PROFESSIONAL HYDRAULIC JACKS 61204 User manual

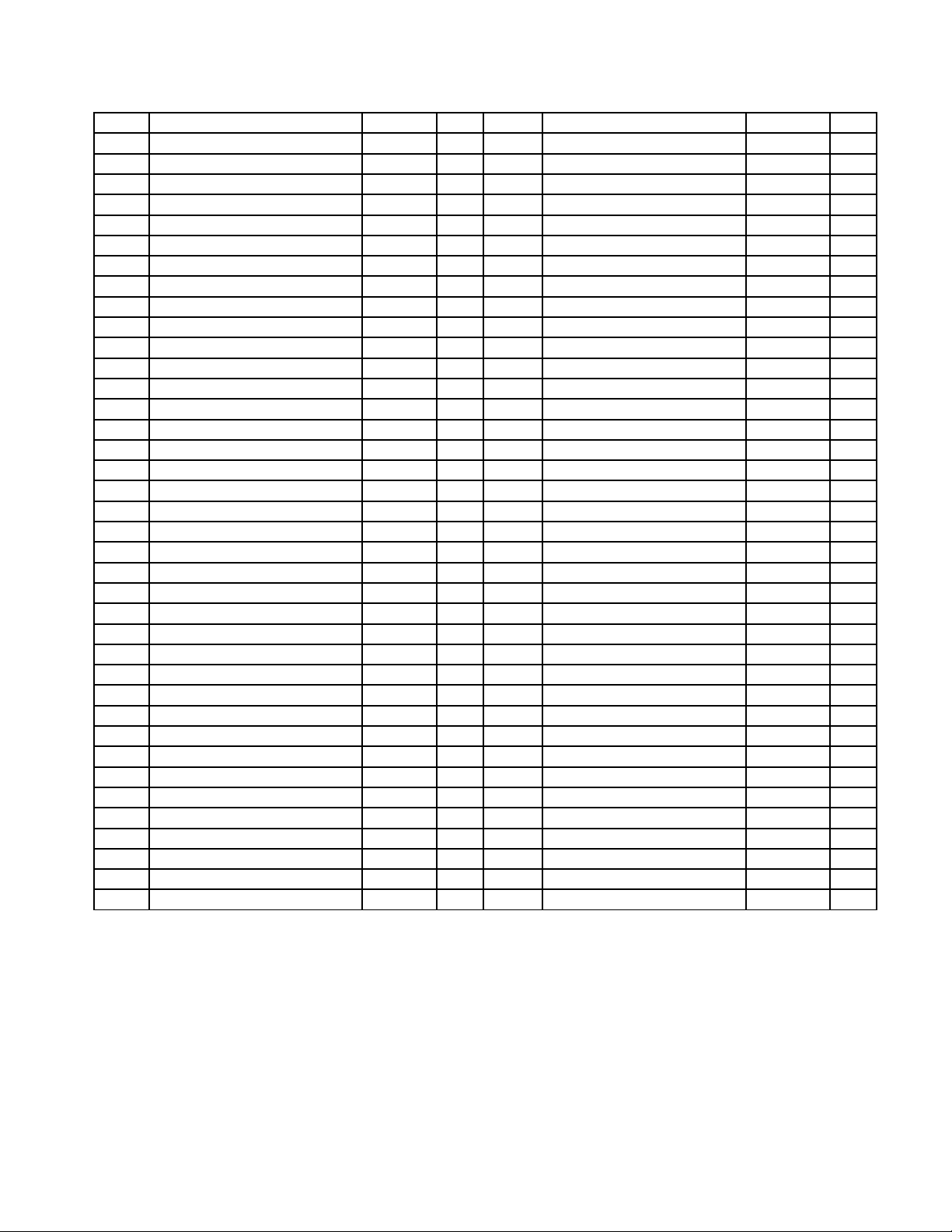

Specifications

Lift

Range Stroke

Saddle

Adapter E t.

Overall

Length

Overall

Width

Overall

Height

Net

Weight

Min.11-1/2”

Max. 17-1/2”

6” 1-3/4”,2-1/2”,

4”,3/4”

25” 14-1/4” 55” 165 lbs

You will need the manual for the safety warnings and precautions, assembly instructions, operating

and maintenance procedures, parts list and diagram. Keep your invoice with this manual. rite the

invoice number on the inside of the front cover. Keep the manual and invoice in a safe and dry place

for future reference. WARNING: hen using tool, basic safety precautions should always be

followed to reduce the risk of personal injury and damage to equipment.

Keep area clean. Cluttered areas invite injuries.

Observe work area conditions. Do not use machines or power tools in damp or wet locations.

Keep children away. Do not let them handle machines, tools, or extension cord.

Store idle equipment. hen not in use, tools must be stored in a dry location to inhibit rust.

Do not force tool. It will do the job better and more safely at the rate for which it was intended.

Use the right tool for the job. Do not attempt to force a small tool or attachment to do work of

a larger industrial tool.

Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving parts.

Use eye and ear protection. Always wear ANSI approved impact safety goggles at all times.

Do not overreach. Keep proper footing and balance at all times. Do not reach over or across

running machines.

Maintain tools with care. Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and changing accessories. Inspect the cord on the tools

periodically and if damaged have them repaired.

Disconnect power. Disconnect the compressor when not in use.

Check for damaged parts. Before using any tool, any part that appears damaged should be

carefully checked to determine that it would operate properly and perform its intended

function. Check for alignment and binding of moving parts; any broken parts or mounting

fixtures; and any other condition that may affect proper operation.

Do not overload this jack. Maximum capacity is 50 tons.

This jack is for lifting purposes only.

Do not move the load while on the jack.

Assembling the bottle jack

1.The jack comes fully assembled and easily connects to an air compressor.

2.The air hose connecting the air compressor with the jack should be short as possible.

3.Installation of an air filter and oiler on the compressor end is recommended.

4.Use of a 3 horsepower or larger compressor is recommended.

Optional Purchase: Adaptors, the adapter holder needs to be assembled to the handle. Use 2 U-

bolts, 2 nuts, and 2 spring washers to complete assembly. The three spare adapters fit on the

adapter holder when not in use. Be sure to lock each adapter in place on the adapter holder by using

a hitch pin.

Operation

1. ith the air compressor hose properly hooked up to the air valve assembly, the jack is ready to be

used. Test the jack before attempting to lift a vehicle.

2.Remove the air valve assembly from the handle, and squeeze the lever to raise the piston by

locking the lock lever in place; the piston will be raised automatically.

3.To stop the piston movement, release the lock lever (squeeze the lever tightly against the air valve

body and swing away the lock lever), and release the lever allowing it to return to its original position.

4.To lower the piston, slowly turn the handle knob counter clock wise to open the release valve.

hen the piston is lowered, close the handle knob by turning clockwise.

5.To change the handle position, pull the lock lever, which will release the handle lock. Position the

handle in one of the three available positions. Make sure the handle engages in one of the three

position holes, and push down on the lock lever to lock the handle in place.

6.The handle is to be used only for moving the jacks. hen using the jack, never apply your body

weight to the handle.

Using the adapters (purchased separately): The adapters are used individually and drop into the

top of the piston rod assembly. Before lifting a vehicle inspect the vehicles contact point, which will

come in contact with the jack adapter. Pick an adapter that has the right size and shape to match this

contact point. Always make sure the contact point and the adapter are clean and grease free before

attempting to lift the vehicle. Make sure the adapter is positioned directly under the contact point

before attempting to jack up the vehicle.

Maintenance

NOTE: The manufacturer has calibrated the jack’s safety valve. Never attempt to disassemble the

safety valve.

1.Use good quality hydraulic tool oil once or twice a month to lubricate the air motor.

2.Oil in oil tank should be replaced once per year, or more often with heavy use. Use only good

quality hydraulic tool oil. (To access the oil tank, remove the screw).

NOTE: Occasionally, air bubbles can become trapped inside the hydraulic system thereby reducing

the efficiency of the jack. Purge air from the hydraulic system as needed by doing the following

steps:

1.Remove the upper cover.

2.Loosen the bolt one half turn.

3.Close the release valve.

4.Operate the air pump repeatedly tightening and loosening the bolt.

5.Tighten the bolt when the piston begins to rise. Verify that the piston can rise to the maximum

position.

Cleaning the air filters

1.Periodically remove the air filter located inside the air valve body. ash the air filter in a suitable

solvent, and blow dry making sure all dust and particles are removed from the filter.

2.Periodically remove the screw-in type air filter ash and blow-dry as described in the paragraph

above.

Storage

hen the jack in not in use, always make sure that the piston rod assembly is fully collapsed. Do not

leave the jack outdoors. Always store indoors in a dry, clean location.

Parts List

Item

No

Description Part

No

Qty Item

No

Description Part No Qty

1.1 heel shaft 120011 2 6.14 Spring washer 120614 4

1.2 asher 120012 2 6.15 Lower cover 120615 1

1.3 heel shaft 120013 2 7.1 Packing washer 120071 1

1.4 Snap ring 120014 2 7.2 Muffler cover 120072 1

2.0 Piston rod assembly 120020 1 7.3 O-ring 120073 1

2.1 Piston rod 120021 1 7.4 Valve rod 120074 1

2.2 Packing 120022 1 7.5 Rubber pad 120075 1

2.3 Screw 120023 1 7.6 Packing washer 120076 1

2.4 Bushing 120024 1 7.9 Hex socket screw 120079 4

2.5 Snap ring 120025 1 7.10 Filler element 120710 1

2.7 Packing retainer 120027 1 7.11 Filler cover 120711 1

2.8 Cylinder 120028 1 7.12 2.5 Steel ball 120712 1

2.12 Bolt 120212 2 7.13 Steel ball 120713 2

2.13 Packing 120213 2 8.1 Plunger cover 120081 1

2.14 Spring retainer 120214 1 8.2 Air pump body 120082 1

2.15 Safety valve 120215 1 8.3 NL Retainer 120083 1

2.16 Spring 120216 1 8.4 O-ring 120084 1

2.17 Nut 120217 1 8.5 Packing guide 120085 1

2.18 Oil seal 120218 1 8.6 Nut 120086 1

2.19 O-ring 120219 2 8.7 Spring 120087 1

2.20 Oil tank 120220 1 8.8 asher 120088 1

2.21 Spring 120221 4 8.9 Plunger 120089 1

2.22 Spring plunger 120222 1 8.10 Retainer 120810 1

2.23 Machine screw 120223 4 8.11 O-ring 120811 1

2.24 Nut 120224 4 8.12 O-ring 120812 2

2.25 Oil strainer 120225 1 8.13 Piston 120813 1

2.29 Packing 120229 1 8.14 Steel ball 120814 2

2.31 Spare ring 120231 1 10.30 Air valve assembly 121030 1

2.32 Back up ring 120232 1 10.1 Valve body 120101 1

3.2 Oil box 120033 1 10.2 Nut 120102 1

3.4 Bolt 120034 1 10.3 O-ring 120103 1

3.5 Spring 120035 1 10.4 O-ring 120104 1

3.6 Steel ball 120036 1 10.5 Packing 120105 1

3.7 Steel ball 120037 1 10.6 Throttle 120106 1

3.8 Copper packing 120038 1 10.7 Spring 120107 1

3.9 Separator 120039 1 10.8 Lever 120108 1

3.10 Back up ring 120310 1 10.9 Lever pin 120109 1

3.12 O-ring 120311 1 10.10 Lock lever 121010 1

3.13 Bolt 120312 3 10.12 Pump elbow 121012 1

3.14 Spring washer 120313 3 10.13 Hose connector 121013 1

4.0 Release valve assembly 120314 3 10.14 Spring 121014 1

4.1 Valve 120040 1 10.15 Air hose 121015 1

4.2 O-ring 120041 1 10.16 Hose band 121016 2

4.3 Guide 120042 1 10.22 Filler 121022 1

4.4 Universal joint 120043 1 50.0 Power unit assembly 120500 1

4.5 Spring pin 120044 1 12.0 Holder adapter ass’y 120120 1

4.6 Spring pin 120045 1 12.1 Adapter A 120121 1

4.8 O-ring 120046 1 12.2 Adapter B 120122 1

4.9 asher 120048 1 12.3 Adapter C 120123 1

4.10 Packing 120049 1 12.4 Adapter D 120124 1

4.11 Snap ring 120410 1 12.5 Holder adapter ass’y 120125 1

5.0 Handle assembly 120411 1 12.6 U-bolt 120126 2

5.1.1 Upper handle 120050 1 12.7 Nut 120127 4

5.1.2 Lower handle 120511 1 12.8 Spring washer 120128 4

5.2 Knob 120512 1 12.9 Hitch pin 120129 4

5.3.1 Connecting rod 120052 1 12.30 Repair kit 120130 1

5.3.2 Connecting rod 120531 1

5.4 Spring pin 120532 1

5.5.1 Stopper 120054 1

5.5.2 Stopper 120551 1

5.6 Lock lever 120552 1

5.7 Spring pin 120056 1

5.8 Spring 120057 1

5.9 asher 120058 1

5.11 Handle fork 120059 3

5.12 Bolt 120511 1

5.13 Spring washer 120512 1

5.14 Connecting rod 120513 1

5.15 Connecting rod 120514 1

5.16 Universal joint 120515 1

5.17 Spring pin 120516 1

5.18 Spring pin 120517 1

5.19 Spring pin 120518 1

5.20 Cotter pin 120519 1

5.21 Bolt 120520 1

5.22 Spring washer 120521 2

5.23 Bolt 120522 1

6.1 Frame 120523 1

6.3 Handle fork bracket 120061 1

6.6 Upper cover 120063 1

6.7 Machine screw 120066 1

6.8 Lock washer 120067 4

6.9 Bolt 120068 4

6.12 Bolt 120069 4

6.13 Bolt 120612 4

Table of contents

Other PROFESSIONAL HYDRAULIC JACKS Tools manuals

Popular Tools manuals by other brands

JessEm Tool

JessEm Tool 02101A Operating instructions and parts manual

Eastwood

Eastwood 21302 instructions

Parkside

Parkside PDST 10 B3 Translation of the original instructions

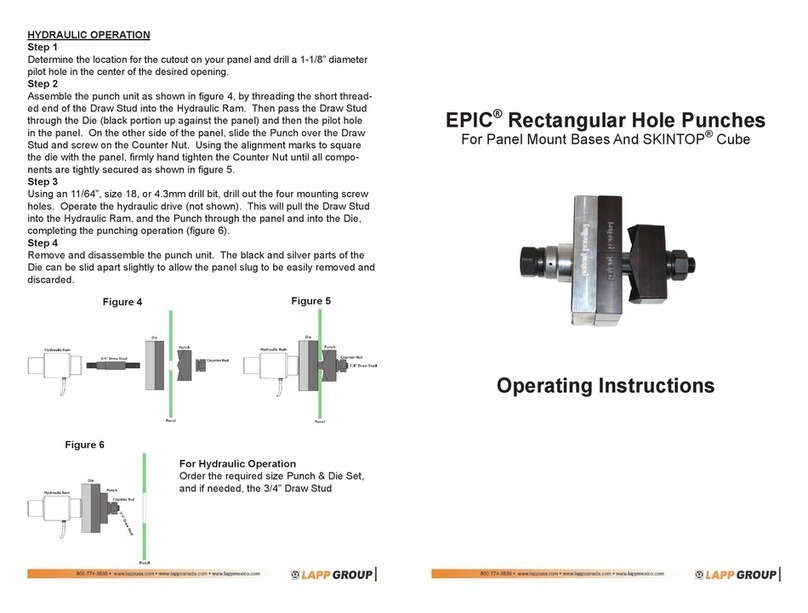

Lapp Group

Lapp Group EPIC Rectangular Hole Punches operating instructions

WOOD'S POWR-GRIP

WOOD'S POWR-GRIP LJ6VHWBP instructions

EGAmaster

EGAmaster 56066 operating instructions