i

Contents

1 Preparing for installation······························································· 1-1

Safety recommendations ·········································································································· 1-1

General safety recommendations ························································································ 1-1

Electrical safety················································································································ 1-1

Laser safety ···················································································································· 1-2

Examining the installation site···································································································· 1-2

Temperature and humidity·································································································· 1-2

Cleanliness ····················································································································· 1-2

Cooling ·························································································································· 1-3

ESD prevention················································································································ 1-3

EMI ······························································································································· 1-4

Lightning protection ·········································································································· 1-4

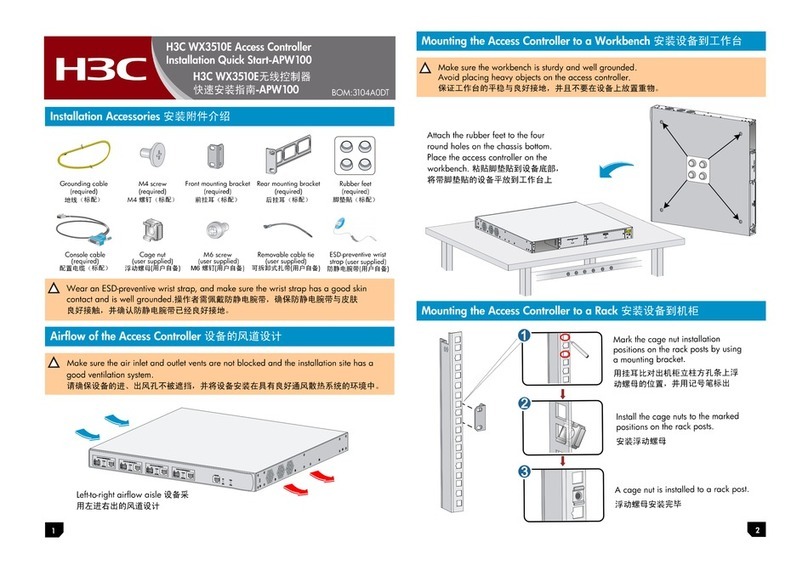

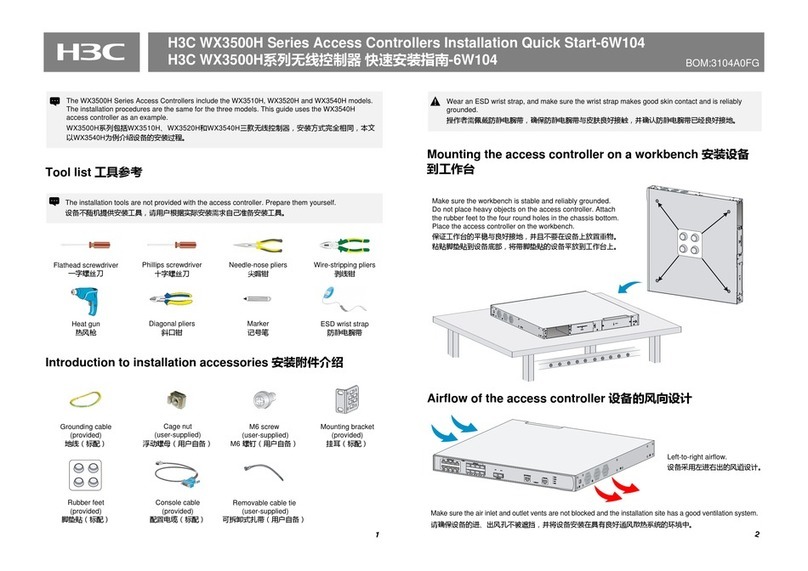

Installation accessories ············································································································ 1-5

Installation tools······················································································································ 1-6

Pre-installation checklist ··········································································································· 1-7

2 Installing the device····································································· 2-1

Confirming installation preparations ···························································································· 2-1

Installation flow······················································································································· 2-2

Mounting the device on a workbench ·························································································· 2-2

Installing the device in a 19-inch rack ·························································································· 2-3

Installation methods ·········································································································· 2-3

Mounting brackets and slide rails ························································································· 2-3

Installing cage nuts ··········································································································· 2-4

Rack-mounting the device by using front and rear mounting brackets and slide rails ······················· 2-5

Rack mounting the device by using front and rear mounting brackets ·········································· 2-7

Rack-mounting the device by using the front mounting brackets ················································· 2-9

Grounding the device············································································································· 2-10

(Optional) Installing network port lightning protectors ···································································· 2-12

(Optional) Installing a surge protected power strip ········································································ 2-13

Connecting interface cables ···································································································· 2-13

Connecting the console cable and setting terminal parameters ················································ 2-13

Connecting Ethernet cables······························································································ 2-14

Connecting the power cord ····································································································· 2-15

Connecting the AC power cord·························································································· 2-15

Connecting the device to an RPS ······················································································ 2-16

Verifying the installation·········································································································· 2-17

Starting the device ················································································································ 2-17

3 Troubleshooting ········································································· 3-1

Power failure·························································································································· 3-1

Symptom ························································································································ 3-1

Solution·························································································································· 3-1

Software loading failure ············································································································ 3-1

Symptom ························································································································ 3-1

Solution·························································································································· 3-1

4 Hardware management and maintenance ········································ 4-1

Displaying hardware information for the device·············································································· 4-1

Displaying software and hardware version information for the device··········································· 4-1

Displaying operational statistics for the device ········································································ 4-2

Displaying detailed information about the device ····································································· 4-3

Displaying the electronic label data for the device···································································· 4-3

Displaying the CPU usage of the device ················································································ 4-4

Displaying the memory usage of the device ··········································································· 4-4

Displaying the operating state of the built-in fans····································································· 4-5

Displaying the operating state of power modules····································································· 4-5