General

The manual provides important information to

familiarize you with safe operating procedures and

operator maintenance requirements for the Gradall/

534B-9MaterialHandler.

If you have any questions regarding the material

handler, contact your Gradall Material Handler

Distributor.

Operator Qualifications

Operators of the material handler must be in good

physical and mental condition, have normal reflexes

and reaction time,good vision and depth perception

and normal hearing. He/she* must not be using

medication which could impair his abilities nor be

under the influence of alcohol or any other drug

during the work shift.

The operator should also possess a valid, applicable

driver’s license and must have completed a course of

training in the safe operation of this type of material

handling equipment.

In addition, the operator must read, understand and

comply with instructions contained in the following

material furnished with the material handler:

This Operator’s Manual

FIEIRough Terrain Forklift Safety Manual

GradallMaterial HandlerSafety Manual

All instruction decals and plates

Any optional equipment instructions furnished

The operator must also read, understand and

comply with all applicable Employer, Industry and

Governmental rules, standards and regulations.

Regardless of previous experience operating similar

equipment, the operator must be given sufficient

opportunity to practice with the 534B-9 Material

Handler in a safe, open area(not hazardous to people

or property) to develop the skills and “ feel” required

for safe, efficient operation.

Though no offense or discrimination is intended,

only the masculine pronouns will be used

throughout the remainder of this manual.

Orientation

When used to describe location of components in

the material handler, the directions front, rear,

right and left relate to the orientation of a person

sitting in the operator’s seat.

INTRODUCTION

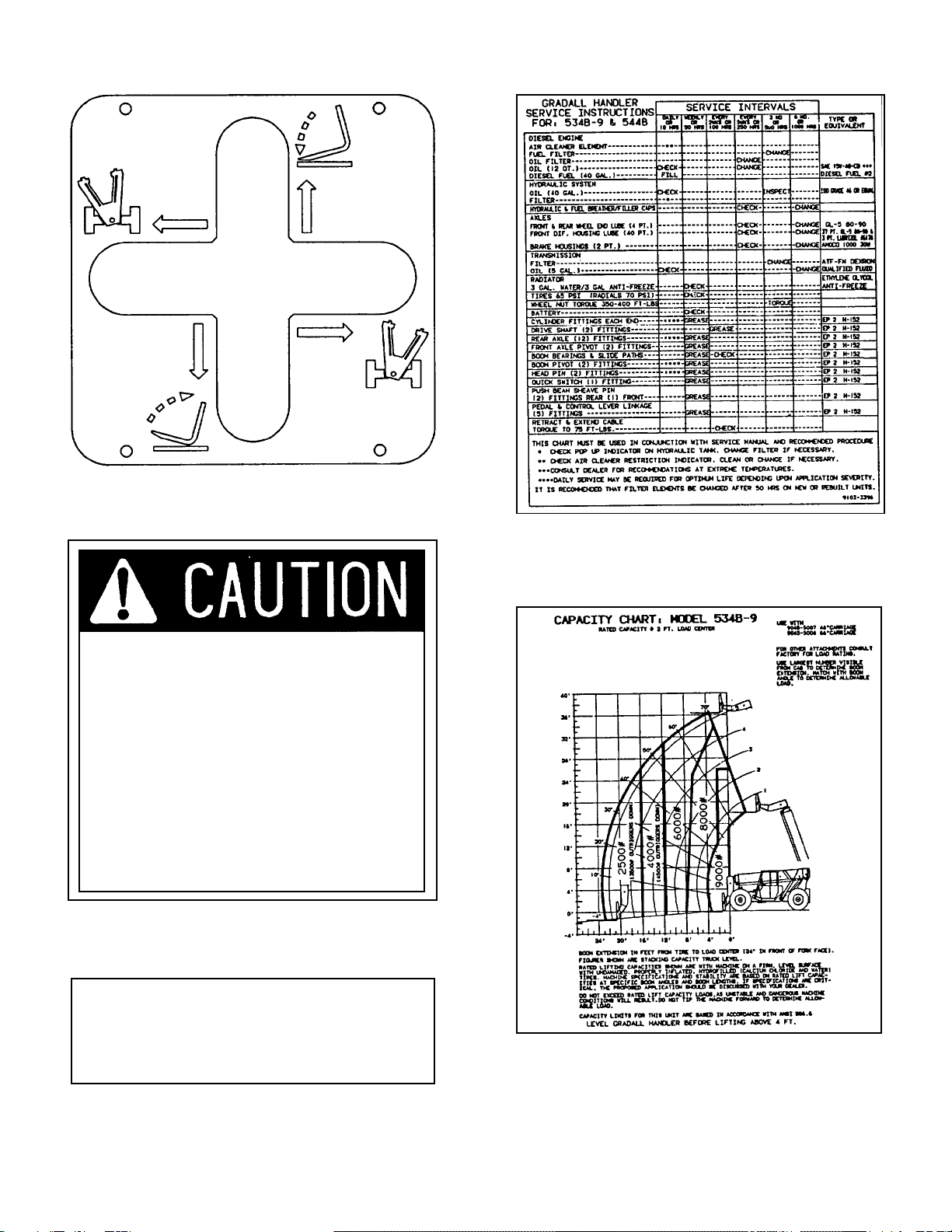

Related Manuals & Decals

Separate publications are furnished with the

material handler to provide information

concerning safety, replacement parts, maintenance

procedures, theory of operation and vendor

components. Replacement manuals, decals and

instruction plates can be ordered from your Gradall

MaterialHandler Distributor.

Serial Number Location

Specify Model and Serial Numbers when ordering

parts and when discussing specific applications and

procedures with your distributor. The model/serial

number plate is located on the right cab wall.

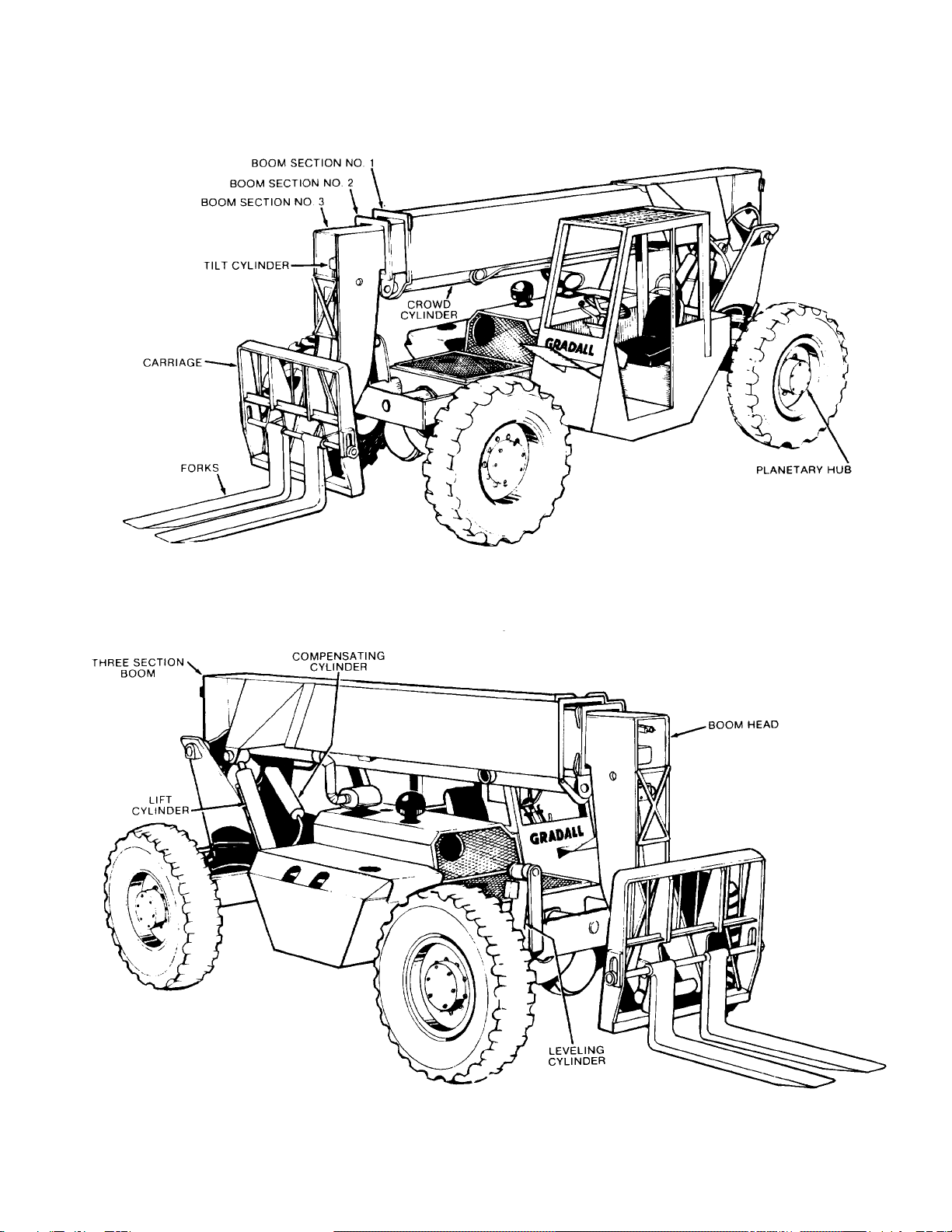

Nomenclature

The illustrations on page 3 include nomenclature

applied to major components of the material handler.

The term “handler” will be used throughout the

balance of this manual in place of the words”material

handler”.

2

*