Du line

®

Fieldbus Installationbus

2Specifications are subject to change without notice (12.12.2008)

Dupline®®is a registered trademark. A product of the CARLO GAVAZZI Group

The Configurator has two cable slots.

One slot (RJ12 plug) for programming

the modules and the second slot (Jack

plug) is for testing /simulating directly

on the Dupline®bus.

There are two modes of operation for

the Carpark Configuration unit:

1. Configuration mode and

2. GTU mode.

In Configuration mode the unit can set

up the Dupline®Carpark Monitor

GP3482 9091 724 module or the

Dupline®Carpark Sensor GP6220

22xx 724 modules.

In GTU mode the unit can monitor the

Carpark units on the Dupline®bus.

Pressing the ”Read/ On” button powers

on the unit in either Configuration

mode or the GTU mode.

The modes are entered automatically

according to the connection used. If

the RJ connection is used, the Config-

uration mode will be entered. If the

jack connector is used, the GTU mode

will be entered.

When the Configurator is in GTU

mode, the tactile key “0 / 9” has the

function as “Mode/Enter”.

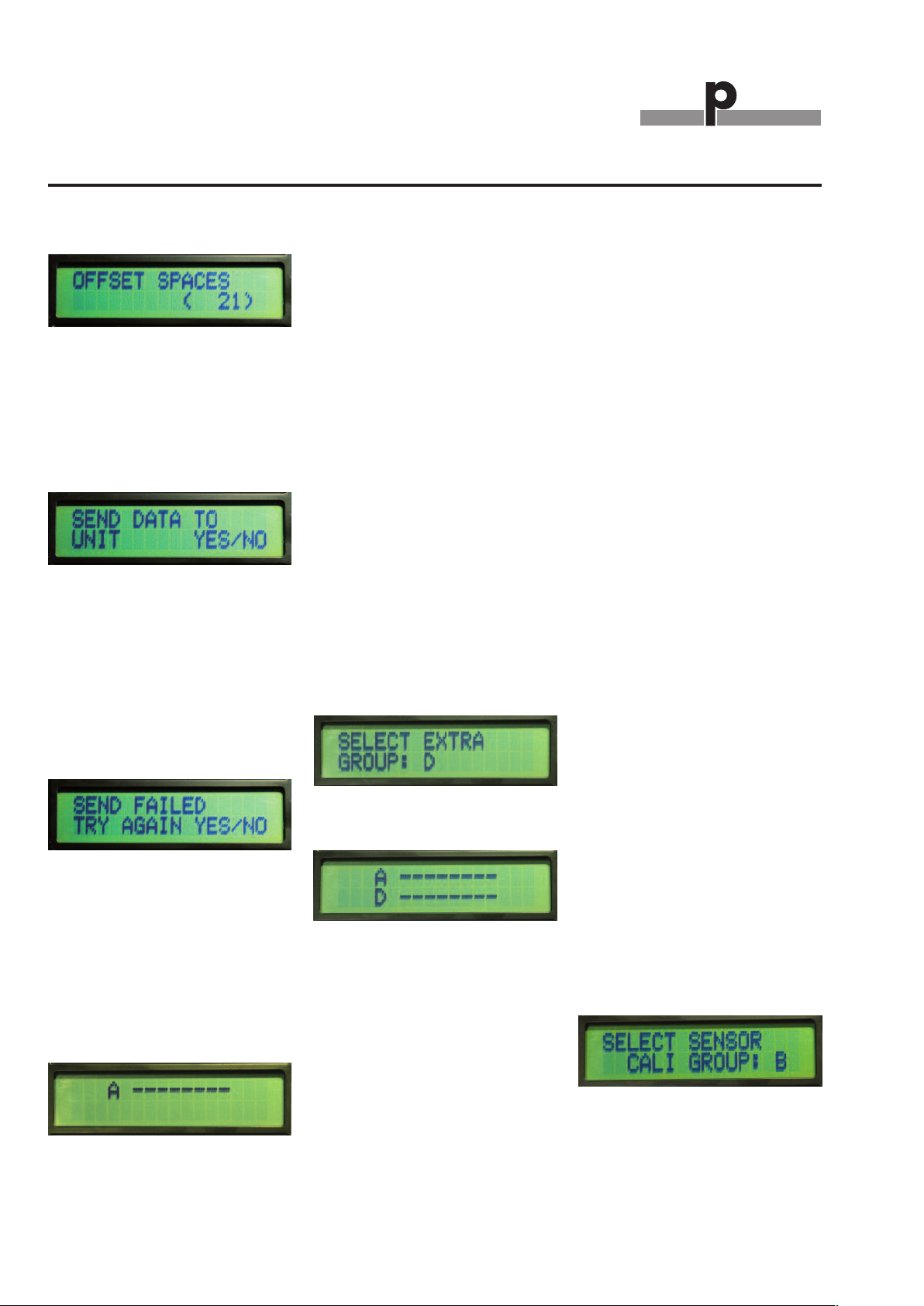

Explanat on of the symbols n the

d splay:

Marks an active channel

Marks an inactive channel

Indicate the use of a “Lane Detec-

tion Sensor”

Indicate the use of a “Calibration

address”

When the button 1 in a given group is

pushed for more than 1sec. the entire

group is activated.

Activated channels in a group

Fig.1

When a selection has to be made the

choices are marked as or

The current status/ selection from pre-

vious configuration is shown with

active notation or

Conf gurat on mode:

When connected to a Carpark sensor

or Carpark monitor through the RJ12

plug, Configuration mode is enabled.

When activating the unit, the text

“Configurator mode selected!” is

shown shortly in the display, followed

by the text “Config Unit begin?” When

pressing the “YES” button, the Config-

urator will start reading the connected

unit; “Reading Configuration” is shown

in the display while reading is in

progress.

If a Carpark sensor is connected, the

user can in “Mode selection” select

between “Normal” mode or “Lane”

mode.

Configuration of a sensor

Fig. 2

Normal mode: Standard sensor mode

detects the presence of a Car in the

parking space and light the red LED

and sends a signal out on the L1 bus.

When the parking space is empty the

LED will change to green and also

send a signal out on the L1 bus.

Lane mode: The sensor is placed in

the ceiling above the Lane and detects

the car before it enters into the parking

area. The Carpark system will count

down the total amount of free places

because of the moving Car, and show

the reduced amount on the monitor.

This is to prevent to many moving

Cars in a specific Carpark area.

It is possible to see and change the

status and calibration channel for the

connected sensor.

See/Change status and calibration for

sensors

Fig. 3

If a monitor is selected, the user can in

“Mode selection” select between

“Master” mode or “Slave” mode.

Configuration of master/slave

Fig. 4

Slave mode:

A slave monitor is connected directly

to the sensors. Each slave monitor can

handle up to 127 sensors. The bus

where the sensors are connected is

named the L1 bus. The communica-

tion between the Slave monitors and

the Master monitor is named the L2

bus.

The maximum ID number is 480. See

Fig. 5. It means that it is possible to

install 480 L1 busses in a system.

In “Slave” mode the monitor can oper-

ate either in “Normal” mode or “Roof”

mode. See Fig. 6.

It is possible to change/see the “cali-

bration” address for the specific slave.

The calibration address in the Configu-

rator should be the same as the cali-

bration address for the sensors. See

fig.3 and 7.

Device ID for Slave mode

Fig. 5

Mode selection for Slave mode

Fig. 6

Calibration in Slave mode

Fig. 7

In “Normal operation Mode” the user

must know if a “Lane Detector Sensor”

is used on the L1 bus. If the user does

Mode of Operation

GP73800080