1 / 189

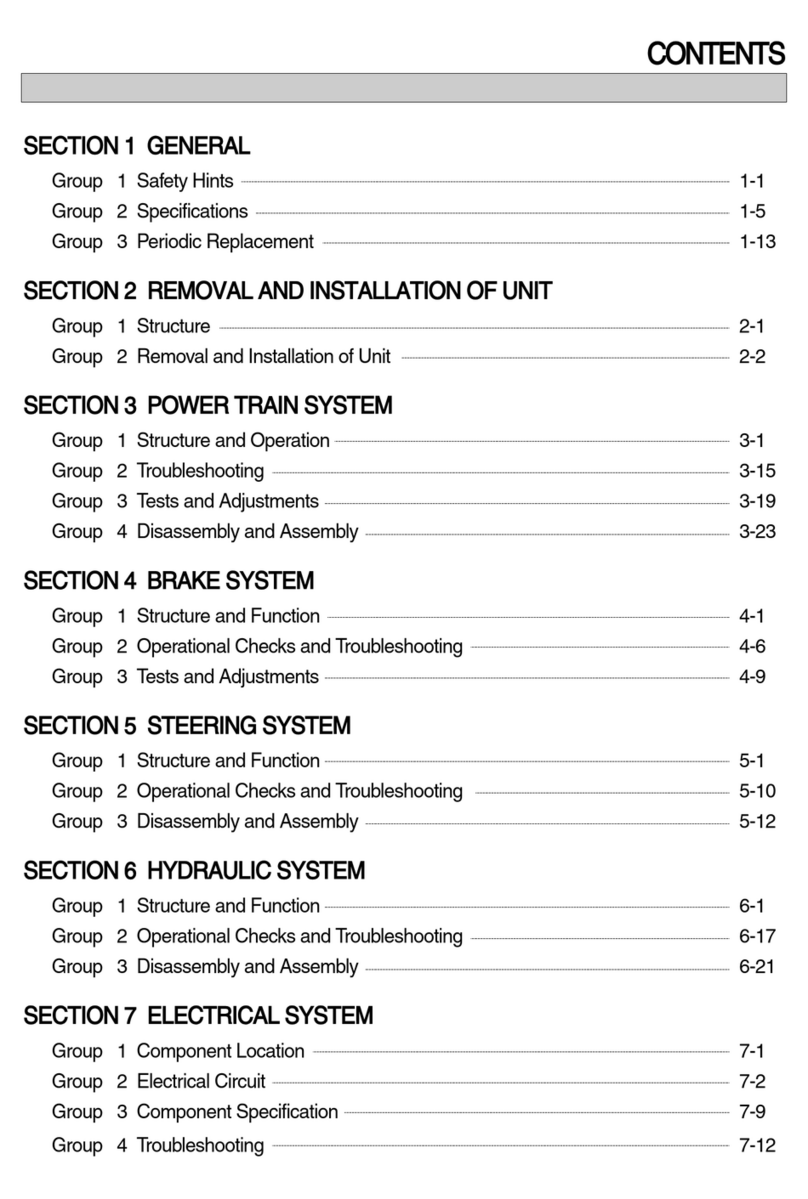

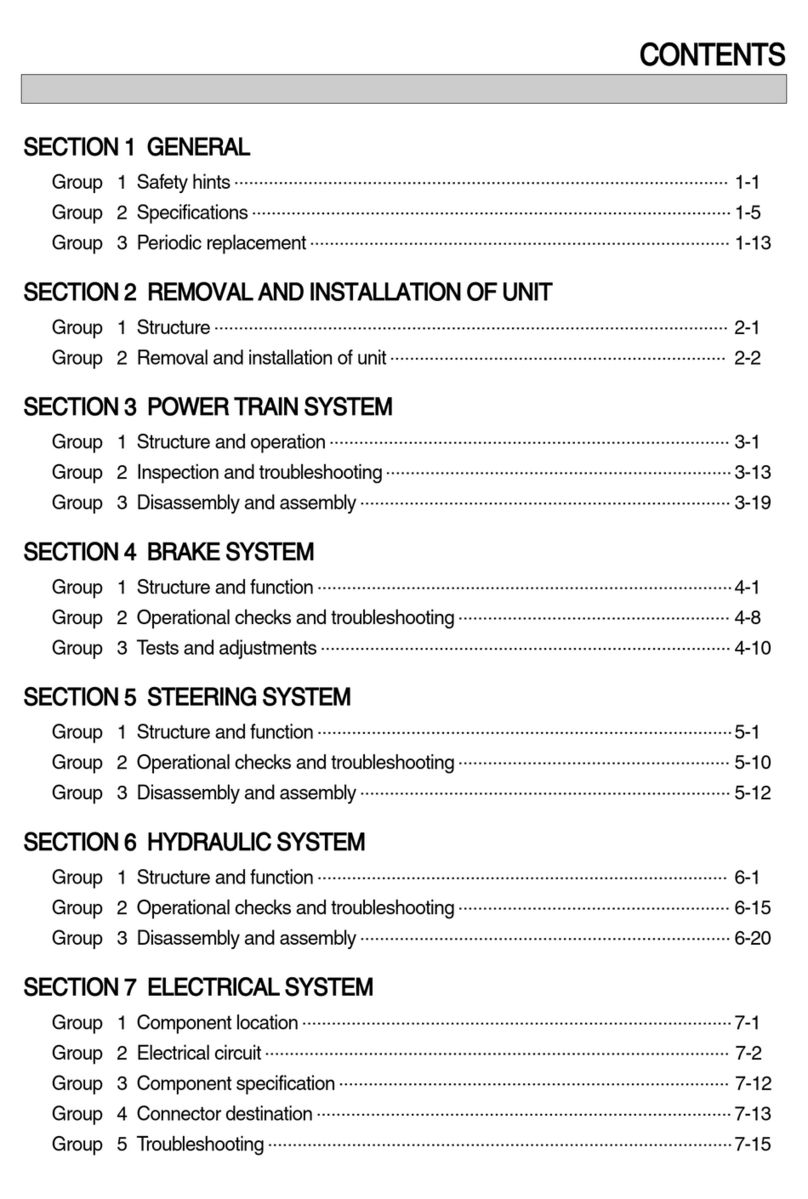

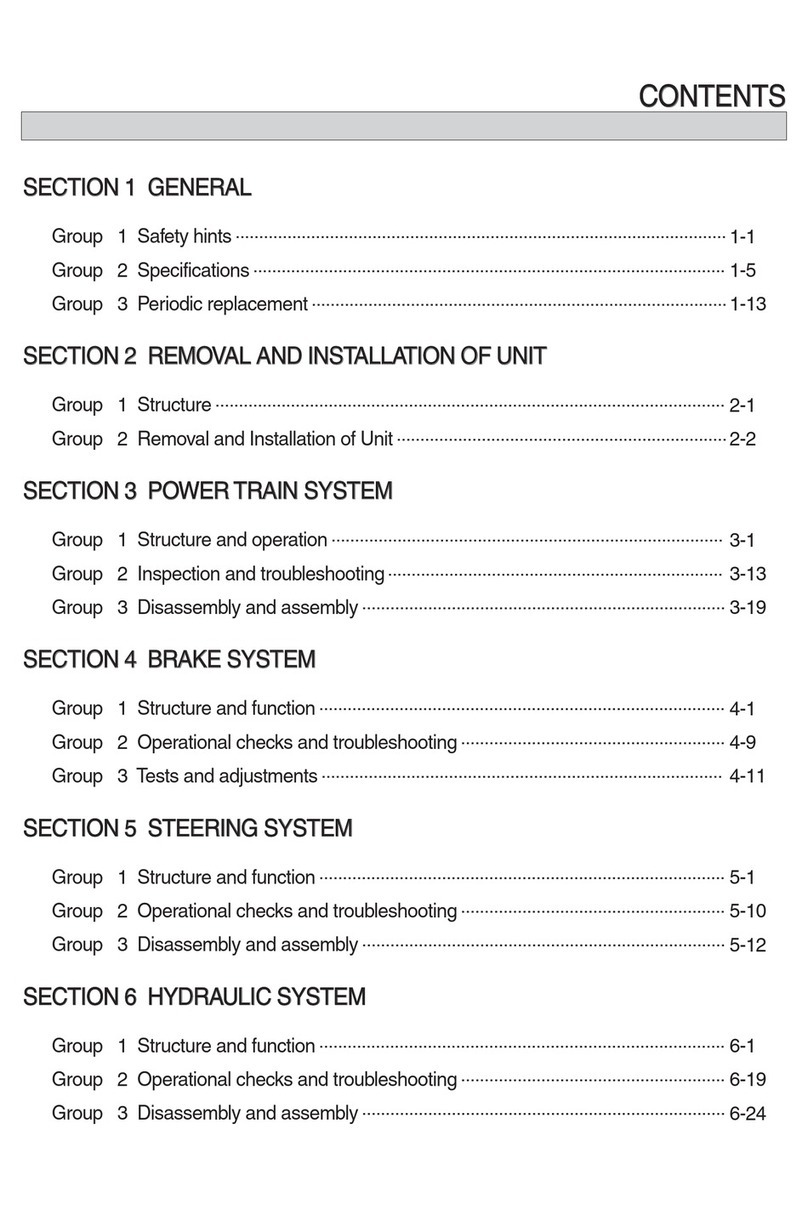

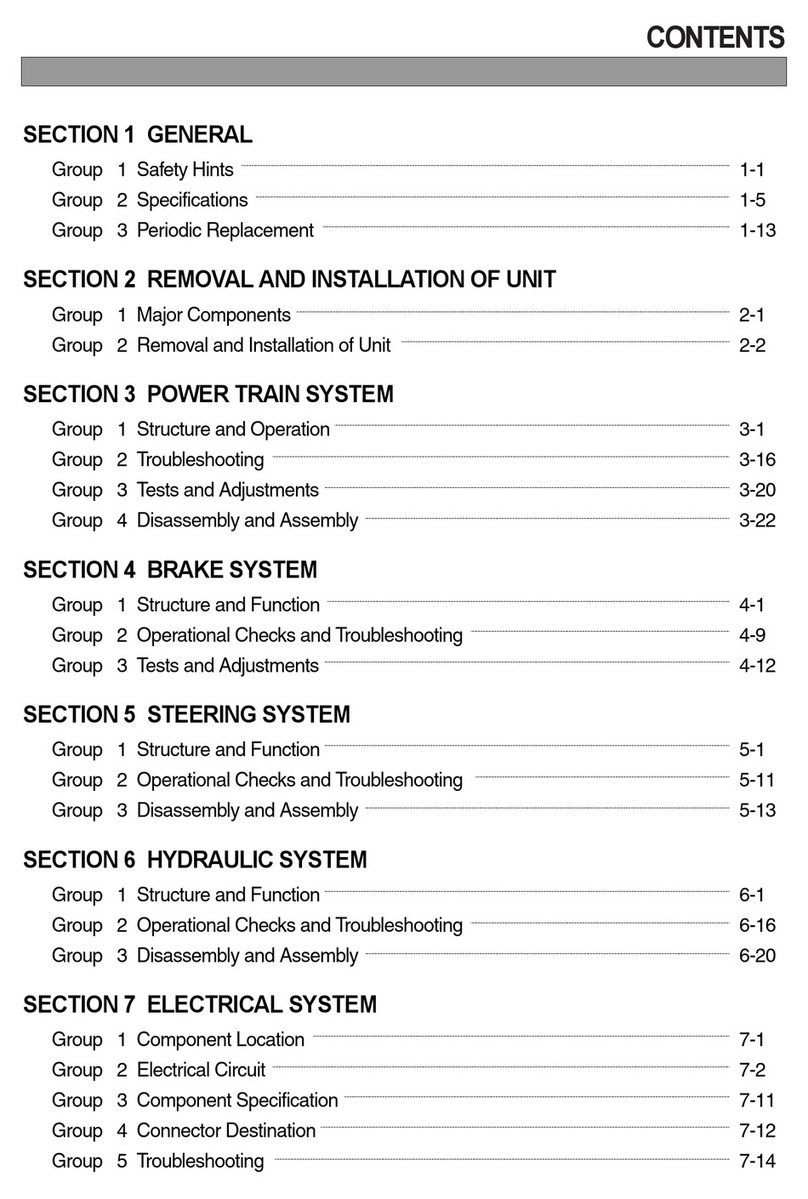

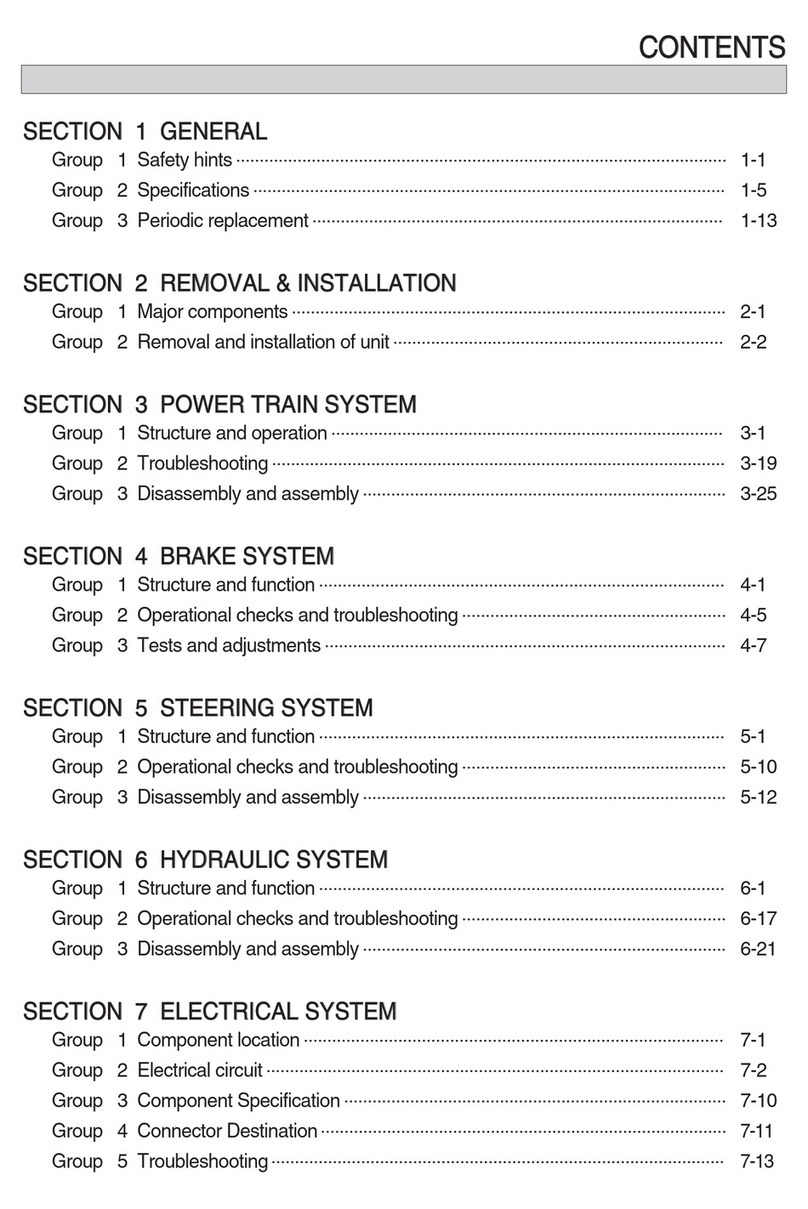

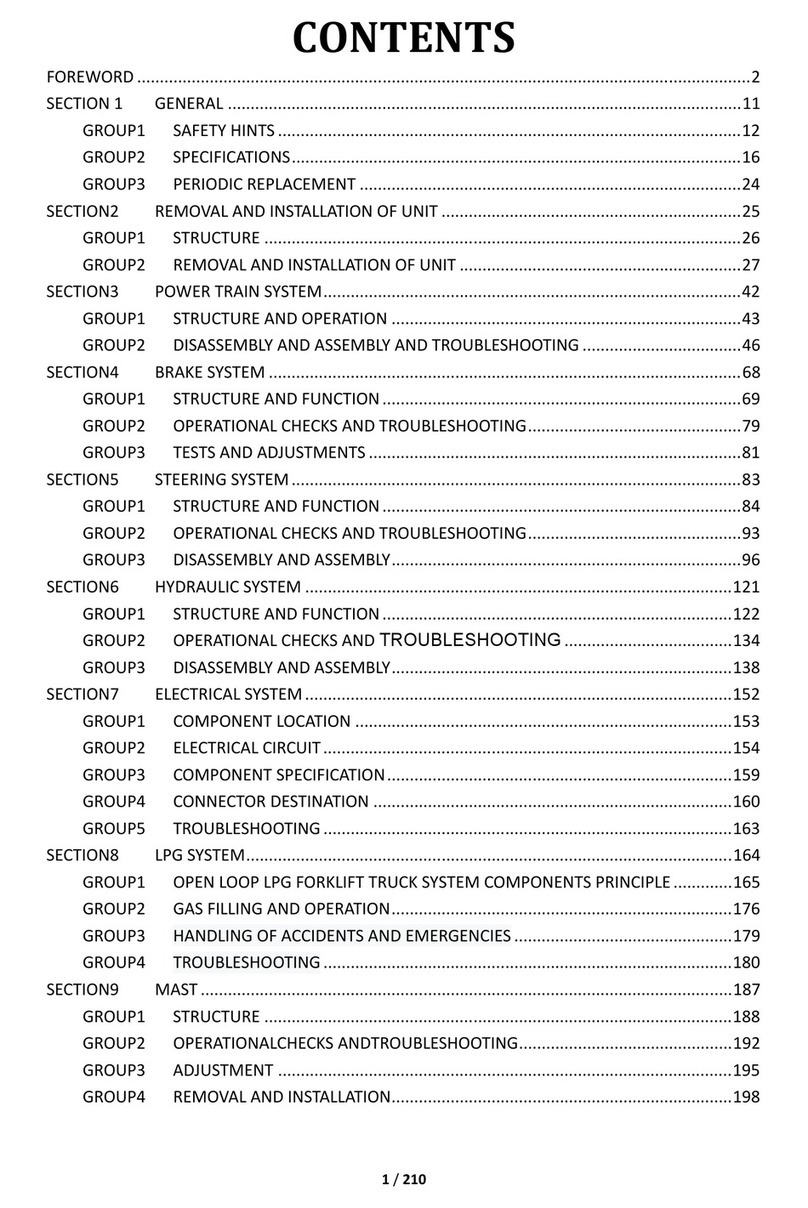

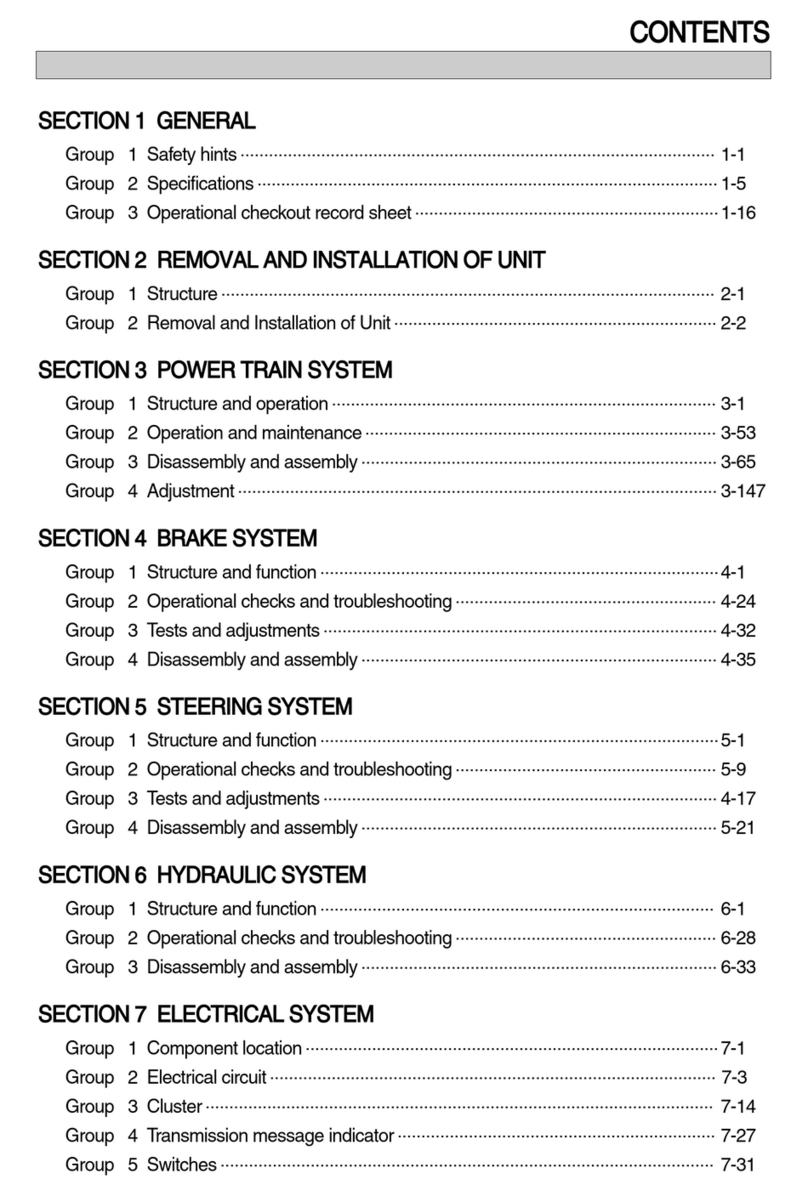

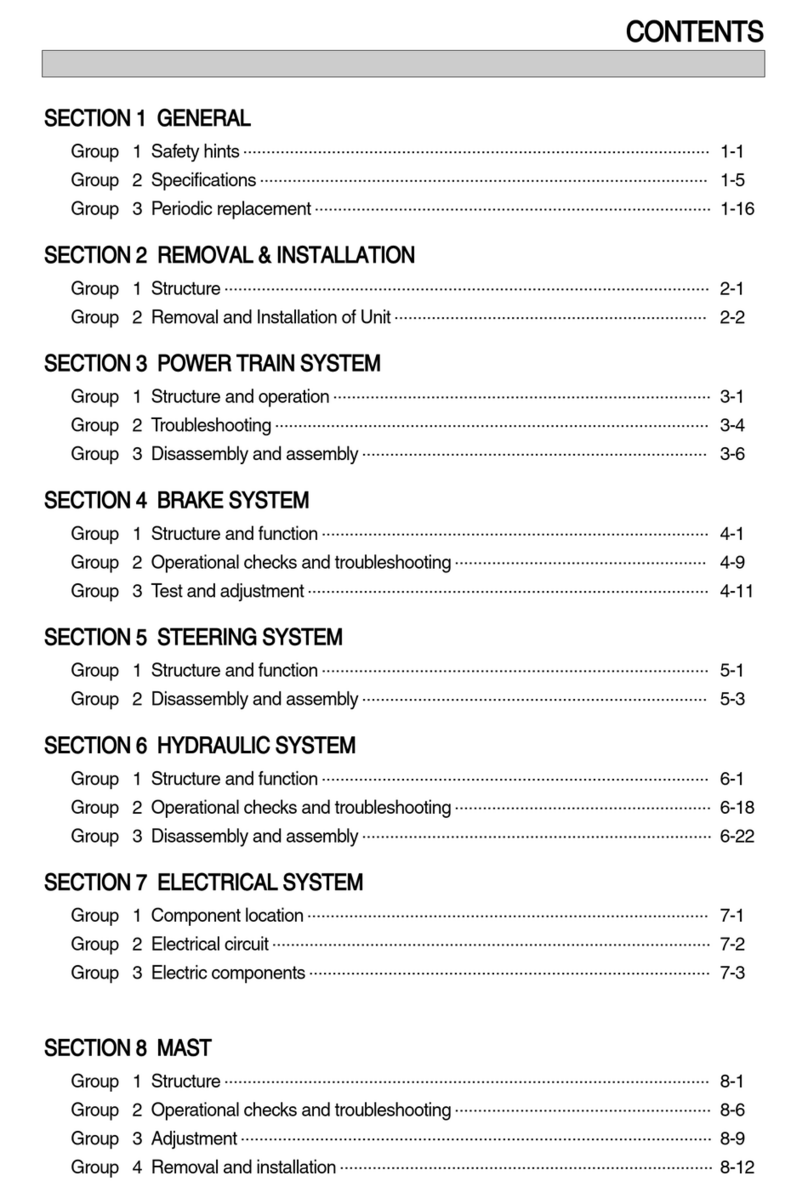

CONTENTS

FOREWORD ....................................................................................................................................... 2

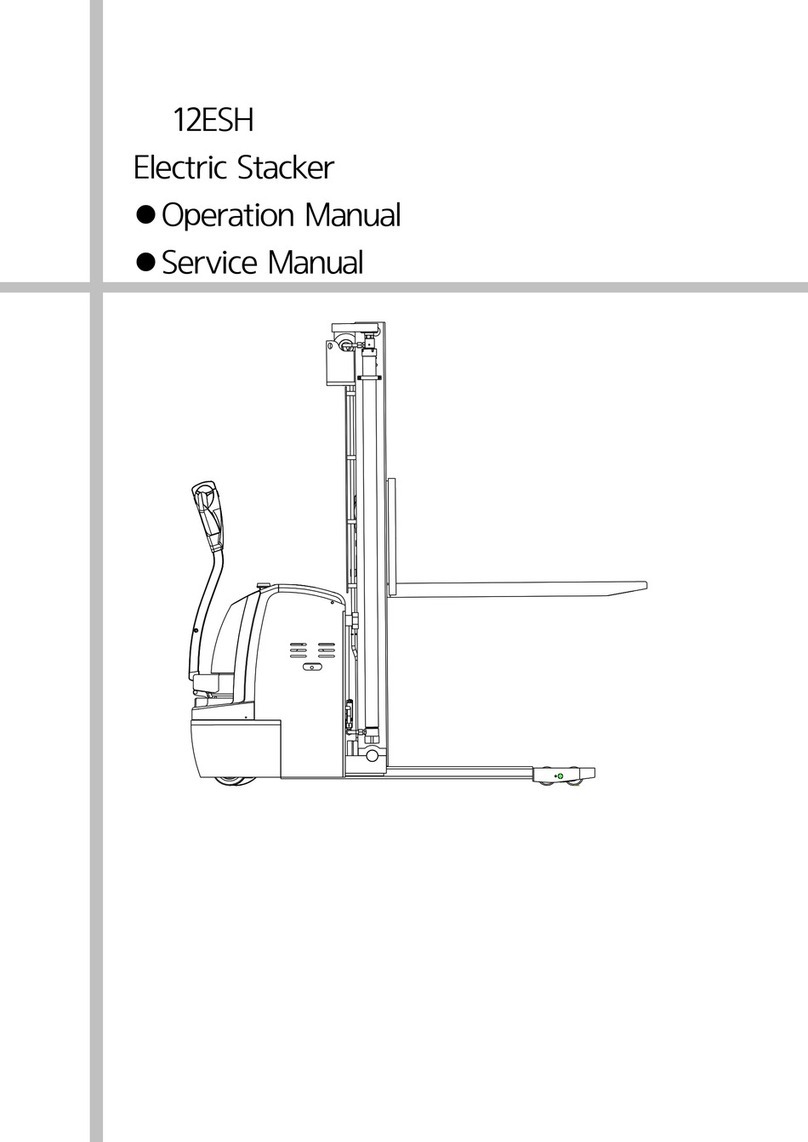

SECTION 1 GENERAL ................................................................................................................. 11

GROUP1 SAFETY HINTS ...................................................................................................... 12

GROUP2 SPECIFICATIONS ................................................................................................... 16

GROUP3 PERIODIC REPLACEMENT .................................................................................... 24

SECTION2 REMOVAL AND INSTALLATION OF UNIT .................................................................. 25

GROUP1 STRUCTURE ......................................................................................................... 26

GROUP2 REMOVAL AND INSTALLATION OF UNIT .............................................................. 27

SECTION3 POWER TRAIN SYSTEM ............................................................................................ 42

GROUP1 STRUCTURE AND OPERATION ............................................................................. 43

GROUP2 DISASSEMBLY AND ASSEMBLY AND TROUBLESHOOTING ................................... 46

SECTION4 BRAKE SYSTEM ........................................................................................................ 68

GROUP1 STRUCTURE AND FUNCTION ............................................................................... 69

GROUP2 OPERATIONAL CHECKS AND TROUBLESHOOTING ............................................... 79

GROUP3 TESTS AND ADJUSTMENTS .................................................................................. 81

SECTION5 STEERING SYSTEM ................................................................................................... 83

GROUP1 STRUCTURE AND FUNCTION ............................................................................... 84

GROUP2 OPERATIONAL CHECKS AND TROUBLESHOOTING ............................................... 93

GROUP3 DISASSEMBLY AND ASSEMBLY ............................................................................. 96

SECTION6 HYDRAULIC SYSTEM .............................................................................................. 121

GROUP1 STRUCTURE AND FUNCTION ............................................................................. 122

GROUP2 OPERATIONAL CHECKS AND TROUBLESHOOTING ............................................. 134

GROUP3 DISASSEMBLY AND ASSEMBLY ........................................................................... 138

SECTION7 ELECTRICAL SYSTEM .............................................................................................. 152

GROUP1 COMPONENT LOCATION ................................................................................... 153

GROUP2 ELECTRICAL CIRCUIT .......................................................................................... 154

GROUP3 COMPONENT SPECIFICATION ............................................................................ 161

GROUP4 CONNECTOR DESTINATION ............................................................................... 162

GROUP5 TROUBLESHOOTING .......................................................................................... 165

SECTION8 MAST ..................................................................................................................... 166

GROUP1 STRUCTURE ....................................................................................................... 167

GROUP2 OPERATIONALCHECKS AND TROUBLESHOOTING .............................................. 171

GROUP3 ADJUSTMENT .................................................................................................... 174

GROUP4 REMOVAL AND INSTALLATION ........................................................................... 177