1. Introduction

Thank you for purchasing the CAS CI-6000A weighing indicator.

We have designed this equipment with many advanced features, high quality construction, and user-

friendly menu driven programming.

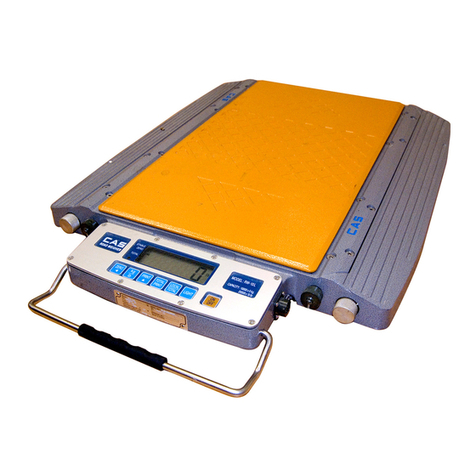

CAS indicator is shaped firmly and delicately designed to coincide with the special requirements of

several industrial fields and includes many functions and various external interfaces. Also, it contains

help display functions to be used easily.

Before using CI-6000A, It is recommended to read this manual carefully and to apply

the function application fully.

Precautions

Observe the following safety precautions :

Warning

When any damage or defect

occurs, contact your CAS

authorized dealer immediately

for proper repair.

Insert plug firmly to wall outlet to

prevent electric shock.

Scale must be grounded to

minimize electricity static. This

will minimize defect or electric

shock.

Do not pull the plug by its cord

when unplugging. Damaged

cord could cause electric shock

or fire.

To prevent from fire occurring,

Do not place or use the scale

near flammable or corrosive

gas.

To reduce electric shock or

incorrect reading, Do not spill

water on the scale or place it in

humid condition.