www.mc-techgroup.com LA | 1.01.01 3

Contents

1General information..............................................................................................................4

2Declaration of conformity ....................................................................................................4

3Safety instructions ...............................................................................................................5

4Warranty................................................................................................................................5

5Used terms and signal indications......................................................................................6

6Introduction...........................................................................................................................8

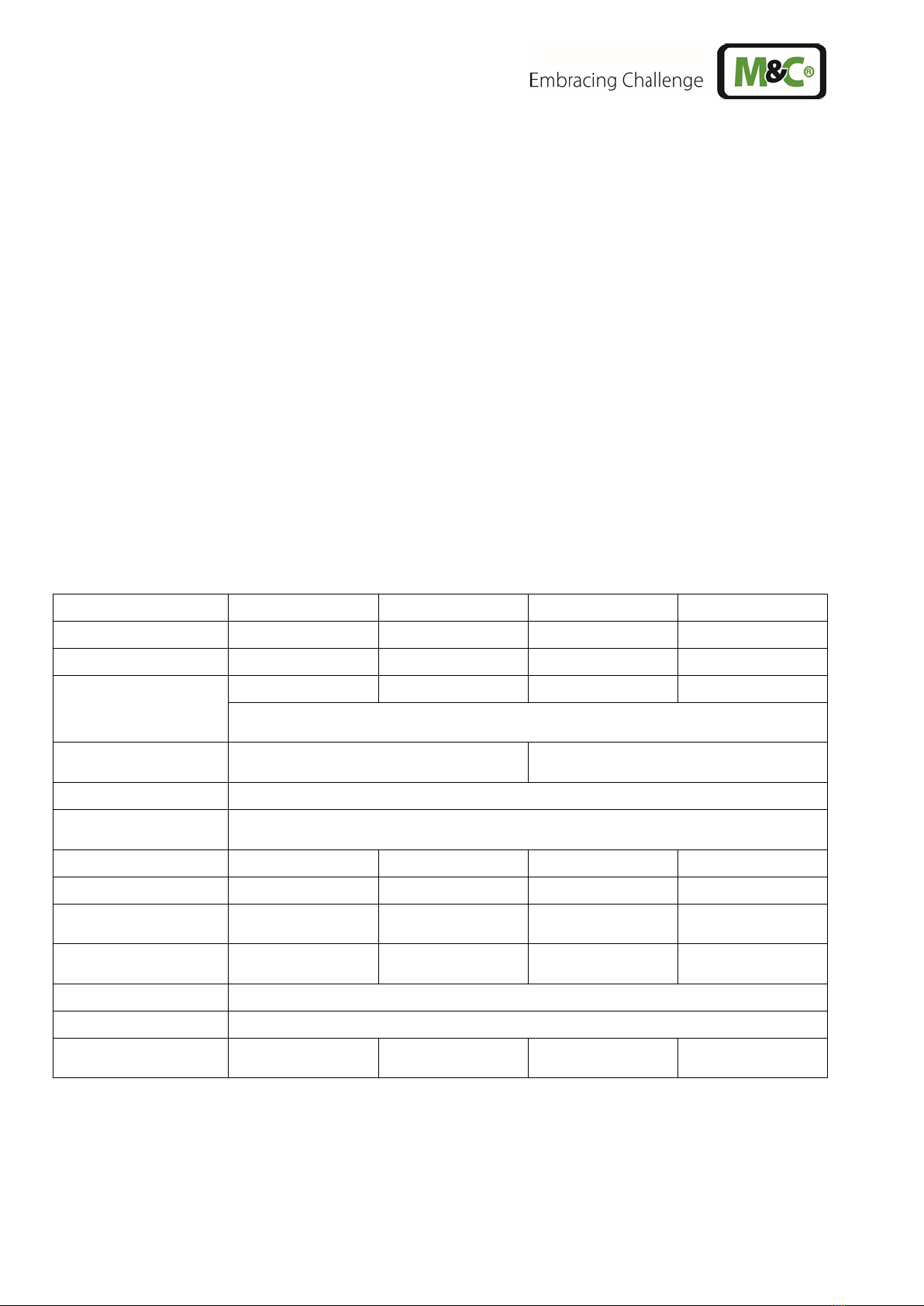

7Application............................................................................................................................8

8Technical Data......................................................................................................................8

9Description............................................................................................................................9

10 Receipt of goods and storage............................................................................................10

11 Installation instructions and Dimensions.........................................................................11

12 Mounting.............................................................................................................................13

12.1 Factory pre-assembly of complete monitoring units.....................................................13

12.2 Mounting the sensor LA1S into the universal filter .......................................................14

12.3 Mounting of the sensor LA1S into the flow chamber LS...............................................14

12.4 Mounting the Sensor LA25S onto the Universal filter...................................................15

12.5 Mounting the Sensor LA25S into the flow chamber LS25............................................16

13 Supply connections............................................................................................................16

13.1 Electrical connections..................................................................................................16

13.1.1 Electronic controller LA1.1 ...................................................................................17

13.1.2 Electronic controller LA1.4 ..................................................................................18

13.2 Pneumatic connections................................................................................................20

14 Commissioning...................................................................................................................21

14.1 Commissioning with a dry sensor ................................................................................21

14.2 Function test................................................................................................................21

14.3 Adjustment of sensitivity ..............................................................................................22

14.4 Adjustment of alarm holding function...........................................................................23

15 Closing down......................................................................................................................23

16 Maintenance and repair......................................................................................................23

17 Spare parts list....................................................................................................................25

18 Appendix.............................................................................................................................25

List of illustrations

Figure 1 Flow chamber LS with liquid sensor LA1S...................................................................... 12

Figure 2 Flow chamber LS 25 with liquid sensor LA25S ............................................................... 12

Figure 3 Liquid sensor LA1S with filter F...-...D and LA25S with Filter FSS-...-D........................... 13

Figure 4 Mounting of the sensor LA1S into flow chamber LS........................................................ 15

Figure 5 Electrical connection and dimensions LA1.1................................................................... 18

Figure 6 Electrical connection and dimensions LA1.4................................................................... 19

Figure 7 LA1.4 assembly diagram ................................................................................................ 20

Figure 8 Flow diagram LA1.1, 115/230 V 50/60 Hz....................................................................... 26

Figure 9 Flow diagram LA1.1, 24V AC/DC.................................................................................... 27

Figure 10 Flow diagram LA1.4, 115/230V 50/60Hz......................................................................... 28

Figure 11 Flow diagram LA1.4, 24V AC/DC.................................................................................... 29