Catalog

Catalog

Catalog

Catalog

Correct

Correct

Correct

Correctuse

us e

use

useand

an d

and

andapplication

ap plication

application

application...........................................................................................1

1.

1.

1.

1.Truck

Tr uck

Truck

TruckDescription

De scription

Description

Description.........................................................................................................2

1.1Application..............................................................................................................2

1.2Assemblies.............................................................................................................3

1.2.1ControlHandle.............................................................................................4

1.2.1Keyswitch....................................................................................................4

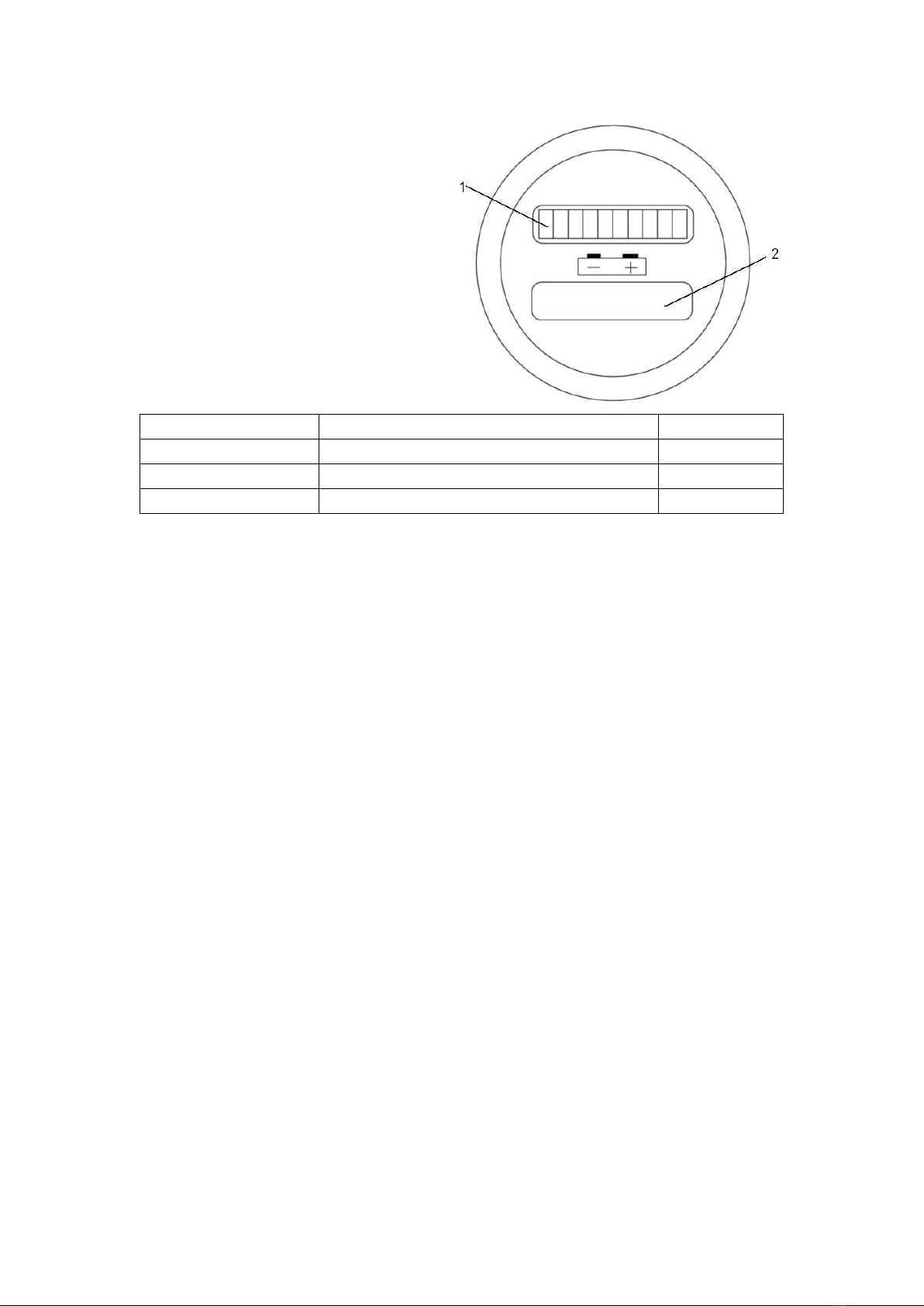

1.2.3Batterydischargeindicator.........................................................................5

1.3Identificationpointsanddataplates....................................................................6

1.3.1Truckdataplate...........................................................................................7

1.4.StandardVersionSpecifications..........................................................................7

1.4.1Performancedataforstandardtrucks.......................................................8

1.4.2Dimensions...................................................................................................9

2.Transport

2.Transport

2.Transport

2.Transportand

an d

and

andCommissioning

Co mmissioning

Commissioning

Commissioning.................................................................................11

2.1Transport...............................................................................................................11

2.2UsingtheTruckfortheFirstTime.......................................................................

1

1

2.3Duringbrake-in.....................................................................................................12

3.Operation

3.Operation

3.Operation

3.Operation......................................................................................................................13

3.1SafetyRegulationsfortheOperationofForkliftTrucks....................................13

3.2Operateandrunthetruck...................................................................................14

3.2.1Preparing...................................................................................................14

3.2.2Travel.........................................................................................................14

3.3.3Lifting,transportinganddepositingloads................................................16

3.3.4Parkingthetrucksecurely........................................................................17

4.Battery

4.Battery

4.Battery

4.BatteryMaintenance

Ma intenance

Maintenance

Maintenance&

&

&

&Charging

Ch arging

Charging

Charging.............................................................................18

4.1Safetyregulationsforhandlingacidbatteries..................................................18

4.2Batterytype&dimension...................................................................................18

4.3Chargingthebattery............................................................................................18

4.4Batteryremovalandinstallation..........................................................................19

4.5Batterymaintenance............................................................................................20

4.6BatteryDisposal...................................................................................................20