PROformance Hoops PROVIEW Series User manual

ADJUSTABLE HEIGHT

GOAL SYSTEM

PROVIEW SERIES

554PV

2 www.proformancehoops.com 1-888-353-4667

THANK YOU!

Thank you and congratulations for purchasing a Proformance Hoops Goal - the

finest basketball goal system on the market today! You will discover that

Proformance Hoops is unsurpassed in product innovation, quality and integrity in

the basketball equipment industry. We are focused on designing and engineering

products that meet and exceed the expectations of demanding players and

withstand today’s toughest playing environments.

LAY OUT PLAYING COURT

Consider the following to determine where to install the basketball goal:

Whether the goal is to be installed into a landscaped area next to the playing surface or

into a hard-surfaced area.

Backboard size and its extension distance from the structures.

If court markings are to be used.

Amount of playing surface desired beneath the goal.

Other functions of playing surface (such as driveway, tennis court, etc.)

There must be at least 18” clearance behind the back of the Goal Post to allow room to

operate the goal height adjusting crank.

When the rim is set to the regulation height of 10 ft. the distance from the face of the

backboard to the front of the Goal Post is, depending upon the PROforce (PF) or

PROview (PV) model, shown in the figure below.

1-888-353-4667 www.proformancehoops.com 3

SAFETY INSTRUCTIONS

GOAL ASSEMBLY

IMPORTANT: Concrete must cure a minimum of 72 hours before installing goal.

IMPORTANT: Safe assembly of the goal requires two to three people in good physical

condition and capable of lifting 80-100 lbs (36-45 kg) each.

IMPORTANT: Locate and familiarize yourself with all the parts of the goal before

beginning assembly.

REQUIRED TOOLS AND MATERIALS:

Level

Rubber Mallet

12' Tape Measure

Phillips Screwdriver

Ratchet

Sockets or wrenches:

15mm (9/16")

19mm (3/4")

24mm (15/16")

27mm (1-1/16")

Failure to follow these safety instructions may result in serious injury or death and/or

property damage.

Do not install or use this product unless the instructions within this manual have been carefully

read and understood.

Consult Proformance Hoops if you do not understand the instructions in this manual or need

additional information

Know what’s below ground. “Call before you dig” the hole for the ground anchor. For the US

the number is 811.

If using a ladder during assembly, use extreme caution. Two or three people are recommended

for safe installation and assembly.

Installation and assembly of this product will require lifting and bending that may result in

injury to anyone not accustomed to this type of activity.

Ensure there are no overhead power lines within a 20 ft. (7m) radius of the goal location.

Climate, corrosion or misuse could result in system failure.

The Safety Rod stops the Main Extension Arm at a rim height of 7 ft (2.13m). Attempting to

adjust further down will damage the Arm. If the Safety Rod is removed, adjustment of the rim

below a height of 6 ft. (1.83m) will cause internal damage to the mechanism.

DO NOT HANG on the rim or any part of the goal system. This includes the backboard, support

braces and net.

During play, especially when performing dunking activities, players should keep their faces

away from the backboard, rim and net. Serious injury could result if teeth or face come in

contact with the backboard, rim or net. Do not wear jewelry or other loose objects that could

become entangled with the net.

Twice yearly, check the goal system for loose hardware, excessive wear and signs of corrosion.

Repair the system before use.

Never play on damaged equipment.

PARTS LIST

4

ITEM QTY DESCRIPTION

A 1 5"x5"Main Post

B 1 Actuator

C 1 Spring-Assist Cartridge

D 1 Pole padding

E 1 Gusset Padding

F 1 Main Extension Arm

G 2 Upper Extension Arm

H 1 Backboard

I 1 Safety rod 20mmdia ITEM QTY DESCRIPTION

J 1 Sleeve for Spring Cartridge 1 2 Nylon Washer M18

K 1 Rim Height Indicator 2 10 Nylon Washer M16

L 1 Flex Rim (Separate pack) 3 2 Nylon Washer M12

M 1 Rim Pad (Pre-attached) 4 1 6mm Lock Pin

N 1 Rim Height Sticker 5 1 Hex Bolt M18x320mm

6 3 Hex Bolt M16x320mm

U1 1 Anchor Template 7 1 Hex Bolt M16x245mm

U2 4 16mm Anchor J-bolts 8 1 Hex Bolt M16x120mm

U3 8 Thick washer for J-bolts 9 1 Hex Bolt M16x135mm

U4 12 Hex nut M16 10 2 Hex Bolt M12x35mm

U5 4 Anchor Rebar 36"L 11 2 Washer forM18 Bolt

U6 4 Lock Washer M16 12 12 Washer forM16 Bolt

13 4 Washer forM12 Bolt

R1 4 Carriage Bolt M10x50mm 14 1 Lock Nut M18

R2 4 Washer M10 15 7 Lock Nut M16

R3 4 Flange nut M10 16 2 Lock Nut M12

UNDERGROUND PARTS

PARTS LIST

HARDWARE LIST

RIM HARDWARE

U1

U2

U4

U4

U4

U5

U6

U3

U3

A

B

C

F

G

G

H

IJ

K

L

N

5

11

11

14

6

12

12

12

15

7

12

2

12

15

6

12

2

12

15

R2 R3

R1

12 8

9

2

2

12

15

10 13

313 16

16 13 313 10

4

2

Crank

5

! !

WARNING

STEP1

A.

B.

C.

STEP2

A.

Nylon washer #1 may

be factory installed

14 11

11 5

Rubber pad

face upward.

A

F

1

Slide the Main Extension Arm (F) over the top of the

Main Post (A) and attach to the lower pivot tube

welded on front side of Pole (A) with one Hex bolt

M18x320mm (#5), two Flat washer M18 (#11), two

Nylon washers M18 (#1), and one Lock nut M18

(#14).

Do not over tighten this bolt and nut.

Note: make sure the Nylon washers locate between Main

Extension Arm (F) and Main Post (A).

U6

U3

U4

FIGURE 1B

Playing Court

Back

FIGURE 1C

FIGURE 1A

U3

U2

Slide a 18mm Thick Washer (U3) over each of the J-Bolts (U2) as shown in FIGURE 1A.

Remove the Padding from Main Post (A). Place the Main Post (A) over the J-Bolts. Slide a

16mm Thick Washer (U3), a Lock washer 16mm (U6) and thread a 16mm Hex Nut (U4) to each

J-bolt. Tighten the Nuts only a few turns onto the J-Bolts as shown in FIGURE 1B.

If the Main Post (A) is not exactly vertical, adjust the 16mm J-Bolt Hex Nuts (U4) located under

the Post base. Tighten all of the Hex Nuts (U4) Above Post base when Main Post (A) is vertical.

NOTE: Face the Main Post (A) with Actuator Bracket facing away from playing court (as shown in FIGURE

1C).

6

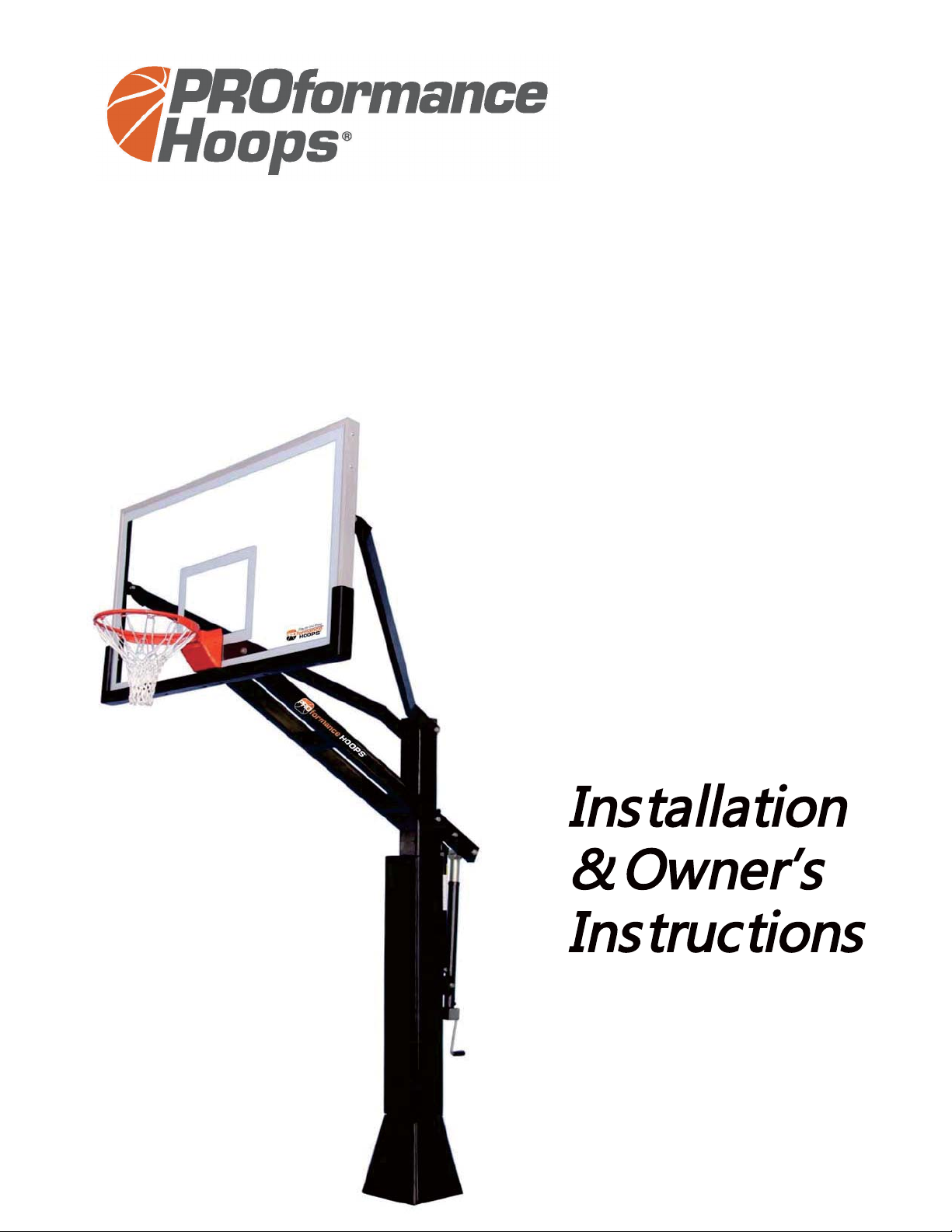

STEP 3

STEP 4

A.

STEP 5

A. Attach the 2 Upper Extension Arms(G) to Main Post (A) with a Hex

(#7), two Flat Washers M16(#12), 2 Nylon washersBolt M16x245mm

(#2), one Lock Nut M16 (#15).

Do not tighten at this time.

F

A

C

B

8

12

2

12

15

2

2

12

15

6

12

9

12

2

2

12

15

B

A

6

12

12

15

F

Removable

crank handle

7

12

2

G

G

2

12

15

FA

A.

B.

C.

Connect Actuator to Main Extension arm.

Place the upper bracket of Actuator(B) between

the last set of welded tubes on the Main Extension

Arm (F), attach the two parts using Hex bolt M16X320mm

(#6), two Flat Washers M16 (#12), one Lock nut (#15).

Connect Actuator(B) to the mounting bracket welded

in the middle of Post (A), using one Hex Bolt

M16x135mm (#9), two flat Washers for M16 Bolt (#12),

two Nylon Washers (#2), and one Lock Nut for M16 bolt

(#15).

Note: make sure Nylon washers go between Actuator and

Mounting Bracket.

Attached Crank handle to the actuator. Slide Removable

Crank handle onto the shaft sticking out of Gear Box

(Actuator), lock it in place with attached pin.

Slide Steel Sleeve (J) thru the tube welded at the top end of Spring-

Assist Cartridge (C). Slide the Rim Height Indicator (K) over Steel

sleeve, leave it beside the Spring-Assist Cartridge (C).

Place the top of Spring-Assist between Main Extension (F), align the

Steel Sleeve (J) with the second set of welded tubes on the Main

Extension Arm (F), slide one Washer M16 (#12) over one Hex Bolt

M16x320mm (#6), and slide this Bolt all the way thru Main Extension

Arm (F), one Nylon washer M16 (#2), Steel Sleeve (J), another Nylon

washer (#2), and the other side of Main Extension Arm (F).

Secure it with one Flat washer M16 (#12), one lock nut M16 (#15).

Do not over tighten this bolt because this is the pivot point.

Make sure the Plastic Rim Height Indicator (K) hang freely along side

of Spring-Assist Cartridge.

Note: Nylon washer locates between Steel sleeves (J) and Main Extension

arm (F).

J

K

B.

C.

Attach the bottom of Spring-assist Cartridges (C) to the Main pole Bracket

by using a Hex Bolt M16x120mm (#8), two Flat Washers M16 (#12), two

Nylon Washer M16 (#2) and one Hex Nut M16 (#15).

Note: Nylon washer goes between Pole bracket and (C).Cartridge

Remove and discard the Steel spreader bracket from the Spring-Assist

Cartridges (C).

7

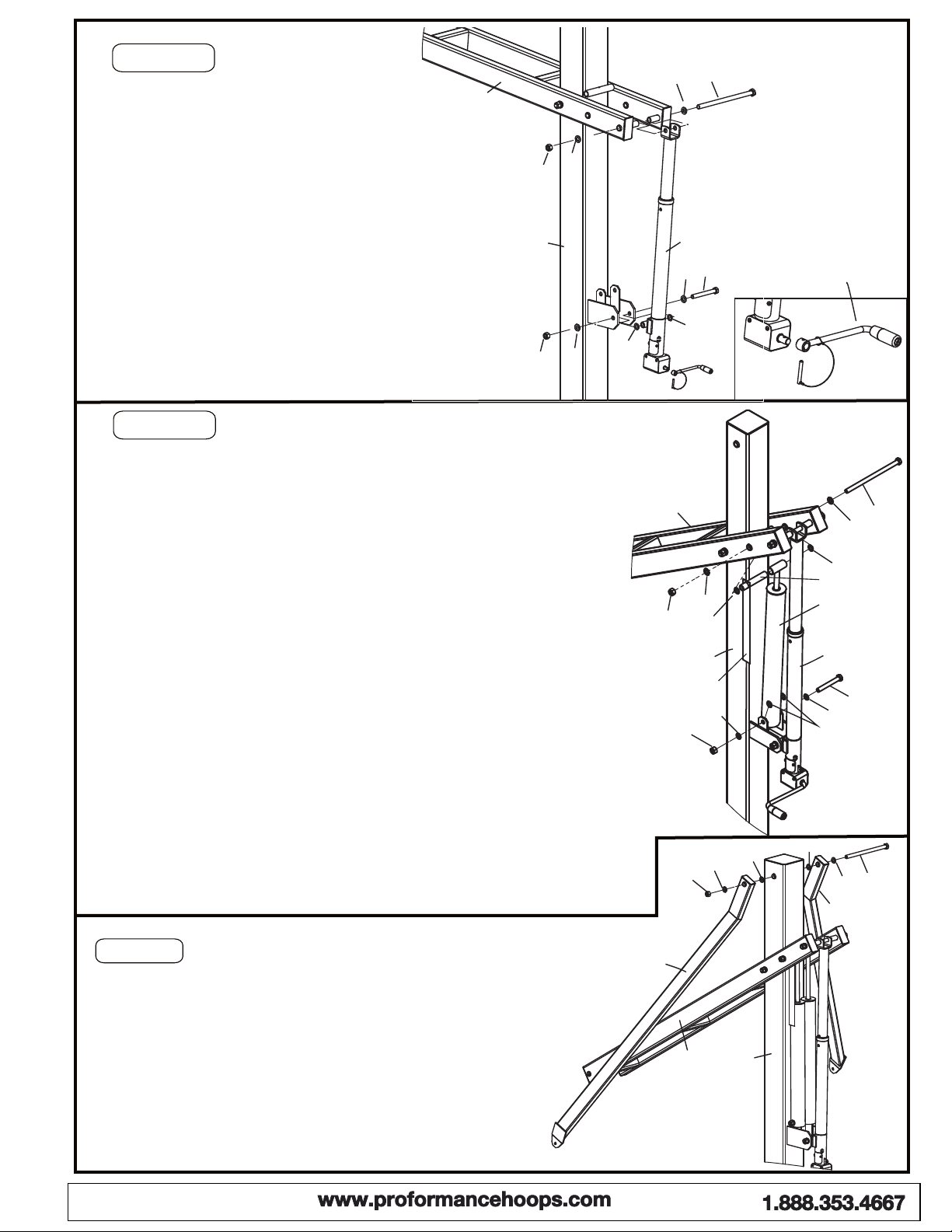

STEP 8

A. After everything is square, make sure all nuts on the

system have been tightened.

NOTE: But do not over tighten the Nuts, make sure the unit

can be adjusted up and down.

B. To apply the Rim Height Sticker(In the manual pack), first use

a tape measure to crank rim up to exactly 10’ from the playing

surface. Use a pencil to make a mark on the Spring-assist

Cartridge(C) where the bottom of the Rim Height Indicator(K)

stops. Then, peel and apply Rim Height Sticker to outside

of Spring-assist Cartridge(C) lining up the pencil mark with the

C. Attach Post Pad and Gusset Pad to Main Post(A) as shown.

B.Mount the rim to the Mounting bracket on Backboard(H)

using the hardware supplied in rim box.

NOTE: Use a level to make sure rim is level side to side

before tightening nuts.

STEP 7

A.

B.

Remove the screws on Rim spring box cover, open

the Spring box.

Re-attach Spring box cover to the Rim with removed

screws.

A.

C.

10

B

A

4

I

Rim Height

Sticker

C

Slide Safety Rod (I) thru the tube welded on the backside

of Main Post (A), align the holes each other and secure it

with one Lock Pin 6mm (#4). See detail .B

D.

F

GH

10

13 313 16

16

13

3

13 10

G26

12

12

15

R1 R2 R3

L

H

Crank the Main extension arm as low as possible.

Attach the Backboard to Main Extension Arm (F) by

using a Hex Bolt m16x320mm (#6, two M16 Flat

Washers(#12), two Nylon washers (#2) and one Lock Nut

M16 (#15).

Note: Nylon washers go between Main extension arm Bracket

(F) and Backboard mounting bracket.

Connect Upper Extension Arms (G) to Backboard

(H), using 2 Hex bolts M12x35mm (#10), 4 Flat

Washers M12 (#13), 2 Nylon washers M12 (#3) and

2 Lock nuts M12 (#16).

Note: Put Nylon washers between backboard plate and

Upper extension connecting plate.

8 www.proformancehoops.com 1-888-353-4667

WARRANTIES

BUYER AGREES THAT ALL PRODUCTS SOLD BY PROFORMANCE HOOPS CARRY THE FOLLOWING WARRANTY

Subject to proper installation, and normal intended use, all structural components of ProView Series*, Pro Series*, Force Series*,

and Wall Mount Basketball Systems are warranted to the original owner to be free of defects in materials and workmanship for the

duration of ownership by the original retail purchaser, subject to the limitations below. The Basketball Systems will be covered by this

warranty for a period of five years. Proformance Hoops shall have the right to require the purchaser to deliver the allegedly defective

products to Proformance Hoops for testing, repair, or replacement. Proformance Hoops shall not be responsible for any expense

associated with the replacement or removal of the product from its application for such delivery. Freight and Handling charges may

apply to covered warranty parts. Modification of any product by the customer, unless approved by Proformance Hoops, will void all

warranty. Where listed as “LIMITED”, the warranties shall cover damage of failure that occurs during the course of NORMAL or

INTENDED USE of the product. Normal or intended use shall be described as activity that is necessary for the participation in the sport

for which the equipment is damaged. NOT COVERED is damaged caused by deliberate hanging, multiple player hanging, vandalism,

non-basketball activities, or any other activity that could be regarded as abusive.

Padding Warranty: Multi-Purpose Backboard Edge Padding: one year limited; Indoor Backboard Edge Padding: five year limited

(indoor only); Custom-Fit Pole Padding: one year limited; Wrap-Around Pole Padding: one year limited.

NOT COVERED BY THIS WARRANTY

Use in non-residential applications of Glass backboards.

Use in non-residential applications of Tradition complete systems.

Any products subjected to abuse, negligence, improper installation, vandalism, acts of God, alteration of product or any other

events beyond the control of Proformance Hoops.

Paint or rusted parts.

Deterioration of product due to time and wear.

Normal deterioration of products due to atmospheric conditions, weather, rust, wear and tear (including paint), or other causes that do

not affect functional use are not covered by Proformance Hoops warranties. All warranties are valid only when product is used in the

intended application, and when installed according to Proformance Hoops instructions. Warranty will be void if maintenance

instructions in the Owner’s Manual are not followed, including jack lubrication on a bi-yearly basis. If you did not receive an Owner’s

Manual, please contact ProformanceHoops.com and one will be sent to you.

WARRANTY CLAIMS: All returns must be arranged through the local dealer if available. Warranties do not cover dealer service

charges, labor charges, freight or travel expense associated with replacement, repair, or removal of warranty item. A warranty claim

form must be completed, and photos submitted for any item you wish to claim under warranty. If the purchase was not made through a

dealer, this form is available by email. In response to your claim, you will receive an order confirmation as well as a notice stating

whether Proformance Hoops needs your warranty item returned. Proformance Hoops will notify you if we determine that the item

cannot be claimed under warranty. Proformance Hoops is not responsible for any charges for labor to install or repair defective

product prior authorization. Proformance Hoops will determine the most economical method to either repair or replace

product before any work is to commence.

TO THE MAXIMUM EXTENT PERMITTED BY LAW, THIS WARRANTY AND THE REMEDIES SET FORTH HEREIN ARE

EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES

OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IF PROFORMANCE HOOPS CANNOT DISCLAIM OR

EXCLUDE IMPLIED WARRANTIES UNDER APPLICABLE LAW, THEN TO THE EXTENT POSSIBLE ANY CLAIMS UNDER SUCH

IMPLIED WARRANTIES SHALL EXPIRE OR EXPIRATION OR THE APPLICABLE WARRANTY PERIOD. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO

YOU. PROFORMANCE HOOPS DOES NOT ASSUME OR AUTHORIZE ANY PERSON TO ASSUME FOR US, ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF OUR PRODUCTS.

TO THE MAXIMUM EXTENT PERMITTED BY LAW, PROFORMANCE HOOPS ASSUMES NO RESPONSIBILITY FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHICH MAY ARISE FROM THE PURCHASERS OR USE OF OUR EQUIPMENT.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGE, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

IF ANY PROVISION OF THIS WARRANTY IS INVALID, VOID OR UNENFORCEABLE IN ANY INSTANCE OR RESPECT, THE

UNENFORCEABLE PROVISION WILL BE SEVERED AND REFORMED TO EFFECT THE INTENT OF THIS LIMITED WARRANTY

TO THE MAXIMUM EXTENT POSSIBLE, AND THE REMAINING PROVISIONS SHALL CONTINUE IN FULL FORCE AND EFFECT

AND SHALL BE ENFORCED TO THE FULL EXTENT PERMITTED BY LAW.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state

0415

This manual suits for next models

1

Table of contents

Other PROformance Hoops Accessories manuals

Popular Accessories manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI DLI-P360L M Series instruction manual

Axis

Axis 0734-001 installation instructions

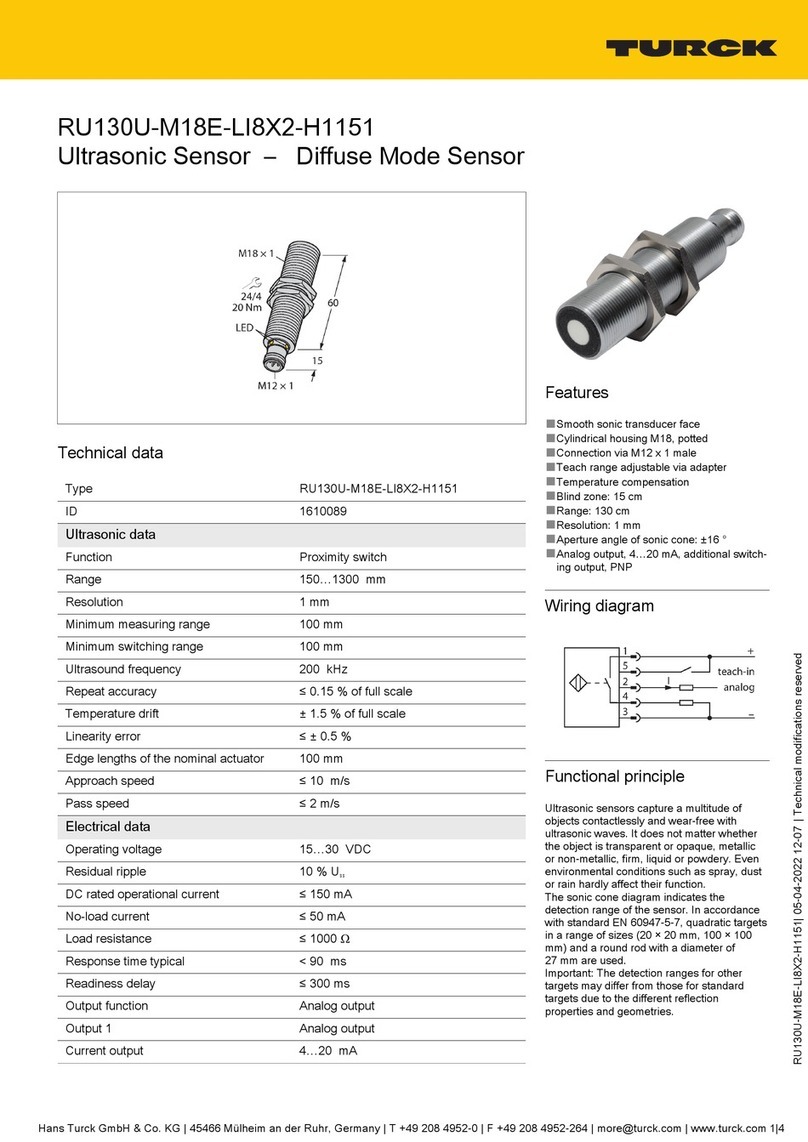

turck

turck RU130U-M18E-LI8X2-H1151 quick start guide

Skov

Skov DOL 68 Technical user guide

Craftsman

Craftsman 486.24508 Assembly instructions

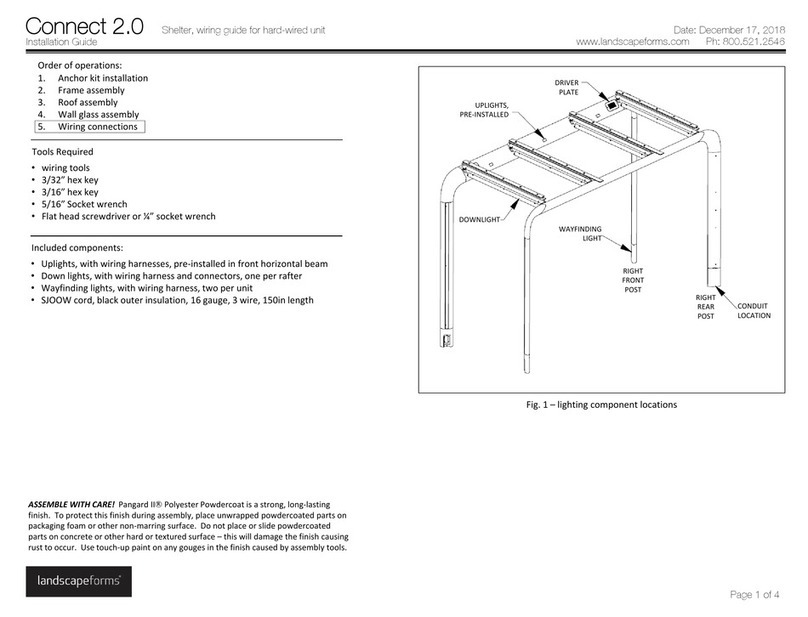

Landscape Forms

Landscape Forms Connect 2.0 installation guide

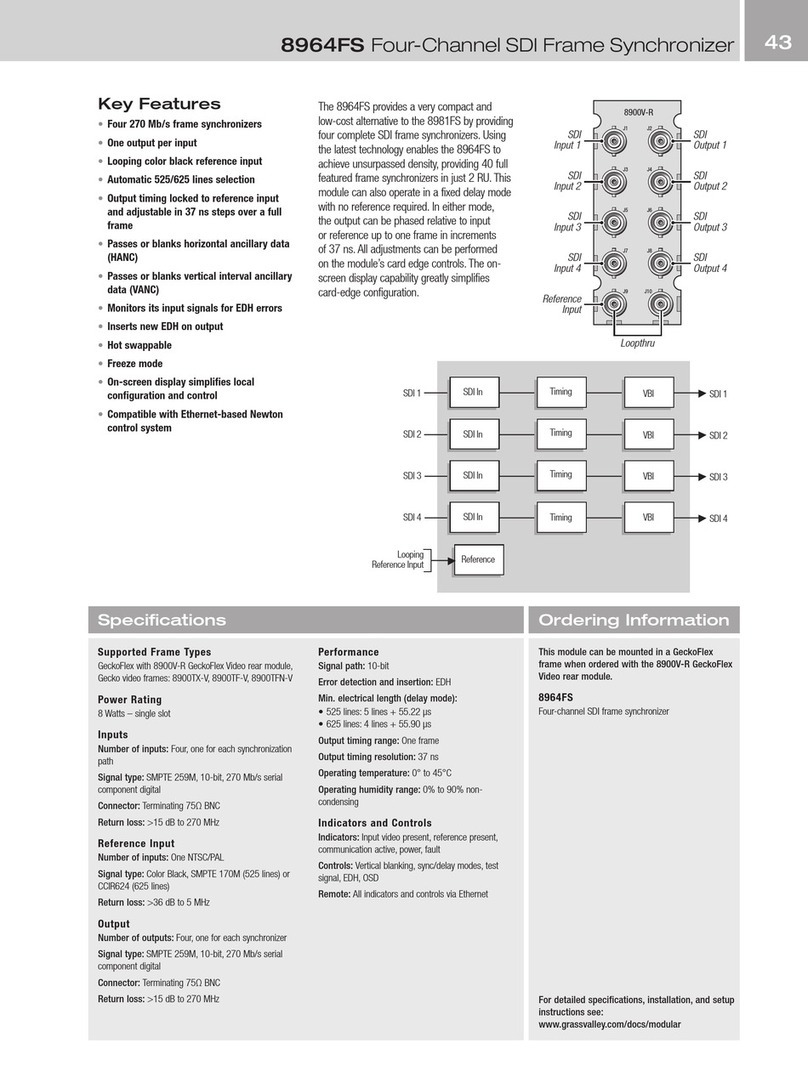

GRASS VALLEY

GRASS VALLEY 8964FS - datasheet

Cedes

Cedes GridScan/Pro SI Installation and operation manual

CAS

CAS CI-6000A Series manual

PCB Piezotronics

PCB Piezotronics Y482B06 Installation and operating manual

Apogee Instruments

Apogee Instruments SU-200 owner's manual

Vernier

Vernier Go Direct Light and Color GDX-LC manual