HANGCHA CPCD30/35-XW43E-RT Quick start guide

I

OPERATION MANUAL

2.5-3.5T Rough terrain forklift truck

Operational and Maintenance Manual

Original Instruction

CPCD30/35-XW43E-RT

CPCD25-XW43E-RT

CPCD30/35-XW33E-RT

CPCD25-XW33E-RT

CPCD30/35-XW33C-RT4

CPCD25-XW33C-RT4

CPCD30/35-XW43C-RT4

CPCD25-XW43C-RT4

CPCD30/35-XW98C-RT4

CPCD30/35-XW98E-RT2

CPCD25-XW98C-RT4

CPCD25-XW98E-RT2

HANGCHA GROUP CO., LTD

12/2019

II

Foreword

2.5-3.5T Rough terrain forklift truck is a new developed forklift of Hangcha Group.

It owns characteristics as High vehicle capacity, novel structure and superior

performance. This manual introduces safety, operation, transportation, lubrication, brief

structure and maintenance method of trucks. Driver, maintenance personnel and

equipment manager must read and comprehend this manual before use.

Because of the update and improvements of our products, there may be some differences

between this operation manual contents and your forklift truck.

Illustration adopted by this manual may vary from your truck structure.

This manual is also available for container forklift and forklift equipped with attachment.

Please contact Hangcha Group or your sales agent if you have any questions regarding

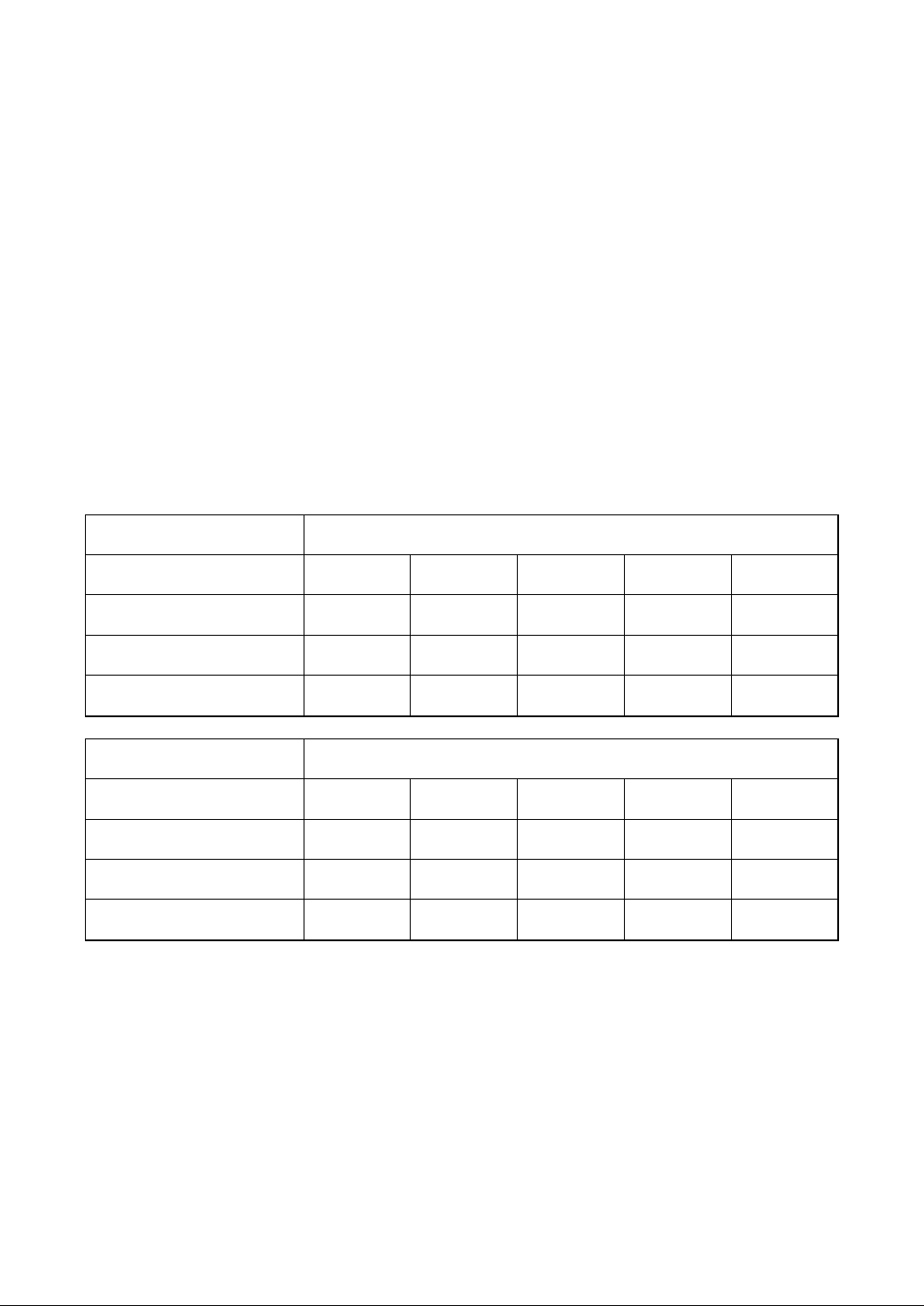

this manual. Standard model

Load center mm(in)

500(19.7)

Model

CPCD15-

CPCD18-

CPCD20-

CPCD25-

CPCD30-

Rated capacity kg( lb)

1500(3300)

1750(3850)

2000(4400)

2500(5500)

3000(6600)

Model

CPCD35-

CPCD40-

CPCD45-

CPCD50-

CPCD55-

Rated capacity kg( lb)

3500(7700)

4000(8800)

4500(10000)

5000(11000)

5500(12000)

Load center mm(in)

600(23.6)

Model

CPCD15-

CPCD18-

CPCD20-

CPCD25-

CPCD30-

Rated capacity kg( lb)

1350 (3000)

1600(3500)

1800(4000)

2250(5000)

2700(6000)

Model

CPCD35-

CPCD40-

CPCD45-

CPCD50-

CPCD55-

Rated capacity kg( lb)

3200(7000)

3650(8000)

4000(9000)

4500(10000)

5000(11000)

III

CE model: optional maximum lifting height 6000 mm

Careful

Bearing capacity chart

This chart shows the

relationship between the location

of the load center distance and the

maximum load. Before loading,

check whether the load and load

center distance are within the

allowable range of bearing

capacity chart. If the shape of the

load is complex, place the heaviest

part of the load in the center of the

fork and close to the shelf.

Note; The vehicle tonnage value shown below is based on the load center distance of

500mm.

Model

Engine

Hydraulic

transmission

Load

center(mm)

CPCD30/35-XW43E-RT

Cummins

QSF2.8T3NA49

Diesel engine

RTE350-120000-G00

CPCD25-XW43E-RT

RTE250-120000-G00

CPCD30/35-XW43C-RT4

RTE350-120000-G00

CPCD25-XW43C-RT4

RTE250-120000-G00

CPCD30/35-XW33E-RT

4TNE98-BQFLC

Diesel engine

RTE350-120000-G00

CPCD25-XW33E-RT

RTE250-120000-G00

CPCD30/35-XW33C-RT4

RTE350-120000-G00

CPCD25-XW33C-RT4

RTE250-120000-G00

CPCD30/35-XW98C-RT4

Kubota

V2607-CR-TE5

B

Diesel engine

RTC350-120000-G00

CPCD30/35-XW98E-RT2

RTE350-120000-G00

CPCD25-XW98C-RT4

RTC350-120000-G00

CPCD25-XW98E-RT2

RTE250-120000-G00

©11/2019 HANGCHA GROUP CO., LTD

Actual LiftingCapacity

mm

Mast Model

RATEDCAPACITIESANDLOADGENTRESGRAPH

LoadCenter DistanceB CapacityWithMast Vertical

mm

kg

Attachment Model

Max.Lift Height A Serial No.

RT

FORINDUSTRIALUSE- ACCORDINGTOSTANDARDISO22915-2

FORROUGHTERRAINUSE- ACCORDINGTOSTANDARDISO22915-13

kg

IV

Content

Content .................................................................................................................IV

I. General rules ......................................................................................................1

II. Name of main parts or component.....................................................................3

1. Instruments.................................................................................................4

CAN Bus Instrument(W98) ........................................................................... 11

2. Controls and switches...............................................................................17

3. Truck body and others ..............................................................................23

III. Safety rules.....................................................................................................28

IV. Maintenance...................................................................................................34

1. Daily maintenance(8hours)..................................................................34

2. Weekly maintenance(40hours).............................................................37

3.Every One and a half months ....................................................................41

4.Every half year maintenance (1000 hours) ................................................44

5.Annual maintenance (2000 hours).............................................................46

6.Others........................................................................................................47

V. Structure and stability of truck .........................................................................50

VI. Operation........................................................................................................52

VII. Parking ..........................................................................................................55

VIII. Maintenance.................................................................................................57

1. Preventive maintenance schedule............................................................57

2. Torque Specifications................................................................................66

3. Periodic replacement of key safe parts.....................................................67

4. Table for the oil used in the truck ..............................................................68

5. Lubrication system drawing ......................................................................70

IX. Labels:Stick various nameplate and mark at different position of the truck..71

X. Truck transporting, lifting, towing.....................................................................76

XI. Main technical performance parameter ..........................................................77

XII. Operational method of lead acid battery........................................................89

XIII. Use, installation and safety rules of attachment ...........................................92

XIV. Description of OPS System..........................................................................94

XV. Relevant safety command and standard.......................................................96

XVI.Maintenance record.......................................................................................98

1

I. General rules

To keep the truck and you safe, obey these rules below:

1. Only trained and authorized operators shall be permitted to operate the truck.

2. Before starting truck you should check all control and alarm devices; if any are damaged, DO

NOT operate until it is repaired.

3. When carrying a load, do not overload. The forks should insert in the load completely and evenly.

It is not permitted use only one fork to load.

4. You should operate the truck smoothly when starting, turning, traveling, braking and parking. On

a slick or wet road, decrease speed when turning.

5. Lower the forks and tilt the mast backwards when traveling with a load.

6. If the slope angle is bigger than 10%, travel forward up slope and backward down slope. Never

turn sideways or stack load on an incline.

7. Be aware of bystanders, barriers, potholes and overhead clearances.

8. DO NOT allow passengers or persons to stand on the fork.

9. DO NOT stand or walk under the fork.

10. DO NOT operate the truck or attachment from any position except the operator‘s seat.

11. DO NOT carry the load unpackaged. Be careful when carrying large loads.

12. Take care not to lose load when lift height is higher than 3 meters, take protective measures if

necessary.

13. Travel with load as low as possible and tilt back the mast.

14. When driving over a dock-board or bridge-plate, be careful and drive slowly.

15. Make sure that there is no naked flame near the area, never smoke. The driver should not

remain seated when adding fuel.

16. Treat the truck with attachments as a loaded truck

17. When leave the truck, you should put the forks down, make the shift lever in neutral, shut down

the engine and cut the power. When parking on a grade, make sure to tighten the brake lever. If

necessary, use a block when parking on a grade for a long time.

18. If the truck suddenly gets out of order, or for leakage of electrolyte, hydraulic oil or brake oil

when lifting goods or grade climbing, leave truck in safe state and contact service technician

immediately.

19. During installation and assembly, there will be noise and vibration. Please choose the right tool

and assembly method. Minimize the noise and vibration as soon as possible to reduce noise

pollution.

20.Rough Terrain forklift Truck mainly used in the field of urban engineering construction sites, pipe

laying, field development, operations, and other mountain forest, and loading and unloading

operations forces used the army as well as loading and unloading dock yard containers.

21. Move the truck to the place where respects traffic when it anchors. If the reason is brake or turn

system, move it by a suitable truck (Refer to the part of truck carrying); other reasons, use a

suitable truck to move, tie the cord outside of truck. Please abide by the traffic regulations when

moving the truck on roads.

22. DO NOT operate the truck or load cargo after removing the hood, water tank cover board,

overhead guard, or load backrest of mast.

23. Make sure there is enough light around the work area. At night, use the head lamps.

24. Handle with automatic pitch fork of the forklift when the load must not make lateral operation, so

as not to lose balance and forklift components of the damage caused.

25. Before hydraulic oil temperature rises, do not tilt the mast forward, backward or lift the mast to

the limit when in idling.

26. No modifications or alterations to a powered industrial truck, which could affect, for example,

capacity, stability or safety requirements of the truck, shall be made without the prior written

approval of the original truck manufacturer, its authorized representative, or a successor thereof.

This includes changes affecting, for example, braking, steering, visibility and the addition of

removable attachments. When the manufacturer or his successor approves a modification or

alteration, the manufacturer or successor shall also make and approve appropriate changes to

2

the capacity plate, decals, tags and operation and maintenance handbooks.

27. In the event the truck manufacturer is no longer in business and there is no successor in the

interest to the business, the user may arrange for a modification or alteration to a powered

industrial truck manufacturer and the user shall:

(1) Arrange for the modification or alteration to be designed, tested and implemented by an

engineer(s) expert in industrial trucks and their safety;

(2) Maintain a permanent record of the design, test(s) and implementation of the modification or

alteration;

(3) Approve and make appropriate changes to the capacity plate(s),decals, tags and instruction

handbook;

(4) Affix a permanent and readily visible label to the truck stating the manner in which the truck

has been modified or altered together with the date of the modification or alteration, and the

name and address of the organization that made the modification or alteration.

3

II. Name of main parts or component

1. Fork

2. Load backrest

3. Tilt cylinder

4.Mast

5.Lift cylinder

6. Steering wheel

7. Overhead guard

8. Seat

9. Cover hood

10. Counterbalance weight

11. Rear wheel

12. Truck frame

13. Front wheel

4

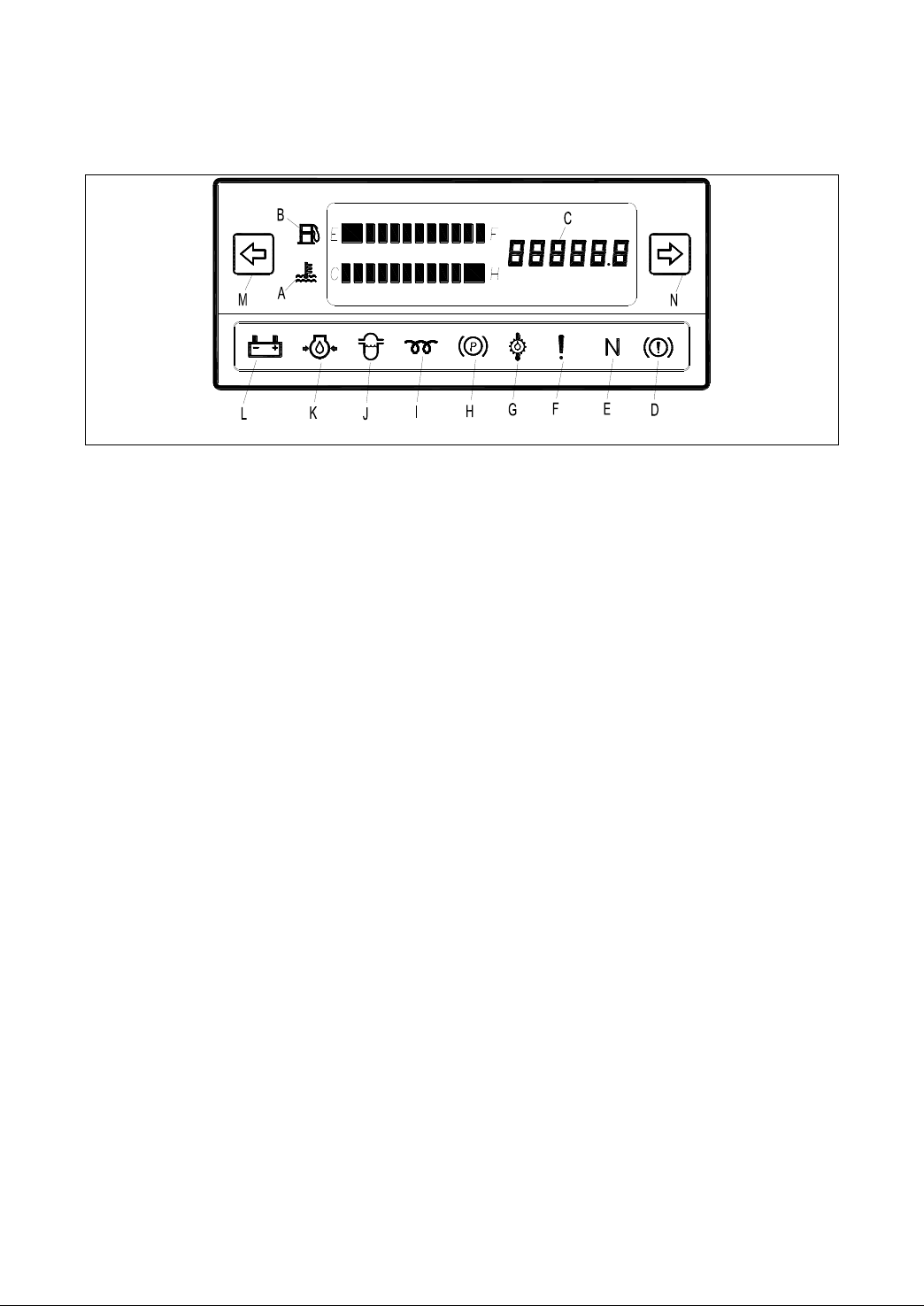

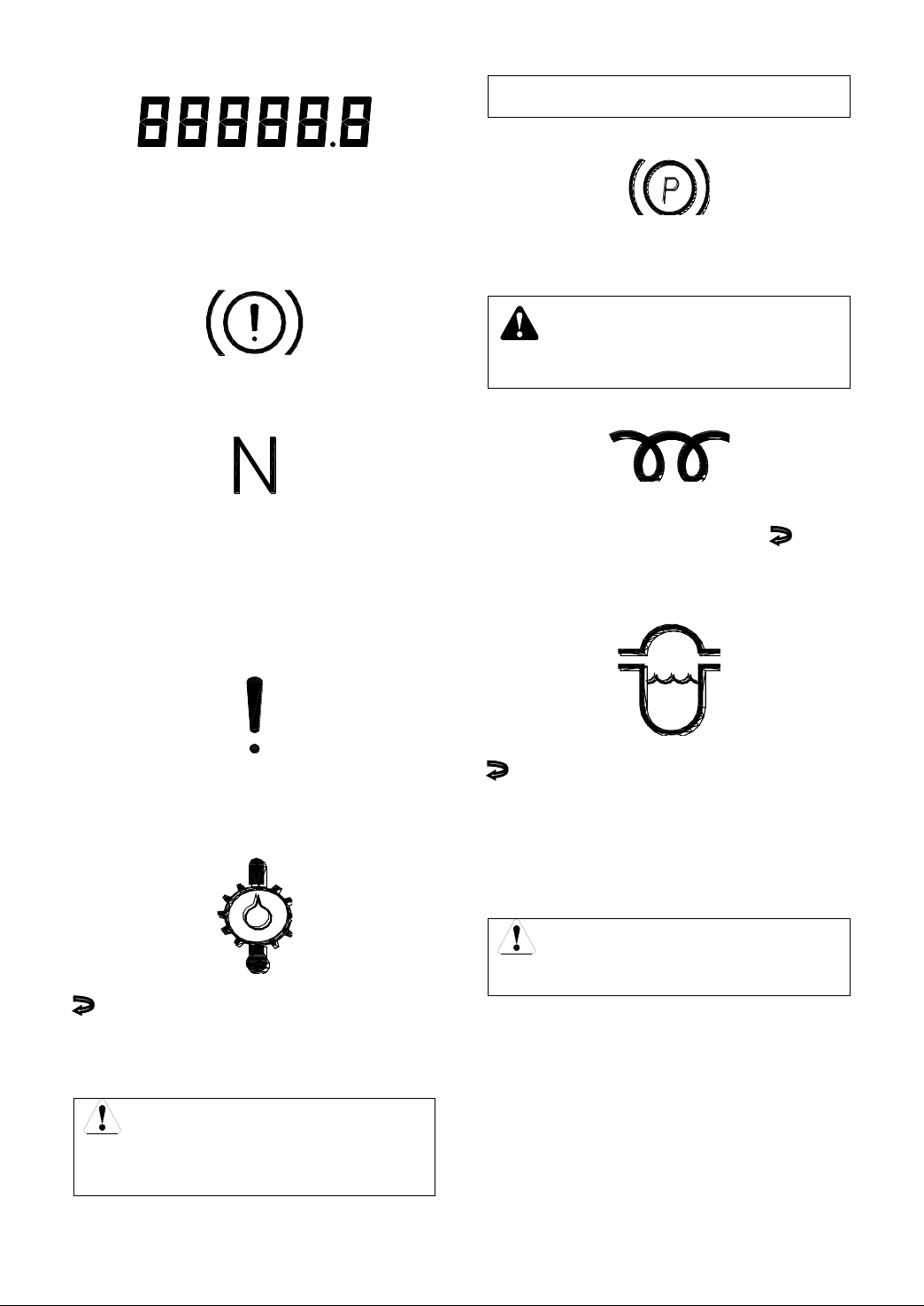

1. Instruments

(Two-wheel drive rough terrain forklift truck)

A.Water temperature gauge

B.Fuel gauge

C.Timer

D.Accumulator warning indicator

E. Neutral position start-up

indicator

F. OPS indicator

G.Transmission oil temperature

warning light

H. Parking indicator

I. Preheat indicator light

J. Oil water seperator Indicator light

K.Engine oil pressure warning light

L. Charging indicator light

M. Left turning indicator

N. Right turning indicator

5

Instrument of the state shown in Figure

Water temperature gauge [A]

This gauge indicates the oil temperature in

the torque converter transmission box when

the key is at ┃(ON) position. In normal status,

LED Displayed in the range of 40 ℃-110 ℃

Caution

If LCD display in the red zone , please stop the

truck at once. Decrease the engine speed to

make the engine cool. Check the cooling fluid if

enough and the fan belt‘s elasticity if fit.

Fuel gauge [B]

The gauge indicates the fuel level in the tank

when the key is at ┃(ON) position.

Suggest filling up the fuel tank after work

every day.

6

Hour meter [C]

This meter measures working time of engine

when the key is at ┃(ON) position. The meter

increase one number every working hour.

Use meter to schedule lubrication and

maintenance periods.

Accumulator warning indicator [D]

This indicator light does not work on the

forklift.

Neutral position start-up indicator [E]

Put the steering handle in the neutral position

when truck on the temporarily stop, the light

will indicated on

The truck can be started up only in the neutral

position.

It‘s prohibited for truck in the neutral position

sliping when it‘s on the slope.

OPS indicator [F]

When this light is on, it means driver leave the

seats or not sitting on the seat correctly.

Transmission oil temperature warning

light [G] (Hydraulic Forklift)

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

During work time if the oil temperature exceed

the normal rang(60~120。C) the indicator light

on.

Caution

If the pointer enters the red range, stop the

operation instantly and slow down engine

speed to cool the coolant and wait until the

pointer goes into the green range, and have

a check then.

Parking indicator [H]

Parking indicator shows on means brake is

affected, Please loosen the parking handle

(hand brake handle), the parking indicator will

shows off.

Warning

It will damage the engine and

transmission, etc. when indicated.

Glow indicator (I) [Diesel truck]

Turn the key to ―ON‖ position and the

indicator lights up for a moment. After the

indicator goes out, turn the key to . ―Start‖

position

Sedimentor indicator (J) [W10,W55,W56

diesel truck]

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

This lamp lights up when water in sedimentor

reaches to a certain level, while the engine is

running.

If this lamp continues to stay lit or lights up

during the engine running, stopping the

engine and discharge water immediately.

Caution

If continue working when the lamp is light.

The fuel injection pump may be damaged.

7

Engine oil pressure alert lamp(K)

This lamp indicates the pressure condition of

engine lube oil. Although it lights up when the

engine switch is set at ―ON‖, once the engine

starts up and the accelerator pedal is pressed,

this lamp goes out.

Caution

If this light continues to stay lit or lights up

during operation, the pressure is lower than

0.05Mpa and should be checked

immediately.

Charging indicator (L)

This lamp indicates the battery condition of

charge. The lamp comes on when the ignition

switch is set at ┃―ON‖, but it goes out as the

engine starts and accelerator pedal is

pressed.

Caution

If the light continues to stay lit or lights up

during operation, the charging rate is low

and should be checked immediately.

Left turning indicator [M]

Right turning indicator [N]

When the truck turns left, the indicator is set

forward, the lamp lights up.

When the truck turns right, the indicator is set

backward, the lamp lights up.

Air filter indicator [O]

When the light is on, it indicates the air inlet

system is blocked, stop the truck and clean

the air filter.

8

(Four-wheel drive rough terrain forklift truck)

Water temperature gauge

This gauge indicates the oil temperature in

the torque converter transmission box when

the key is at ┃(ON) position. In normal status,

LED Displayed in the range of 60 ℃-110 ℃

Caution

If LCD display in the red zone , please stop the

truck at once. Decrease the engine speed to

make the engine cool. Check the cooling fluid if

enough and the fan belt‘s elasticity if fit.

Fuel gauge

The gauge indicates the fuel level in the tank

when the key is at ┃(ON) position.

Suggest filling up the fuel tank after work

every day.

Hour meter

This meter measures working time of engine

when the key is at ┃(ON) position. The meter

increase one number every working hour.

Use meter to schedule lubrication and

maintenance periods.

Caution

When reaching the first 100h, the

spanner logo will flash one hour at

regular intervals to reminder of the

maintenance to the forklift. Refer to

monthly maintenance after first flash.

Refer to periodical maintenance

schedule for per period. Take the actual

flashing time as standard.

Charging indicator

This lamp indicates the battery condition of

charge. The lamp comes on when the ignition

switch is set at ┃―ON‖, but it goes out as the

engine starts and accelerator pedal is

pressed.

Caution

If the light continues to stay lit or lights up

during operation, the charging rate is low

and should be checked immediately.

Engine oil pressure alert lamp

This lamp indicates the pressure condition of

engine lube oil. Although it lights up when the

engine switch is set at ―ON‖, once the engine

starts up and the accelerator pedal is pressed,

this lamp goes out.

Caution

If this light continues to stay lit or lights up

9

during operation, the pressure is lower than

0.05Mpa and should be checked

immediately.

Glow indicator [Diesel truck]

Turn the key to ―ON‖ position and the

indicator lights up for a moment. After the

indicator goes out, turn the key to . ―Start‖

position

Sedimentor indicator [Diesel truck]

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

This lamp lights up when water in sedimentor

reaches to a certain level, while the engine is

running.

Transmission oil temperature warning

light(Hydraulic Forklift)

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

During work time if the oil temperature exceed

the normal rang(60~120。C) the indicator light

on.

Caution

If the pointer enters the red range, stop the

operation instantly and slow down engine

speed to cool the coolant and wait until the

pointer goes into the green range, and have

a check then.

Engine fault indicator

[Electronic-controlled engine]

When the engine gets out of order, this

Indicator will be on. then it must immediately

stop, according to an engine fault table

troubleshooting.

Can be judged according to the fault

indicator lamp (flash code), Can be based on

the fault indicator (flash code) judgment, or

ECU diagnostics port connected to diagnostic

equipment, read the fault code information

stored in the ECU.

For more information, see engine manual.

OnlyCummins engine forklift truck :

When this light is on, it means one important

engine working is beyond the prescribed

limits of engine protection calibration, engine

power can be reduced, you must stop and

check.

Neutral position start-up indicator

[Electric-switch]

Put the steering handle in the neutral position

when truck on the temporarily stop, the light

will indicated on

The truck can be started up only in the neutral

position.

It‘s prohibited for truck in the neutral position

sliping when it‘s on the slope.

OPS indicator [Optional]

When this light is on, it means driver leave the

seats or not sitting on the seat correctly.

Parking indicator

Parking indicator shows on means brake is

affected, Please loosen the parking handle

(hand brake handle), the parking indicator will

shows off.

Warning

It will damage the engine and

transmission, etc. when indicated.

If this lamp continues to stay lit or lights up

during the engine running, stopping the

engine and discharge water immediately.

10

Caution

If continue working when the lamp is light.

The fuel injection pump may be damaged.

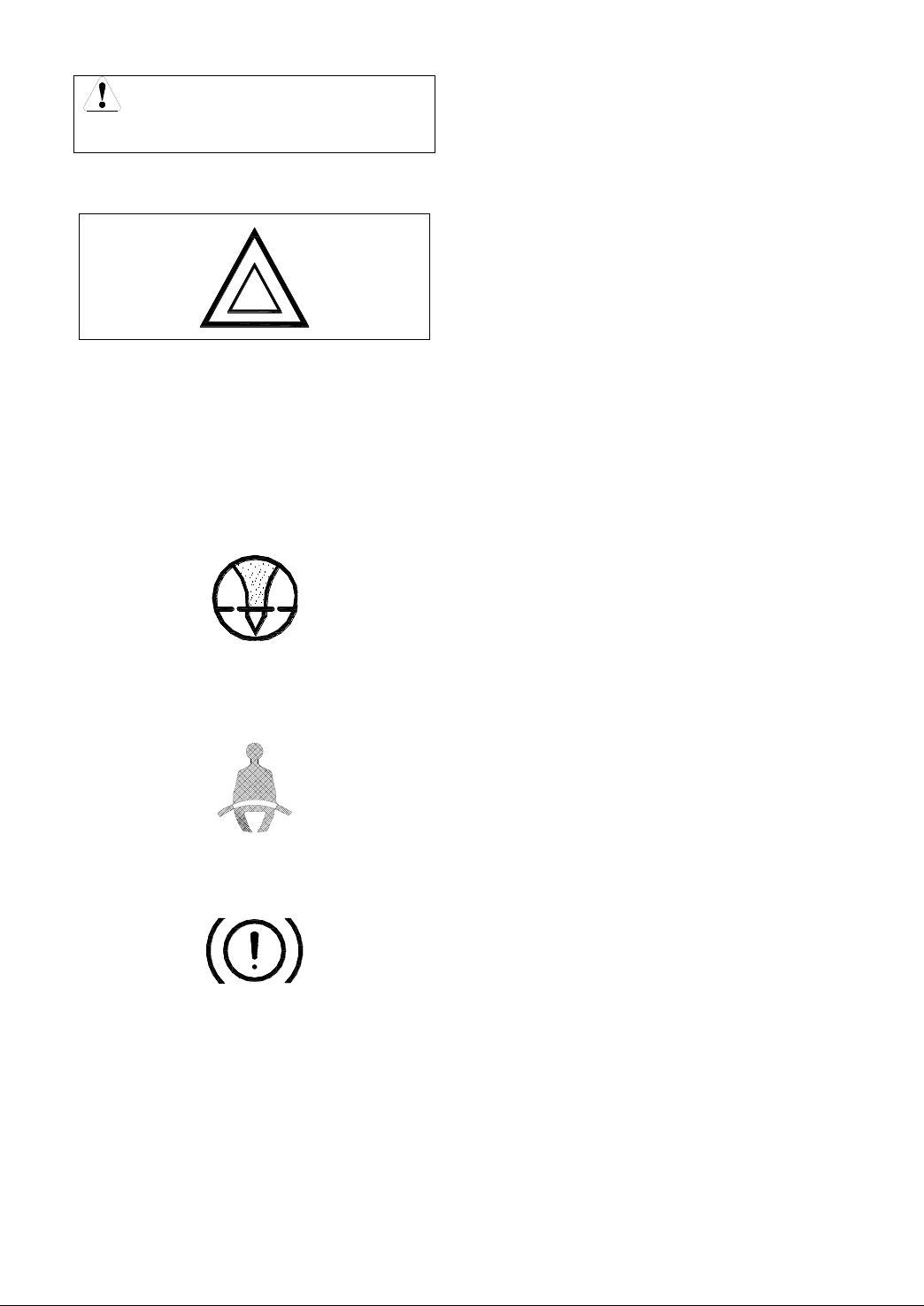

Severe warning indicator

[Electronic-controlled engine]

OnlyCummins engine forklift truck:

When this light is on, it indicates the engine is

in severe work condition and the engine

power reduced severely. If condition stays

and starts engine protection shut-down, then

this indicator will flash 30 seconds before

engine shut down to warn the impending

shut-down.

Air filter indicator

When the light is on, it indicates the air inlet

system is blocked, stop the truck and clean

the air filter.

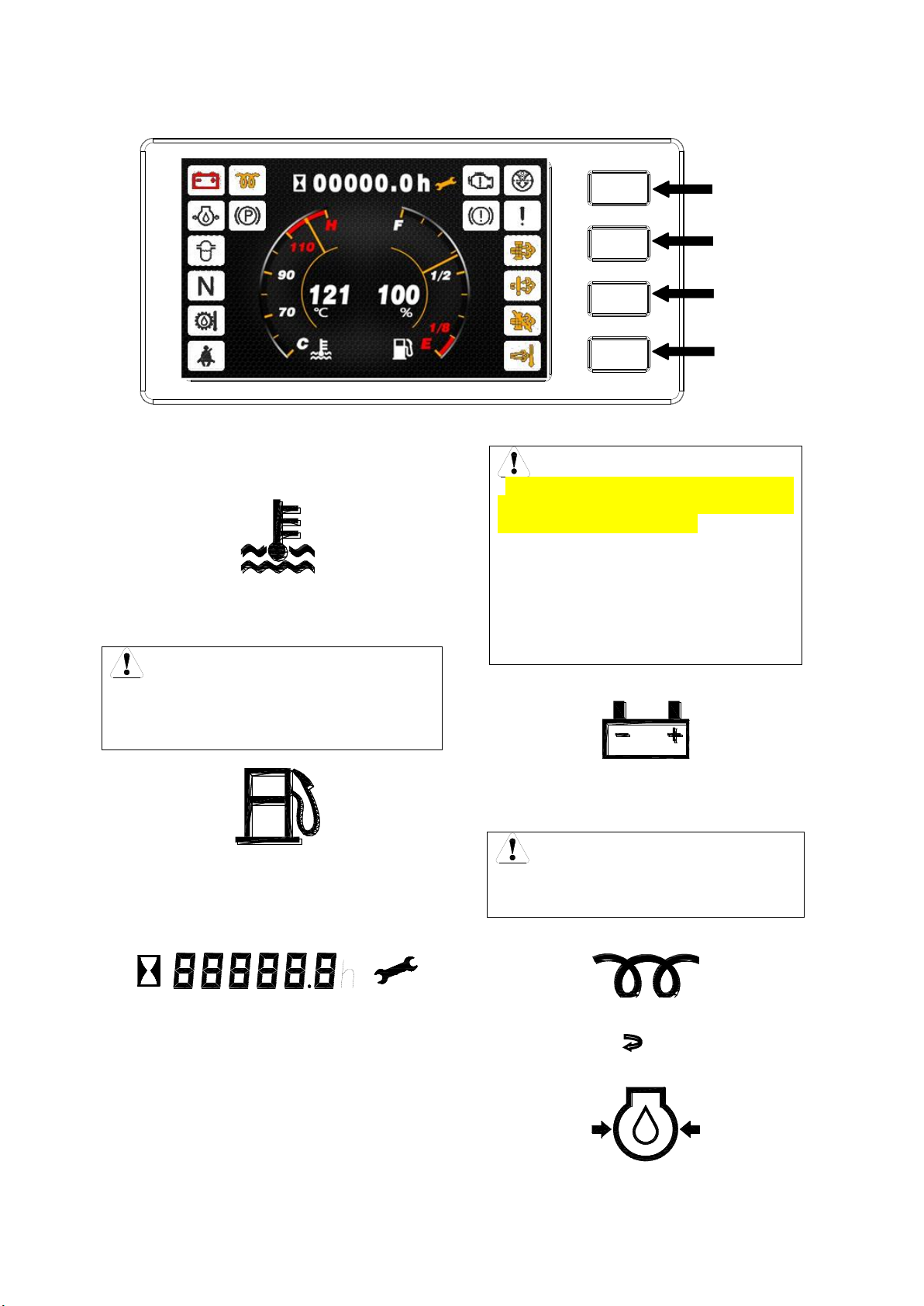

Seat belt warning indicator [Optional]

When thislight is on, it means not wearing a

seatbelt or not locked.

Accumulator warning indicator

This indicator light does not work on the 1-X5

ton forklift.

11

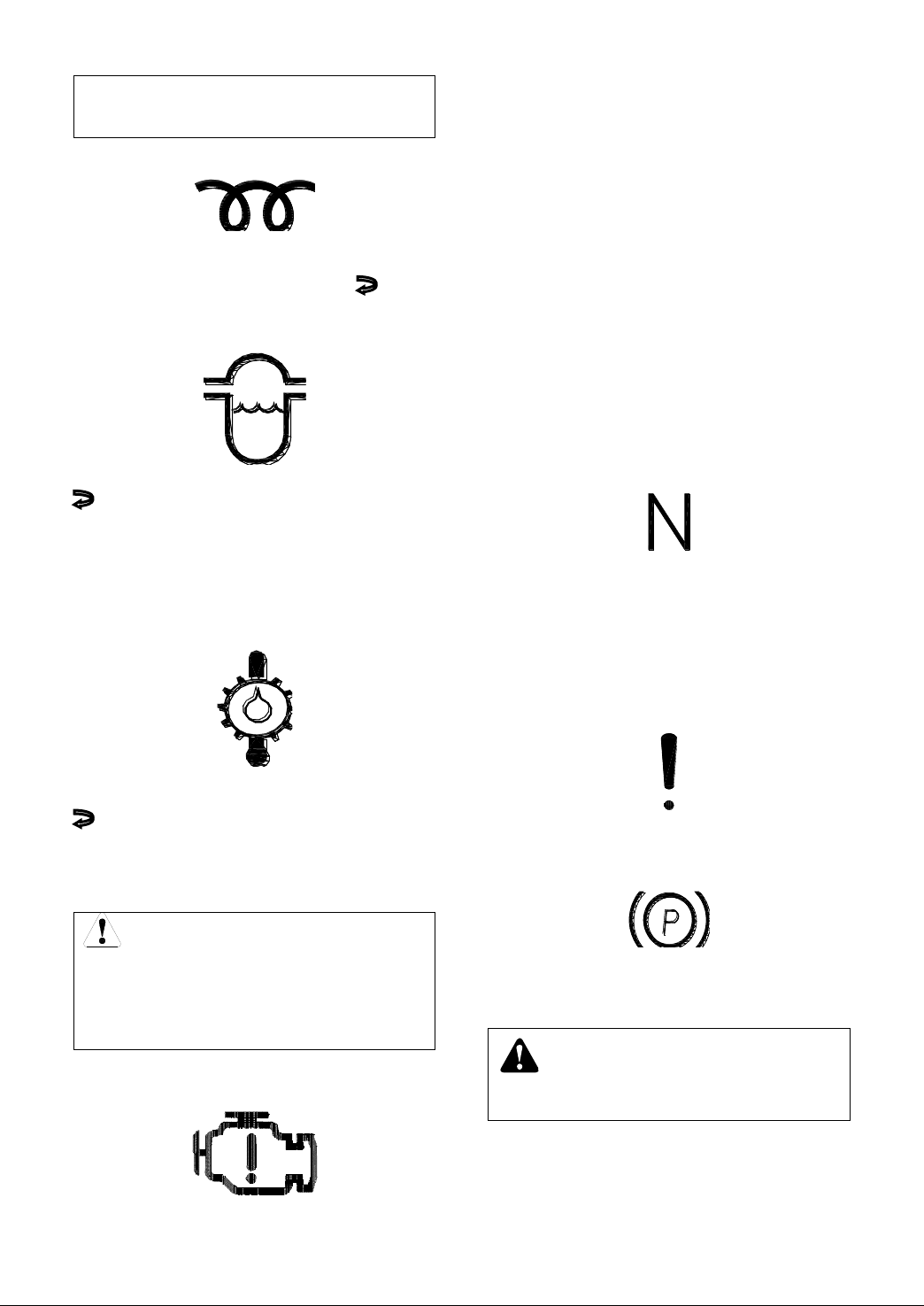

CAN Bus Instrument(W98)

KUBOTA Diesel engine, Main page

A. Instrument indicator lamp

Water temperature gauge

This gauge indicates the oil temperature in the

torque converter transmission box when the key

is at ┃(ON) position. In normal status, LED

Displayed in the range of 40 ℃-110 ℃

Caution

If LCD display in the red zone , please stop the

truck at once. Decrease the engine speed to

make the engine cool. Check the cooling fluid if

enough and the fan belt‘s elasticity if fit.

Fuel gauge

The gauge indicates the fuel level in the tank

when the key is at ┃(ON) position.

Suggest filling up the fuel tank after work every

day.

Hour meter

This meter measures working time of engine

when the key is at ┃(ON) position. The meter

increase one number every working hour.

Use meter to schedule lubrication and

maintenance periods.

Caution

When the time meter increases every

100h (the factory default time interval is

100h, which is adjustable), the spanner

logo will flash one hour at regular

intervals to reminder of the maintenance

to the forklift. Refer to monthly

maintenance after first flash. Refer to

periodical maintenance schedule for per

period. Take the actual flashing time as

standard.

Charging indicator

This lamp indicates the battery condition of

charge. The lamp comes on when the ignition

switch is set at ┃―ON‖, but it goes out as the

engine starts and accelerator pedal is pressed.

Caution

If the light continues to stay lit or lights up

during operation, the charging rate is low

and should be checked immediately.

Glow indicator [Diesel truck]

Turn the key to ―ON‖ position and the indicator

lights up for a moment. After the indicator goes

out, turn the key to . ―Start‖ position

Engine oil pressure alert lamp

This lamp indicates the pressure condition of

KEY4

KEY3

KEY2

KEY1

12

engine lube oil. Although it lights up when the

engine switch is set at ―ON‖, once the engine

starts up and the accelerator pedal is pressed,

this lamp goes out.

Caution

If this light continues to stay lit or lights up

during operation, the pressure is lower than

0.05Mpa and should be checked

immediately.

Parking indicator

Parking indicator shows on means brake is

affected, Please loosen the parking handle (hand

brake handle), the parking indicator will shows

off.

Warning

It will damage the engine and

transmission, etc. when indicated.

Sedimentor indicator [ diesel truck]

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

This lamp lights up when water in sedimentor

reaches to a certain level, while the engine is

running.

If this lamp continues to stay lit or lights up during

the engine running, stopping the engine and

discharge water immediately.

Caution

If continue working when the lamp is light.

The fuel injection pump may be damaged.

Neutral position start-up indicator

Put the steering handle in the neutral position

when truck on the temporarily stop, the light will

indicated on

The truck can be started up only in the neutral

position.

It‘s prohibited for truck in the neutral position

sliping when it‘s on the slope.

Transmission oil temperature warning light

(Hydraulic Forklift)

In normal state, once the starter is set to

―ON‖ position, this lamp lights up. After the

engine is started up, it goes out.

During work time if the oil temperature exceed

the normal rang 60℃~120℃the indicator light

on.

Caution

If the pointer enters the red range, stop the

operation instantly and slow down engine

speed to cool the coolant and wait until the

pointer goes into the green range, and have

a check then.

Seat belt warning indicator [Optional]

When thislight is on, it means not wearing a

seatbelt or not locked.

OPS indicator

When this light is on, it means driver leave the

seats or not sitting on the seat correctly.

Air filter indicator [O]

When the light is on, it indicates the air inlet

system is blocked, stop the truck and clean the

air filter.

Accumulator warning indicator [D]

This indicator light does not work on the forklift.

13

High exhaust temp. lamp

W98Engine:lamp on

Caution

Remind the driver of high exhaust

temperature during regeneration, and pay

attention to safety.

Inhibit Regeneration Lamp

This light indicates that the regeneration state

of the engine is limited and the requested

regeneration cannot be performed at this time.

Caution

Work in an environment that is not suitable

for DPF regeneration. Turn on the

regeneration prohibition. After leaving, the

regeneration prohibition should be lifted in

time to turn off the regeneration prohibition

indicator so that active regeneration can

continue.

Warning

If active regeneration is always prohibited,

the exhaust filter will be blocked, exhaust is

blocked, and the forklift's performance will

deteriorate until the engine fault indicator is

activated .

EATS fault indicator lamp

To indicate that the engine EATS (Exhaust After

Treatment System) has failed or falls outside of

specified operating parameters.

At the same time, the engine fault light is on.

Regeneration Needed/Request Lamp

There are three working states: driving

regeneration, parking regeneration, service

regeneration (after-sale program).

In the first case, the regeneration indicator

lights up permanently and is in the regeneration

working state. No manual intervention is required

at this time, and only the normal working state

needs to be maintained.

The regeneration reminder will automatically

go out, which also means that the particulate

matter processing is completed.

What the driver has to do is to reduce the

light load running time as much as possible in

order to increase the exhaust temperature and

shorten the regeneration time.

In the second case, prompt to stop and start

parking regeneration.

Parking regeneration meets the following

conditions:

①The forklift is parked on a well ventilated flat

road.

②Pull up the handbrake.

③Release the accelerator pedal.

④The reversing operation lever is kept in

neutral (N range).

⑤Preheat the forklift until the water temperature

reaches 70 ℃.

Ahazard warning sign is placed near the exhaust

port.

Turn on parking regeneration (see instrument

key operation instructions).

After the regeneration is complete, the lamp will

turn off automatically, and after 2-3 minutes the

engine returns to normal idle speed, you can

shut down the engine.

Caution

Parking regeneration: parking state, not

conducive to heat dissipation. Keep away

from flammable materials and keep a safe

distance from people.

Drivers should pay attention to protection,

do not leave the scene, and always pay

attention to the engine condition during

regeneration.

It is best not to stop in the middle, otherwise

it is easy to cause DPF failure.

Warning

In case of emergency, parking regeneration

must be prohibited, exit any one of the

parking regeneration conditions ②③④.

W98 Engine

The indicator light flashes during driving. If

the parking regeneration is not performed in time,

it is easy to cause DPF jams and may damage

14

the DPF.

If the regeneration indicator flashes while

driving, and the engine fault indicator also lights

up, stop immediately.

Contact the factory maintenance personnel

or after-sales to check the engine fault code.

After there are no other faults, start parking

regeneration.

Kubota engine

light flashes

Engine fault Code

(SPN: 3701 FMI:15)

The third case is service regeneration.

DPF has been seriously blocked, the engine has

reduced power and torque limit, the forklift

cannot work normally, contact the after-sales

service to complete the service regeneration.

Engine fault indicator [Electronic-controlled

engine]

When the engine gets out of order, this

Indicator will be on. then it must immediately

stop.

Press the key on the right side of the instrument

to view, or ECU diagnostics port connected to

diagnostic equipment, read the fault code

information stored in the ECU.

15

B. Instrument key operation instructions

B.1 Engine fault information display page

(1) KUBOTA diesel engine

No fault

Fault

Back

Next

Prev

Back

①Enter the engine fault information display page: Main page=》Key 4

②Fault query page turning: press key 2 or key 3 to page turning (page turning key is not

displayed when there is no fault at present)

③Return to main page: press key 1 to return to main page

B.2 Forklift operation parameters and interface switching between Chinese and English

①Enter the engine information display page: Main page=》key 2 or key 3

②Language switch: press key 3 to switch language (Chinese / English)

③Return to main page: press key 1 to return to main page

蓄电池电压 发动机转速 机油压力 转速负载

Ash 负载 SOOT 负载 进气温度 行驶速度

%

VDC r/min

℃km/h

%

Bar

%

Battary

Voltage

Ash

Load

Engine

Speed

SOOT

Load

Oil

Pressure

Intake Air

Temperature

Load @

RPM

Vehicle

Speed

%

VDC r/min

℃km/h

%

Bar

%

KUBOTA diesel engine

B.3 Settings page

(1) Set page actions

保养提醒

返回

高级设置

Back

Setting

Enter the setting page: Main page=》Key 1

Enter the maintenance page: Main page=》Key 1=》Key 2, to enter the maintenance

page

Enter the Emissions setting page: Main page=》Key 1=》Key 3, to enter the emissions

setting page

Enter advanced setting page: Main page=》Key 1=》Key 4, Enter the password input

16

page of advanced settings maintenance personnel

Return to main page: press key 1 to return to main page

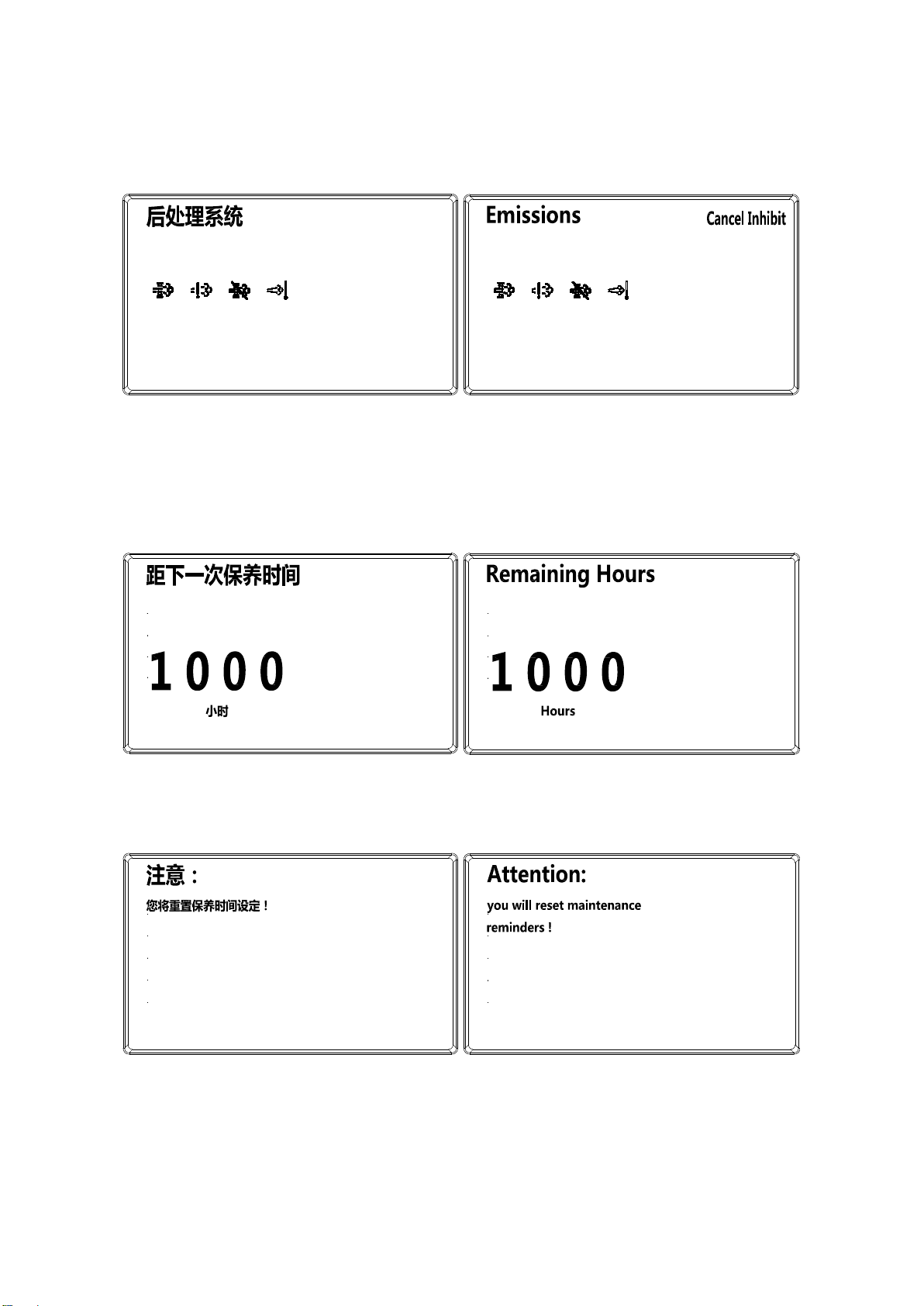

(2) DPF Emissions function setting page (Diesel engine)

请求再生

返回

禁止再生

取消禁止

Regen

Back

Inhibit

Cancel inhibit: press the key 4,The DPF is to burn (DPF-regenerate) trapped particulate

matters in an automatic way.

Inhibit: press key 3,DPF-regenerate function of OFF

Regen: press key 2, Turn on DPF parking regeneration

Return to the setting page: press key 1 to return to the setting page

(3) Maintenance reminder maintenance page

a.Remaining hours query page

重置

返回

Reset

Back

Reset: press the key 2 to jump to the maintenance time reset page to reset the remaining

hours of maintenance to the Set the initial value (maintenance interval).

Back: press key 1 to return to the setting page

b. Maintenance time reset page

确定

返回

Confirm

Back

Confirm:press the key 2 to confirm the reset.After the confirmation, it will automatically return

to the maintenance query page.

Back: press key 1 to return to the setup page.

This manual suits for next models

11

Table of contents

Other HANGCHA Forklift manuals

HANGCHA

HANGCHA R Series User manual

HANGCHA

HANGCHA J Series User manual

HANGCHA

HANGCHA XF Series Quick start guide

HANGCHA

HANGCHA XC Series User manual

HANGCHA

HANGCHA XF Series User manual

HANGCHA

HANGCHA CBD20-AMC1 Installation guide

HANGCHA

HANGCHA CBD15-A2MC1 User manual

HANGCHA

HANGCHA XE Series User manual

HANGCHA

HANGCHA CPD10-A User manual