ProGear 1310 User manual

IMPORTANT: Read all instructions carefully before using this product.

Retain this owner’s manual for future reference.

The specifications of this product may vary from this photo and, subject to

change without notice.

INDOORELLIPTICAL

1310.2‐070914

SERVICE -------------------------------------------------------------------------2

LABEL PLACEMENT ----------------------------------------------------------3

PRODUCT SAFETY ---------------------------------------------------------- 4

OVERVIEW DRAWING -------------------------------------------------------5

PART LIST ---------------------------------------------------------------------- 6

HARDWARE & TOOLS LIST----------------------------------------------- 9

ASSEMBLY ---------------------------------------------------------------------- 10

COMPUTER ---------------------------------------------------------------------16

ADJUSTMENTS ----------------------------------------------------------------18

MAINTENANCE ---------------------------------------------------------------- 19

TROUBLESHOOTING --------------------------------------------------------20

WARM UP ----------------------------------------------------------------------- 21

WARRANTY -------------------------------------------------------------------- 22

FAX FORM ---------------------------------------------------------------------- 23

TABLEOFCONTENTS

1

IMPORTANT: FOR NORTH AMERICA ONLY

To request product service and order

replacement parts, please call our

customer service department at:

1-844-641-7920

Monday through Friday, 8:00 AM-5:00 PM Pacific Standard Time,

or email us at: service@paradigmhw.com

Please visit our website at www.paradigmhw.com.

Please have the following information ready when requesting for service:

Your name

Phone number

Model number

Serial number

Part number

Proof of Purchase

Before returning this product to the store please contact

customer service at the contact number.

Paradigm Health & Wellness, Inc.

1189 Jellick Ave.

City of Industry, CA 91748 USA

SERVICE

2

LABELPLACEMENT

3

Basic precautions should always be followed, including the following safety

instructions when using this equipment. Read all instructions before using this

equipment.

1. Before exercising and to avoid injuring your muscles, it is highly recommended

that you perform warm-up exercises for each muscle group. Please refer to

Warm Up section of the Owner’s Manual.

2. Please make sure all components are not damaged and are working order

before using. This equipment should be placed on a stable, flat surface. Using

a mat or similar material on the ground is recommended.

3. Please wear proper clothes and shoes when using this equipment. Do not

wear loose clothing that may get caught by any part of the equipment.

4. Only perform maintenance or adjustments that are instructed in this manual.

Should any problems arise, discontinue use and consult with customer service

at Paradigm.

5. Be careful when stepping on or stepping off the pedals. Always hold onto the

handlebars first and make sure the pedal at your side is at its lowest position,

then step on. With your other leg, stride over the main frame and come to rest

onto the other pedal. To ensure the pedals run smoothly, push or pull on the

handlebars first, then follow with leg motion. To dismount, reduce pedaling

speed gradually before you stop. When stepping off the machine, make sure

one pedal is at its lowest position and step out of there before stepping out of

the pedal at the highest position.

6. Keep dry - do not operate in wet or moist condition.

7. Do not use the equipment outdoors.

8. This equipment is for household use only.

9. Only one person should be on the equipment at a time.

10.Keep children and pets away from the product at all times.

11.This machine is designed for adults only.

12.This product requires a minimum of 6 feet of space for safe operation.

13.If you feel any chest pains, nausea, dizziness, or short of breath, you should

stop exercising immediately and consult with your physician before continuing.

14.The maximum weight capacity for this product is 275 lbs/125 kgs.

WARNING:Before beginning any exercise program consult your

physician. This is especially important for the people who are over 35 years

old or who have pre-existing health problems. Read all instructions before

using any fitness equipment.

CAUTION:Read all instructions carefully before operating this

product. Retain this Owner’s Manual for future reference.

4

PRODUCTSAFETY

OVERVIEWDRAWING

5

No. Description Qty No. Description Qty

001 Handrail Arm End Cap Ø25 2 023 Right Bolt for Right Crank

Ø16x89xL23 1

002 Right Handrail Arm Ø25x1.8x980 1 024 Wave Washer Ø28xØ17x0.3 4

003 Handrail Arm Foam Grip

Ø24xØ34x280 2 025 Right Foot Bar 1

004 Handrail Arm Plastic Bushing

Ø28.5xØ25.4x84 2 026 Spring Washer Ø20xØ13x2.0 2

005 Bolt M10x18 2 027 Nylon Nut for Right Crank 1/2” 1

006 Spring Washer Ø10x Ø18x3.0 2 028 Right Crank 6.7", 1/2" 1

007 Washer Ø28xØ16.2xδ5.0 2 029 Computer XLG-203 1

008 Powder Metal Bushing

Ø24.5xØ16x14 10 030 Hand Pulse Handlebar End Cap

Ø25x1.5 2

009 Right Handrail 1 031 Hand Pulse Sensor 2

010 Phillips Pan Head Self Tapping

Screw ST4.2x20 8 032 Hand Pulse Handlebar Foam Grip

Ø24xØ30x240 2

011 Right Handrail Decoration Cover

A 100x80x38 1 033 Hand Pulse Handlebar 1

012 Bolt M10x55 2 034 Wire Grommet Ø12.1 3

013 Nylon Nut M10 6 035 Hand Pulse Sensor Wire

L=500 mm 2

014 Right Handrail Decoration Cover

B 100x80x37 1 036 Bolt M8x35 2

015 Screw ST4.2x20 6 037 Rotation Rod Ø15.8x376(M10x22) 1

016 Powder Metal Bushing

Ø14xØ10x10 4 038 Extension Sensor Wire L=650 mm 1

017 Bolt M8x43 4 039 Hand Pulse Handlebar Support

Frame End Cap 40x20x1.5 2

018 Nylon Nut M8 4 040 Hand Pulse Handlebar Support

Frame 1

019 Washer Ø8 8 041 Spring Washer Ø6 2

020L Left Foot Pedal 349x150x56 1 042 Nut M6 2

020R Right Foot Pedal 349x150x56 1 043 Flange Nut M10x1xB10 2

021 Bolt M10x45 4 044 Eyebolt M6x33 2

022 Right Cover 696x286x91 1 045 Nut M10x1xB5 2

PARTLIST

6

No. Description Qty No. Description Qty

046 Big Curve Washer Ø8xØ20x2.0 6 073 Sensor with Wire L=900 mm 1

047 Bearing 6000ZZ 3 074 Chain Pulley 1

048 Flywheel Ø450x35 P=6.35 1 075 Left Crank 6.7", 1/2" 1

049 Flywheel Axle M10x1.0xL140 1 076 Left Cover 696x286x90 1

050 Spacer Ø15xØ10x28 1 077 Left Handrail 1

051 Bolt M10x57 4 078 Left Foot Bar 1

052 Front Stabilizer Ø50x1.5 1 079 Left Bolt for Left Crank

Ø16x89xL23 1

053 Front Stabilizer End Cap Ø50 2 080 Foot Pedal Support Bracket

245x38xδ3.0 2

054 Big Curve Washer Ø10xØ25x2.0 4 081 Left Handrail Decoration Cover A

100x80x39 1

055 Cap Nut M10 4 082 Left Handrail Decoration Cover B

100x80x38 1

056 Main Frame End Cap 60x30x1.5 2 083 Nut M14xB8 1

057 Bolt M5x33 1 084 Chain 1

058 Tension Bracket 119x30x35 1 085 Rear Stabilizer Ø50x1.5x540 1

059 Tension Pad 115x25x6 1 086 Left Handrail Arm Ø25x1.8x980 1

060 Bearing Cup 2 087 Screw ST4.2x25 2

061 Ball Bearing 2 088 Bottle Holder 133x89x86 1

062 Bearing Nut I 15/16" 1 089 Bolt M5x15 2

063 Washer Ø40xØ24x3.0 1 090 Protection Cover for Tension

Control Knob Ø38x19 1

064 Tension Control Knob M8x43 1 091 Nut M8xB4 1

065 Washer Ø5xØ10x1.0 1 092 Crank Cover Ø24 2

066 Nylon Nut M5 1 093 Bolt M8x37 8

067 Cap Nut M6 1 094 Nut Cap M8 6

068 Mainframe 1 095 Flange Nut M10x1.25x10 2

069 Rear Stabilizer End Cap Ø50 2 096 Nut Cap S18 2

070 Bearing Nut II 7/8" 1 097 Small Magnet Ø15x7 1

071 Washer Ø34.5xØ23x2.5 1 098 Nylon Nut for Left Crank 1/2” 1

072 Nut 7/8" 1 099 Serrated Lock Washer External

Teeth Ø10xØ18x1.0 2

PARTLIST

7

No. Description Qty No. Description Qty

100 Spring Washer Ø8 4 104 Phillips Pan Head Self Tapping

Screw ST4.8x20 1

101 Bolt M6x45 2 105 Nut M14x20 1

102 Transport Wheel Ø23xØ6x32 2 106 Handrail Arm Round Plug Ø25x1.5 2

103 Nylon Nut M6 2 107 Washer Ø10x20x2.0 2

PARTLIST

8

HARDWARE&TOOLSLIST

9

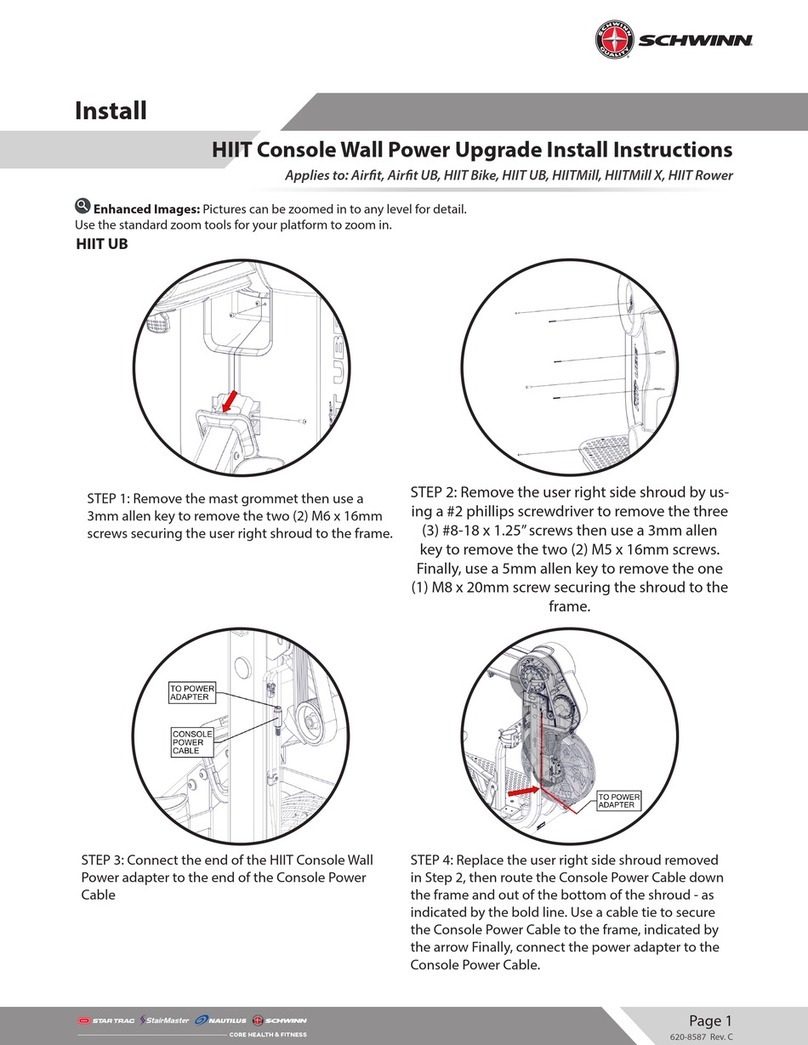

STEP 3

STEP 4STEP 5

STEP 2

STEP 1

RL

1. Front and Rear Stabilizers Installation:

Align the Front Stabilizer (52) onto the front curve of the Mainframe (68). Make sure the

arrow is pointing UP on the front stabilizer and that the Transport Wheels (102) position

toward the front and parallel off the floor. Attach two Bolts (51) and on the other ends of

bolts with two Big Curve Washers (54) and two Cap Nuts (55). Using the flat wrench,

tighten the cap nuts until firm.

Align and attach the Rear Stabilizer (85) onto the rear curve of the Mainframe (68) with two

Bolts (51) and the other ends with two Big Curve Washers (54) and two Cap Nuts (55).

Using the flat wrench, tighten the cap nuts until firm.

Hardware:

ASSEMBLY

10

Tool:

Open-Ended Flat Wrench

(51) Bolt 4 PCS

(55) Big Curve Washer 4 PCS

(56) Cap Nut 4 PCS

2. Handrails, Foot Bars, and Rotation Rod Installation:

Using S6 Allen Wrench, remove two Bolts (5), two Spring Washers (6), two Washers (7),

and two Wave Washers (24) PRE-ASSEMBLED from both ends of the Rotation Rod (37).

Insert the Rotation Rod (37) into the hole on top of the Mainframe (68). Slide the Right

Handrail (9) onto the Rotation Rod (37) and secure in place with one set of the above

hardware that was removed. Use one S6 Allen Wrench to secure the bolt on one end of

the rod and the other S6 Allen Wrench to the bolt on the other end of the rod to tighten the

bolts until firm. Repeat step above for the left side.

ASSEMBLY

Tools:

S6 Allen Wrench

S6 Allen Wrench with

Phillips Screwdriver

Open-Ended Flat Wrench

S10 Allen Wrench

Important:

Installing right bolt into right

crank can only be done by

turning right (clockwise).

R for right bolt

L for left bolt

Important:

Installing left bolt into left

crank can only be done

by turning left

(counterclockwise).

11

It is important that you first read and understand the procedures before installing the bolts

to the cranks. Left bolt and left nylon nut are reverse threaded and the correct direction to

tighten is by turning to the left (counterclockwise). If not done correctly, the bolts

and/or cranks may be damaged or stripped.

Insert the Right Bolt for Right Crank (23) and Wave Washer (24) through the right side of

the Right Foot Bar (25). Align the right foot bar with the Right Crank (28) so that they are

perfectly center. Screw the Right Bolt for Right Crank (23) through the crank by turning

right (clockwise) by hand until it stops. Put a Spring Washer (26) and screw the Nylon

Nut (27) by turning right onto the bolt by hand until it stops. Use one flat wrench to secure

the nylon nut and S10 Allen Wrench to tighten the bolt through the nylon nut until firm.

For correct tightness, the bolt’s threads MUST protrude out through the nylon nut until no

longer turns. Proper tightness is extremely important to prevent parts from coming loose

or damage during use.

Repeat this procedure for the left side assembly and note that left bolt and left nylon nut

are tighten by turning to the LEFT (counterclockwise). Cover both Nylon Nuts (27, 98)

with two Nut Caps (96).

Attach both Right Handrail Decoration Covers A and B (11, 14) onto the end of the Right

Handrail (9) with two Phillips Pan Head Self Tapping Screws (10) and two Screws (15).

Tighten screws with the S6 Allen Wrench with Phillips Screwdriver provided. Repeat this

procedure for the left side assembly.

Hardware:

ASSEMBLY

CORRECT

INCORRECT

INCORRECT

Note: In order to install the bolt properly, keep it perfectly

straight when the bolt goes through the foot bar and the

crank. If the bolt is connected to the crank at an angle,

damage to the bolt and/or the crank may occur.

Please make sure the right bolt is for the right crank only

and the left bolt is for the left crank only. If done

incorrectly, the bolts and/or cranks may be damaged or

stripped.

12

(23) Right Bolt for Right Crank 1 PC

(24) Wave Washer 2 PCS

(26) Spring Washer 2 PCS

(27) Nylon Nut for Right Crank 1 PC

(79) Left Bolt for Left Crank 1 PC

(98) Nylon Nut for Left Crank 1 PC

(96) Nut Cap

2 PCS

(10) Phillips Pan Head Self

Tapping Screw 4 PCS

(15) Screw 4 PCS

3. Hand Pulse Handlebar Support Frame, Bottle Holder, and Hand Pulse Handlebar

Installation:

Attach the Hand Pulse Handlebar Support Frame (40) onto the Mainframe (68) with four

Bolts (93), four Spring Washers (100), and four Washers (19). Using the S6 Allen Wrench,

tighten the bolts until firm.

Connect the Sensor Wire (73) coming out from the Mainframe (68) to the Extension

Sensor Wire (38) coming from the bottom of the Hand Pulse Handlebar Support Frame

(40). Make sure the connectors “click” when connected. See Figure A.

Attach the Bottle Holder (88) onto the Hand Pulse Handlebar Support Frame (40) with two

Bolts (89). Using the screwdriver, tighten both Bolts (89) until firm.

Attach the Hand Pulse Handlebar (33) onto the top end of the Hand Pulse Handlebar

Support Frame (40) with two Bolts (36), two Spring Washers (46), and two Nut Caps (94).

Using the flat wrench, tighten the cap nuts until firm.

Hardware:

ASSEMBLY

13

Tools:

S6 Allen Wrench

S6 Allen Wrench with

Phillips Screwdriver

Open-Ended Flat Wrench

A

(36) Bolt 2 PCS

(46) Spring Washer 2 PCS

(94) Nut Cap 2 PCS

(19) Washer 4 PCS

(93) Bolt 4 PCS

(100) Spring Washer 4 PCS

(89) Bolt

2 PCS

4. Right and Left Foot Pedals Installation:

Attach two Foot Pedal Support Brackets (80) onto both the Right/Left Foot Bars (25, 78)

with four Bolts (17) and the other ends with four Washers (19) and four Nylon Nuts (18).

Use a flat wrench to secure the nylon nut and S6 Allen Wrench to tighten the bolt through

the nylon nut until firm. For correct tightness, the bolt’s threads MUST protrude out

through the nylon nut until no longer turns.

Attach the Right Foot Pedal (20R) onto the Right Foot Bar (25) with two Bolts (21) and two

Nylon Nuts (13). Using a flat wrench, tighten the nylon nuts until firm. For correct

tightness, the bolt’s threads MUST protrude out through the nylon nut until no longer turns.

Repeat step above for the left side.

Hardware:

ASSEMBLY

14

Tools:

S6 Allen Wrench

Open-Ended Flat Wrench

(17) Bolt 4 PCS

(19) Washer 4 PCS

(18) Nylon Nut 4 PCS

(13) Nylon Nut 4 PCS

(21)Bolt 4PCS

5. Right/Left Handrail Arms and Computer Installation:

Insert the Right Handrail Arm (2) onto the Right Handrail (9) and secure with two Bolts

(93), two Big Curve Washers (46), and two Nut Caps (94). Use a flat wrench to secure

the nylon cap and S6 Allen Wrench to tighten the bolt through the nylon cap until firm.

Repeat step above for the left side.

Connect the Extension Sensor Wire (38) coming out from the top side of the Hand Pulse

Handlebar Support Frame (40) to the wire with a male connector coming out from the

Computer (29). Make sure the connectors “click” when connected.

Connect the two Hand Pulse Sensor Wires (35) from the Hand Pulse Handlebar (33) to

the two wires with female connectors coming out from the Computer (29). Make sure

the connectors “click” when connected.

Place the Computer (29) onto the plate of the Hand Pulse Handlebar (33) then slide it down

to lock in position.

ASSEMBLY

15

Tools:

S6 Allen Wrench

Open-Ended Flat Wrench

Hardware:

(46) Big Curve Washer 4 PCS

(93) Bolt 4 PCS

(94) Nut Cap 4 PCS

SPECIFICATIONS:

TIME ----------------------------------------------------00:00-99:59 MIN: SEC

SPEED -------------------------------------------------0.0-999.9 MPH

DISTANCE --------------------------------------------0.00-99.99 MILE

CALORIE ----------------------------------------------0.0-999.9 KCAL

PULSE ------------------------------------------------- 40-200 BPM

USING YOUR COMPUTER

The computer can be activated by pressing the MODE button or by pedaling.

If you leave the equipment idle for 4 minutes, the power will turn off

automatically.

MODE BUTTON FUNCTIONS:

Press the MODE button once to select the desired function of the computer.

Press and hold the MODE button for 4 seconds to reset all data values.

COMPUTER FUNCTIONS:

SCAN: Press the MODE button until the arrow points to SCAN, the computer

will automatically scan through each function except the PULSE function every

6 seconds.

TIME: Press the MODE button until the arrow points to TIME, the computer

will display your elapsed workout time in minutes and seconds.

SPEED: Press the MODE button until the arrow points to SPEED, the

computer will display the current training speed.

DISTANCE: Press the MODE button until the arrow points to DISTANCE, the

computer will display the cumulative distance traveled during workout.

CALORIE: Press the MODE button until the arrow points to CALORIE, the

computer will display the ESTIMATED number of calories you are burning

during the workout. Please note that the readings are only estimates and

there are many factors that can’t be accounted for such as fitness level, body

fat percentage, age, weight and gender.

PULSE: Press the MODE button until the arrow points to PULSE, the

computer will

display your current heart-rate readings only if BOTH hands are gripping the

hand-pulse sensors. No readings or inaccurate readings may occur if only

one hand is gripping the hand-pulse sensor.

COMPUTER

16

HOW TO INSTALL THE BATTERIES:

1. Remove the battery cover on the back of the computer.

2. Place two "SIZE-AA" batteries into the battery housing.

3. Insure batteries are correctly positioned and battery springs are in proper

contact with batteries.

4. Re-install the battery cover.

5. If the display is illegible or only partial segment appears, remove the

batteries and wait 15 seconds before reinstalling.

COMPUTER

17

Adjusting the Tension Control Knob

To increase the tension, turn the tension

control knob in a clockwise direction.

To decrease the tension, turn the

tension control knob in a counterclockwise

direction.

Adjusting the Rear Stabilizer End Cap

The Elliptical has to be set up on a

flat surface. Otherwise, shaking or

wabble might occur during the

workout. Please use the following

method to adjust the Elliptical Level.

IMPORTANT: Please follow this important

step to ensure the stability of the elliptical

when in use.

ADJUSTMENTS

18

Tension Control Knob

Rear Stabilizer End Cap

Adjusting the Rear Stabilizer End Cap #69:

The Rear Stabilizer End Cap #69 is designed

with different angle surfaces to level the Elliptical.

Please rotate the Rear Stabilizer End Cap #69 till

one of the surfaces firmly settle on the floor.

Table of contents

Other ProGear Elliptical Trainer manuals