ROUBLESHOOTING

6083966-R4

T

6

3.3 Fork Position Function

Five potential problems can affect the fork positioning

function:

• Binding due to bending damage, wear, lack of

lubrication.

• Incorrect hydraulic pressure or flow from truck.

• Flow restrictor fittings plugged or improperly

adjusted.

• Solenoid equipped: Electrical circuits faults, defective

solenoid coil or valve.

• External leaks due to worn or defective cylinder

seals.

3.3-1 Supply Circuit Test

1 Check the pressure supplied by the truck at the

carriage hose terminals. Pressure must be within

the range shown in Specifications, Section 5.1.

PRESSURE TO THE FORK POSITIONER MUST NOT

EXCEED 3500 psi (241 bar).

2 Check the flow volume at the carriage hose terminal.

Flow must be within the range shown in Specifications

Section 5.1.

3 Fully open the forks. Hold the lever in the OPEN position

for several seconds. Release the lever and check for

external leaks at the fittings, tubing, hose, and manifold.

3.3-2 Fork Position Circuit Test

1 If equipped, press the solenoid button. Listen for a

'click' as the solenoid valve. If no sound is heard, check

the fuse, wiring and coil. Repair as necessary.

IMPORTANT: Solenoid-operated valve should be

plumbed so that the solenoid is energized during the

fork-positioning function.

2 Fully open or close the forks. If the forks move

unevenly, slowly or not at all, check flow restrictors for

contamination or improper adjustment. Refer to Section

4.1. Speed should be 3 in. (75 mm) per second at

specified flow rate.

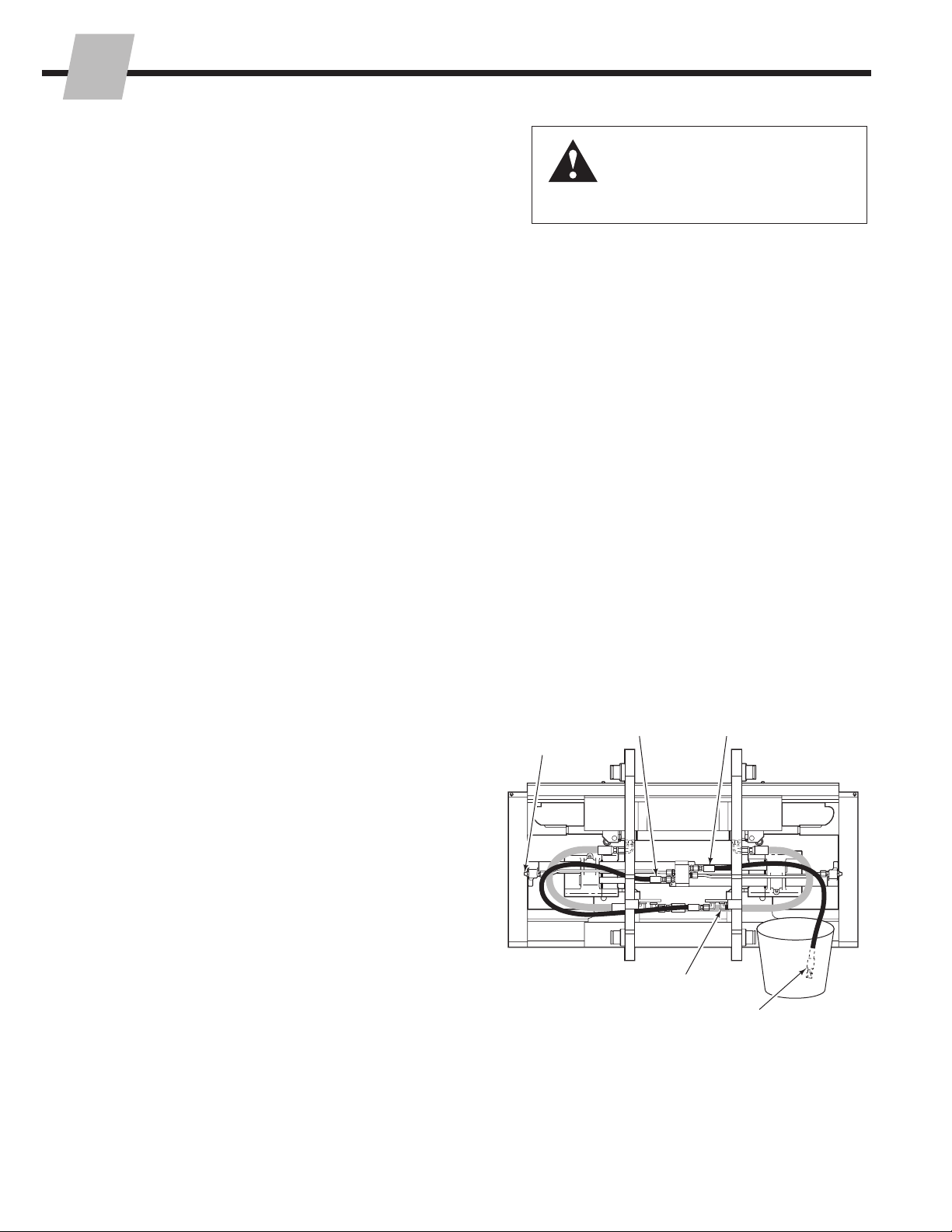

3 If forks still do not move correctly, fully close forks. Turn

the truck off. Relieve the attachment's system pressure.

Disconnect the OPEN supply hose from the truck hose

terminal and route to a drain bucket. Cap the supply

fitting.

4 Start the truck and slowly actuate the CLOSE forks lever

until forks are fully closed. Hold lever for 5 seconds.

• If there is substantial hydraulic flow out of the drain

hose, one of the cylinders has faulty piston seals.

Replace the complete unit or service the piston seals

(see Section 4.2).

• If there is little or no hydraulic flow out of the hose,

the problem is not hydraulic. Refer to Section 3.3.

FP1121.eps

Flow Restrictors

(each end)

2

3

CLOSE Forks

Supply Hose

OPEN Forks

Supply Hose

Cap supply fitting

Hose end in

the bucket

Back (Driver's) View

WARNING: Before removing any

hoses, relieve pressure in the hydraulic

system. With the truck off, open the

truck auxiliary control valve(s) several

times in both directions.