Proflex G9 User manual

ProFlex®G9

SERVICE MANUAL Your System Configuration

Temperature Controls

Microprocessor - 4th Gen

4 Hose / 4 Gun

Single Motor / Pump

Voltage Requirements

220 VAC, Single Phase, 40 A

07/08/20 Rev A

1723 W. Hamlin Rd | Rochester Hills, MI 48309

248.853.2011 | www.hotmelt-tech.com

No One Puts It Together Like HMT®

Intended Use

Benchmark® and ProFlex® adhesive melters and components are designed to melt

and pump thermoplastic hot melt adhesives and sealants. Any other use is considered

to be unintended. Hot Melt Technologies (HMT) will not be liable for personal

injury or property damage resulting from unintended use. Intended use includes

the observance of HMT safety instructions. HMT recommends obtaining detailed

information on the hot melt materials being used.

The product is only intended for use in industrial applications and may

only be used to melt and pump thermoplastic hot melt adhesives

(e.g. EVA, PSA, APO, Polyamid).

The product may only be installed, assembled, commissioned, operated,

maintained, repaired, de-commissioned and disposed of by trained

personnel.

The product may only be operated with compatible original components

and original accessories from Hot Melt Technologies Inc.

The product is to be used exclusively for the purpose described herein

and within the limits defined in this document. The product must not

be modified with respect to its structure or its safety features without

the written consent of Hot Melt Technologies. No changes to the

software or hardware of HMT products are permitted. Only use

original spare parts, original accessories or standard parts that

have been approved by HMT.

The instructions are part of this product. No applications other than those described

in the instructions are permitted.

Improper Use

Examples of misuse of the product include:

Melting and pumping of unsuitable adhesives

(e.g. PUR-Polyurethane hot melt adhesives)

In defective condition

With electrical cabinet open

With the tank lid open

Melting and pumping materials which, when under vacuum or pressure,

can pose a health hazard or endanger safety in the workplace

(e.g. solvents, explosive or highly flammable materials)

Cleaning the product with highly flammable materials (e.g. solvents)

Use in environments that require cleaning of the product with jets or

sprays of water

Processing of food

Residual Risks

In the design of the Benchmark and ProFlex systems, every measure was taken

to protect personnel from potential danger. However, some residual risks can

not be avoided:

Risk of burns from hot material

Risk of burns when filling the tank, from the tank lid, and from the hose

and gun exposed metal surfaces.

Risk of burns when conducting maintenance and repair work for which

the melter or components must be heated up.

Material fumes may be hazardous. Always avoid direct inhalation.

Product Introduction

©2020 Hot Melt Technologies, Inc

Table of Contents ......................................................................................................... 3

Safety & Set Up ..........................................................................................................4-5

Operating Instructions................................................................................................6-8

Front Panel Controls.................................................................................................6

Temperature and System Controls...........................................................................7

Front Panel ...............................................................................................................8

Electrical ...................................................................................................................9-10

Fuse & Relay Chart.................................................................................................... 9

Schematic................................................................................................................ 10

Warranty Information .................................................................................................11

©2020 Hot Melt Technologies, Inc Page 3

Proflex®G9-4

Page 4 ©2020 Hot Melt Technologies, Inc

Proflex®G9-4

Safety & Set Up

WARNING

Do not allow the pump motor to stall. A prolonged stall may damage

the motor and other components.

Do not connect or disconnect electrical connectors, or remove

components, with the power on. This will prevent arcing of electrical

contacts and possible failure of components.

Always close and secure the control panel access cover to protect

internal electrical components.

Always operate the system with the tank full and lid on.

Prior to dismantling, assembly, or adjustment of certain service parts

(hose/gun fittings, pump assemblies, etc.), the part(s) being serviced

should be preheated to reduce the chance of stripping threads or

ruining components.

Working on or around hot melt adhesives and equipment can cause

severe burns.

Use eye protection, gloves and protective clothing while operating

and/or servicing hot melt equipment.

Before installing any hot melt equipment, determine proper electrical

requirements per all applicable codes.

At Hot Melt Technologies, we pay special attention to the needs of

operators and service personnel when designing equipment, but

molten hot melt adhesives are dangerous and can cause severe burns.

Extreme care must be exercised to insure personnel safety.

Fire, explosion, personal injury, property, and/or equipment damage

can result if the material(s) used in or around any hot melt adhesive

supply unit are toxic, heat, or re sensitive. Always read the

manufacturer’s recommended use guidelines.

All HMT units are equipped with over temperature protection as

a necessary safety device. Run-away heating can cause hot melt

materials to exceed their ashpoint.

STOP

STOP

If incorrectly used, this machine can cause severe injury.

Those who use and maintain the machine should be trained in

its proper use, warned of its dangers, and should read the entire

manual before attempting to set up, operate, adjust or service

the machine.

©2020 Hot Melt Technologies, Inc Page 5

Proflex®G9-4

Safety & Set Up

08/01/19 Rev A

Before Using Your Hot Melt System

It is your responsibility and obligation to

make sure your system:

Has been properly installed off the floor and

on a steady, level work surface away from

combustible materials.

Has been located in such a way that the controls

are away from the operator and that the control

panel is securely closed at all times.

Is the right capacity system for the intended use.

Is connected to the proper power supply.

(See Below).

Is only used to do what a hot melt system is

designed to do.

Is not used by anyone unable to operate

it properly.

Is used in an area where the room temperature

does not fall below 65°F.

Is used in an area which is free from blowing air

caused by cooling fans, open doors or windows.

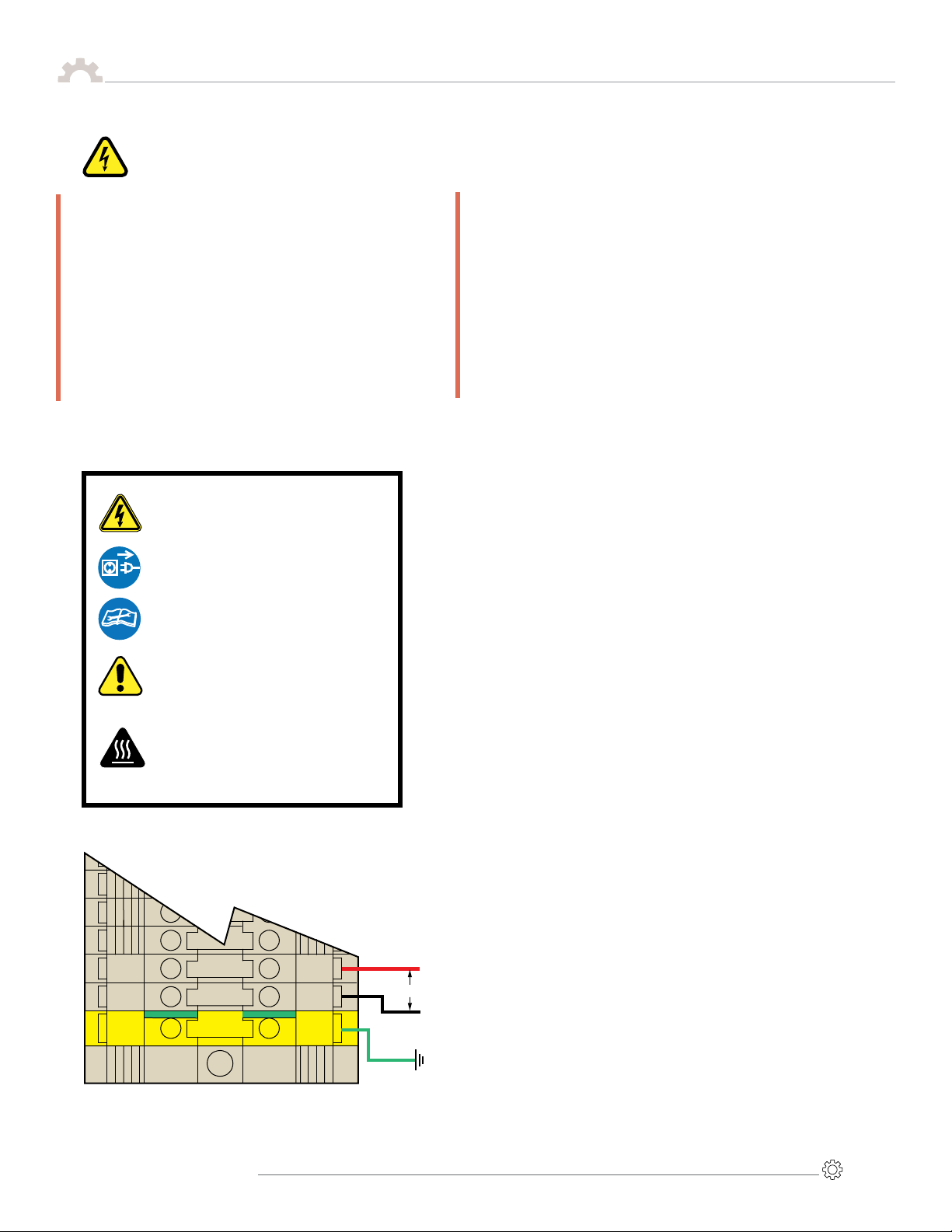

Basic Electrical Power Connections

For 220 VAC Operation

A fused 40 A 220 VAC electrical supply is required.

Performance problems will occur with voltages

less than 208 VAC or greater than 240 VAC.

Total amperage draw will depend on the final

system configuration; number of hoses & length,

guns, accessories, etc.

Do not allow the system to share the same circuit

with other electrical items. A dedicated supply is

recommended.

Do not use an extension cord.

If you change the configuration of your system in

any way that may affect the electrical

requirements (ex. add a gun, longer hose,

automate, etc.) call HMT Technical Service &

Support at 248-853-2011 for assistance.

L2

L1

G

L2

L1

G

L2 (R)

L1 (B)

G (G)

220 VAC Single Phase

Control Box

Protect your hot melt equipment by installing a

GFEP (Ground Fault Equipment Protector) device

in your distribution panel.

HMT recommends that hot melt systems be

protected from unintended line-to-ground

currents by installing an appropriate ground fault

equipment protection (GFEP) device. Contact

HMT Technical Service & Support or a qualied

electrical contractor for more information. When

installing a GFEP device always comply with local

electrical codes.

Prevent Serious

Equipment Damage

LEGEND: SAFETY SYMBOLS

Electric Shock Hazard: Line Voltage

Present with Machine Power Off. Risk

of electrical Shock or Burn

Disconnect Power Before Servicing

Consult Service Manual

Warning/Caution: Used to draw

attention to Hot Surface Warnings,

Over Temp Alarms, Hose Routing

Practices, and other safety notifications.

Hot Surface: Surface and surrounding

area may be hot. Exercise extreme

caution and utilize proper Personal

Protective Equipment (PPE).

Page 6 ©2020 Hot Melt Technologies, Inc

Proflex®G9-4

Operating Instructions

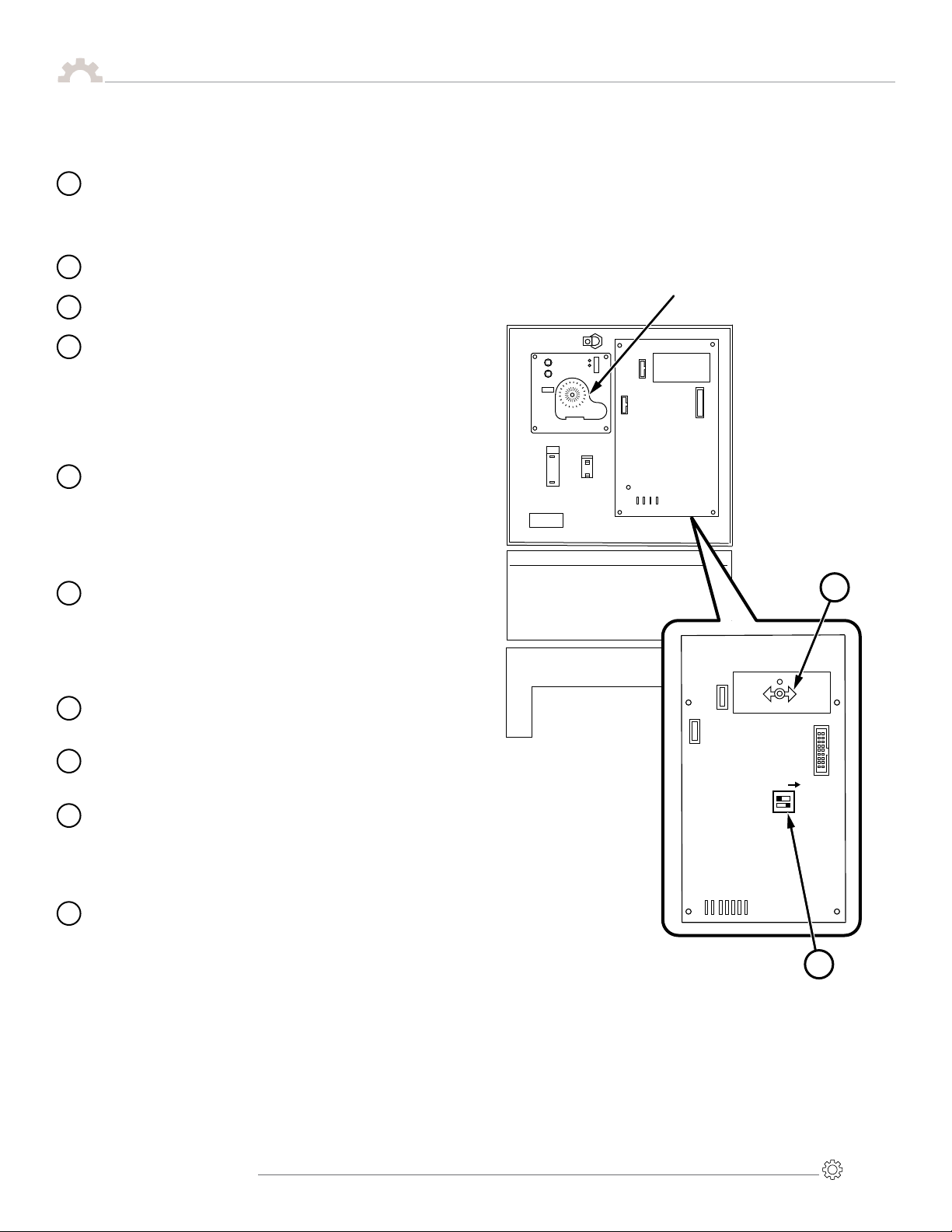

Front Panel Controls

Temperature Display

000

Temperature

Set-Back Control

20-70%

G-9

#3

#4

#3

#4

220 Volt

340-143 Rev:D

000

2

11

13

15

3

8

1

10

®

12

7

4

6

5

9

14

1

2

3

4

7

5

6

Main Power Switch: Turns the system “ON” or “OFF.“

Service Clock: Displays the number of hours that the system

has been ON.

Audible Over Temp Alarm: Sounds when a zone is in

Over Temp. (See #6).

High Limit: Limits the Set Point for any zone; adjustable

between 250°F and 475°F.

To Adjust the High Limit: Turn the system off. Press and hold

down the High Limit button and turn the Power Switch ON.

The display will show the current High Limit.

Release the High Limit button and use the Arrow Keys to

adjust High Limit Up or Down. Turn the Main Power Switch

OFF then ON again. All zones will default to the new High

Limit and must be reset.

Arrow keys and Set Mode LED: See # 4, 11, 12, 13, and 16

for usage.

Zone Status:

Sensor Fault: The LED will light and indicate that no RTD

sensor input is present in the selected zone.

Over Temp: The LED will light and affected zone LED will blink

if temperature exceeds High Limit by 25°F (14°C). The audible

Over Temp Alarm will also sound.

Ready: The LED will light when the zone temperature rises

to its respective set point.

Low Temp: The LED will light when the zone temperature

is below its respective set point. It is normal for all zones

to indicate “Low Temp” as the system heats from a

cold start-up.

Temperature Display: Displays Set or Actual temperatures of

heated zones (e.g. Tank, Hose, Gun, Grid) as well as programmed

values of other features (e.g. High Limit, Auto Standby Timer,

etc.). During operation the actual Tank temperature is displayed

(as default display).

07/08/20 Rev A

©2020 Hot Melt Technologies, Inc Page 7

Proflex®G9-4

Temperature and System Controls

Operating Instructions

8

9

Zone Temp and Status Display buttons: Press and hold any

zone button, (e.g. Tank, Hose, Gun, Grid) to display the set

temperature, then release to see the actual temperature.

The selected zone’s status (Sensor Fault, Ready, etc.) will also

be displayed in the Zone Status area.

Hose/Gun On/Off buttons: Turns the power ON or OFF to each

hose/gun group individually. The LED illuminates accordingly.

Front Panel Lock: Used to secure the front panel. To enhance

the systems tamper resistance, a key lock option is available.

Auto Standby Timer*:

To change, place Set/Run switch in set position. Push the

Auto Standby button and use the “+” and “–” arrows to

adjust from 0 to 5 hours. Return the Set/Run to run position.

Power OFF Timer:

To change, place Set/Run switch in set position. Push the

Power Off button and use the “+” and “–” arrows to adjust

from 0 to 5 hours. Return the Set/Run to run position.

Manual Standby*:If activated, LED will light and all

temperatures will lower to set % value.

To change % of standby, place Set/Run switch in set

position. Push the Temperature Set Back Control button

and use the “+” and “–” arrows to adjust from 20% to 70%.

Return the Set/Run switch to run position. The programmed

% applies to both Auto and Manual Standby.

Pump Ready Delay Timer*:If additional melted adhesive is

needed, this feature adds up to 60 minutes of time before

allowing the pump motor to work.

To change, place Set/Run switch in set position. Push the

Pump Ready delay button and use the “+” and “–” arrows

to adjust from 0 to 60 minutes. Return the Set/Run switch

to run position.

Pump Ready: The pump motor will not operate until

the actual tank temperature is within 25°F (14°C)

of set temperature.

Pump ON/OFF Switch: The pump will only operate when: this

switch is ON, the “READY” LED is lit (see #14 above), and a

trigger input is provided.

Set/Run switch*:Should be in Run Mode during normal

operation. Place in Set Mode to change set temperatures

of any zone, (e.g. Tank, Hose, Gun, Grid) or values of other

features (e.g. High Limit, Auto Standby Timer, etc.). Return

switch to Run Mode when nished with adjustment(s).

All Zone Ready: To restrict operation of the pump until

all active zones, (e.g., Tank, Hose and Gun) have reached

their respective Ready Temp, set the All Zone Ready dip

switch to ON.

°F vs °C: Dip switch used to change from °F or °C

(default is Fahrenheit) For Celsius set the switch to ON.

10

11

12

13

14

15

17

16

Set Mode Run Mode

ALL ZONE READY

CELSIUS

ON

16

17

Optional 24-7 Timer

(934-247)

*System will return to normal operation if no adjustments are made for 15 seconds.

Set Mode LED on front panel will flash, indicating switch is still in Set Mode position.

07/08/20 Rev A

Page 8 ©2020 Hot Melt Technologies, Inc

Proflex®G9-4

Operating Instructions

Temperature Display

000

000

Temperature

Set-Back Control

20-70%

220 Volt

340-143 Rev: D

G-9

#3

#4

#3

#4

6

7

45

3

1

2

BILL OF MATERIALS

ITEM DESCRIPTION PART NO QTY

1Control Box Assembly 934-912 1

2 Pump Switch, 10 A 211-010 1

3 Main Power Switch, 40 A, 220 VAC 211-017 1

4 Service Clock 243-004 1

5Over Temp Alarm 243-006 1

6 Decal 340-143 1

7a Front Panel Latch, Non-Locking 340-030 1

7b Front Panel Latch, Locking (Optional) 340-032 1

07/08/20 Rev A

Front Panel

©2020 Hot Melt Technologies, Inc Page 9

Proflex®G9-4

TANK HEATER FUSE

ITEM DESCRIPTION REPLACE WITH PART NO

TF1/TF2 2400 W

3000 W

4800 W

6000 W

15 A, 600 VAC (KLKR)

20 A, 600 VAC (KLKR)

30 A, 600 VAC (KLKR)

35 A, 600 VAC (KLKR)

214-315

214-320

214-330

214-335

TEMP CONTROL BOARD

ITEM DESCRIPTION REPLACE WITH PART NO

F3/F3B Hose up to 12'

Hose 12'-20'

Hose 12'-24'

5 A, 125 VAC (GMA)

8 A, 125 VAC (GMA)

10 A, 125 VAC (GMA)

214-105

214-108

214-110

F4/F4B Handgun 2 A, 125 VAC (GMA) 214-102

Automatic Valve –Call TSS

F5/F5B Hose up to 12'

Hose 12'-20'

Hose 20'-24'

5 A, 125 VAC (GMA)

8 A, 125 VAC (GMA)

10 A, 125 VAC (GMA)

214-105

214-108

214-110

F6/F6B Handgun 2 A, 125 VAC (GMA) 214-102

Automatic Valve –Call TSS

F7/F7B Hose up to 12'

Hose 12’-20’

Hose 20’-24’

5 A, 125 VAC (GMA)

8 A, 125 VAC (GMA)

10 A, 125 VAC (GMA)

214-105

214-108

214-110

F8/F8B Handgun 2 A, 125 VAC (GMA) 214-102

Automatic Valve –Call TSS

F9/F9B Hose up to 12'

Hose 12'-20'

Hose 20'-24'

5 A, 125 VAC (GMA)

8 A, 125 VAC (GMA)

10 A, 125 VAC (GMA)

214-105

214-108

214-110

F10/F10B Handgun 2 A, 125 VAC (GMA) 214-102

Automatic Valve –Call TSS

MOTOR CONTROL BOARD

ITEM DESCRIPTION REPLACE WITH PART NO

F1/F2 Transformer

Primary 1 A, 125 VAC (GMA) 214-101

F3/F4 Transformer

Secondary 1 A, 125 VAC (GMA) 214-101

F5/F7 A/C Motor 1

D/C Motor 1

5 A, 125 VAC (GMA)

8 A, 125 VAC (GMA)

214-105

214-108

F6/F8 Accessory Output 2 A, 125 VAC (GMA) 214-102

Temp Control Board to Sensor Board Cable (220-048)

(Not shown)

Set Mode Run Mode

F9

F7

F10

F8

F4

F2

F1

F3

CR5

F16

F15

F7 F8

HOSE

GUN

HOSE GUN

F9 F10

HOSE

GUN

F17

F18

HOSE GUN

HOSE

GUN

F5 F6

HOSE GUN

HOSE

GUN

F13

F14

F11

F12

F3 F4

HOSE GUN

HMT 241

TANK SSR Serial Number

SSR3 SSR2

SSR4

SSR5SSR6

SSR7

SSR8

SSR9

109 164 179 107 108 127A 131 177 128A 132 178

Accessory

2

Accessory

1

TRANSFORMER PRIMARY

TRANSFORMER SECONDARY

CR4

CR3

CR2

110

111

114

115

117

118

121

122

124

125

169

170

171

172

173

174

175

176

113

112

145

116

146

147

120

119

143

123

149

150

151

152

153

154

155

156

157

158

159

160

161

162

Hose 1

Gun 1

Hose 2

Gun 2

Hose 3

Gun 3

Hose 4

Gun 4

106 105

MOTOR 1

MOTOR 1

ACCESSORY

ACCESSORY

Microprocessor

Board Cable

(220-052)

Motor

Control

Board

(245-035)

Temp

Control

Board

(245-041)

Microprocessor

Board

(245-040)

Motor/Accessory

Relay

(213-008)

Tank Relay

(213-100)

Tank Over

Temp Relay

(213-030)

F4

F3

F3B

F4B

F6

F5

F5B

F6B

F9

F7

F7B F8B F9B F10B

RTD Sensor

Board

(245-042)

F10

Hose/Gun

Relay

(213-025)

F8

TF1

TF2

F2

F1

F4

F3

F5

F6

F8

F7

Side Button Board

(245-037)

Push Button

Board Cable

(220-049)

GFEP

Hoses/Guns

(211-100)

GFEP, Single Motor

Fuse & Relay Chart

Electrical

Page 10 ©2015 Hot Melt Technologies, Inc

Proflex®G9

Electrical

CONNECTOR

IDENTIFICATION

C1 Tank

C2 Hose 1

C3 Hose 2

C4 Motor 1

C5 Accessory 1

C6 Accessory 2

C7 Motor 2

C8 Hose 3

C9 Hose 4

Ground

L2

147

05/03/17 REV: D

Ground Fault

Equipment Protector

(Hoses & Guns)

1

2

LINE

LOAD

GF1

GF2 N

GF3

GF4

N

LINE

LOAD

Ground Fault

Equipment Protector

(Hoses & Guns)

Main

“ON/OFF”

Breaker

100

130

102

113

120

151

157

Hose 1 Heater

Gun 1 Heater

Hose 2 Heater

Gun 2 Heater

Hose 3 Heater

Gun 3 Heater

Hose 4 Heater

Gun 4 Heater

F16: Gun 3 (L2)

F8: Gun 3 (L1)

F15: Hose 3 (L2)

F7: Hose 3 (L1)

F14: Gun 2 (L2)

F6: Gun 2 (L1)

F13: Hose 2 (L2)

F5: Hose 2 (L1)

F3: Hose 1 (L1)

F12: Gun 1 (L2)

F4: Gun 1 (L1)

F11: Hose 1 (L2)

G

System Ready

Out

C6-8

162

138

150

156

(F4)Secondary

120V

24V

220V

(F2)Primary

(F1)Primary

166

167

168

Accessory 2

Output

Accessory 1

Output

Accessory 2

Input

Accessory 1

Input

C5-7

C6-7

C5-6

C6-6

C6-4

C5-4 C5-5

C6-5

F9: Motor

Tank

RTD

Hose 1

RTD

Hose 2

RTD

Hose 4

RTD

Hose 3

RTD

Gun 1

RTD

Gun 4

RTD

Gun 3

RTD

Gun 2

RTD

C9-2

C9-3

C9-4

C9-5

C8-2

C8-3

C8-4

C8-5

C3-2

C3-3

C3-4

C3-5

C1-10

150

151

152

153

154

154

156

SRSR178132128A177131127A108107179164109

2CR

110 111 114 115 117 118 121 122 124 125 169 170 171 172 173 174 175 176

F10: Accessory 2

F8: Accessory 1

F7: Motor

Motor Switch

Pump Motor

C4-3 C4-4

C1-2

C1-3

C2-8

C2-9

C2-10

C2-11

C3-8

C3-9

C3-10

C3-11

C8-8

C8-9

C8-10

C8-11

C9-8

C9-9

C9-10

C9-11

104A

103A 178

177

179

133

134

139

135

Over Temp

Safety Relay

C6-9

F9: Hose 4 (L1)

F17: Hose 4 (L2)

F10: Gun 4 (L1)

F18: Gun 4 (L2)

157

161

158

159

160

162

C2-2

C2-3

C2-4

C2-5

106 105

113

112

145

116

146

147

120

119

148

123

149

Tank Heater Circuit

Tank Heater Relay

2CR 102B

C1-15 Tank Fuse TB-2

102E

100A

102D

1CR

102C

43

L1

Tank Fuse TB-1

102A

1CR

462

1

165

109

128

127

138

130

164

131

132

104

163

136A

136

137

137A

1 0

GFEP, Single Motor

SYMBOL LEGEND

Hose 1

1CR

4 3

1CR

4 3

C2-6

5

LINE

LOAD

24V Transformer

Motherboard

Power Supply

Board Mounted Fuse

Terminal Block

Fuse Description

RTD Temperature

Sensor

Capacitor and Motor

Breaker Switch

Heater

Amber Light

Relay Number

Relay (Coil)

Wire Location

Relay Number

Relay (Contacts)

Wire Location

AMP Connector

& Pin Number

AMP Quick Disconnect

Stakon Connector

Wire Termination

Ground Fault Alert

(Hose & Gun Zones)

Schematic

POWER CONNECTION

220 VAC, Single Phase

L1 220 V L2 G

©2015 Hot Melt Technologies, Inc Page 11

Proflex®G9

Electrical

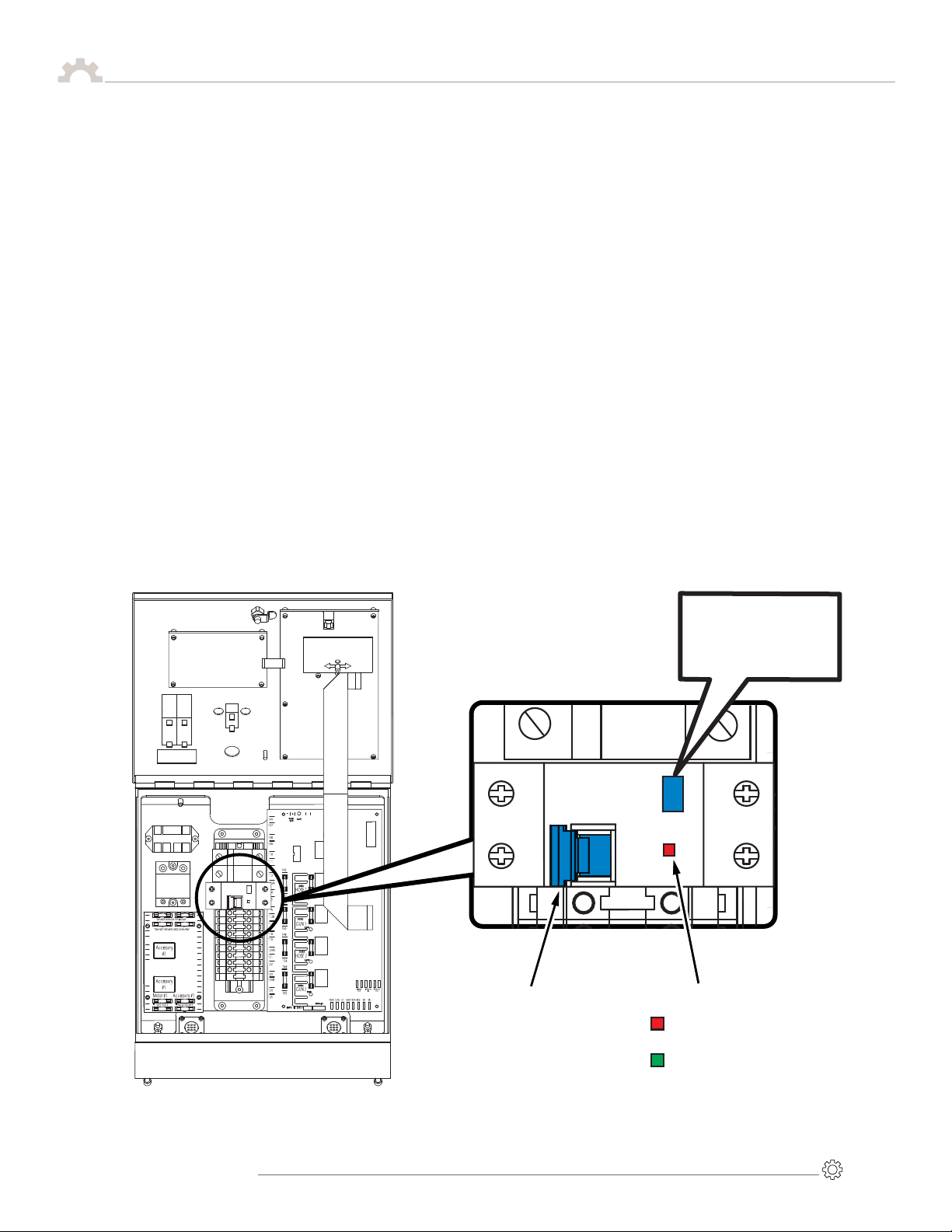

Ground Fault Equipment Protection (GFEP)

Genesys 2 340-222

Set Mode Run Mode

Ground Fault Equipment Protector (GFEP)

Indicator Window

ON - Hose and Gun Zones

are Active

OFF - Hose and Gun Zones

are Inactive

ON/OFF Switch

(Pictured in ON Position)

TEST

LOAD

LINE

Test every 3 months

per manufacturer’s

recommendation.

This adhesive dispensing system is equipped with a Ground Fault Equipment

Protector (GFEP) that has been installed on the circuit powering the hose

and gun zones. This GFEP is designed to protect the hoses from

an unintended ground fault.

GFEP must be switched ON (Indicator window RED) for hose and gun

zones to heat.

If a ground fault is detected on any hose or gun zone, the GFEP will

switch OFF (Indicator window GREEN) removing power from all hose

and gun zones.

If the GFEP switches OFF due to a ground fault during operation,

contact HMT Technical Service & Support for assistance.

Page 12 ©2015 Hot Melt Technologies, Inc

Proflex®G9

This Warranty extends to the original purchaser only and commences on the date

of the original purchase.

Any part of the Hot Melt Technologies (HMT) adhesive supply unit (ASU)

manufactured by HMT and found in the reasonable judgement of HMT to be

defective in material and workmanship, will be repaired or replaced by HMT without

charge for parts or labor.

This Warranty is limited to:

a) One (1) year from initial use,

b) Eighteen (18) months from date of purchase, or

c) Two thousand (2,000) hours of use, whichever comes rst.

The ASU including any defective part must be returned to HMT within the warranty

period. All transportation expenses to HMT for warranty work and the expense

of returning it to the owner will be paid for by the owner. HMT’s responsibility in

respect to claims is limited to (at its option) making the required repairs, adjustment,

or replacements. No claim of breach of warranty shall be cause for cancellation of

the contract of sale of any HMT ASU.

This warranty does not cover any ASU that has been subject to misuse, abuse,

negligence,or accident, or which has been operated in any way contrary to the

operating instructions. Warranty does not apply to any damage to the ASU that is

the result of improper maintenance or installation.

This warranty does not cover any ASU that has been altered or modied by the

customer. In addition, the warranty does not extend to repairs made necessary

by normal wear or by the use of hot melt materials in the ASU which in the

reasonable opinion of HMT are either incompatible with the ASU or adversely affect

its operation, performance, or durability. This warranty does not extend to any

accessory attachments to the ASU that are warranted separately for different periods

of time. Other components supplied by HMT as part of a system will carry

the warranty of the original manufacturer.

This warranty does not extend to an ASU damaged during shipment. Risk of loss or

damage to the ASU shall pass to the buyer.

HMT reserves the right to change or improve the design of any ASU, or part of an

ASU, without assuming any obligation to modify any ASU previously manufactured.

HMT assumes no responsibility for incidental, consequential or other damages

including but not limited to: expense for hot melts, delivery or return freight

expenses, mechanics travel time, telephone or telegraph charges, rental of a like

product during the time warranty repairs are being performed, travel, loss or

damage to personal property, loss of revenue, loss of use of the ASU, loss of time

or inconvenience.

Warranty Information

Warranty Information

Table of contents