HANGCHA CBD15-A2MC1 User manual

ELECTRIC PALLET TRUCK

CBD15-A2MC1

CBD15-A2MC1-F

OPERATION AND MAINTENANCE

MANUAL

Original Instruction

HANGCHA GROUP CO., LTD.

8/2017

Mini Range

FOREWORD

Thank you very much for purchasing the A series mini range electric pallet truck of Hangcha

Group .

A series mini range electric pallet truck is a newly developed product for warehouse logistic, it

owns characteristics as advanced performance, comfort operation, safety and security, low

maintenance cost, and is an ideal tool for handling goods in warehouse, supermarket and

workshop.

Before use the truck, relative persons must read and understand the manual, get to know how to

safely operate and maintain the truck.

Part one of this manual is about the brief introduction and correct operation of the mini range

electric pallet truck, which will tell you how to operate safely and maintain preventively; part two

will tell you the structure, working principle and maintenance of the electric pallet truck. To ensure

safety and exert the truck’s potential, all the personnel that in charge of operation maintenance

and management must read this manual thoroughly.

As the improvements of products of our company, there may be some differences between this

operation manual with your forklift truck.

If you have any questions please keep touches with HANGCHA GROUP CO., LTD. sales

department or let the agents know.

© 8/2017 HANGCHA GROUP CO., LTD

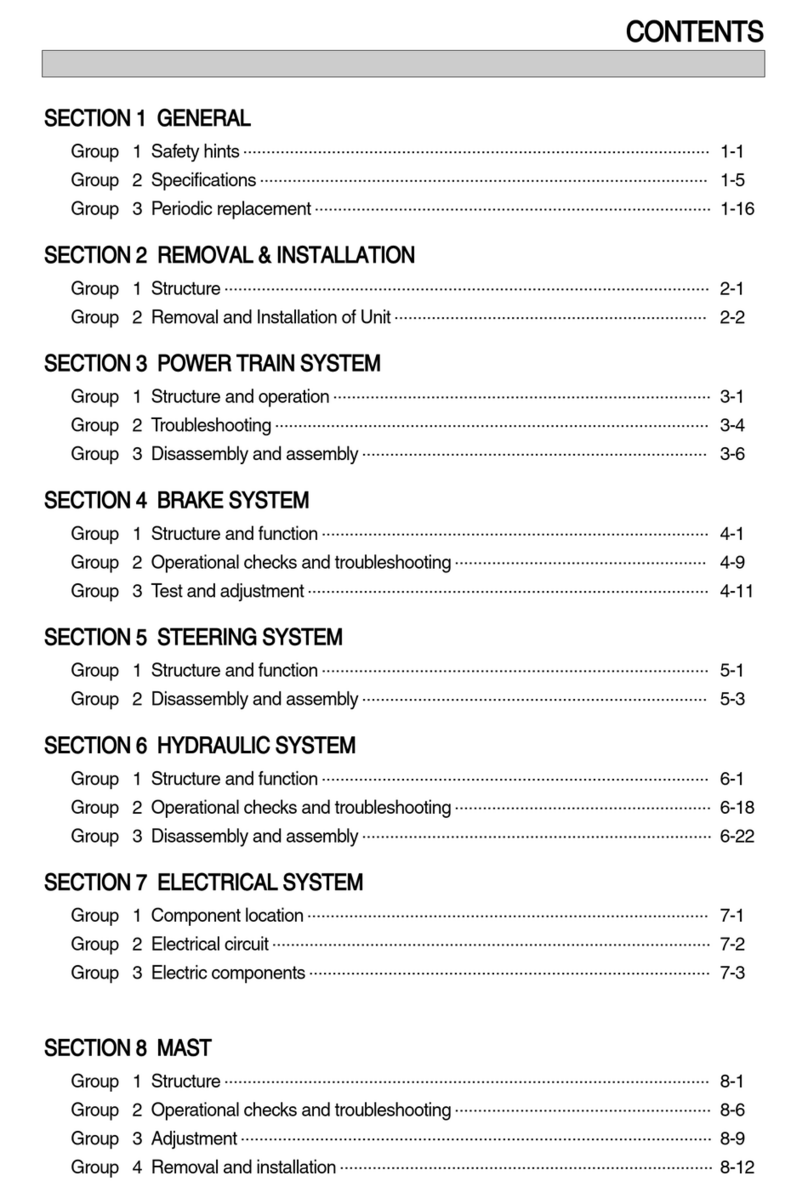

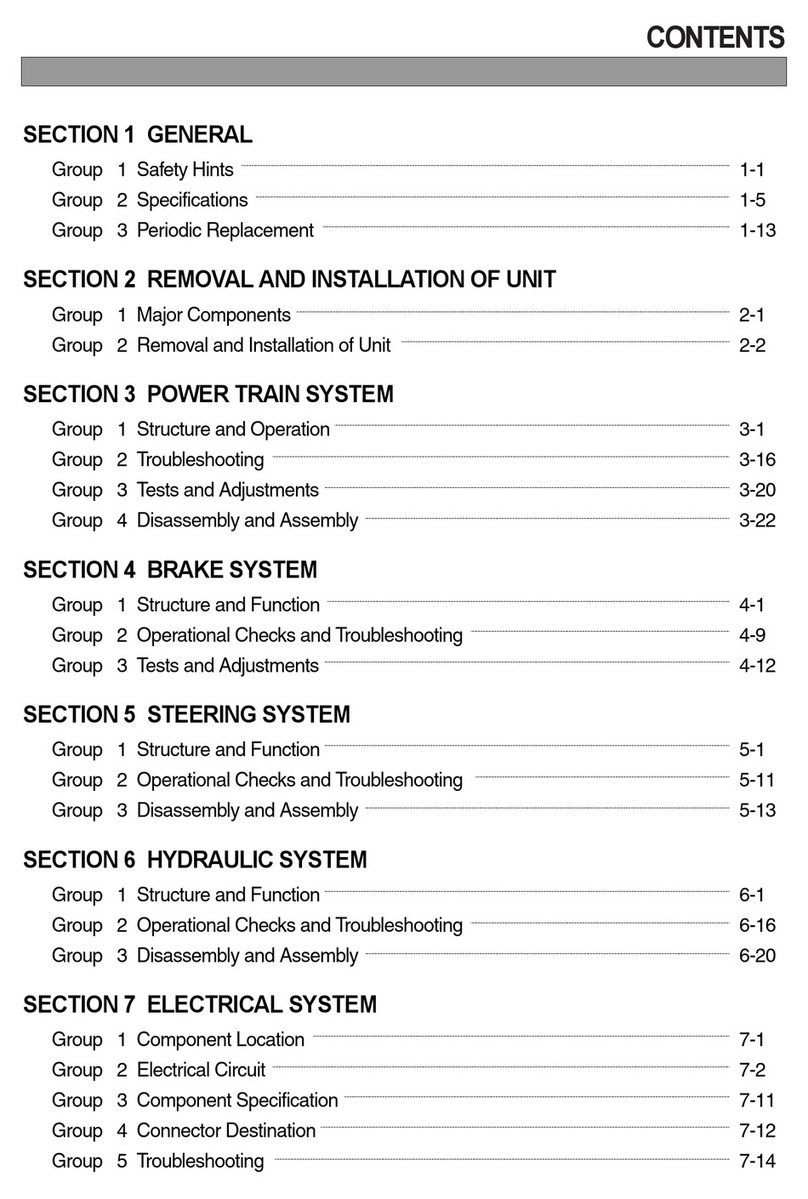

Contents

Part Ⅰ:Operation and Maintenance.......................................................................................... 1

1 Notice for use.......................................................................................................................... 1

1.1 General.................................................................................................................................... 1

1.2 Use as required ....................................................................................................................... 1

1.3 Approved application conditions.............................................................................................. 2

1.4 Cautions for the use of cold storage truck............................................................................... 3

1.5 Proprietor responsibilities........................................................................................................ 3

1.6 Attachment installation or modification to the truck................................................................. 4

2 Truck introduction.................................................................................................................... 5

2.1 General.................................................................................................................................... 5

2.2 Functional description.............................................................................................................. 6

2.3 Main part introduction.............................................................................................................. 8

2.4 Display and control.................................................................................................................. 9

2.4.1 Display................................................................................................................................... 11

2.5 Standard technical data......................................................................................................... 12

2.6 Product plates and warning labels location........................................................................... 13

3 Safety Instructions................................................................................................................. 15

4 Transport............................................................................................................................... 19

4.1 Lifting by crane ...................................................................................................................... 19

4.2 Securing the truck during transport....................................................................................... 20

4.3 Transport................................................................................................................................ 21

5 Battery................................................................................................................................... 22

5.1 Safe operation rules for battery use...................................................................................... 22

5.2 Maintenance of the Battery.................................................................................................... 22

5.3 Battery charging..................................................................................................................... 24

5.3.1 Power interface ..................................................................................................................... 24

5.3.2 Battery charging steps........................................................................................................... 24

5.3.3 Additional charge................................................................................................................... 25

5.4 Replacing battery................................................................................................................... 26

6 New truck breaking-in ........................................................................................................... 27

7 Operation............................................................................................................................... 28

7.1 Check before operation ......................................................................................................... 28

7.2 Start up .................................................................................................................................. 30

7.3 Travelling ............................................................................................................................... 31

7.4 Braking................................................................................................................................... 32

7.5 Steering.................................................................................................................................. 32

7.6 Stopping................................................................................................................................. 32

7.7 Loading.................................................................................................................................. 33

7.8 Unloading............................................................................................................................... 33

7.9 Park the truck securely.......................................................................................................... 35

8 Deposit the truck for long time.............................................................................................. 36

8.1 Deposit for long time.............................................................................................................. 36

8.2 Start running after deposit for a long time............................................................................. 36

9 Maintenance.......................................................................................................................... 37

9.1 Maintenance general............................................................................................................. 37

9.2 Periodic maintenance schedule............................................................................................. 38

9.3 Remove or installing the hood............................................................................................... 41

9.4 Remove or installing the drive wheel cover........................................................................... 42

9.5 Truck used oil and lubrication................................................................................................ 43

9.6 Check the fuses..................................................................................................................... 44

10 Relevant safety directive or standard (CE)........................................................................... 45

Part Ⅱ:Structure, Principle and Maintenance ....................................................................... 47

1Drive Unit............................................................................................................................. 47

1.1 Data sheet.............................................................................................................................. 47

1.2 Assemble and use notice ...................................................................................................... 48

1.3 Fault and troubleshooting...................................................................................................... 48

1.4 Drive Motor ............................................................................................................................ 49

1.5 Electromagnetic brake........................................................................................................... 53

1.5.1 Electromagnetic brake working principle.............................................................................. 54

1.5.2 Electromagnetic brake installation........................................................................................ 55

1.5.3 Maintenance.......................................................................................................................... 56

1.5.4 Adjust the Air Gap of the Brake............................................................................................. 57

1.5.5 Common fault and troubleshooting....................................................................................... 59

2 Hydraulic system................................................................................................................... 60

2.1 Hydraulic system working principle....................................................................................... 60

2.2 Hydraulic system fault diagnosis and correction................................................................... 61

3 Electric system...................................................................................................................... 62

3.1 Electrical schematic diagram................................................................................................. 62

3.2 Drive motor controller ............................................................................................................ 63

3.2.1 Maintenance.......................................................................................................................... 63

3.2.2 Diagnostics and Troubleshooting.......................................................................................... 64

Attachment:Table for bolt’s tightening torque.............................................................................. 66

1

Part Ⅰ:Operation and Maintenance

1 Notice for use

1.1 General

Truck in this manual is only for lifting and transporting loads.

It must be used, operated and maintained according to the information in this manual. Any other

uses are outside the design envelope and can lead to injury to persons or damage to equipment

and property.

1.2 Use as required

–Pick and place goods with trays.

–Transport goods with trays.

–Do not carry people.

–Do not over load.

–Do not push or pull loads.

–Do not work together on the same goods by multiple pallet trucks.

2

1.3 Approved application conditions

-Used in specified area as factory, tourist attraction and recreation place.

-Operation only on secure, level surfaces with sufficient capacity.

-Operation only on routes that are visible and approved by the proprietor.

-Use in specified rated load.

-Average environment temperature under continuous operating condition +25℃.

-The highest environment temperature in the short term (≤1h) +40℃.

-The lowest environment temperature under normal indoor conditions when operation +5℃.

-The lowest environment temperature under normal outdoor conditions when operation

-20℃.

-Altitude: ≤2000m.

-Negotiating inclines up to a maximum of 6 %.

-It is prohibited to travel crosswise or obliquely. When going uphill with loads, keep the loads

in front; when going downhill, keep people in front.

WARNING

It’s prohibited to use this equipment in the anti-explosion area.

Special equipment and authorisation are required if the truck is to be used in

extreme conditions (e.g. cold stores).

Cold-storage truck should meet the followings when working:

According to different grade of cold-storage truck, operate in cold storage based on standard

continuous working time. The recommended working times of our trucks are as follows:

-Do not work continuously over 2 hours in the cold storage above -18℃;

-Do not work continuously over 15 minutes/hour in the -18℃~-30℃cold storage.

3

1.4 Cautions for the use of cold storage truck

-Use special oil for cold storage, maintain and replace periodically.

-All cold storage trucks cannot be shut down or parked in cold storage, or it may cause

damage of hydraulic system and electric system.

-Before entering the cold storage, do necessary hydraulic and traction motion to the

cold-storage truck, and then enter the cold storage after temperature rises.

-If there is condensate water on the truck surface after the truck left the cold storage, only after

the surface is dry or the condensate water is complete dry can the truck enters the cold

storage again.

-Shorten the maintenance period of the lubricating point to avoid its premature wear.

-Battery cannot be empty for a long time after discharging, charge in time to keep high

electrolyte proportion and avoid electrolyte freezing.

-Different truck models with operations can improve each truck functions in the cold storage.

-If the truck malfunctioned in the cold storage, remove it from the cold storage immediately and

repair in buffer zone or maintenance area.

1.5 Proprietor responsibilities

For the purposes of the present operating instructions the “proprietor” is defined as any natural or

legal person who either uses the industrial truck himself, or on whose behalf it is used. In special

cases (e.g. leasing or renting) the proprietor is considered the person who, in accordance with

existing contractual agreements between the owner and user of the industrial truck, is charged

with operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose for which it is

intended and that there is no danger to life and limb of the user and third parties. Furthermore,

accident prevention regulations, safety regulations and operating, servicing and repair guidelines

must be followed. The proprietor must ensure that all users have read and understood these

operating instructions.

Failure to comply with the operating instructions shall invalidate the warranty. The same applies if

improper work is carried out on the truck by the customer or third parties without the permission of

the manufacturer.

4

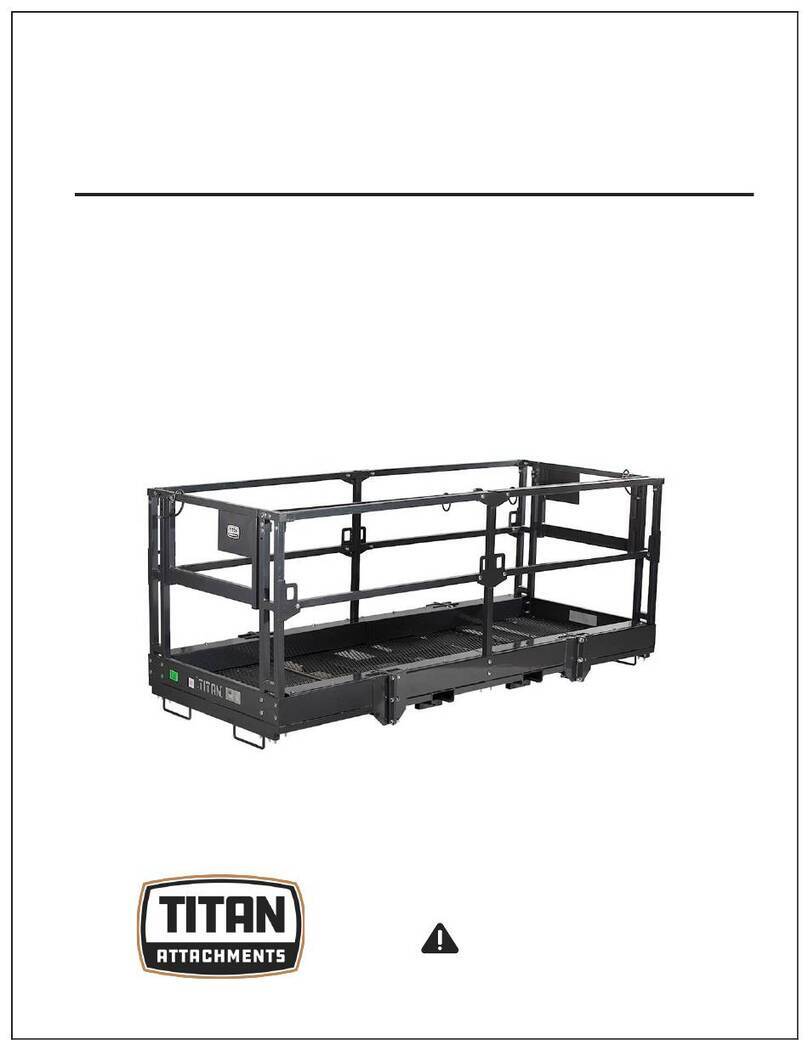

1.6Attachment installation or modification to the truck

Without authorization by the manufacturer, it is not allowed to modify the truck privately.

The mounting or installation of any attachments which will interfere with, or supplement, the

functions of the truck is permitted only after written approval by the manufacturer has been

obtained. If necessary, the approval of local authorities has to be obtained.

Without the prior written approval of the original manufacturer, its authorized representative or its

successor, any change to the truck that may influence its performance, such as rated capacity,

stability or security, is not allowed. Changes include brake, steering, vision or dismountable

attachment. When the manufacturer or its successor approve to changes of the vehicle, it also

needs to make corresponding modification to vehicle nameplate, decals, logo and brochures.

In the event the truck manufacturer is no longer in business and there is no successor in the

interest to the business, the user may arrange for a modification or alteration to a powered

industrial truck manufacturer and the user shall:

a) Arrange for the modification or alteration to be designed, tested and implemented by an

engineer(s) expert in industrial trucks and their safety;

b) Maintain a permanent record of the design, test(s) and implementation of the

modification or alteration;

c) Approve and make appropriate changes to the capacity plate(s),decals, tags and

instruction handbook;

d) Affix a permanent and readily visible label to the truck stating the manner in which the

truck has been modified or altered together with the date of the modification or alteration,

and the name and address of the organization that made the modification or alteration.

5

2 Truck introduction

2.1 General

A series mini range electric pallet truck described in this manual should work under low working

strength and its continuous working time should not surpass one hour.

Users can get relevant information as rated load from the product model.

Model

Meaning

CBD

Electric pallet truck

15

Rated load capacity×100kg

A

Product serial number

2

The second version

M

Mini Range

C1

Controller type

F

Cold storage type

6

2.2 Functional description

Truck body system

–Beautiful and compact outline, concise and fluent line.

–Adopted steel stamping and injection moulding process is sturdy and durable.

–The chassis adopts 3-wheel structure, and equips with side supporting system, it is safe and

reliable.

Driving system

–Drive unit adopts wheel type, with compact and simple structure.

–Permanent-magnetic drive motor owns excellent performance.

–High performance electromagnetic brake.

Braking system

–It owns three emergency braking functions as release brake, reverse brake and

electromagnetic brake to ensure travelling safety.

–It owns slope anti-slide function to ensure safety.

Operation steering system

–New ergonomics designed control handle owns acceleration, reversing, horn, braking,

lifting/lowering, emergency reverse functions, thus makes operation easier.

–Emergency reversing button on the control handle head can prevent driver from hurt when

encountering emergency in backward driving.

–Steering angle +/- 90°.

Hydraulic system

–Modularization hydraulic power unit owns low noise, low vibration, stable and reliable lifting

and lowering.

Lifting system

–Adopted single-cylinder two-connecting rod structure is simple and reliable, with good lifting

synchronism.

Electric system

–24V Electric system.

–Latest CURTIS permanent magnetic control system.

7

–Built in charger, maintenance-free colloidal battery.

–Electric quantity display meter and charging indicator indicates battery quantity and charging

process.

–Emergency disconnect switch.

–The standard equipped electronic lifting limitation and soft landing system protect working

motor and loads from damaging

8

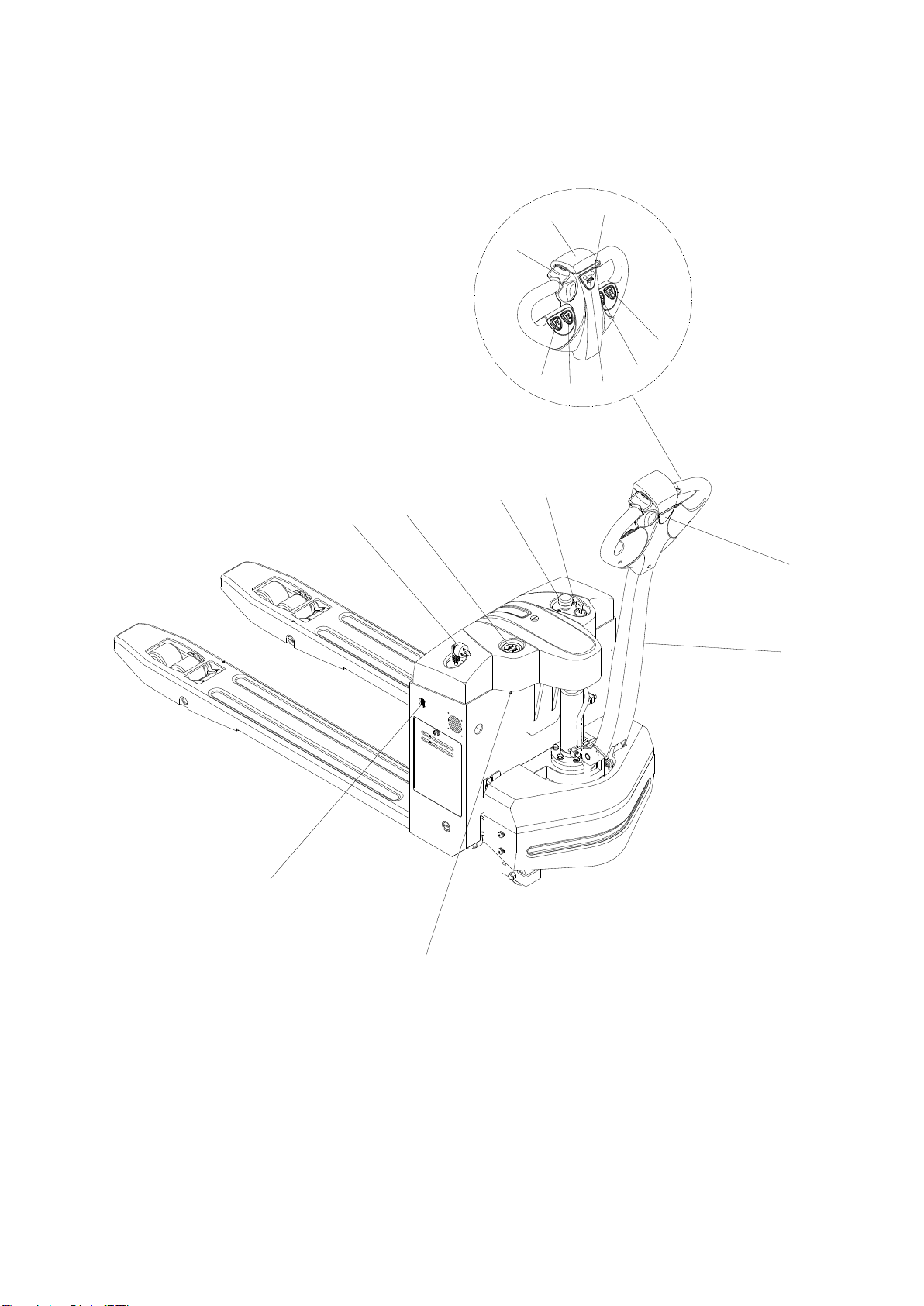

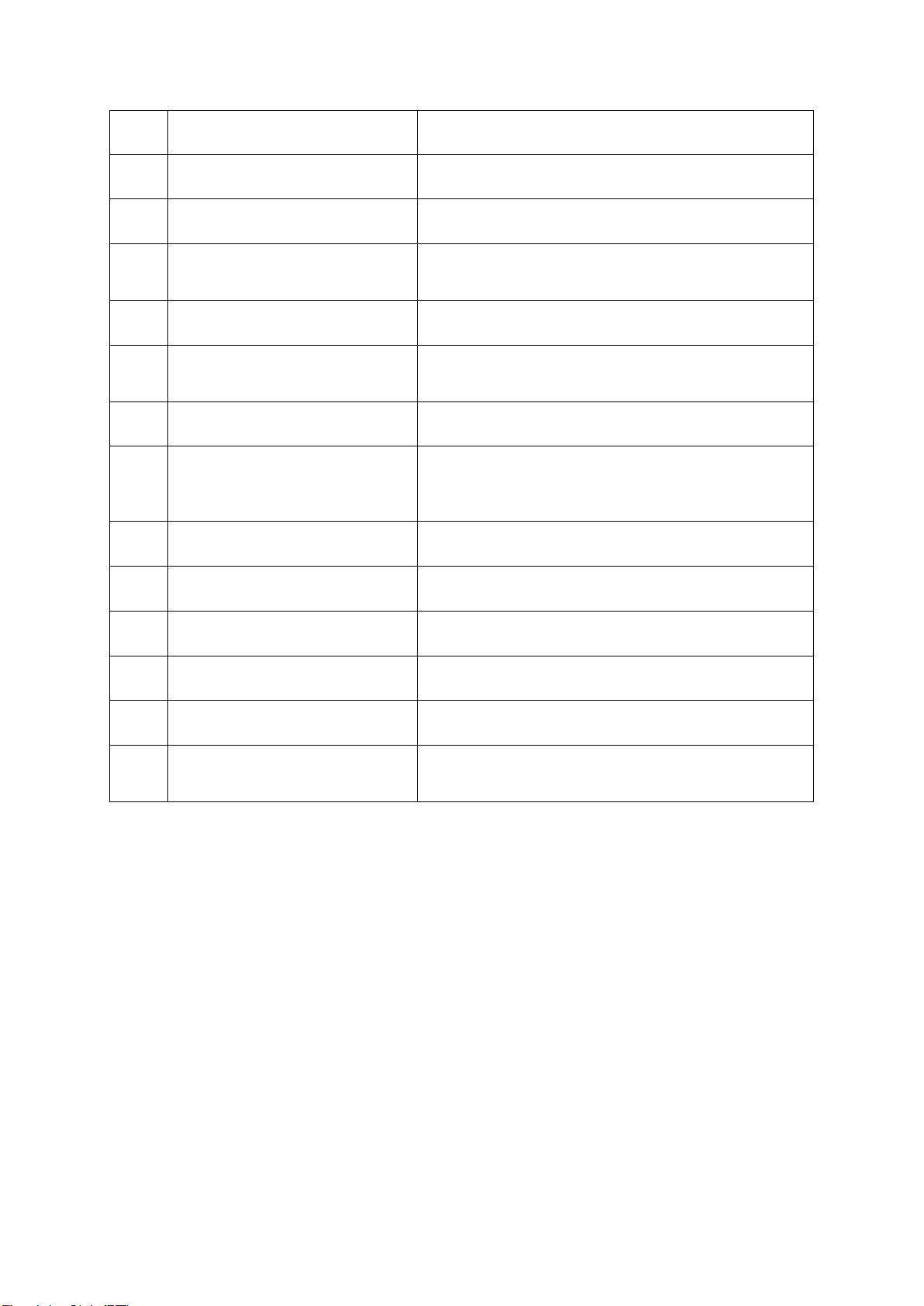

2.3 Main part introduction

Item

Description

Item

Description

1

Control handle

10

Load wheel

2

Control lever

11

Fork

3

Lift cylinder

12

Wire fixator

4

Drive wheel cover

13

Battery charging plug(built-in plug)

5

Caster wheel

14

Instrument

6

Drive wheel

15

Hood

7

Fault indicator

16

Emergency stop switch

8

Side door (built-in battery)

17

Key switch

9

Charging light indicator (with built-in charger)

1

2

3

4

5

6

5

7

8

9

10

11

17

16

15

14

13

12

9

2.4 Display and control

2

7

9

17

16

14

13

19 20 21 20

19

22

23

22

18

10

Item

Designation

Function

2

Control lever

Control the steering and brake of the truck.

7

Fault indicator

Normally on normal condition. Failure regularity, see

the failure code.

9

Charging light indicator

Green light: Fully charged.

Yellow lingth: Fault

Red light: Charging

13

Battery charging plug(built-in

plug)

Insert the plug into the power outlet for battery

charging.

14

Instrument

Shows the accumulated operating hours of the truck,

the residual capacity of the battery and the fault

code(refer to “Instrument” part)

16

Emergency stop switch

Cut the connection with the battery, close all electric

function and brake.

17

Key switch

Switches the control current ON and OFF.

The truck cannot be operated by unauthorized

persons when the key has been removed from the

switch.

18

Upright traveling button

Press the button, the control lever in vertical state

truck can run.

19

“Lower”button

Lower lifting device.

20

“Lift”button

Raise lifting device. When the battery is consumed

about 80%, lifting function will be locked.

21

Horn button

Give out sound warning signal.

22

Travel switch

Control travelling direction and speed.

23

Collision safety switch

Truck moves away from operator.

Protect the operator from extrusion damage under

emergent circumstances.

11

2.4.1 Display

Instrument [14]

It displays battery power.

10 LED display bars display battery discharging status. One LED means 10% battery power. As

the battery power reduces, 10 LED will light up one by one from right to left.

When the remaining capacity is less than 40%, need to stop charging.

Fully charged Need charge Low charging status

One red LED flashing means the truck start to use reserve power (30~20% of battery power).

When it is lower than 20% of battery power(low charging status), two red LED flashes and power

is locked. Only after the battery power recovered to 20% or above can re-use the lifting function.

Charging light indicator [9]

It displays charger running state.

–Red light flashes-it is charging.

–Yellow light is on- charging fault.

–Green light is on- charging finishes.

Notes: Overnight charging recommend after use !

01

CURTIS

01

CURTIS

01

CURTIS

12

2.5 Standard technical data

The following technical data are all standard data. Our company reserves the right of alteration

and extension.

Characteristics

Model

CBD15-A2MC1

CBD15-A2MC1-F

Operator type

Pedestrian

Load capacity

Q (kg)

1500

Load center

c(mm)

600

Wheelbase

y(mm)

1285

Weight

Service weight with battery

kg

220

Wheels﹠Tyres

Tyre type

PU

Tyre size/Quantity,operator side

mm

Φ210×70/1

Tyre size/Quantity,load side

mm

Φ80×64/4

Tyre size/Quantity,Additonal wheels

mm

Φ70×40/2

Tread, operator side

b10(mm)

404

Tread, load side

b11(mm)

400

Dimensions

Lift height

h3(mm)

120

Fork height, lowered

h13(mm)

80

Overall length

L1(mm)

1669

Overall width

b1(mm)

568

Fork size

s/e/L(mm)

50×160×1150

Outside fork width

b5(mm)

560/680

Ground clearance, center of wheelbase, min

m2(mm)

30

Min, right angle stacking aisle width1000×1200 across forks

Ast(mm)

18501)

Min, ringht angle stacking aisle width 800×1200 across forks

Ast(mm)

19002)

Outer turning radius, min

Wa(mm)

14003)

Performance

Travel speed, laden/unladen

km/h

4.5/4.9

Lift speed, laden/unladen

mm/s

50/60

Lowering speed, laden/unladen

mm/s

40/45

Max Gradeability, laden/unladen

%

6 / 15

Motor﹠Battery

Drive motor power

kW

0.65

Lift motor power

kW

0.8

Battery voltage, rated capacity

V/Ah

2×12/70

Battery weight

kg

50

Controller mode

Curtis DC

13

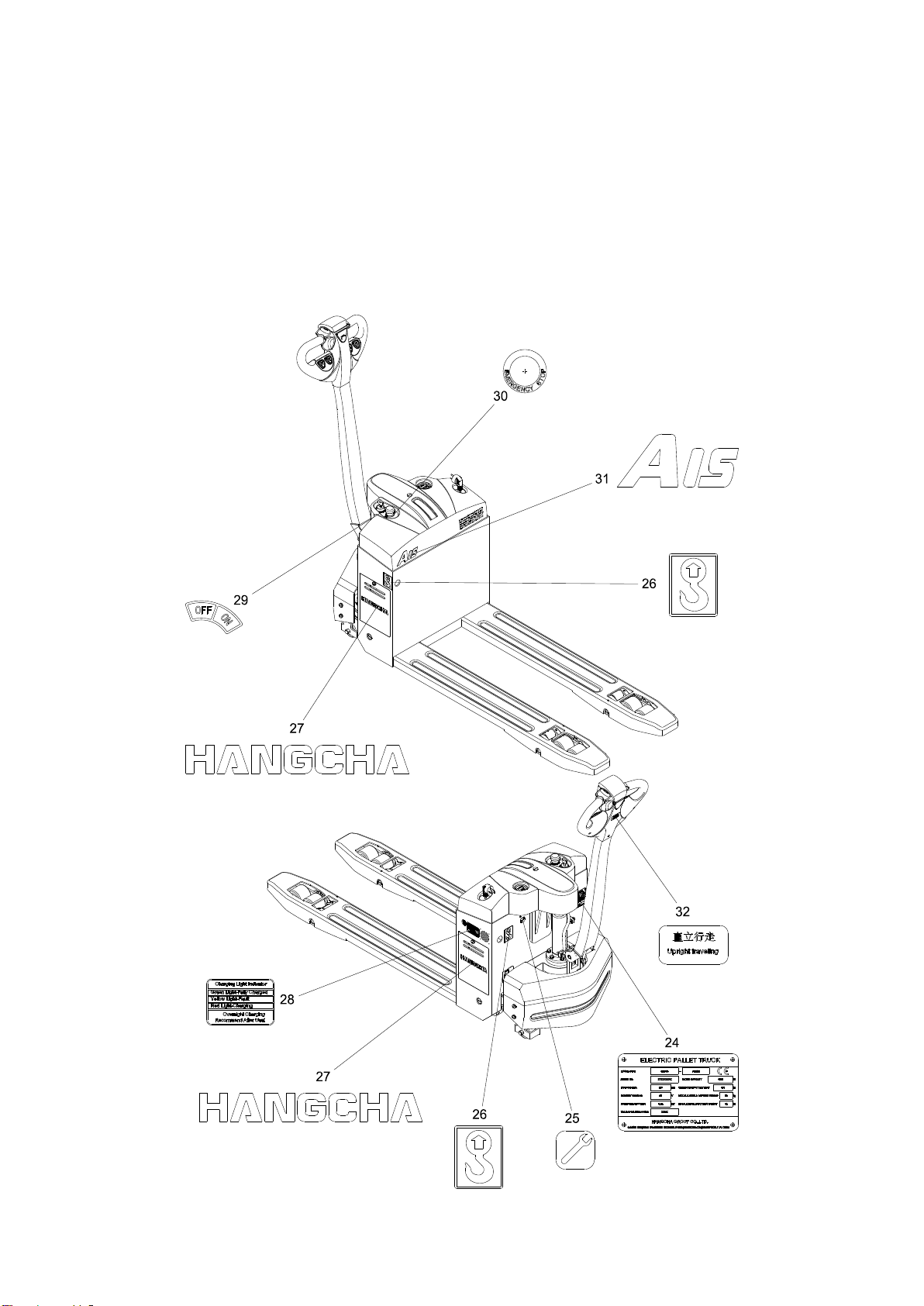

2.6 Product plates and warning labels location

Plates and labels, such as nameplate, load curve plate, warning labels must be legible, if

identification is unclear, and must be replaced.

The figure below shows the approximate location of the various identity resides. Before operating

the truck, please understand the meaning of the various identities.

14

Item

Description

24

Nameplate: The rated capacity on the nameplate is the max. load capacity by the label

listed equipment. Any change to the forklift or other equipment may change rated

capacity.

25

Fault indicator

26

Hoist label: Strap points for crane lifting.

27

Manufacturer’s logo

28

Charging light indicator. Overnight charging recommend after use !

29

Key switch:“OFF” position is off,“ON” position is on.

30

Emergency stop label: press this button when in emergency, thus the truck power is

off.

31

Series tonnage label:A series, rated capacity is 1.5t.

32

Walking upright.

15

3Safety Instructions

1) Only trained and authorized operator

shall be permitted to operate the truck.

2) Operator must wear helmet, working

shoes and uniform

3) Never carry people.

4) It is not allowed to reconfigure the truck

without manufacturer’s permission.

5) Do not work in flammable and

combustible environment.

6) Check the oil, fluid leakage, deformation,

flexibility in certain time. If neglected,

service life of forklift will be shorted and

in serious condition there will be

accident.

–Make sure change the “safety parts”

during the schedule maintenance.

–Wipe off the oil, grease or water on the

soleplate, foot pedal and control lever.

–No smoking or any spark, smoke near

the battery when checking.

–Be careful of scald when checking motor

and controller.

7) The controller equips with energy

accumulator, do not touch between B+

and B- to avoid electric injury. If you

need check or clean the controller,

connect load(like contactor coil or horn

or bulb or resistance) between

controller B+ and B- to discharge the

controller capacity.

8) Whenever you find the forklift abnormal,

stop the truck, put on the DANGEROUS

or FAULT sign to the truck, remove the

key, and report to the managing person.

Only after eliminating the fault can you

use the truck.

16

–If there occurs to fault, battery electrolyte,

hydraulic oil leakage when lifting loads,

going up and down the slope, please

organize staff to repair.

9) Internal battery may generate explosive

gas, it’s prohibited any flame close the

battery. Never allow the tools close two

poles of the battery to avoid spark or

short circuit.

10) The work ground of forklift shall be solid

and smooth concrete surface or similar

ones. Pre-check the ground condition of

working site. Tidy the working site, clean

obstacle, sweep macadam, muddy sand

and wipe off greasy dirt.

11) Do not overload.

12) Before start, press the horn and make

sure no people around.

13) Goods are not allowed to deviate the

fork center, when goods is deviating the

fork center, turn or pass uneven road,

you are easily to fall. Meanwhile,

possibility of turnover will increase.

14) Avoid sudden drive, stop or turn.

15) Do not drive the truck when the forks in

high position.

16) When handling bulky loads, which

restrict your vision, please operate the

machine in reverse or have a guide.

17) Cause the wheels of pallet truck is small,

it is not allowed to run on the street, and

only for driving in specified stacking

place.

18) It’s forbidden to put the head, hand, foot

or body under the forks. Never stand on

the fork.

Failure

This manual suits for next models

1

Table of contents

Other HANGCHA Forklift manuals

HANGCHA

HANGCHA CPCD30/35-XW43E-RT Quick start guide

HANGCHA

HANGCHA XC Series User manual

HANGCHA

HANGCHA XF Series User manual

HANGCHA

HANGCHA XE Series User manual

HANGCHA

HANGCHA CPD10-A User manual

HANGCHA

HANGCHA J Series User manual

HANGCHA

HANGCHA R Series User manual

HANGCHA

HANGCHA CBD20-AMC1 Installation guide

HANGCHA

HANGCHA XF Series Quick start guide