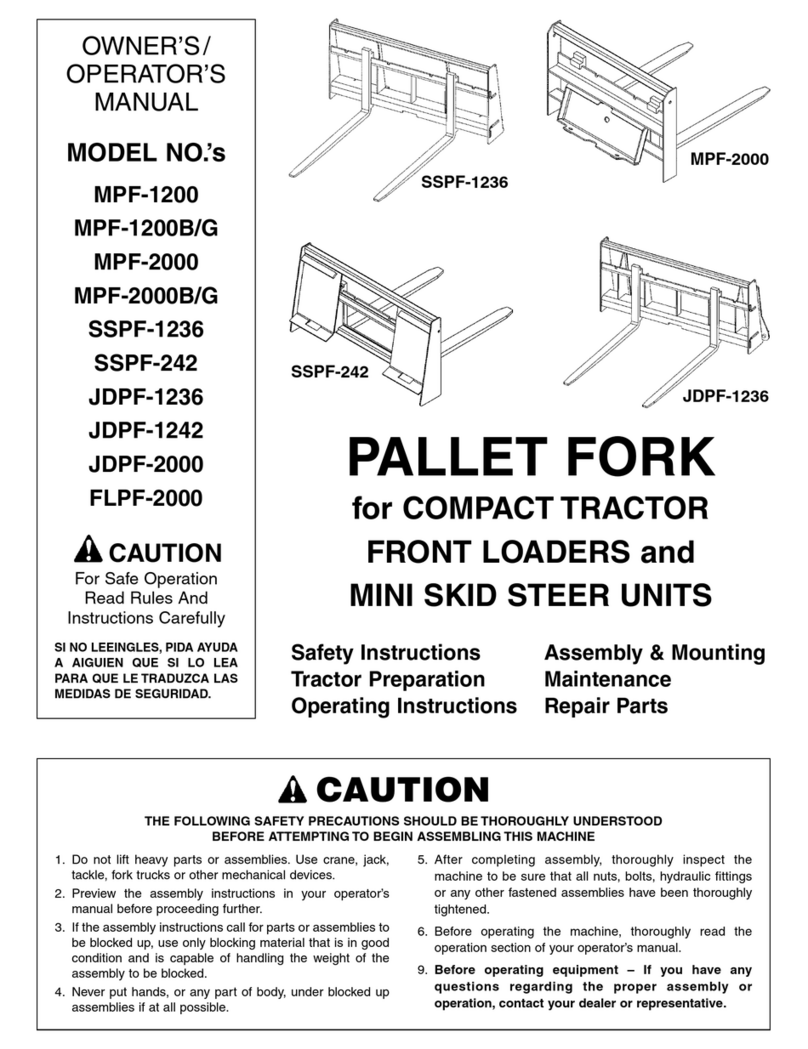

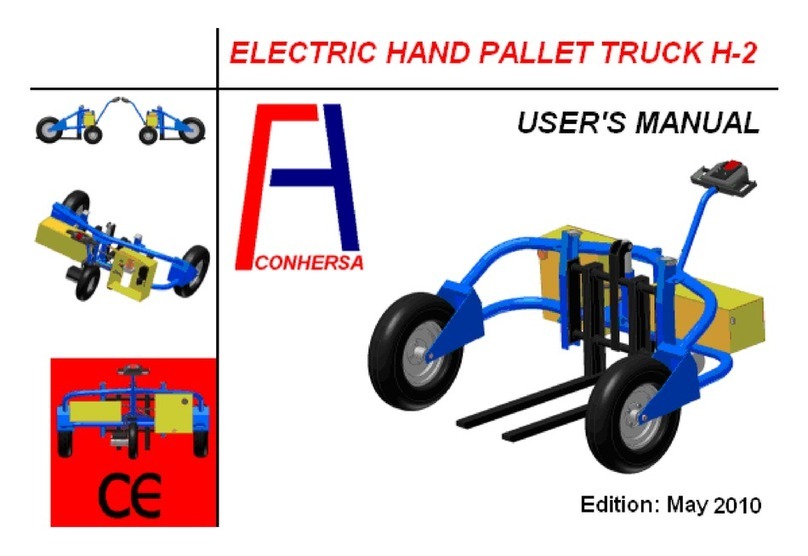

Specifications

Lift

Range Overall

Length

Saddle Net

Weight

Min.15-3/4”

Max. 28-1/8” 26-1/2” Min.2-1/2”

Max.18” 92 lbs

Failure to follo these arnings could cause a loss of load, damage to equipment, and/or failure of

equipment, hich may result in personal injury or property damage.

This jack is designed to remove or install only automotive or truck transmissions.

Using the jack in a manner for hich it is not designed may result in injury or

damage to equipment.

The load must not exceed the maximum rated capacity of 1 ton.

Stay out from underneath the load at all times.

Secure the load to the jack.

Use the jack on hard, level surfaces only.

Lo er the load completely before moving the jack.

This is a lifting device only.

Al ays ear safety glasses hen using this equipment.

Center load on saddle before lifting.

Never ork on, under or around load until it is properly supported.

Do not use this product for any other purpose other than that for hich it as

intended.

Caution

Read, study and understand the operating instructions before use. You must never overload the jack and

use on level surfaces. Make sure the release valve never gets adjusted.

Description

This jack has a lo enough profile to raise forklifts and a high enough profile to raise farm equipment,

tractors, and some earth moving equipment.

Operation

To raise the load:

1.Put the handle into the handle socket, and then tighten the handle scre .

2.Close the release valve tightly (by turning clock ise). Do not over-tighten.

3.Position jack under load so that the arm lifting point ill contact load firmly and the load is centered so it

cannot slip.

4.Operate jack handle until arm- lifting point approaches the load. Once again check to see that arm lifting

point is correctly positioned.

5.Raise load to desired height.

To Lo er Load:

1.Open release valve very slo ly (by turning the handle counter clock ise).

2.When release valve is opened, the arm- lifting point ill be lo ered.