Profibus PB-Q ONE User manual

Revision overview

PB-QONE - User Manual 3

Revision overview

Date

Revision

Change(s)

10/10/2017

0

First version

© Copyright 2017 Indu-Sol GmbH

We reserve the right to amend this document without notice. We continuously work on further developing

our products. We reserve the right to make changes to the scope of supply in terms of form, features and

technology. No claims can be derived from the specifications, illustrations or descriptions in this

documentation. Any kind of reproduction, subsequent editing or translation of this document, as well as

excerpts from it, requires the written consent of Indu-Sol GmbH. All rights under copyright law are expressly

reserved for Indu-Sol GmbH.

Contents

PB-QONE - User Manual 4

Contents

Revision overview 3

Contents 4

1Introduction 6

1.1 General 6

1.2 Functional overview 6

1.3 Scope of supply 7

1.4 System requirements 8

1.5 Safety information 8

2Commissioning 9

2.1 Software installation 9

2.2 Connect device to PC 9

3Connection to the PROFIBUS system 10

3.1 Basics 10

3.1.1 Warning about measurements on running systems 10

3.1.2 Connection types for PROFIBUS devices 10

3.1.3 Adapter cable 10

3.1.4 Measuring locations 11

3.2 Connection versions 12

3.2.1Measurements during system downtime 12

3.2.2 Measurements on the running system 13

3.2.2.1 Connection type D-Sub connector with service jack 13

3.2.2.2 Connection via permanently installed measuring point PBMA (IP20) 14

3.2.2.3 Connection type M12 (IP67) 15

4Perform and document measurement 16

4.1 General information 16

4.2 Network 17

4.2.1 Topology 17

4.2.2 Device list 19

4.2.3 List of measuring points 19

4.3 Quality values 20

4.3.1 Standard measurement 20

4.3.2 Additional functions 21

5Telegrams 22

PB-QONE - User Manual 5

6Results 24

6.1 Network overview 24

6.2 Device details 25

6.3 Event list 26

6.4 Comparison 26

7Report 27

8Technical data 28

8.1 Technical drawing 28

9Appendix 29

9.1 Sample log 29

9.2 Sample plan 31

Introduction

PB-QONE - User Manual 6

1 Introduction

1.1 General

The PB-QONE is an easy to use, powerful measuring device for comprehensive inspection of PROFIBUS

master systems. It offers separate testing of the physical condition of the bus (signal quality) and the

telegram traffic. The device can be used for acceptance measurement on new systems for inclusion in the

acceptance report, as well as for targeted troubleshooting of existing systems.

Its integrated master simulator enables testing of the communication quality without a need for the PLC to

be operational. This enables pre-inspection of complete systems and their parts during the commissioning

stage, with the goal of providing stable bus systems for trouble-free production in the long term.

The device is connected to a PC or notebook via a USB interface, which also provides the power supply. It

is controlled with the “Indu-Sol Suite” software.

1.2 Functional overview

The PB-QONE is designed to assist you with inspection, troubleshooting, and the isolation of root causes.

To this end, it offers the following functions:

Feedback-free bus coupling at suitable existing measuring points during running operation

Automatic detection of the baud rate

Automatic identification of all devices on a bus system (LiveList)

Device and measuring-point-based display of signal ratios:

oGeneral quality value

oSignal to noise ratio and slope gradient

oOscilloscope display with selection options for detailed evaluation

Long-term monitoring of all devices (continuous measurement) with minimum, maximum, and average

quality values

Editable measuring point and segment management

Wear inspection by comparing current readings with stored measurements

Integrated master simulator for inspection of system without a master (commissioning phase)

Real-time monitoring of the entire data traffic and checking for telegram errors, with entries into the

event list

In-depth telegram analysis with option for variable trigger setting

Easy documentation of measurements in the form of an acceptance report and topology plan

Introduction

PB-QONE - User Manual 7

1.3 Scope of supply

The scope of supply comprises the following individual parts:

Measuring device PB-QONE

D-Sub 9-pin adapter cable (for connecting to a PROFIBUS system)

USB cable (2 m)

CD with operating software “Indu-Sol Suite” and device manual

Please check the contents are complete before putting into operation.

Figure 1: PB-QONE delivery condition

Introduction

PB-QONE - User Manual 8

1.4 System requirements

The following Windows versions are supported: Windows 7, Windows 8, Windows 10.

The following minimum hardware requirements apply for the PC or notebook used:

CPU: Dual Core, Core I3 or better

RAM: 4 GB

Screen resolution: ≥ 1024x768 pixels (XGA)

Graphics: DirectX 9.0c capable graphic board (supported by most on-board

graphic boards)

USB interface: 2.0 (no other devices should be connected to the USB hub)

1.5 Safety information

Never open the housing of the PB-QONE

Opening the housing immediately voids any warranty

If you suspect that the device is defective, then return it to the supplier

Commissioning

PB-QONE - User Manual 9

2 Commissioning

2.1 Software installation

The PC software “Indu-Sol Suite” includes the required USB driver and needs to be installed on

the PC or notebook before the PB-QONE is connected for the first time.

The “Indu-Sol Suite” software is included on a CD-ROM. The installation requires administrator rights. If the

CD-ROM does not start automatically after inserting, then manually start the “setup.exe” file in the main

directory.

Future updates can be found on the Internet at www.indu-sol.com, under downloads.

The installation is performed after selecting the language, agreeing to the end user licence agreement, and

making the installation settings. Then the software is fully available for the following measurements.

2.2 Connect device to PC

Use the included USB cable for connection to the PC or notebook, including power supply.

Preferably connect the device directly to a USB port on the PC or notebook. Connecting via

external USB hubs or docking stations of notebooks may cause problems.

Connection to the PROFIBUS system

PB-QONE - User Manual 10

3 Connection to the PROFIBUS system

3.1 Basics

3.1.1 Warning about measurements on running systems

Caution: When connecting a measuring device, effects on the system to be inspected cannot be

ruled out completely. With unstable PROFIBUS systems, malfunctions of the system may occur

in rare cases. Always observe the connection information!

3.1.2 Connection types for PROFIBUS devices

Depending on the device version, there are different ways to connect bus modules to a PROFIBUS network:

Connecting via plug-in connectors

oD-Sub plug-in connector, usually with an integrated terminal resistor, and optionally with an

additional service jack

oM12 screw-in connector in the field for higher IP ratings

oSpecial manufacturer-specific hybrid plug-in connectors for routing the power supply over the bus

in conjunction with special cables

Direct cable connection via terminals

Due to the typical linear structure of the PB networks, the available measuring points are usually limited to

the connecting points of the bus devices. Alternatively, the use of additional measuring points (e.g. Profibus

measurement adapter, PBMA) may be viable.

3.1.3 Adapter cable

The standard scope of supply of the PB-QONE includes the 9-pin D-Sub adapter cable. An M12 adapter kit

is available as an optional accessory.

Use only the short original cables with special pin allocation for connecting to a PROFIBUS

network. No more than two D-Sub connectors must be cascaded to the service jack at a time.

Figure 2: Improper cascading of D-Sub connectors

The use of active connecting cables with integrated repeaters for measurement is not possible.

Connection to the PROFIBUS system

PB-QONE - User Manual 11

3.1.4 Measuring locations

In principle, the PB-QONE is able to perform measurements at any point in a PROFIBUS system. Please

note that the use of repeaters and converters (OLM, data light barriers, wireless transmission) creates

separate physical segments that need to be evaluated individually.

A complete and in-depth analysis of the overall PROFIBUS system requires measurements to be performed

at the beginning and the end of each physical segment. If problems are detected that cannot immediately

be classified clearly, then at least one additional measurement should be performed in the middle.

Connection to the PROFIBUS system

PB-QONE - User Manual 12

3.2 Connection versions

3.2.1 Measurements during system downtime

If D-Sub connectors with an additional service jack are present on all bus devices, then the

PB-QONE is simply connected there as shown in the image. If a D-Sub connector without a service jack is

installed, then the D-Sub adapter cable can be inserted below. Note that cascading more than two D-Sub

connectors should be avoided at all cost.

For M12 connection technology, the M12 adapter cable (optional) is looped into the bus.

For all connection versions requiring adapter installation, the bus must be opened. This causes

short-term disruptions in communication, which is why a system shutdown is required.

Figure 3: Measuring points during system downtime

Connection to the PROFIBUS system

PB-QONE - User Manual 13

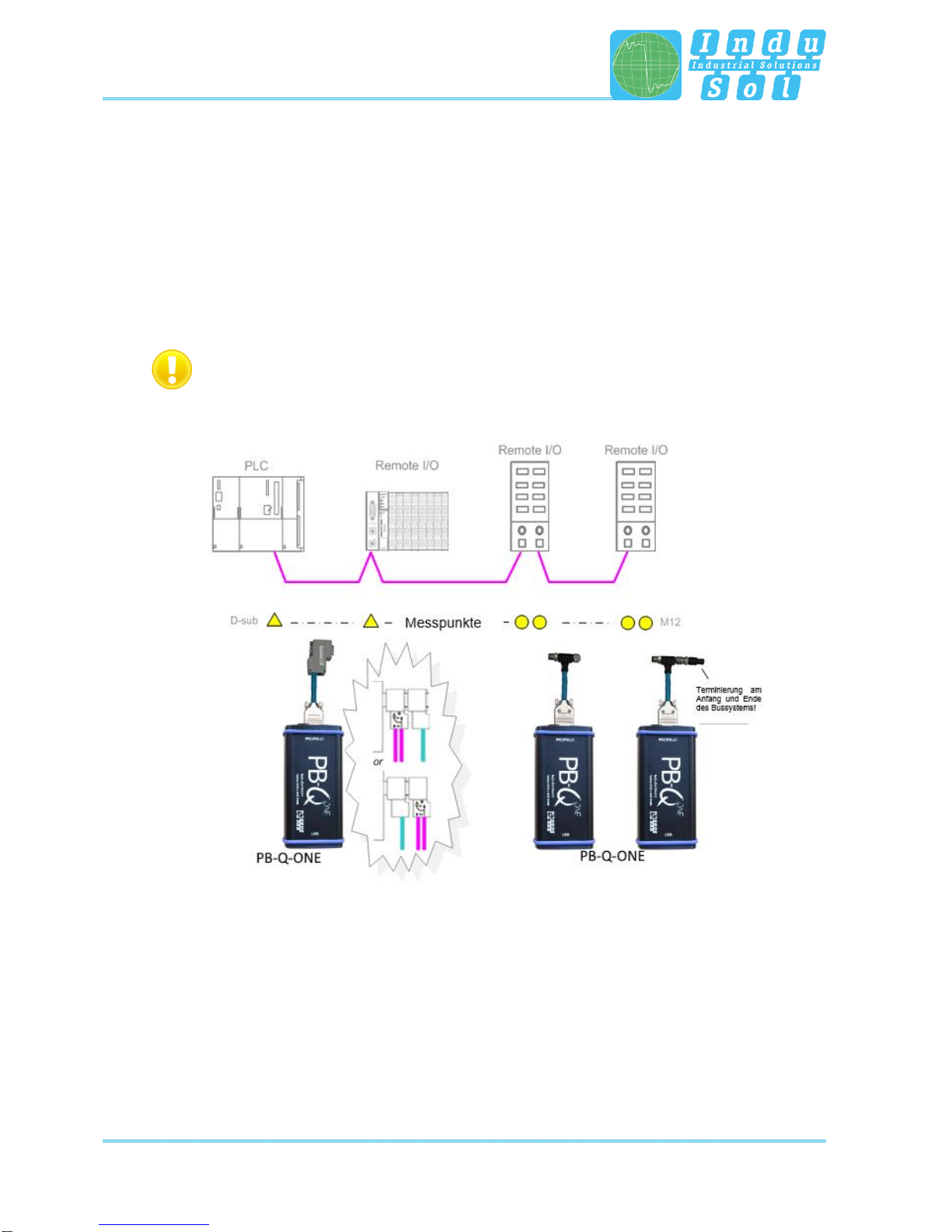

3.2.2 Measurements on the running system

No intervention into the master system is possible on running systems, as this would automatically lead to

bus faults and loss of production. The PB-QONE can only be connected and run at the existing measuring

points (e.g. PB connector with service jack on the CPU). In order to be able to perform a status quo analysis

under production conditions on all existing segment ends, this should be considered during the system

planning stage. If the use of appropriate connectors is not possible, then measuring adapters (e.g. PBMA

–IP20, PBMX –IP67) can be used.

3.2.2.1 Connection type D-Sub connector with service jack

If D-Sub connectors with an additional service jack are installed on all bus devices, then the PB-QONE is

simply connected there as shown in the image.

Figure 4: Measuring points via the service jack

Connection to the PROFIBUS system

PB-QONE - User Manual 14

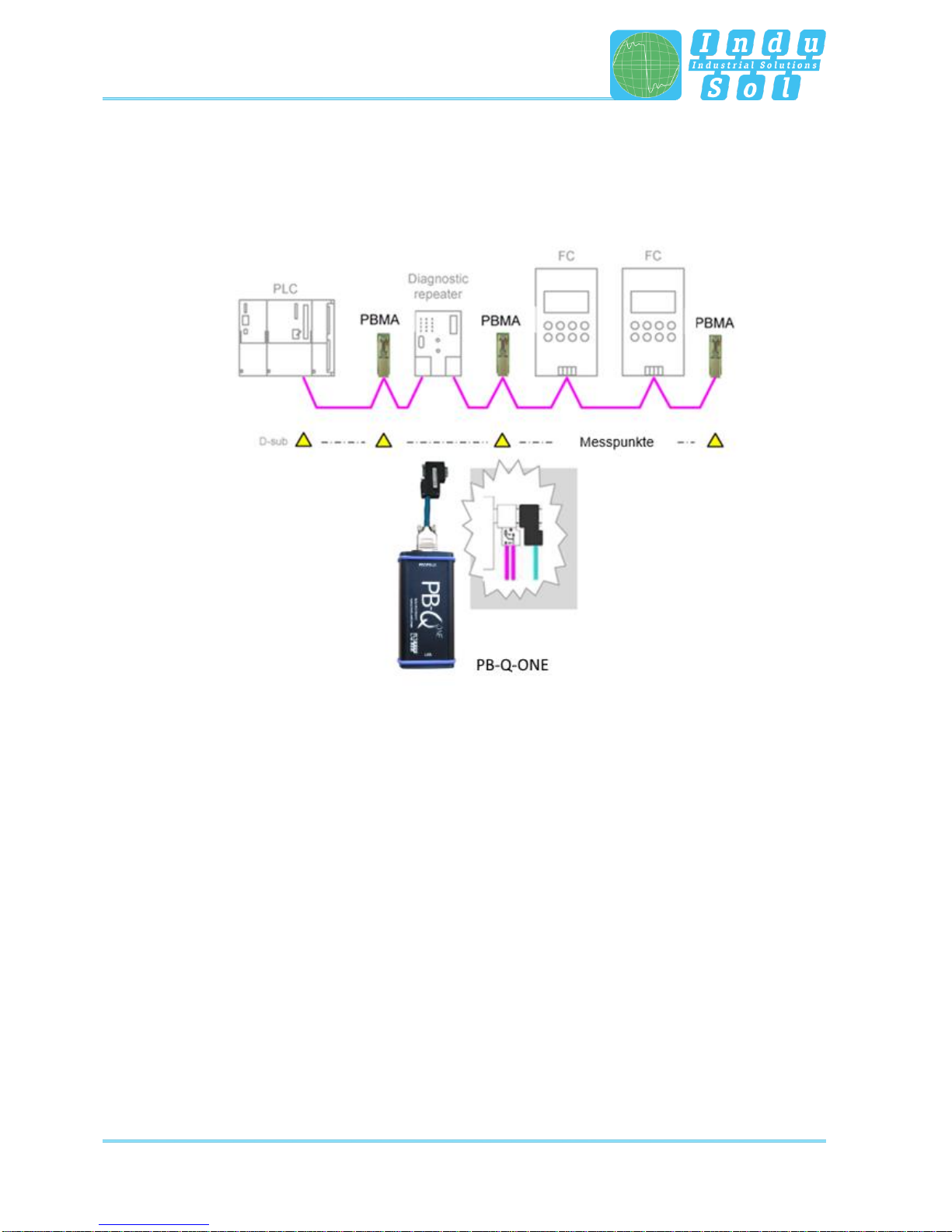

3.2.2.2 Connection via permanently installed measuring point PBMA (IP20)

For measurement during running operation, Profibus measuring adapters (PBMA) have been permanently

integrated into the system.

Figure 5: Example of permanently installed measuring points (PBMA)

Connection to the PROFIBUS system

PB-QONE - User Manual 15

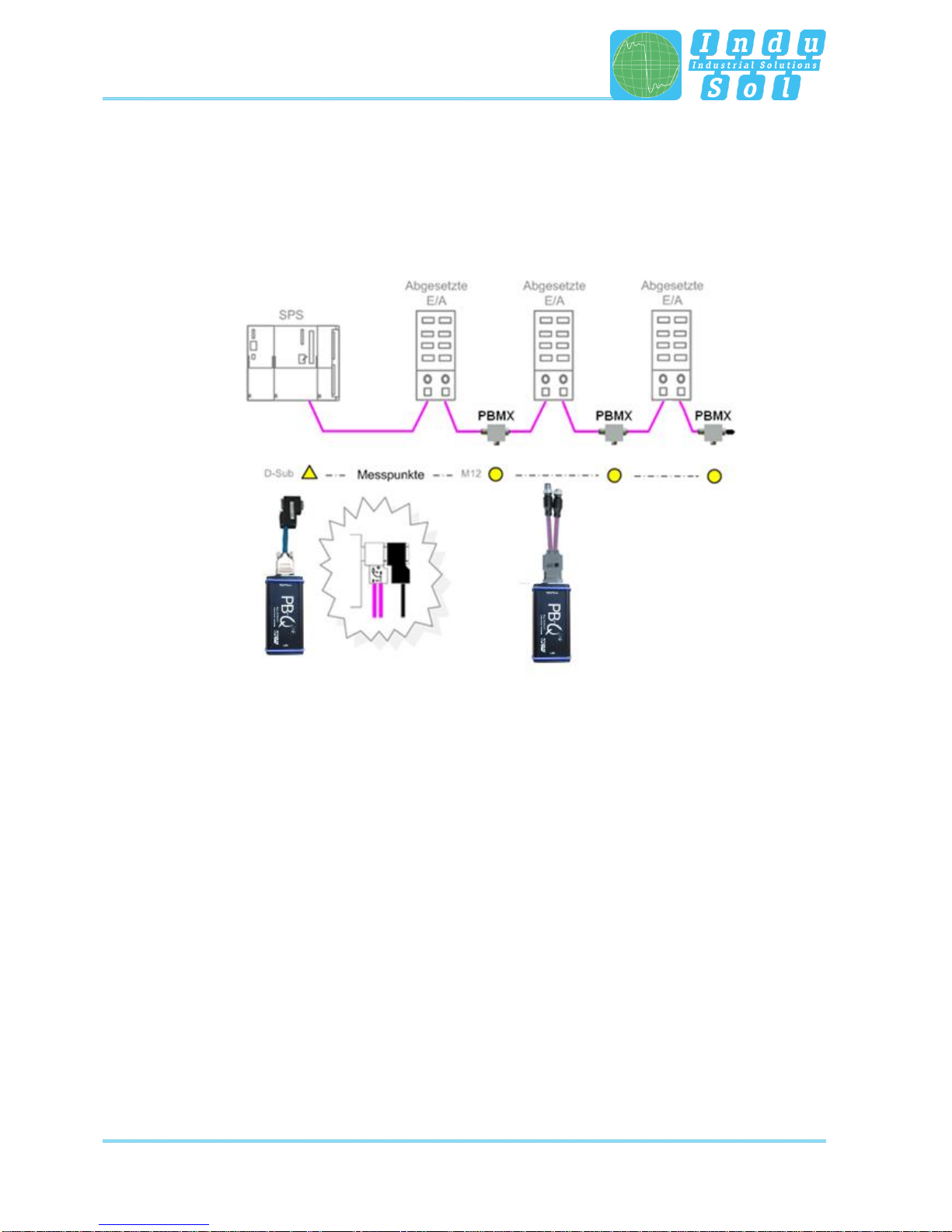

3.2.2.3 Connection type M12 (IP67)

For measurement during running operation under IP67 conditions, Profibus measuring adapters (PBMX)

have been permanently integrated into the system. An M12 adapter (optional) is required for connecting

measuring devices.

Figure 6: Example of permanently installed IP 67 measuring points (PBMX)

Perform and document measurement

PB-QONE - User Manual 16

4 Perform and document measurement

4.1 General information

All measurements taken with PB-QONE and the respective entries are summarized in a measurement file

(*.pbn) for storage and later retrieval. For a structured analysis of several systems, it is therefore useful to

create a separate measurement file for each master system. It can be used as a basis for additional

measurements later to provide an easy way of performing before-after comparisons.

The system language can be selected between English and German under “Settings”.

In “GSD management”, the *.gsd files of each Profibus device are stored in the system. This file defines

the characteristic communication features of the relevant slave. The PB-QONE uses this information for

detecting the device type as well as manufacturer-specific information.

Figure 7: File management

Perform and document measurement

PB-QONE - User Manual 17

4.2 Network

4.2.1 Topology

After connecting the PB-QONE to the computer via USB, connecting the measuring adapter to the Profibus

system, and starting the software, the network overview is displayed with the detected baud rate

(Figure 8).

Figure 8: Home screen

The system designation can be entered in the field “Network name”. The function “Scan devices” lists the

detected devices in ascending order of address (Figure 9). This is the basis for future measurement steps.

Figure 9: Device list

Perform and document measurement

PB-QONE - User Manual 18

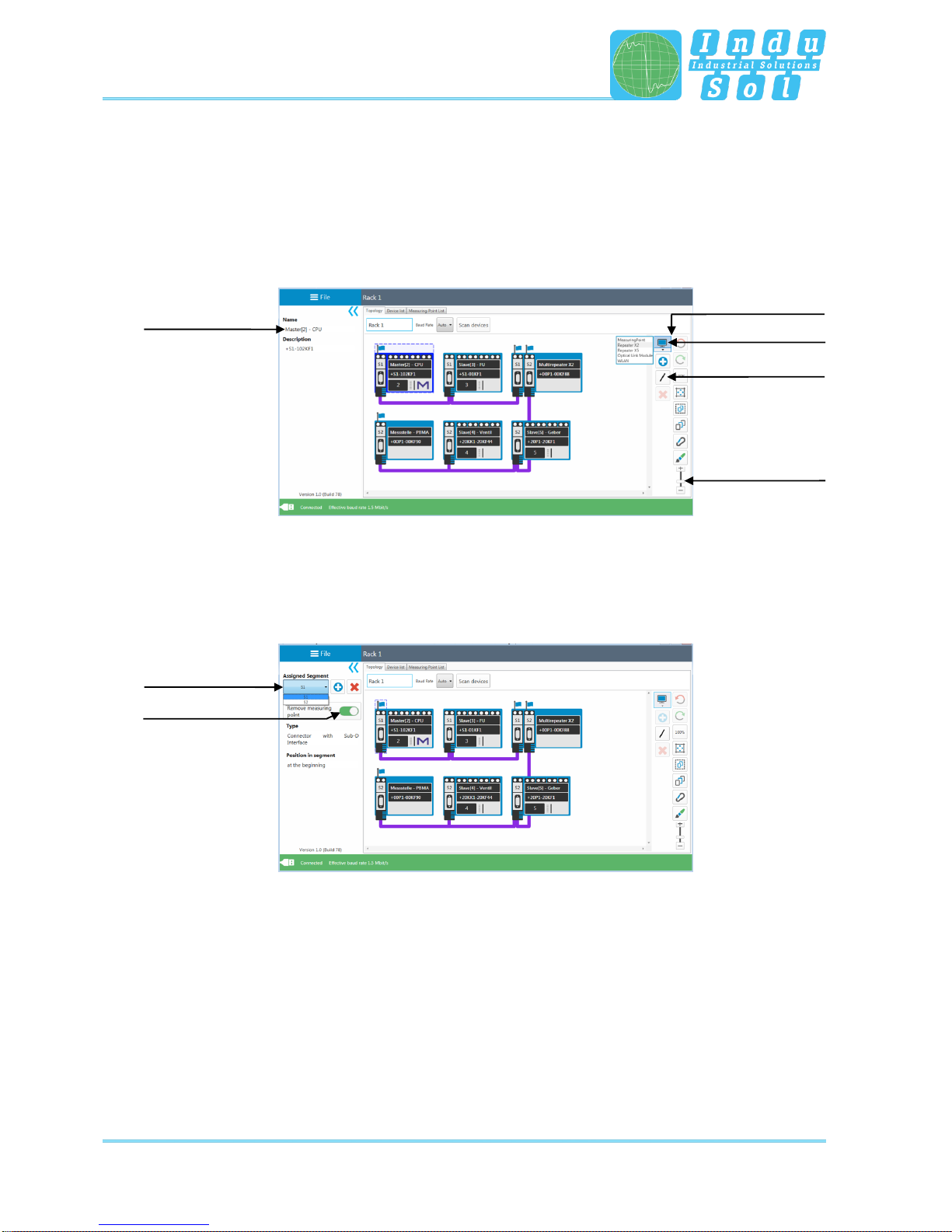

The topology plan is a prerequisite for structured measurements and creating a detailed system description.

In the topology overview, a complete representation of the actual system structure with device descriptions,

segmentation and measuring points can be realised. Selecting individual devices enables more detailed

naming (e.g. with device type, equipment identifier). The tools in the drop-down menu enable the integration

of additional modules without a dedicated Profibus address (measuring points, repeaters, optical fibre

converters, wireless converters) and the connection of the overall system (Figure 10).

Figure 10: Topology

Segment and measuring points are assigned by selecting the relevant connection points of the end devices.

After defining the measuring point and allocation to a segment, the relevant segment number is

automatically assigned to all modules connected in this segment (Figure 11).

Figure 11: Assign measuring points

Device selection

Create connections

Editing the

highlighted device

Drop-down

menu

Zoom

Segment selection

Assign measuring

point

Perform and document measurement

PB-QONE - User Manual 19

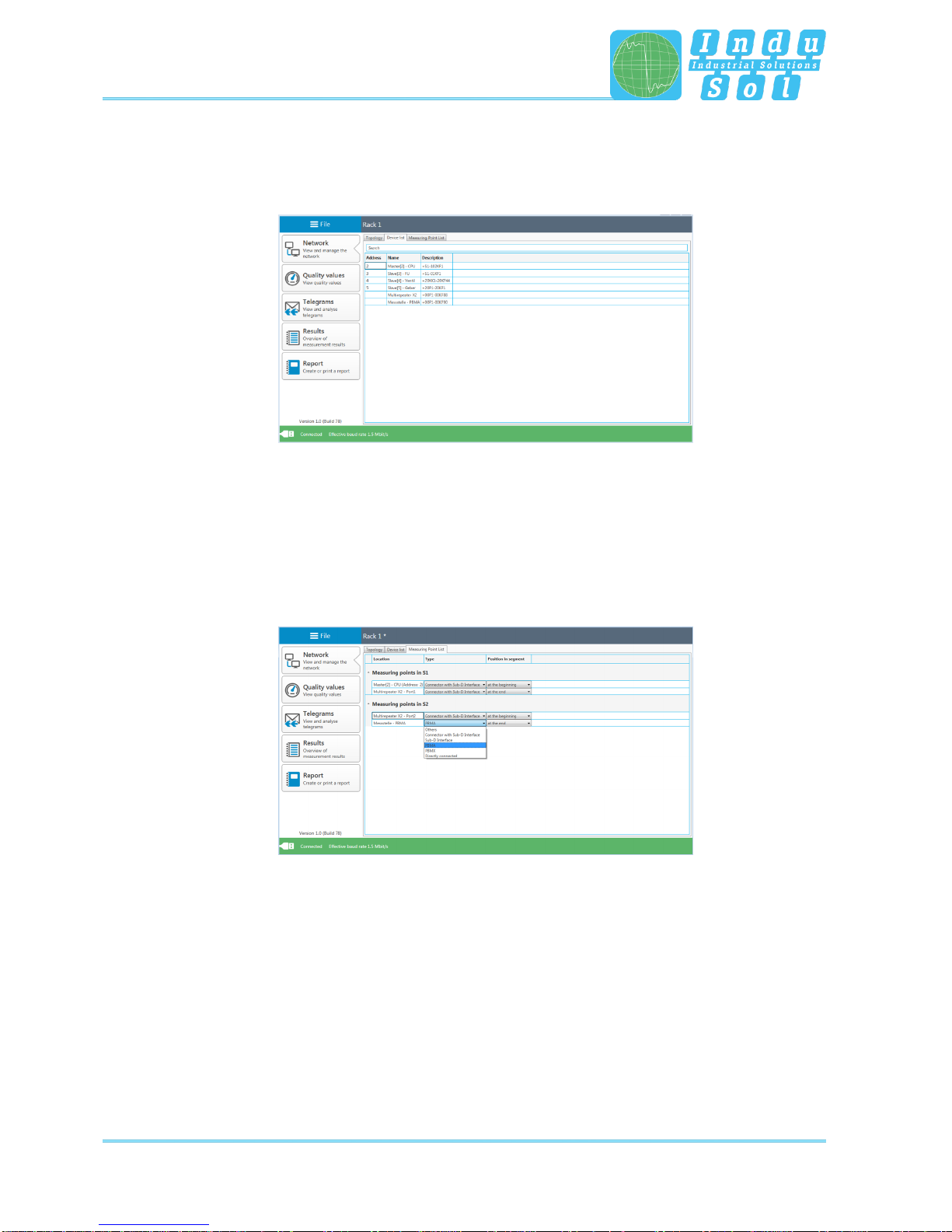

4.2.2 Device list

The “Device list” sub-item provides a complete overview of all topology entries in table form. Inputs as well

as search and sorting functions can be performed here.

Figure 12: Device list

4.2.3 List of measuring points

The list of measuring points is a segment-specific overview of all measuring points in the system. The

entries in the “Topology” tab are the starting point. For completion and better definition of the list, the

measuring point type (e.g. connector with Sub-D interface, PBMA) as well as the position on the segment

(at the beginning or end) can be assigned via the relevant drop-down menu.

Figure 13: List of measuring points

Perform and document measurement

PB-QONE - User Manual 20

4.3 Quality values

4.3.1 Standard measurement

The quality values represent the main criterion for evaluating the physical communication conditions. For a

complete system analysis, measurements need to be performed in all segments on both ends. The device

addresses determined by the “Scan devices” function serve as a reference.

Figure 14: Quality values

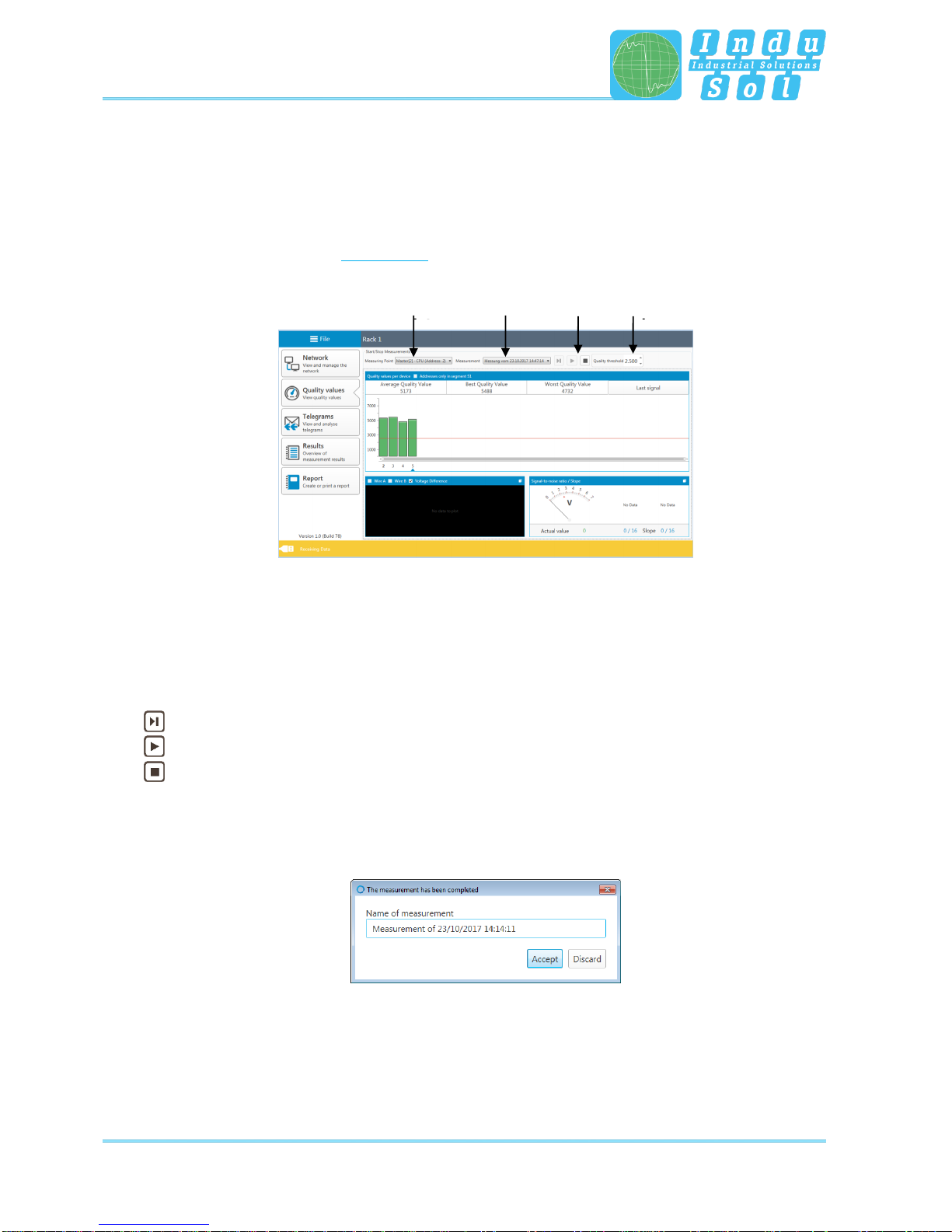

Select the measuring point before starting the measurement. Finally, press the relevant start button to

decide whether to perform a single or a continuous measurement. Clicking on the stop button terminates

these functions and displays the results of the quality values for the overall system. The icons used have

the following meaning:

Start new single measurement (single cycle with all device addresses)

Start new continuous measurement (continuous measurement of all devices)

Stop measurement (stops the current measurement)

After completing the measurement, the system automatically outputs a file name suggestion with a time

stamp. You may change the name or store the data under the default name (Figure 15). This makes it

possible to recall all measurements for the relevant measuring points later.

Figure 15: Info measurement finished

Selection

Measuring

point

Selection

Measurement

Start/

Stop

Setting

Threshold

value

Table of contents

Popular Test Equipment manuals by other brands

System Sensor

System Sensor RTS151 Installation and maintenance instructions

Biuged

Biuged BGD 527 instruction manual

Midtronics

Midtronics Celltron ULTRA instruction manual

Woodsonix

Woodsonix SB800U Operating Guide and Technical Information

Fluke

Fluke 719 Series user manual

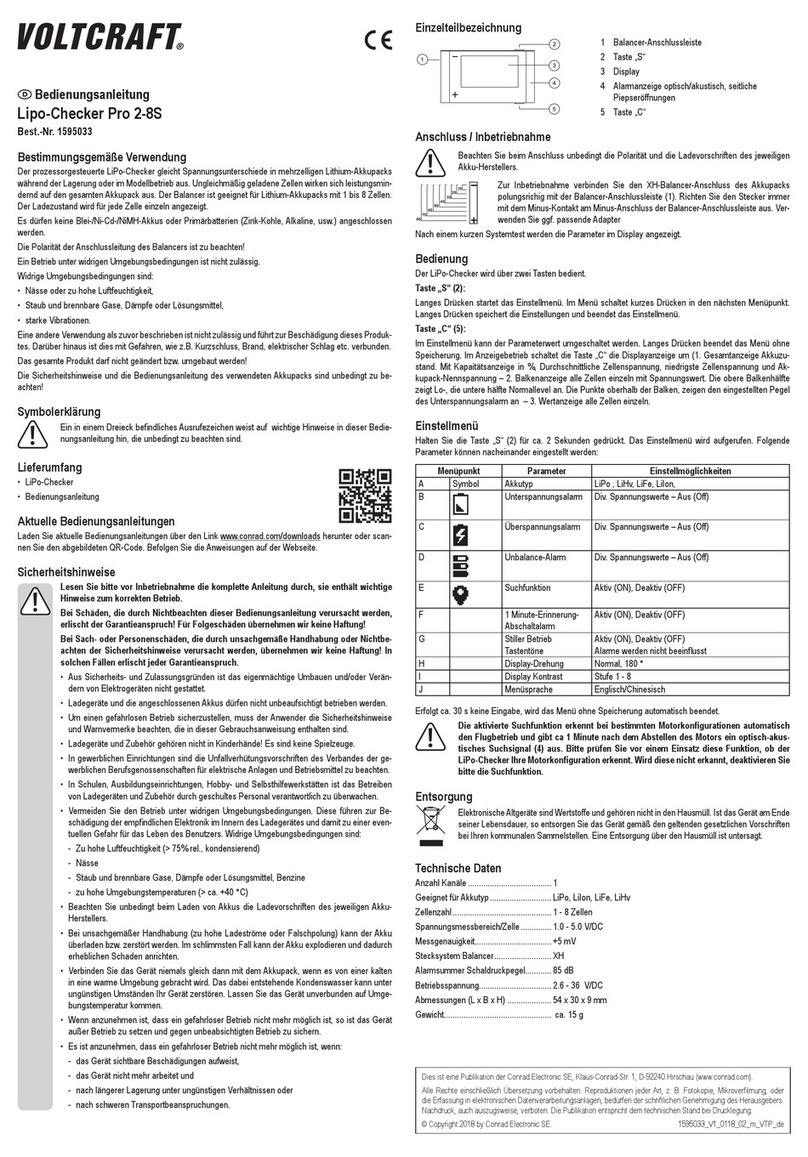

VOLTCRAFT

VOLTCRAFT LiPo Checker Pro 2-8S operating instructions