ProFire PF2100 User manual

PF2100 USER MANUAL

For Firmware E1.8.217 Rev. 1.0

TABLE OF CONTENTS

PF2100 MANUAL For Firmware E1.8.217 Rev. 1.0

1 INTRODUCTION

1.1 Important Safety Information

1.2 HW & FW Versioning

1.3 Approvals

1.4 Available Models

1.5 Included Components

1.6 Common Applications & Optional Hardware

1.7 System Diagram

1.8 Terminal Card Descriptions

2 INSTALLATION

2.1 Installation Warnings

2.2 Mounting Considerations

2.3 Terminal Card Diagram

2.4 Wiring

3 USER INTERFACE & SETTINGS

3.1 User Interface

3.2 Menu Navigation

3.3 Menu Map

3.4 Initial System Settings

3.5 Optional Settings

3.6 System Operation

4 SYSTEM BEHAVIOR

4.1 System Behavior

4.2 Process Control

4.3 Contact Behavior

5 EXPANSION CARDS

5.1 4-20mA Expansion Card

5.2 Modbus Expansion Card

6 TROUBLESHOOTING

6.1 Common Issues & Solutions

6.2 Shutdown Messages

6.3 Alarm Codes

6.4 Warning Messages

6.5 Flame Detection Troubleshooting Guide

6.6 Thermocouple Troubleshooting Guide

APPENDICES

A PID Tuning Procedure

B Field Calibration

C Resetting to Defaults

54

1 | INTRODUCTION

The PF2100 BMS (Burner Management System) is an electronic control and monitoring system designed

for use on a wide array of natural draft burner industrial applications. It provides electronic pilot ignition,

flame detection, temperature control, and remote monitoring. In addition to being an extremely useful

tool, it improves safety by preventing the flame from being lit under unsafe conditions.

1.1 | Important Safety Information

Installation and use must conform to the directions in this manual.

System must be properly connected to earth-ground for effective operation of flame detection circuitry.

Electrical devices connected to the controller must meet certain electrical standards and be within

voltage limits.

Replacement fuses must be ceramic and of correct rating.

Avoid unauthorized replacement of the fuse.

WARNINGS

This equipment is suitable for use in class 1, division 2, groups abcd or non-hazardous locations only.

Do not service unless area is known to be non-hazardous.

Do not open when energized.

EXPLOSION HAZARD

Do not disconnect while circuit is live unless area is known to be non-hazardous or equivalent.

Substitution of components may impair suitability for class 1, division 2.

FOR ANY QUESTIONS PLEASE VISIT OR CALL US.

www.profireenergy.com | 1.855.PRO.FIRE

!

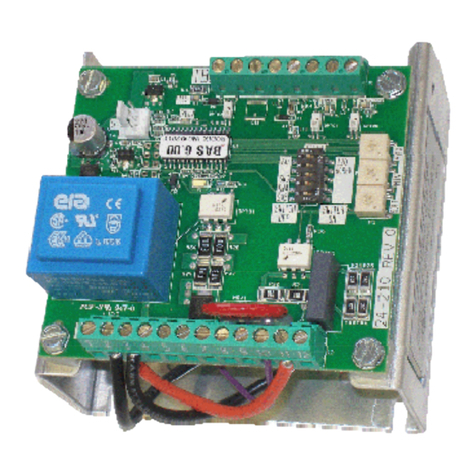

1.2 | HW & FW Versioning

This version of the manual was written for use with PF2100 systems that have the following hardware

and firmware versions.

ITEM HW VERSION FW VERSION

Door Card v1.71 E1.8.217

Terminal Card v2.4.2 E1.8.217

4-20mA Card v3.0 v4.1

Modbus Card v2.0 v4.4

4-20mA Repeater Card v1.2 v4.1

Data Logging Card v2.4 v5.1

System hardware and firmware versions can be found printed on separate labels inside of the enclosure

on each circuit board.

1.3 | Approvals

CSA C22.2 No. 199, 3rd Edition

ANSI Z21.20, 15th Edition

UL 372, 6th Edition

Class I, Zone 2,

AEx, nA IIC, T4, IP66

Ex nA IIC T4 IP66

CSA C22.2 No. 0-M91

CSA C22.2 No. 0.4-04

CSA C22.2 No. 94-91

CSA C22.2 No. 213-M1987

CSA E60079-0:2007

CSA C22.2 No. 60079-15:12

ANSI-ISA-12.12.01-2007

UL No. 60079-0, Ed. 6

UL No. 60079-15, Ed. 4

#248705

1.4 | Available Models

The PF2100 is available in two configurations: Base Model and Internal Coil Model.

The Base Model is for use with externally mounted ignition coils. This is useful when the controller

must be mounted more than 5m (15ft) away from the burner. An external ignition coil can be purchased

separately from Profire for use with this model.

The Internal Coil Model includes a built-in ignition coil and can be used whenever the controller can be

mounted less than 5m (15ft) away from the burner.

Optional expansion cards are also available:

4-20mA Repeater Expansion Card (1PS166)

(PFP- 210BGY) Modbus Expansion Card

(PFP-210BHZ) Data Logging Expansion Card (210BKZ)

76

BASE MODELS

MODEL # MODEL DESCRIPTION

E0000 Base Model

E0400* Base Model with 4-20mA Repeater Expansion Card

E0R00 Base Model with 4-20mA Repeater Expansion Card

E0M00 Base Model with ModBus Expansion Card

E04M0* Base Model with 4-20mA Repeater Expansion Card and Modbus Expansion Card

E04M0 Base Model with 4-20mA Repeater Expansion Card and Modbus Expansion Card

INTERNAL COIL MODELS

MODEL # MODEL DESCRIPTION

EC000 Internal Coil Model

EC400* Internal Coil Model with 4-20mA Repeater Expansion Card

ECR00 Internal Coil Model with 4-20mA Repeater Expansion Card

ECM00 Internal Coil Model with Modbus Expansion Card

EC4M0* Internal Coil Model with 4-20mA Repeater Expansion Card and Modbus Expansion Card

ECRM0 Internal Coil Model with 4-20mA Repeater Expansion Card and Modbus Expansion Card

*Discontinued model

1.5 | Included Components

CODE DESCRIPTION E0000 E0400 E0M00 E04M0 EC000 EC400 ECM00 EC4M0

A PF2100 • • • • • • • •

B Mounting Brackets & Screws • • • • • • • •

C Installation Guide • • • • • • • •

D Internal Coil • • • •

E Ferrules (2) • • • •

F Straight Silicone Boots (2) • • • •

G Ignition Cable (20ft) • • • •

H 4-20mA Repeater Expansion Card • • • •

I Modbus Expansion Card • • • •

EXPANSION CARDS

F

A

E

I

G

B

D

H

C

GENERAL FEATURES

Designed for use with natural draft fire tube heaters

Meets or exceeds all relevant codes and standards

Easy installation with clearly marked component I/O

Easily accessible removable terminal connections

Rapid 3 second shut-down on flame-out

Electronic spark ignition

Low-power operating mode to accommodate solar panel or TEG applications

Auto-relight or manual operation

Transient protected and fail-safe circuits

All solid state circuit components

CSA compliant for Class I, Division 2 locations

Certified for use on B.149 compliant valve trains

Optional internal or external ignition coil

INPUTS & OUTPUTS

Digital inputs for safety interlock device connections (6)

Digital outputs (5)

4-20mA output (1)

Flame-rod input (1)

Thermocouple inputs (3)

TECHNICAL SPECIFICATIONS

TEMPERATURE RATINGS MIN MAX

Operating Range -40˚C (-40˚F) +55˚C (+130˚F)

Storage Range -40˚C (-40˚F) +80˚C (176˚F)

98

POWER CONSUMPTION 12V 24V

Controller only, display ON 2.6 W 2.9 W

Controller only, display OFF 1.1 W 1.2 W

Maximum Total Current Draw 5A 5A

Maximum Valve Current Draw 2A 2A

Ignition Voltage (Internal Coil) up to 20 kV up to 40 kV

TERMINAL BLOCKS VALUE

Maximum Wire Gauge 12 AWG

STATUS CONTACT VALUE

Type Dry

MAX Voltage 40VDC

MAX Continuous Current 250mA

Impedance (When Closed) 15Ω

PHYSICAL DIMENSIONS VALUE

Width 30.9 cm (12.15 in)

Height 23.4 cm (9.23 in)

Depth 13.4 cm (5.28 in)

WEIGHT VALUE

E0000 Model 4.0lbs / 1.8kg

E0400 Model 4.5lbs / 2.0kg

E0M00 Model 4.5lbs / 2.0kg

EC000 Model 6.0lbs / 2.6kg

E0R00 Model 4.5lbs / 2.0kg

FUSES VALUE

Main Fuse Rating 5A / 250 V Ceramic, Fast Blow

Status Contact Fuse Rating 250mA / 125V Ceramic, Fast Blow

Replacement Main Fuse LittelFuse 0314005.HXP

Replacement Status Contact Fuse LittelFuse 0453.250 or 0451.250

1.6 | Common Applications & Optional Hardware

Below are examples of some of the many applications that the PF2100 can be used in.

Line Heater

Dehydrator

Combustor

Tank Heater

Separator

Treater

Gas Production Unit

Amine Reboiler

Thermal Oxidizer

Depending on your installation type, other components may be required. Commonly requested hardware

includes:

Mounting Hardware

Channel Bar

Conduit Ports

Liquid Tight Ports

Rubber Grommets

Wire

Ignition Wire

Thermocouple Wire

Rods And Connectors

Kanthal Ignition Rods (Various Lengths)

Valves

DC Solenoids

Safety Valves with Proof of Closure

Proportional Valves

Thermocouples

Single, Type K

Dual Element, Type K

Pilot Assembly

Nozzles

Brackets

Mixers

Orifices

Autonomy

Batteries

Solar Chargers

Solar Panels

Accessories

Modbus Expansion Cards

4-20mA Repeater Expansion Cards

Data Logging Expansion Cards

External Ignition Coil

Please contact Profire Sales for further information.

1.7 | System Diagram

1110

(door to terminal)

F2

SP

AREFUSE

Status+

Status-

Start+

Start-

ESD+

ESD-

Proofof Closure+

Proofof Closure-

HighPressure+

HighPressure-

LowPressure+

LowPressure-

Level+

Level-

HighTemp_TC+ (Yellow)

HighTemp_TC- (Red)

Process_TC+(Yellow)

Process_TC-(Red)

AUX_TC+(Yellow)

AUX_TC-(Red)

HighFire+/Main+

4-20mAOut-

4-20mAOut+

EarthGround

Common

12/24VDC

Coil-

Coil+

Ion+

Ion-

HighFire- / Main-

LowFire+

LowFire-

Pilot+

Pilot-

1

2

3

6

5

4

XXXXXX-XXXXX

XXX-2.3.0

XXXXXX

SPAREFUSE

RESET

E

v1.8.005

4-20mA REPEATER CARD

INTERNAL COIL

MODBUS or DATALOGGING CARD

RIBBON CABLE

FW VERSION LABEL

KEYPAD FLEX CABLE

HW SERIAL / VERSION LABEL

TERMINAL CARD

DOOR CARD

(optional)

(optional)

(optional)

DOOR & KEYPAD

SERIAL / MODEL LABEL

ENCLOSURE

1.8 | Terminal Card Descriptions

This table provides connection details and a brief description of each terminal.

TERMINAL EXPECTED CONNECTIONS DESCRIPTION

12/24VDC Input power from a DC source Input power 10VDC- 28VDC, 5A MAX

Common Ground back to DC source Internally connected to EGND

EGND Earth Ground

4-20mA Out + Proportional Valve positive terminal or PLC

4-20mA positive input

This output can be used for either Proportional

Valve Control or echoing the Process

Temperature to a PLC.

A resistance of 120Ω to 250Ω is expected.

4-20mA Out - Ground return for the 4-20mA output

HighTemp_TC + (YELLOW) High Temp Thermocouple positive lead “TYPE K” thermocouple must be connected

between the “+” and “-” terminals and must

not be electrically connected to ground.

An uninterrupted connection using “TYPE K”

thermocouple wire is required for an accurate

reading.

HighTemp_TC - (RED) High Temp Thermocouple negative lead

Process_TC + (YELLOW) Process Thermocouple positive lead

Process_TC - (RED) Process Thermocouple negative lead

AUX_TC + (YELLOW) Aux Thermocouple positive lead

AUX_TC - (RED) Aux Thermocouple negative lead

TERMINAL EXPECTED CONNECTIONS DESCRIPTION

High Fire/Main + High Fire / Main Valve positive terminal Solenoid valves must be connected between

the “+” and “-” terminals. The negative

terminal is not directly connected to ground so

a common return wire for the High Fire, Low

Fire and Pilot valves cannot be used.

Maximum continuous current is 2A. If Low

Power mode is enabled, a peak load of 4A is

permitted.

High Fire/Main - High Fire / Main Valve negative terminal. Do not

connect to ground.

Low Fire + Low Fire Valve positive terminal

Low Fire - Low Fire Valve negative terminal. Do not connect

to ground.

Pilot + Pilot Valve positve terminal

Pilot - Pilot Valve negative terminal. Do not connect to

ground.

Ion + Flame Detection positive input. Connect to flame

rod or external coil Ion terminal (depending on

configuration)

A Kanthal rod should be placed directly in

the pilot flame and connected to this input.

The pilot assembly must be grounded for the

flame detection to function properly. Input

is protected from high voltage and can be

connected in series with the high voltage

terminals of an external ignition coil, allowing

a single flame rod to be used for both ignition

and flame detection.

A 65VAC signal is applied to the flame rod.The

source impedance is very high so there is no

danger of sparking.

Ion - Flame Detection negative input. Connect to

ground screw on pilot assembly or burner

housing.

Ground return for flame detection.

Coil + Driver for the low voltage primary of the ignition

coil.

The primary of the ignition coil should be

connected to this terminal. The 12/24VDC

input power will be applied for 1 ms and

turned off for 50 ms while sparking.

This output is protected by a 250mA thermal

fuse.

Coil - Ground return for the ignition coil.

1312

TERMINAL EXPECTED CONNECTIONS DESCRIPTION

Status + Connect to PLC positive input contact or other

alarm device.

The status “+” and “-” contacts will be closed

when the system is running and opened when

the system is shutdown. Dry contact output to

indicate system status to an external device.

ie. PLC. Note that the contacts are DC only

and are not internally connected to power or

ground.

40VDC, 250mA, 15Ω

Status - Connect to PLC negative input contact or other

alarm device.

Start + Remote start input from an external device. ie.

PLC.

Dry contact switch is expected.The input

is internally pulled up to 9VDC via a 3.75kΩ

resistance. Jumper “+” and “-” if not used.

All input contacts can use a single common

ground return if desired.

Start - Ground

ESD + External Shutdown input, typically plant ESD loop.

ESD - Ground

Proof of Closure + Proof of Closure from main valve(s).

Proof of Closure - Ground

High Pressure + Input from a mechanical High Pressure switch.

High Pressure - Ground

Low Pressure + Input from a mechanical Low Pressure switch.

Low Pressure - Ground

Level + Input from a float-switch mounted in the bath. Dry contact switch is expected.The input

is internally pulled up to 9VDC via a 3.75kΩ

resistance. Jumper “+” and “-” if not used.

All input contacts can use a single common

ground return if desired.

Level - Ground

2 | INSTALLATION

The PF2100 can be used with many different systems. Before you begin installation, identify which

system the BMS will be used to control. In addition to this document, Profire has an Installation Guide

and several installation specificWhitepapers available describing common scenarios. These can be found

at www.profireenergy.com.

The steps provided here are general and can help you to identify questions that need to be answered to

complete the installation process. If you are new to the PF2100, you should read this whole section and

follow the instructions closely.

Steps

1. Review all installation warnings

2. Install the system

3. Connect the required wiring including Power, Valves,

Thermocouples, and Ignition Coil / Flame Detection wiring

4. Connect any additional wiring as required for your specific

application. Commonly used lines include the Status Contact,

Dry Contact Inputs, 4-20mA Temperature Output, and

Expansion Cards

To know which options are required, you should consult the engineer or technician who designed the

site. You should also be familiar with the local electrical and gas code for the site.

2.1 | Installation Warnings !

Before installing the PF2100, please review the following list of warnings. Failure to consider these

warnings may result in death, electrocution, property damage, product damage, and/or government fines.

1. The PF2100 is not intended for use on burners greater than

12.5 MMBtuh. It is against code in many locations.

2. To use the PF2100 on burners greater than 5 MMBtuh, it is

recommended that the low fire feature with two safety shutoff

valves be used. At least one of these valves should use Proof

of Closure. This is required in many locations.

3. Failure to properly ground the pilot assembly back to the

PF2100’s Ion terminal may result in accidental electrocution,

product damage, or simply failure to ignite the pilot.

4. The PF2100 generates 20kV - 40kV at its high voltage output

terminal which can cause cardiac arrest. Do not touch or

place any object near the ignition coil’s high voltage terminal

or connected ignition wire while the product is operating.

Even without making physical contact with the terminal, it is

possible to draw a spark from several inches away, especially

if the pilot bracket is not properly grounded.

5. Never leave the PF2100 running unattended without the

door screws securely tightened down.This is to prevent

moisture from getting inside of the enclosure and damaging

1514

the product. Moisture damage to the internal circuitry is not

covered by the product warranty if the door has been left

open.

6. All conduit ports drilled into the PF2100 enclosure must be

CSA/NEMA Type 4 rated and be sealed in order to maintain the

Type 4 rating.

2.2 | Mounting Considerations

The PF2100 is typically mounted near the burner it is controlling or in another location that is both safe

and easily accessible. The recommended mounting height is 1.5m (5ft) above the ground or platform for

the comfort of the operators.

PLEASE CONSIDER THE FOLLOWINGWHEN CHOOSING AN INSTALL LOCATION:

Accessability

The system should be easily accessible so that the operator can change settings and observe

its operation. It is preferable that the system be mounted facing away from the sun to make

it easier to read the display and LED indicators on the front panel.

Security

In some situations, it may be desirable to mount the system in a location not accessible to

the general public to prevent accidental or intentional tampering.

Operator Safety

Avoid placing the system in locations that are dangerous to the operator. Examine the area

surrounding the potential installation site and look for such things as nearby open flames or

close proximity to tanks that might overflow, and other harmful situations.

Performance

Choose a mounting location that allows ground and ignition wires to be kept as short as

possible. This ensures the best ignition and flame detection.

Product Protection

To protect the system from being damaged, it should not be mounted:

1. Where chemicals may splatter or bubble over from a tank onto

the system. Chemicals on the keypad may interfere with an

operator’s ability to control the product or view the display and

LED indicators.

2. Directly to a heated tank where excessive heat may damage

the product. Refer to the maximum operating temperature

listed in this document.

3. On anything that may tip over due to wind or snow. Some

examples include poles not set properly into the ground or

tripods not secured with anchor bolts or guy wires.

4. In locations that may be prone to flooding.

CONDUIT AND CABLE CONSIDERATIONS

1 8 5 5 PR O FI R E

NHAZARD

ECTWHILECIRCUITISLIVE UNLESSAREAISKNOWN

HAZARDOUSOREQUIVALENT

RTISSEMENT:RISQUED’EXPLOSION

NEPASDEBRANCHERTANTQUELE CIRCUIT EST SOUSTENSION, A

MOUNSQU’ILNES’AGISSED’UNEMPLACEMENT NON DANGEREAUX

WARNING:EXPLOSIONHAZARD

SUBSTITUTIONOFCOMPONENTSMAYIMPAIR SUITABILITY FOR

CLASSI,DIVISION2.

AVERTISSEMENT:RISQUED’EXPLOSION

LASUBSTITUTIONDECOMPOSANTS PEUT RENDURE CEMATERIEL

INACCEPTABLEPOURLESEMPLACEMENTSDECLASSE I, DIVISION 2

UCTIVE

EINCLASSI, DIVISION 2,

DOUSLOCATIONSONLY.

1101-009-E0000Rev3.0

FLAME

MC#248705

1 85 5 PRO F I R E

WARNING:EXPLOSIONHAZARD

DONOTDISCONNECTWHILE CIRCUIT IS LIVE UNLESS AREA ISKNOWN

TOBENON-HAZARDOUS OR EQUIVALENT

AVERTISSEMENT:RISQUED’EXPLOSION

NEPASDEBRANCHERTANT QUELE CIRCUITESTSOUS

TENSION,A

MOUNSQU’ILNE S’AGISSED’UN EMPLACEMENT NON DANGEREAUX

WARNING:EXPLOSIONHAZARD

SUBSTITUTIONOFCOMPONENTS MAYIMPAIR SUITABILITY FOR

CLASSI,DIVISION 2.

AVERTISSEMENT:RISQUED’EXPLOSION

LASUBSTITUTIONDE COMPOSANTS PEUT RENDURE CE MATERIEL

INACCEPTABLEPOURLES EMPLACEMENTSDE CLASSE I, DIVISION 2

CSA22.2No. 199-2007

ANSIZ21.20-2007

UL1998-2004

Class1,Div 2, Grp ABCD

IP54

T4A,NEMAType4X

INPUT: 12VDC,2.6WDisplayON

12VDC,1.1WDisplayOFF

24VDC,2.9WDisplayON

24VDC,1.2WDisplayOFF

OUTPUT: 12VDC,5AmaxINDUCTIVE

24VDC,5AmaxINDUCTIVE

AMBIENT: -40˚C- +55˚C

THISEQUIPMENTIS SUITABLE FOR USE IN CLASS I, DIVISION 2,

GROUPSABCDOR NON-HAZARDOUS LOCATIONS ONLY.

1101-009-E0000Rev3.0

SERIALNO.

MODELNO.

1PS21-E0000

DEMO

BURNER

MANAGEMENTSYSTEM

2100

DETERMINE DRILL LOCATIONS

CONDUIT AND CABLES AS REQUIRED

MOUNTING INSTRUCTIONS

1. Remove the included bag of components taped to the

mounting brackets.

2. Attach the two mounting brackets to the back of the PF2100

enclosure using the 4 provided screws.

3. Determine the best location to drill holes in the product

enclosure for the wires to enter. It is recommended that these

holes be drilled on the bottom of the enclosure (as shown).

4. Install grommets or conduit ports as required.

1716

5. Securely mount the enclosure to a pole, structure or building

as indicated by the site engineer or technician.

2.3 | Terminal Card Diagram

F2

SPAREFUSE

Status+

Status-

Start+

Start-

ESD+

ESD-

Proof of Closure+

Proof of Closure-

HighPressure+

HighPressure-

LowPressure+

LowPressure-

Level+

Level-

HighTemp_TC+ (Yellow)

HighTemp_TC- (Red)

Process_TC+ (Yellow)

Process_TC- (Red)

AUX_TC+ (Yellow)

AUX_TC- (Red)

High Fire+ / Main+

4-20mA Out-

4-20mA Out+

Earth Ground

Common

12/24VDC

Coil-

Coil+

Ion+

Ion-

High Fire- / Main-

Low Fire+

Low Fire-

Pilot+

Pilot-

1

2

3

6

5

4

XXXXXX-XXXXX

XXX-2.3.0

XXXXXX

SPAREFUSE

RESET

E

v1.8.005

INTERNAL COIL

IGNITIONTERMINALS

STATUS CONTACT OUTPUT

HW SERIAL / VERSION LABEL

EXPANSION CARD SLOT

FLAME DETECTIONTERMINAL

STATUS CONTACT FUSE

LEVEL DRY CONTACT INPUT

PRESSURE DRY CONTACT INPUTS

MISC. DRY CONTACT INPUTS

4-20mA OUTPUT

FW VERSION LABEL

THERMOCOUPLE INPUTS

MAIN FUSE

SPARE MAIN FUSE

SPARE STATUS CONTACT FUSE

DOOR CARD CONNECTOR

POWERTERMINALS

(optional expansion)

VALVE OUTPUTS

2.4 | Wiring

The wiring precautions in this section are important for all PF2100 installations. Please set up your

installations accordingly.

NOTE: If you have not wired a PF2100 system, please refer to the PF 2100 Install Guide for detailed

wiring instructions. Skipping or performing any steps in the guide incorrectly can result in the PF2100 not

functioning properly.

POWER

The PF2100 can be powered from 12VDC or 24VDC. The maximum current that the PF2100 can safely

handle without blowing the main fuse is 5A. The system on its own draws about 100mA.The rest of the

current is used by additional hardware such as valves. Make sure that you select a power supply that is

rated appropriately for the total amount of current that will be consumed by all devices attached to it.

VALVES

There are four valve control outputs on the PF2100: Pilot, Low Fire, 4-20mA Output, and High Fire/Main.

Ensure that each valve has a separate return wire. Multiple valves sharing common return wires will not

function properly.

Pilot Valve

The Pilot valve is required and must be wired for all installations.

Low Fire Valve

The Low Fire valve may also be required by local code or for proper operation of your

particular application. Low Fire is often used on high Btuh burners (burners that exceed 5

MM Btuh) to establish a draft before opening the High Fire valve. Failure to do this on high

Btuh burners can cause the burner to starve itself of oxygen which puts out the flame.

4-20mA Output

The 4-20mA Output can be used to control a proportional valve designed for a 4-20mA

current loop. Using a proportional valve allows for finer control of the burner’s temperature as

opposed to the 2 or 3 levels possible with normal valves. Typically the 4-20mA Output is used

in conjunction with a normal valve.The 4-20mA Output also supports low fire.

High Fire/Main Valve

The High Fire valve is required and must be wired for all installations. This valve is sometimes

called the Main Valve, especially when Low Fire is not used.

NOTE: It is possible to connect multiple valves to the same control output in parallel or series. If you do

this, be sure that the configuration you are using meets local codes and does not exceed the total current

rating of the PF2100.

NOTE: The negative valve control wires are NOT connected directly to ground. Therefore, you cannot use

a common return wire for all valves.

THERMOCOUPLES

The High Temp and Process thermocouple inputs are mandatory and must be connected to a Dual

Element thermocouple. The Auxiliary thermocouple is only needed when a second process temperature

(such as the outlet temperature on a line heater) must be monitored. Otherwise, the Auxiliary

thermocouple terminals can be left unconnected.

All thermocouples are cold junction compensated. For this reason, it is important to make sure that

Type-k thermocouple wire and connectors are used exclusively.The temperature compensation is done

using an ambient temperature sensor located on the terminal card near the thermocouple terminals.

Process Thermocouple

This thermocouple is normally used on the primary temperature control device. The system

shuts down if an open circuit is detected on this thermocouple. It should be placed in the

same thermowell as the HighTemp thermocouple using a dual element thermocouple.

1918

High Temperature Thermocouple

This thermocouple is used for the high-temp shutdown. The system shuts down if an open

circuit, short-circuit or short-to-ground is detected on this thermocouple. It should be placed

in the same thermowell as the Process thermocouple using a dual element thermocouple.

AUX Thermocouple

This thermocouple is optional and can be enabled in menu 5. It can be used to monitor stack

temperature or to control a secondary process temperature. The system shuts down if an

open circuit is detected and the AUX thermocouple is enabled.

All Thermocouples Must Be:

Isolated from ground

Isolated from power

Type-k thermocouples

Connected with 20 AWG or larger Type-k extension wire

Placed a safe distance from high voltage lines and shielded when necessary

STATUS CONTACT

The status contact is a dry contact output containing a solid state relay. It acts as a switch that the

PF2100 controls. Neither contact is internally connected to power or ground so these connections must

be provided externally as required. When the system is running, the contacts are internally connected

together and when the system is not running, the contacts are open circuited. These contacts are often

used for monitoring the PF2100’s status remotely. An alarm, siren, trouble lamp, or PLC are examples of

devices that might use this contact.

THE STATUS CONTACTS ARE RATED FOR DC ONLY so it is important to observe the correct polarity

when attaching a device. The positive status contact terminal should always be at a voltage potential

greater than or equal to the negative terminal. Do not exceed the voltage and current ratings which are

40VDC, 250mA. The impedance when closed is15Ω. There is a fuse on the status contact to protect it. A

spare fuse is also included.

DRY CONTACT INPUTS

There are 6 dry contact inputs on the PF2100. The expected connection to each of these is a switch.

These contacts must all be closed (shorted) in order for the system to start. Jumpers are provided for

each of these by default. If you need to use a particular contact for your application, simply remove the

associated jumper and connect a switch in its place.

Start Contact

The Start Contact can be used to attach a remote start/stop switch. This is often connected

to a PLC dry contact output. When the contact is open, the system is stopped. For safety

reasons, a double action is required to start the system remotely via this contact. This is

accomplished by closing the switch, opening it, and then closing it again. Once the system is

running, open the switch again to stop it.

ESD Contact

The ESD Contact can be used to attach an emergency shutdown switch. This is often

connected to a mushroom switch mounted on a remote panel or to a PLC dry contact output.

When the contact is open, the system is stopped.The system cannot be started via this

contact but this contact must be closed in order to start the system.

Proof of Closure Contact

The Proof of Closure Contact can be used to receive the feedback signal from a Main Valve

that has a Proof of Closure output. If multiple main valves with Proof of Closure outputs are

used, these can be wired together in series. Before the system attempts to light the pilot, it

will check that the Proof of Closure Contact is closed. If it is open, it will not light the pilot.

High Pressure Contact

The High Pressure Contact can be connected to a High Pressure Switch installed in the fuel

train. Typically, this switch is placed immediately after the Main valve in the fuel train. See the

4-20mA Expansion Card section for more details.

Low Pressure Contact

The Low Pressure Contact can be connected to a Low Pressure Switch installed in the fuel

train. Typically, this switch is placed immediately before the Main valve in the fuel train.

The Low Pressure Contact operates using averaged time to help reject brief fluctuations

in gas pressure. The contact must be open continuously for 2 or 6 seconds (depending on

the “Pressure/Level Delay” setting) before the system will shut down. If “Auto Restart” is

enabled, the system restarts automatically when the Low Pressure Contact re-closes. See

the 4-20mA Expansion Card section for more details.

IGNITION COIL / FLAME DETECTION

This section provides some tips to set up the system for reliable ignition and flame detection.

Internal vs. External Coil

If less than 5m (15ft) of ignition wire is required to connect the PF2100 to the burner

housing, the internal coil configuration can be used. Otherwise the external coil configuration

must be used.

The PF2100 system is available with an internal coil or an external coil can be purchased with

or without a separate enclosure.

Wire Lengths

When wiring the ignition and flame detection circuits, the wire length must be carefully

considered. If the wire lengths are too long, the PF2100 may not be able to deliver enough

energy to the ignition rod to ignite the pilot. The PF2100 may also fail to receive a signal from

the flame rod for detecting flame.

Grounding

Properly grounding the pilot assembly back to the PF2100 is critical for proper ignition and

flame detection. A ground wire should run from the Ion- or EGND terminal of the PF2100 to

the pilot assembly. This wire can either be connected to a ground screw on the pilot bracket

or to the burner housing. If connected to the burner housing, use a multimeter to verify that

the burner housing has electrical continuity with the pilot assembly. If not, another wire must

be added to connect it.

Single Rod vs. Dual Rod

A single Kanthal rod can be used for both ignition and flame detection to save cost if desired.

This often results in a performance trade-off between ignition and flame detection. This

option is only available with external coils.

2120

Using two Kanthal rods (one for ignition and one for flame detection) allows for greater

flexibility in rod placement and often yields better performance.

Note that there are three possible ways to wire the ignition coil and flame detection circuit

with the PF2100 as illustrated in the table.

CONFIGURATION (COIL TYPE) SINGLE ROD DUAL ROD

Internal Coil •

External Coil • •

Single Rod Coil Wiring

Use this configuration when you want to save cost by using a single rod.

Ion +

Rod

Coil +

Coil -

2

5

3

4

External Coil, Black Baseplate

C

External Coil, Red Baseplate

B

Ion +

Bakelite

Connector

Coil +

Coil -

2

3

4

Rod

5

Distance Between 2100 and Pilot*

0 to 10 feet

10 to 25 feet

25 to 60 feet

Wire Size Hardware Version

14 to 16 Gauge

7mm Ignition Wire

7mm Ignition Wire

V 1.7 Te rminal Card

V 1.7 Te rminal Card

V 2.4 Te rminal Card

*For single rod installations, the distance is defined as the length 2 plus 5 as shown in the Single

*Rod Coil Wiring Diagram. Note that wire 5 should be no longer than 10 ft.

+

+

Ignition

Coil Straight

Silicone

Boot

PF2100 Pluggable

Header P6

Burner Housing

Ferrule Single

Rod

4

3

2

1

{

{

5

Coil

Ion

1/8” to 1/4”

Red

White

Black

Internal Coil, 3-Wire

A

Rod

Shielded Conduit

5

Ignition Wire

Ion +

Coil +

Coil -

2

3

4

Red

White

Black

Red

White

Black

2322

Dual Rod Coil Wiring

Use this configuration when you want greater flexibility for rod placement.

Rod Positioning

Rod positioning is important for proper ignition and flame detection.The ignition rod should

be positioned (by bending it if necessary) so that there is a ⅛” to ¼” gap between it and the

front of the pilot nozzle. The flame rod should be positioned (by bending it if necessary) such

that 2” to 3” of its length is within the pilot flame. Make sure the ignition rod and flame rod

are not directly in line with each other. Otherwise, the ignition rod may cast a shadow on the

flame rod and cause the system to determine that no flame is present at the flame rod.

Flame Anchoring

Flame anchoring refers to how much in contact the flame is with the pilot nozzle. Poor flame

anchoring causes poor flame detection. Poor flame anchoring can be caused when there

is too much gas pressure resulting in the flame burning primarily outside of the nozzle as

opposed to along the inside and outside surfaces of the nozzle. It can also be caused by wind

or draft from the main burner.

Using Extra Rods to Improve Flame Detection

In some challenging installations such as non-enclosed or high velocity burners, adding one

or two additional rods may be necessary. A second flame detection rod can help in cases

where the flame may blow away from the primary rod from time-to-time. The addition of a

ground rod positioned further away from the nozzle tip can assist with detecting flames that

are not well anchored.

Distance Between 2100 and Pilot*

0 to 10 feet

10 to 25 feet

25 to 60 feet

Wire Size Hardware Version

14 to 16 Gauge

7mm Ignition Wire

7mm Ignition Wire

V 1.7 Te rminal Card

V 1.7 Te rminal Card

V 2.4 Te rminal Card

*The distance is defined as the length of 2 as shown in the diagram.

Ion -

Ignition

Rod

Coil +

Coil -

1

5

3

4

External Coil, Black Baseplate

C

External Coil, Red Baseplate

B

Ion -

Bakelite

Connector

Coil +

Coil -

1

3

4

Ignition

Rod

5

Red

White

Black

Internal Coil, 3-Wire

A

Ignition Rod

Shielded Conduit

5

Ignition Wire

Ion -

Coil +

Coil -

1

3

4

Red

White

Black

Red

White

Black

+

+

Ignition

Coil

2 x Straight Silicone Boot

PF2100 Pluggable

Header P6

2 x Ferrule

Burner Housing

Ignition Rod

Flame Rod

Ground

Screw

4

3

2

1

{

{

5

Coi

l

Ion

1

1/8” to 1/4”

2524

3 | USER INTERFACE & SETTINGS

The user interface has keys, indicator lights, and a display screen for the software interface (including

things such as menus and status screens).

3.1 | User Interface

The physical interface consists of three parts:

1. An illuminated display

2. Indicator lights

3. A keypad

DISPLAY

The screen on the PF2100 displays two lines of text which are used to show system status, warnings,

alarms, prompts, and menus. It is illuminated for ease of reading in both bright sunlight and darkness.

When the system first powers on, the display will show the system name and firmware version for a few

seconds, after this it will show the Home Screen.

KEYPAD DIAGRAM

FLAME

DISPLAY

UP KEY

MODE KEY

PILOT LIGHT

IGNITE LIGHT

DOWN KEY

AUTO LIGHT

MANUAL LIGHT

MAIN LIGHT

MAIN KEY

OK KEY

FLAME LIGHT

STOP KEY

IGNITE KEY

MENU KEY

PILOT KEY

INDICATOR LIGHTS

Flame Light

Indicates that the system is detecting the pilot flame.

Auto Light

Indicates that the system is running in auto mode.

Manual Light

Indicates that the system is running in manual mode.

Pilot Light

Indicates that the pilot valve is open.

Ignite Light

Indicates that the system is sparking to ignite the pilot.

Main Light

Indicates that he main valve is open.

KEYS

Stop Key

Used to stop the system immediately or in other words, turn off the burner.

Menu Key

Used to navigate through the menu.

Up Key

Used to adjust a setting upwards and to scroll up through lists.

Down Key

Used to adjust a setting downwards and to scroll down through lists.

OK Key

Used to enter a menu, acknowledge a prompt, save an edited setting, or return to the home

screen.

Mode Key

Used to toggle between Manual and Auto modes of operation.

Pilot Key

Used in Manual Mode to test the Pilot Valve.

Ignite Key

Used in Manual Mode to test the Ignition Circuit.

Main Key

Used in Manual Mode to test the Main Valve.

2726

3.2 | Menu Navigation

The software user interface is shown on the PF2100 display. While the system is powered, the state of

the system is displayed on the screen. The user can also change settings via this interface. Below is a

diagram showing the various types of information that can be accessed through the interface. The default

system screen at startup and when idling is the Home Screen. Most items are accessed through the

Home Screen but some can be accessed from anywhere in the interface.

PF2100

Menus

Warning

M essag es

Firmware

Ve r si on

Screen

Quick

Se t p o i n t

A d j u st

Automat ic

Mode

Warning

M essag es

Firmware

Ve r si on

Screen

Shut down

M enu

Sy st e m

M enu

Rev i ew

M enu

M anu al

Mode

Certain settings can be viewed only in Manual Mode or only in Auto Mode.

MANUAL VS. AUTO MODE

When the system first powers on, it will normally be in Manual Mode. If the Auto Restart feature is

enabled and no alarm conditions are present, it may switch automatically to Auto Mode after power

up. Otherwise, the user must manually put the system into Auto Mode by using the Keypad, the Start

Contact, or the Modbus Expansion Card. See the System Start Up section for more details.

The main difference between these two modes is that all settings can be adjusted in Manual Mode and a

limited number of settings can be adjusted in Auto Mode. The following table illustrates the differences in

menu access.

ITEM MANUAL MODE AUTO MODE

User Can View and Adjust Menu Settings Yes* via Quick Setpoint

Adjust

User Can Access the Review Menu Ye s No

Process Control Can Be Running Ye s Ye s

System will try to Relight the Burner if the Pilot is Turned Off Due to Normal

Process Control

Ye s Ye s

System State Shown on the Home Screen Always During State Change

System will Attempt to Relight the Burner if the Flame Goes Out Unexpectedly No Ye s

Process Setpoint can be Easily Adjusted via the “Quick Setpoint Adjust” feature No Ye s

The System can be Controlled Manually via the Pilot, Ignite, and Main keys Ye s No

Manual Indicator Light On Ye s No

Auto Indicator Light On No Ye s

*Menus 1-3 only when process control is running, all menus when stopped.

HOME SCREEN

The Home Screen is shown on the display after power up, after waking the display from sleep, and after

the user acknowledges a shutdown message. It is the starting point for most user interaction with the

menu system. To return to the Home Screen from any point in the user interface, the user can press and

hold the “OK”key for three seconds.

On the Home Screen, the Process Temperature is always shown on the bottom line of the display. The

top line differs depending on mode. In Manual Mode, the top line shows the system state. In Auto Mode,

it shows the Process Setpoint instead.

The accessibility of other features from the Home Screen also differs depending on mode. For example,

the System Menus and Review Menu are only accessible in Manual Mode whereas the Quick Setpoint

Adjust feature is only available in Auto Mode. For more information on which features are available in

which modes, refer to the Adjust Settings & Review Status section.

2928

AVAILABLE FEATURES WITHIN OPERATIONAL MODES

MODE DISPLAY MENUS REVIEW SETPOINT ADJUST

Manual System State

Process Temperature

Ye s Ye s No

Auto Process Setpoint

Process Temperature

No No Ye s

SYSTEM STATE

The System State is the Process Control State of the system. It is shown on the display for a few

seconds before and after a state change. In Manual Mode, the top line of the Home Screen always

shows the System State. Go to the Process Control Settings section for a complete list of the Process

Control States.

QUICK SETPOINT ADJUSTMENT

The Quick Setpoint Adjust feature is only available on the Home Screen while running in Auto Mode. It

allows the user to quickly adjust the Process Setpoint using the up and down keys. The change takes

effect immediately and does not need to be saved by pressing ok. If password protection is enabled,

a password will need to be entered before this feature can be used. If the Pilot Off and/or Low Fire

Setpoints are enabled, this feature will also adjust them. In this case, each press of the up or down key

will adjust all of these setpoints by 1 degree up or down. All other setpoints are not affected by this

feature.

SYSTEM MENUS

The System Menus store all of the system settings in an organized fashion. These menus are also used

to show historical and system status information as well as to provide access to calibration features.

These menus cannot be accessed while the system is running in Auto Mode. Some menus can only be

accessed while the system is stopped. Some menus require a Level 2 password and others require an

optional Level 1 password.

REVIEW MENU

The Review Menu provides a quick way for an operator to check key setpoints and system status

(accessible only in Manual Mode).

FIRMWARE VERSION SCREEN

The Firmware Version Screen shows the firmware version of all cards in the system including the Door

Card, Terminal Card, and any installed Expansion Cards.

WARNING MESSAGES

When the system detects a warning condition, it will flash a warning message across the bottom line of

the Home Screen. Some messages can be dismissed by pressing the OK key (eg, “Unit restarted from

LVL event”). Others persist until the warning condition is resolved (eg, “LO Volt Warning”).

SHUTDOWN SCREEN

When the system shuts down as a result of an alarm condition, it will flash the word “SHUTDOWN” in

large text on the display alternately with a more detailed message explaining the reason that the system

shut down. The Shutdown Screen can always be dismissed by pressing “OK,” toggling the Start Contact,

or sending the Start Command via Modbus.

3.3 | Menu Map

For a complete description of each item, please refer to the menu definitions section. The debug

functions are not shown here; if needed they are located in the Field Calibration section of the manual.

NAVIGATION

1. Press MENU until you get to the desired menu.

(The Review menu is accessible by pushing the Down arrow.)

2. Press OK to select an option.

3. Press MENU until you get to the submenu option you want to

change/view.

4. Press or to adjust the selected setting.

5. Press OK to set the new value.

6. Press MENU to cancel changes.

7. Press OK to exit to the home screen.

Ready Proc Temp Menu 1

Setpoints

Menu 2

History

Menu 3

System Info

Pilot Off Setpoint Relights High Temp TC Reading

Review Menu Low Fire Setpoint Flame Fails Process TC Reading

ESD Setpoint Process Setpoint Resets 4-20 mA Output%

Process Setpoint Low Temp Alarm

Setpoint ESDs Ambient Temp

Low Fire Setpoint Deadband High Pressure ESDs Voltage Reading

Pilot Off Setpoint AUX Setpoint Low Pressure ESDs Commission Date

3130

4-20 High Level

Setpoint

PID – Proportional

Band Level ESDs Location

4-20 Low Level

Setpoint PID – Integral Thermocouple Errors

4-20 Pressure Setpoint PID – Derivative Terminal Errors

4-20 Low Pressure

Setpoint System Errors

Flame View Event Log

Aux Temp Clear History

4-20 Level Reading

4-20 Pressure Reading

Alarms

Menu 4

System Startup

Menu 5

Control Setup

Menu 6

Expansion Cards

Auto Restart High Temp ESD

Setpoint

4-20 Expansion Card

Enable

Purge Time Process Control In-put 4-20 Level Units

Pilot to Main Delay Low Fire Enable 4-20 Level Range

Restart Attempts Low to High Fire Delay 4-20 Level Offset

Level Event Restart Pilot off Enable 4-20 Level Low Setpoint

Pressure/Level Delay AUX Temp Mode 4-20 Level High Setpoint

Pressure Restart 4-20 Pressure Units

Alarm Mode 4-20 Output Mode 420 Pressure Range

Password Enable 4-20 Low Fire Setting 4-20 Pressure Low

Setpoint

Display Sleep 4-20 Pressure High

Setpoint

Pilot Valve Power

Setting

MODBUS

Enable/Address

Main Valve Power

Setting 4-20 Card FW Version

System Voltage Setting MODBUS

Card FW Version

Temperature Display

Units

Commission Date

Entry

Commission Location

Entry

Rest to Factory

Defaults

SETPOINTS (MENU 1)

This menu is used to adjust the Process Control Setpoints.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

Pilot Off Setpoint Pilot Off

Setpnt

Adjusts the temperature at which the

Pilot Valve will turn off when Pilot Off is

enabled.

1 to 1349˚C

34 to 2460˚F

85˚C

185˚F

Low Fire Setpoint Low Fire

Setpnt

Adjusts the temperature at which the

Low Fire Valve will turn off when Low

Fire is enabled.

2 to 1349˚C

36 to 2460˚F

Hidden, 85˚C

185˚F

Process Setpoint Proc

Setpnt

Adjusts the temperature at which the

High Fire/Main Valve will turn off

1 to 1349˚C

34 to 2460˚F

80˚C

176˚F

Low Temp Alarm Setpoint Low Temp Alarm

Setpnt

Adjusts the temperature where the

Status Contact will close, if enabled.

Disabled,

1 to 1349˚C

34 to 2460˚F

Disabled

Deadband Deadband Adjusts the Deadband. Used with the

Process Setpoint and sometimes Low

Fire and Aux Setpoints.

1 to 150˚C

1 to 240˚F

2˚C

3˚F

Aux Setpoint AUX Setpnt Adjusts the Auxiliary Setpoint 0 to 1350˚C

32 to 2462˚F

Hidden, 20˚C

68˚F

PID – Proportional Band PID

PB:

Expressed in percent, this is inversely

proportional to the PID controller’s

proportional gain.

0.0 to 999.9% 10.0%

PID – Integral PID

I:

Expressed in Minutes per Reset, this is

the amount of time required for the PID

integral term to yield the same output as

the proportional term.

0.0 to 999.9

min/rst

4.0 min/rst

PID – Derivative PID

D:

Expressed in Minutes, this causes

the PID to compensate based on the

changing error. Disabled by default

0.0 to 999.9

min

0.0 min

HISTORY (MENU 2)

This menu contains informational event counters and the event log.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

Relights Re-Lights Number of Pilot Relight attempts. 0 to 1000 N/A

Flame Fails Flame Fails Number of Shutdowns due to failure to

light the pilot.

0 to 1000 N/A

Resets Resets Number of power failures or manual

resets.

0 to 1000 N/A

ESDs ESDs Number of system shutdowns caused

by faults.

0 to 1000 N/A

3332

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

High Pressure ESDs HPR ESDs Number of High Pressure Shutdowns. 0 to 1000 N/A

Low Pressure ESDs LPR ESDs Number of Low Pressure Shutdowns. 0 to 1000 N/A

Level ESDs LVL ESDs Number of Level Contact Shutdowns. 0 to 1000 N/A

Thermocouple Errors TC Errs Number of Thermocouple Shutdowns. 0 to 1000 N/A

Terminal Card Errors Term Errs Number of Terminal Card Shutdowns. 0 to 1000 N/A

System Errors Sys Errs Number of System Errors Shutdowns. 0 to 1000 N/A

View Event Log View Event Log? Log of recent events Yes/No No

Clear History Clear History? Clears all History and logged events Yes/No No

SYSTEM INFO (MENU 3)

This menu contains diagnostic information about the system.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

High Temp TC Reading Hi Temp TC Current High Temp Thermocouple

reading

-50˚C to

1350˚C

N/A

Process Temp TC Reading Proc TC Current Process Thermocouple reading -50˚C to

1350˚C

N/A

4-20mA Output Percent 4-20

Output

Current status of the 4-20mA Output 0 to 100% N/A

Ambient Temp Ambient Temp Current ambient temperature. Used

for thermocouple cold junction

compensation.

-55˚C to 65˚C

-70˚F to 150˚F

N/A

Voltage Reading System Voltage Current voltage applied to the system 8V to 35V N/A

Commision Date Commission

Date

Date that the system was commissioned

(if entered by user)

DD-MMM-

YYYY

N/A

Location Location The install location of the system (if

entered by user)

N/A N/A

Control State Control State Debug Information N/A Hidden

Terminal Card State Term Card Debug Information N/A Hidden

SYSTEM SETUP (MENU 4)

This menu contains various optional system settings. It cannot be accessed while the PF2100 is running.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

Auto Restart Auto

Restart

Enables system to restart from a power

failure or high voltage event.

On/Off Off

Purge Time Purge Time Adjusts the time from all valves closed

to Pilot relight attempts

10- 900 sec 30 sec

Pilot to Main Delay Pilot to Main

Delay

Adjusts the time from Pilot proven to

Main Valve opening

5- 600 sec 15 sec

Restart Attempts Restart

Attempts

Adjusts the number of Restart Attempts

after an unexpected flame failure before

a shutdown

0- 3 3

Level Event Restart Level Event

Restart

Enables recovery from a Low Level

event

On/Off Off

Pressure/Level Delay PRS/LVL

Delay

Pressure and Level shutdown delay On/Off Off

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

Pressure Restart PRS Restart Allows the system to automatically

restart when a low pressure event

clears. Can also enable control of the

main valve based on the Low Pressure

Contact or Low Pressure Setpoint.

Enabled,

Disabled,

Main Control

Disabled

Alarm Mode Alarm Mode Adjusts the behaviour of Status Contact

relative to Start Contact

Alarm when

Off,

No Alarm

When Off

No Alarm when

Off

Password Enable Password Enable Password Protection (Menu 1-3) On/Off Off

Display Sleep Display Sleep Enable Sleep Mode for the Display Never, After

10 Min

Never

Pilot Valve Power Setting Pilot Solenoid

PWM

Adjusts the Pilot Valve PWM duty cycle Off, 80%,

60%, 40%,

20%

60%

Main Valve Power Setting Main Solenoid

PWM

Adjusts the Main Valve PWM duty cycle Off, 80%,

60%, 40%,

20%

60%

System Voltage Setting System

Voltage

Configures the expected input voltage

for the system

12V, 24V 12V

Temperature Display Units Temp Units Configures the temperature units

displayed by the system

Fahrenheit,

Celsius

Celsius

Commission Date Entry Commission

Date

Set the date that the system was

commissioned

DD-MMM-

YYYY

01-JUN-2012

Commission Location Entry Commission Loc Set the install location of the system. 14

Characters Max.

A-Z, 0-9,-./

Reset to Factory Defaults Rest to Factory

Defaults?

Restore all settings to the factory default Yes/No No

CONTROL SETUP (MENU 5)

This menu contains various optional Process Control settings. It cannot be accessed while the PF2100 is

running.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

High Temp ESD Setpoint High Temp

ESD SETPNT

Adjusts the High Temperature shutdown

setpoint

2 to 1350˚C

36 to 2462˚F

90˚C

194˚F

Process Control Input Process Control Configure the thermocouple used as the

Process Temperature

Process TC,

AUX TC

Process TC

Low Fire Enable Low Fire Enables Low Fire feature and setpoint Disabled,

on at Proc

Setpnt, on

at Low Fire

Setpnt

Disabled

Low to High Fire Delay Low to High Fire

Delay

Adjusts the time from Low Fire Valve

opening to High Fire Valve opening,

when Low Fire is enabled. Values set

above 255 seconds are automatically

set to the value minus 255 seconds. For

example, inputting 275 seconds sets the

actual delay to 20 seconds.

30- 300 sec Hidden, 30 sec

Pilot Off Enable Pilot Off Enables Pilot Off feature and setpoint Disabled,

Enabled

Enabled

Aux Temp Mode AUXTemp Mode Configures how the Auxiliary

Thermocouple is used.

Disabled,

Display Only,

Temp Main

Ctl, Temp ESD

Disabled

3534

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

4-20 Output Mode 4-20 Out Mode Configures 4-20 Output mode Valve Control 1

Valve Control 2,

Temp Output

Disabled

4-20 Low Fire Setting 4-20 Out Lo Fire

Setting

Sets the minimum output for the

4-20mA Output when used for Valve

Control.

0 to 70% 40%

EXPANSION CARDS (MENU 6)

This menu contains settings relating to expansion cards.

MENU MAP ON SCREEN BRIEF DESCRIPTION RANGE DEFAULT SETTING

4-20 Input Card Enable 4-20 Input Card

Enabled

Enable the 4-20mA Expansion Card and

setpoints

No/Yes No

4-20 Level Units 4-20 LVL

Units

Adjusts the display units for the 4-20mA

Level Input

%, m3, BBL,

GAL,L

Hidden, m3

4-20 Level Range 4-20 LVL Range Adjusts Max Level of the tank High Setpoint-

1000

Hidden, 0-120m3

4-20 Level Zero Offset 4-20 LVL Zero

Offset

Adjusts the level reading corresponding

to a 4mA input

0 to Low

Setpoint

Hidden, 0m3

4-20 Level Low Setpoint 4-20 LVL Low

Setpnt

Adjusts 4-20 Low Level trip point 0 Offset- High

Setpoint

Hidden, 60m3

4-20 Level High Setpoint 4-20 LVL High

Setpnt

Adjusts 4-20 High Level trip point Low Setpoint-

Level Range

Max, Disabled

Hidden, 117m3

4-20 Pressure Units 4-20 PRS

Units

Adjusts the display units for the 4-20mA

Pressure Input

PSI, kPa,

inWC, oz, ksc

Hidden, 0-

30.0PSI

4-20 Pressure Range 4-20 PRS Range Adjusts Max pressure of the fuel train High Setpoint-

999.9

Hidden, 30.0 PSI

4-20 Pressure Low Setpoint 4-20 PRS Low

Setpnt

Adjusts 4-20 Low Pressure trip point 0-High

Setpoint

Hidden, 3.0 PSI

4-20 Pressure High Setpoint 4-20 PRS High

Setpnt

Adjusts 4-20 High Pressure trip point Low setpoint

– Max

Pressure.

Disabled

Hidden, 25.0 PSI

MODBUS Enable/Address Modbus Card Enable control and address for the

Modbus Expansion Card

Disabled,

1-254

Disabled

4-20 Card FW Version 4-20 FW Display Expansion Card FW Version N/A N/A

MODBUS Card FW Version MBUS FW Display Expansion Card FW Version N/A N/A

REVIEW MENU

This read only menu allows various commonly needed system settings and status parameters to be

reviewed while the system is running.

MENU MAP ON SCREEN BRIEF DESCRIPTION

ESD Setpoint ESD Setpnt Temp at which system will shutdown

Process Setpoint ProcSetpnt Temp at which High Fire / Main Valve will turn off

Low Fire Setpoint LF Setpnt Temp at which Low Fire Valve will turn off if Low Fire is enabled

Pilot Off Setpoint Pilot off Temp at which Pilot Valve will turn off if Pilot is enabled

4-20 High Level Setpoint HLV Level at which 4-20mA Output contacts will toggle

MENU MAP ON SCREEN BRIEF DESCRIPTION

4-20 Low Level Setpoint LLV Level below which the system will shutdown or wait if Level Event Restart is

enabled

4-20 High Pressure Setpoint HPR Pressure above which the system will shutdown after Main

4-20 Low Pressure Setpoint LPR Pressure below which the system will shutdown or wait if Auto Restart is

enabled

Flame Flame Current Flame Quality

Aux Temp AUX Temp Current Aux Temp reading

4-20 Level Reading LVL Current 4-20mA Level input reading

4-20 Pressure Reading PRS Current 4-20mA Pressure input reading

TC Debug Screen DH=ww TH=xx

TP=yy TA=zz

Shows the current readings of all temperature sensors simultaneously always

in degrees celsius regardless of the display unit setting

DH=Door Card High Temp, Thermocouple

TH=Termincal Card, High Temp Thermocouple

TP=Terminal Card Process Thermocouple

TA=Terminal Card Ambient Thermocouple

Alarms Alarms Lists up to 3 simultaneous alarm codes if any are present

3.4 | Initial System Settings

The following settings need to be modified for every installation.

1. Valve Modulation Settings (Pilot and Main)

2. System Voltage

3. Process Control Settings

4. Process Setpoints (High Temp ESD, Pilot Off, Process, Low

Fire, Low Alarm, Deadband)

VALVE MODULATION SETTINGS

The Pilot and Main Valve outputs can be modulated with a pulsed DC signal to conserve power using

Pulse Width Modulation (PWM). The duty cycle of the modulation can be adjusted independently for

each valve. Each can be set to 100%, 80%, 60%, 40%, or 20%. The 100% setting applies continuous

DC voltage (ie, no modulation) to the valve and is the highest power option. The 20% setting applies DC

voltage 20% of the time and is the lowest power option. Only valves that are compatible with modulation

should be used with a duty cycle of less than 100%. These valves are sometimes called “Low Power” or

“Peak-and-Hold” valves since they require only short periodic voltage pulses to hold the valve open. Do

not use a duty cycle of 100% with low power valves as this can damage them.

If a multimeter is used to measure the valve power, the measured voltage will be reduced proportionally

with the PWM setting.

The pilot and main valve power settings can be adjusted to match the needs of various applications.

Pilot Valve Power Setting (Menu 4)

Adjusts the PWM Duty Cycle of the Pilot Valve output.

Main Valve Power Setting (Menu 4)

Adjusts the PWM Duty Cycle of both the Low Fire and High Fire Valve outputs.

3736

SYSTEM VOLTAGE

The PF2100 is designed to operate with a nominal 12VDC or 24VDC Power Supply. The system will not

be damaged by applying any voltage in or near this range regardless of menu settings. Note that attached

valves are typically not designed to accept both 12VDC and 24VDC. If the valve voltage ratings are

exceeded, the valves may become damaged.

SystemVoltage Setting (Menu 4)

This setting defines voltage limits to protect and allow the proper operation of the attached

valves. If the PF2100 detects that the input voltage is getting close to these limits, it will

display a warning message. If the voltage exceeds these limits, the system will shut down

and cut power to the valves.

The following options are available:

VOLTAGE SETTING CHOOSE THIS OPTION WHEN…

12 V The Power Supply and all valves are 12 VDC

24 V The Power Supply and all valves are 24 VDC

The exact limits used are shown in the following table. Note that the high voltage limits also depend on

the Pilot Valve Power Setting and Main Valve Power Setting which can also be found in Menu 4.

V SETTING PILOT / MAIN VALVE PWM SETTING LOW V ALARM LOW V WARNING HIGH V WARNING HIGH V ALARM

12V At least one equal to 100% <= 8.4V <= 9.9V >= 14.6V >= 15.6V

12V Both less than 100% <= 8.4V <= 9.9V >= 16.1V >= 16.8V

24V At least one equal to 100% <= 17.9V <= 19.9V >= 28.6V >= 30.0V

24V Both less than 100% <= 17.9V <= 19.9V >= 33.1V >= 40.0V

PROCESS CONTROL SETTINGS

For the PF2100, Process Control refers to controlling the temperature of a process. This process usually

involves heating fluid in a tank or pipe. A primary temperature control signal is required for Process

Control. This is called the Process Temperature or Proc Temp. Optionally, an auxiliary temperature control

signal can also be accepted. This signal is called the Auxiliary Temperature or Aux Temp.

Note that these two signals are not necessarily the same as ProcTC and Aux TC which are the names of

the physical thermocouple inputs on the Terminal Card. The Aux Temp signal is only compared to the Aux

Setpoint, if enabled.

There are four settings that directly affect Process Control: Process Control Input, Low Fire Enable, Pilot

Off Enable, and AuxTemp Mode.

Note that changing any of these settings may cause the Process setpoints (High Temp ESD, Pilot Off,

Low Fire, Process, Low Temp Alarm, Deadband, and Aux) to reset to factory defaults. A warning message

will display if this occurs.

Process Control Input (Menu 5)

This setting selects which thermocouple inputs will be used as the primary and auxiliary

temperature control signals as shown in the following table.

SETTING PROC TEMP AUX TEMP

Proc TC Proc TC Aux TC

Aux TC Aux TC Proc TC

In previous firmware versions this could also be set to Disabled. In this case, Process Control

was disabled and the system allowed the burner to always be lit and running. The typical

use for this was to have an external device, such as a PLC, controlling the process.The

PLC would turn the system on and off using the Start contacts. This behaviour can still be

achieved by setting all Process Setpoints to maximum.

Low Fire Enable (Menu 5)

This setting is used to toggle the use of the Low Fire Setpoint for Primary Process Control.

Low Fire can be enabled in two different modes: “On at Proc Setpoint” and “On at Low

Fire Setpoint”. In the first case, the Low Fire Valve will close when it exceeds the Low Fire

Setpoint but will not reopen until it drops below the Process Setpoint minus Deadband. In

the second case, the Low Fire Valve will close when it exceeds the Low Fire Setpoint and will

reopen after it drops below the Low Fire Setpoint minus Deadband.

Pilot Off Enable (Menu 5)

This setting is used to enable/disable use of the Pilot Off Setpoint for Primary Process

Control.

Aux Temp Mode (Menu 5)

When this setting is set to Temp Main Ctl, Auxiliary Process Control is enabled. See the

Auxiliary Temperature Settings section for more details.

PROCESS SETPOINTS

There are seven Process Setpoints in total, four of which may be disabled (hidden from menus). The order

of the setpoints varies depending on the value of the Process Control Input setting.

The following diagrams illustrate the upper and lower bounds of each setpoint and their order. Setpoints

that are shaded may be disabled. When a setpoint is disabled, the upper and lower bounds of the

adjacent setpoints are adjusted accordingly.

Process Control Input Setting: PROC TC

LOW TEMP ALARM DEADBAND*

PROCESS SETPOINT

LOW FIRE SETPOINT

PILOT OFF SETPOINT

HIGH TEMP ESD SETPOINT

AUX SETPOINT

Setting can be hidden / disabled

Deadband Max = 150˚C

*

1350˚C

0˚C

1350˚C

0˚C

AUX TEMP

PROC TEMP

Process Control Input Setting: AUX TC

LOW TEMP ALARM DEADBAND*

AUX SETPOINT

PROCESS SETPOINT

LOW FIRE SETPOINT

PILOT OFF SETPOINT HIGH TEMP ESD SETPOINT

1350˚C

0˚C

1350˚C

0˚C

AUX TEMP

PROC TEMP

Setting can be hidden / disabled

Deadband Max = 150˚C

*

3938

For Process Control, the Proc Temp signal is the one compared to the Pilot Off, Low Fire,

Process, and Deadband setpoints.

High Temp ESD Setpoint (Menu 5)

This setting is used to protect the burner and other equipment from overheating. If either

the High Temp or Process thermocouple readings exceed this setpoint, the burner will

immediately shut down. This setting can be set to a maximum of 1350˚C. The minimum value

is 1˚C higher than the setpoint below it. Depending on which settings are enabled, this will

be the Pilot Off, Low Fire, or Process Setpoint.

Pilot Off Setpoint (Menu 1)

If the Process Temperature goes above this setting, the Pilot Valve will close and the system

state will change to “Waiting on Temp”.This is often done to conserve pilot gas when it is not

needed. This setting is hidden if Pilot Off in menu 5 is set to Disabled. This setting can be set

to a maximum of 1˚C below the HighTemp ESD Setpoint.The minimum value is the same as

the setpoint below it. Depending on which settings are enabled, this will be the Low Fire or

Process Setpoint.

Low Fire Setpoint (Menu 1)

If the Process Temperature goes above this setting, the Low Fire Valve will close and the

system state will change to “Pilot On”. This setting is hidden if Low Fire in menu 5 is set to

Disabled. This setting can be set to a maximum of 1˚C below the HighTemp ESD Setpoint or

the Pilot Off Setpoint if it is enabled. The minimum value is 1˚C above the Process Setpoint.

Process Setpoint (Menu 1)

If the Process Temperature goes above this setting, the Main Valve will close and the system

state will change to “Low Fire”. This setting can be set to a maximum of 1˚C below the High

Temp ESD Setpoint, the Pilot Off Setpoint if enabled, or 1˚C below the Low Fire Setpoint if

enabled. The minimum value is the Low Temp Alarm or Deadband (whichever is larger).

Low Temp Alarm Setpoint (Menu 1)

If the Process Temperature goes below this setting, the Low Temp Alarm will be asserted and

the status contact will open. This setting can be set to a maximum of the Process Setpoint

value. The minimum value is 1˚C. Set to 0˚C to disable the Low Temp Alarm.

Deadband (Menu 1)

The Deadband setting provides a temperature margin below the Process Setpoint. For the

main valve to open, the temperature must be below Process Setpoint minus the Deadband

setting.

The Deadband setting also provides a temperature margin below the Low Fire Setpoint when

the Low Fire Enable setting is set to “On At Low Fire Setpoint”. In this case, the Low Fire

valve will open when the Process Temperature is below the Low Fire Setpoint minus the

Deadband setting and will close when it is above the Low Fire Setpoint.

The Deadband setting also provides a temperature margin below the Aux Setpoint when the

Aux Temp Mode setting is set to “Temp Main Ctl”. In this case, the main valve(s) will open

when the AuxuliaryTemperature is below the Aux Setpoint minus the Deadband setting and

will close when it is above the Aux Setpoint.

This setting can be set to a maximum of 150˚C or the Process Setpoint, whichever is lower.

The minimum value is 1˚C.

AUX Setpoint (Menu 1)

This setpoint is enabled only if AuxTemp Mode in menu 5 is set to “Temp Main Ctl” or

“Temp ESD”. In the first case, if the Auxiliary Temperature goes above the Aux Setpoint, the

main valve(s) will close.The pilot will remain on until the Process Temp exceeds the Pilot

Off Setpoint (if Pilot Off is enabled). In the second case, the system will shut down if the

Auxiliary Temperature goes above the Aux Setpoint. This setting can be set to a maximum of

1350˚C.The minimum value is 0˚C.

3.5 | Optional Settings

4-20MA OUTPUT SETTINGS

The 4-20mA Output is built into the Terminal Card (not part of the 4-20mA Expansion Card). It can be used

to echo the process temperature to a PLC or control a proportional valve.

4-20 Output Mode (Menu 5)

Set the 4-20mA Output mode to Process Temperature, Valve Control 1, or Valve Control 2.

The 4-20mA Output is intended to drive a proportional valve. The signal is scaled such that

4mA = Valve Closed and 20mA = Valve Fully Open. A PID control loop based on Process

Temperature feedback is used to determine how much the valve should be open at any given

point in time. More details can be found in the PID Controller section.

The Valve Controls use a traditional safety solenoid valve connected to the PF2100’s Low Fire

outputs. The Low Fire setting must also be enabled by setting it to “On at Proc Setpoint.”

1. Process Temperature

In this mode, the 4-20mA Output will encode the Proc

Temp signal as a 4-20mA signal. Note that the Proc Temp

may correspond to either the Process Thermocouple or the

AUXThermocouple input depending on the Process Control

setting. The signal is scaled such that 4mA = 0C and 20mA =

the High Temp ESD Setpoint.

2. Valve Control 1

When the PF2100 enters Low Fire, the proportional valve

begins fully closed and linearly ramps so that it reaches the

4-20 Low Fire setting just as the Low to High Fire Delay

elapses. Once High Fire begins, the PID Controller adjusts the

valve accordingly.

3. Valve Control 2

When the PF2100 starts, the proportional valve idles at

the 4-20 Low Fire setting. Once High Fire begins, the PID

Controller adjusts the valve accordingly.

4-20 Low Fire Setting (Menu 5)

This setting is only available when the 4-20 Output Mode is set to Valve Control 1 or Valve

Control 2. It specifies the minimum value that the proportional valve will ever be open.This

is the starting position of the main valve each time it is turned on. It can be set to any value

from 0% to 70%.

ALARM / STATUS CONTACT SETTINGS

The Status Contact will always open if the system is shut down due to an alarm condition. There are two

settings that affect the behavior of the Status Contact: Alarm Mode and LowTemp Alarm Setpoint.

Other manuals for PF2100

2

Table of contents

Other ProFire Controllers manuals

Popular Controllers manuals by other brands

Moons'

Moons' LIN ENGINEERING Silverpak 17C user manual

Johnson Controls

Johnson Controls LN Series installation instructions

Rodix

Rodix FC-44-DC Plus quick start guide

Cisco

Cisco Cisco mds 9216 - fabric switch Configuration guide

RTK

RTK REact 60E Series manual

ZyXEL Communications

ZyXEL Communications Network Device NXC-8160s quick start guide