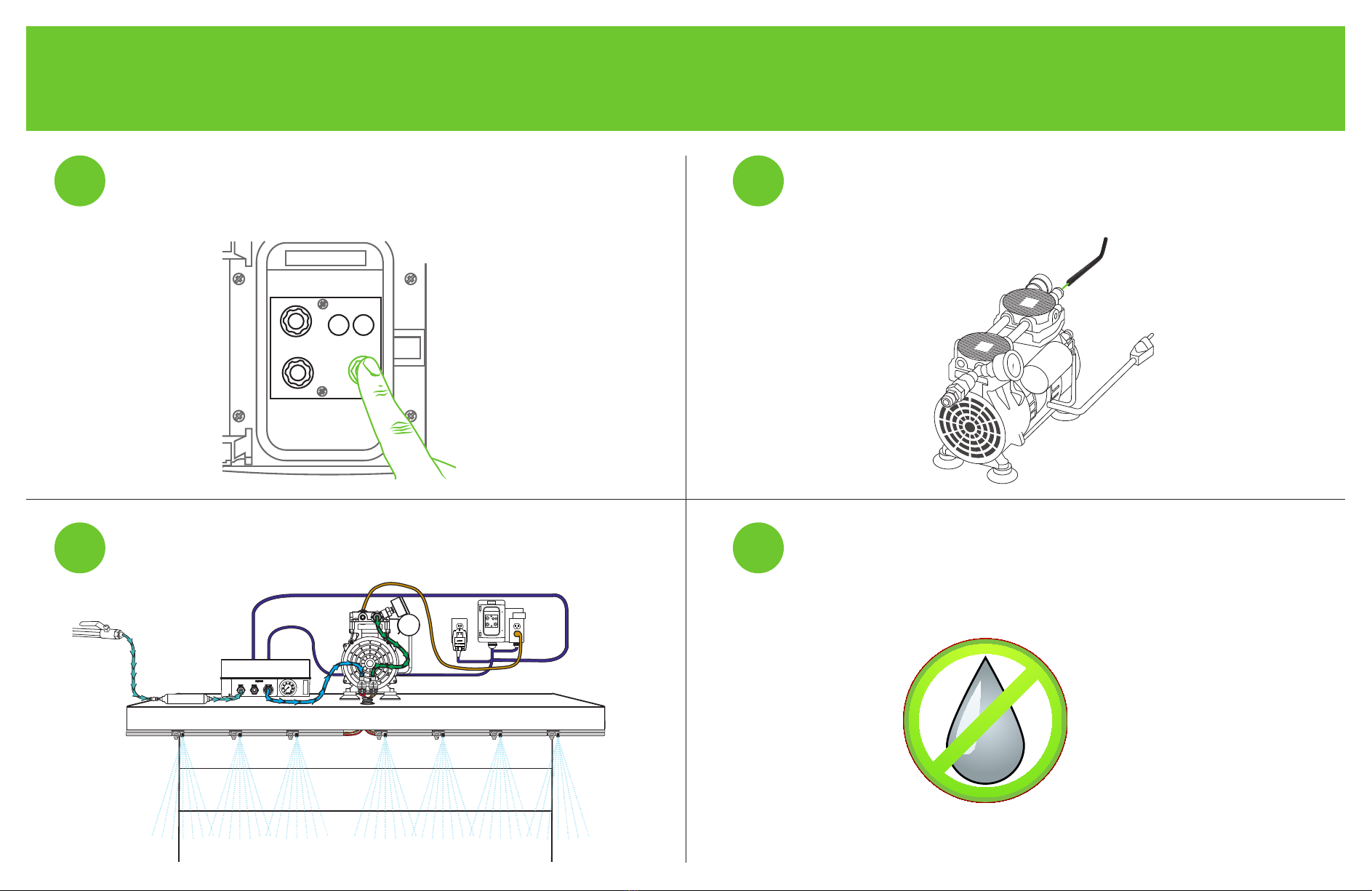

Start-up Procedures

4

21

3

Plug the air compressor(s) into the outlet on the timer box. Plug the

timer’s 110V transformer into the city power supply outlet.

Ensure that you have water and power. Conrm

that everything is plugged in and connected.

Turn on water valve and check the inlet pressure by looking at the

solenoid box gauge. The pressure is factory set to 30 PSI. Adjust the

pressure by opening the solenoid box and rotating the black knob by hand

or screw driver. Increase the water pressure to increase fog density.

Set OFF TIME to its minimum (0.5 min) and ON Time to

maximum settings (2.5 min). Remove the stem plugs from

the air and water lines at the end of the line where the last

nozzle is located.

(See Steps to Set the Timer - pg 20)

20

30

40

60

80

100

120

140

150

16

Start-up Procedures

8

65

7

Flip the toggle switch on the timer box to ON position. The air

compressor should start after 5 seconds. Flush for one cycle and

then replace the stem plugs.

Check the air pressure by looking at the gauge on the air

compressor. The air pressure should be 15-20 PSI (higher

air pressure preferred, but do not exceed 20 PSI). If it’s not

correct, adjust the air pressure on the air compressor with

the allen wrench.

Let the system run for several cycles until all nozzles are spraying. Check for leaks and ensure proper mist pattern.

Ensure all nozzles are spraying. If not, see

Troubleshooting Guide.

1.5

1

0.5 2.5

2.0

MIST POWER

ON TIME

OFF TIME

7

4

0.5 1.5

11

ON

17

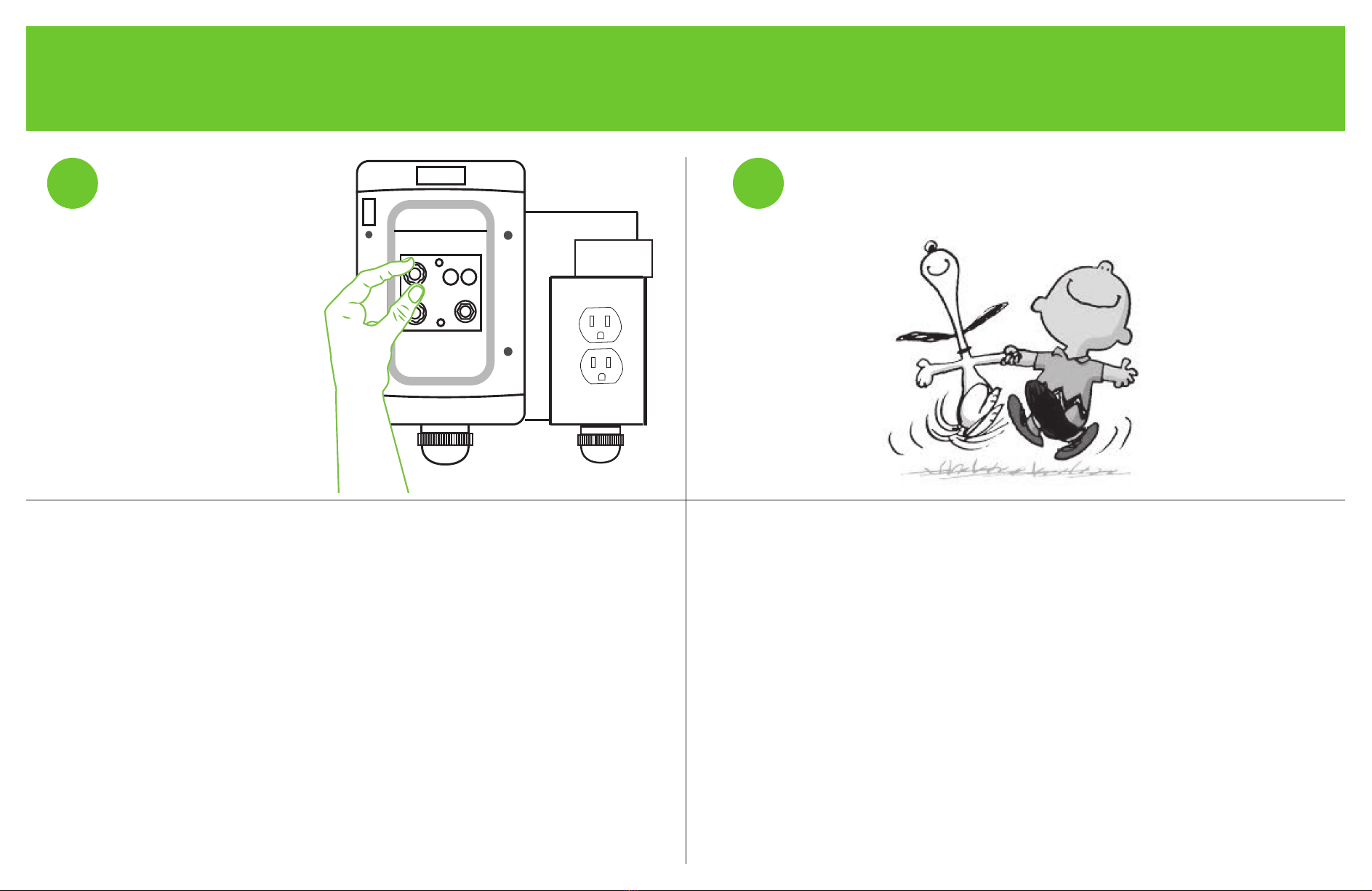

Start-up Procedures

9Set the timer to

recommended settings

(See Recommended

Timer Settings - pg 20).

Do a happy dance.

System is ready for use.

9

18

Timer Settings

• ON Time - 0.5 - 2.5 minutes

Duration of fog cycle.

• OFF Time - 1 - 15 minutes

Duration in between fog cycles.

Factory Presets

IMPORTANT

The factory presets are the

recommended settings for the system.

Only change the settings if there is

too much or too little fog.

The ON time is set by

rotating the black knob

marked ‘ON TIME’

The recommended cycle times are preset at our manufacturing facility.

If repairs or changes have been made to the system, we recommend that you

ushthelinestoensurethatnoparticles,liquidTeon,Teontape,pipedope,

or other foreign matter is present in the system.

The OFF time is set by

rotating the black knob

marked ‘OFF TIME’

1.5

1

0.5 2.5

2.0

MIST POWER

ON

OFF

ON TIME

(minutes)

OFF TIME

(minutes)

8

4.5

115

11.5

1.5

1

0.5 2.5

2.0

MIST POWER

ON

OFF

ON TIME

(minutes)

OFF TIME

(minutes)

8

4.5

115

11.5

FILTER CHANGE

SCHEDULE

for Phosphate Inline Filter

(2FIL-EC-S10-2038-P)

Water quality

PPM coming into

Solenoid Box

Filter

Change

Schedule

>100 quarterly

100 as needed

(monthly)

forinlinemeshlter

in the solenoid box

lter can be cleaned;

only needs to be replaced if

damaged or too clogged to clean

• unscrew cover and

remove mesh screen

• wash screen with a mild cleaner

• scrub with a soft brush if

necessary

• reinstall screen and securely

tighten cover

19

System Warranty

AtProdew,wearededicatedtoprovidinginnovativedesignsandwell-madeproductstotourcustomers’individualneeds.

Iftheproductyoupurchasefromusdoesnotperformtothedesignspecications,weaskfortheopportunitytomakeitright.

Ifyouarestillnotsatised,wewillmakeadjustmentsaccordingtoourLimitedWarrantyandExclusionofRemediesPolicy.

LIMITED WARRANTY AND EXCLUSION OF REMEDIES

Perishable control equipment and component parts distributed by Prodew, Inc., its suppliers and agents, as well as new material

furnished hereunder, is warranted against any defect in materials or service in accordance with factory recommendations providing

that a claim, therefore, is made in writing within the limit set forth as 365 days from the date of invoice for parts (not including nozzles)

and 90 from the date of invoice for labor, and that either Prodew, Inc. or its Authorized Service Agency’s examination, shall disclose to

the Distributor’s satisfaction to be thus defective. PRODEW INC.’S OBLIGATION ON ANY CLAIM IS LIMITED TO REPLACEMENT OR

REPAIR OF THE DEFECT OR MATERIAL F.O.B. FACTORY.

PretreatmentmayadverselyaecttheperformanceofProdew,Inc.’sperishablecontrolequipment.Prodew,Inc.takesno

responsibility for damage resulting from unapproved pretreatment equipment and/or inappropriate maintenance of said equipment.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, OF ANY NATURE WHATSOEVER, INCLUDING THE WARRANTY OF

MERCHANTABILITY, EXCEPT AS SPECIFICALLY SET FORTH HEREIN.

Except as stated above, Prodew, Inc., its suppliers, and agents will not be liable for any loss, injury, or damages to persons or

property resulting from failure of defective operation of any material, equipment, or installation furnished hereunder or delay in

performance of this agreement, nor will it be liable for direct, indirect, special, incidental, or consequential damages of any kind

sustained from any cause. This writing expresses the entire agreement, and no other agreement, statement, or representation shall

be binding unless reduced to writing.

FILTER CHANGE

SCHEDULE

www.prodew.com

sales@prodew.com

770.420.3060 | 866.677.6339

1359 Gresham Road

Marietta, GA, 30066

Other manuals for FogMist Track

1

This manual suits for next models

1

Table of contents

Other Prodew Lawn And Garden Equipment manuals