ProGear Hendrickson HN FR Series User manual

HN FR Service Manual

Pro Gear's Hendrickson HN FR Service Manual to assist in identifying your Hendrickson unit.

If you need any assistance identifying the correct transfer case unit for your truck and

equipment, contact your Hendrickson replacement part specialists at Pro Gear and

Transmission.

Pro Gear Transmission has same day shipping and 1000’s of products in stock and ready to

ship internationally for your next project.

For parts or service contact the Hendrickson specialists at Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407)872-1901

(ffi

HENDRICKSON

/4'e

~m-U

R/1:msClh

Us

®

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series Rear Suspension

SUBJECT: Service Instructions

LIT NO: 17730-285

DATE: December 2012 REVISION: A

TABLE OF CONTENTS

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2 Product Description . . . . . . . . . . . . . . . . . 2

Section 3 Important Safety Notice . . . . . . . . . . . . . . 4

Section 4 Special Tools . . . . . . . . . . . . . . . . . . . . . . . 7

Section 5 Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 6 Preventive Maintenance. . . . . . . . . . . . . 11

Preventive Maintenance Intervals . . . . . . . . 11

Component Inspection . . . . . . . . . . . . . . . . 12

Equalizing Beam End Connection . . . . . . . 13

Axle Brackets. . . . . . . . . . . . . . . . . . . . . . . . 14

Bar Pin End Bushing . . . . . . . . . . . . . . . . . . 15

Bar Pin Shim . . . . . . . . . . . . . . . . . . . . . . . . 15

Bolster Springs . . . . . . . . . . . . . . . . . . . . . . 15

Auxiliary Spring Assembly . . . . . . . . . . . . . . 16

Rebound Strap . . . . . . . . . . . . . . . . . . . . . . 17

Longitudinal and Transverse Torque Rods . . 17

Section 7 Alignment & Adjustments . . . . . . . . . . . 18

Drive Axle Alignment Inspection Procedure . 18

Bar Pin Alignment . . . . . . . . . . . . . . . . . . . . 19

Bar Pin Alignment Shims. . . . . . . . . . . . . . . 21

Auxiliary Spring Shim Evaluation . . . . . . . . . 22

Section 8 Component Replacement . . . . . . . . . . . 23

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Auxiliary Spring . . . . . . . . . . . . . . . . . . . . . . 25

Rebound Strap . . . . . . . . . . . . . . . . . . . . . . 26

Bolster Springs . . . . . . . . . . . . . . . . . . . . . . 27

Vee Bracket. . . . . . . . . . . . . . . . . . . . . . . . . 28

Shock Absorbers . . . . . . . . . . . . . . . . . . . . . 29

Equalizing Beam. . . . . . . . . . . . . . . . . . . . . 30

Bar Pin End Bushings . . . . . . . . . . . . . . . . . 34

Section 9 Torque Specications . . . . . . . . . . . . . . . 38

Section 10 Troubleshooting Guide . . . . . . . . . . . . . . 40

-

[H]

TECBNICAL

®

PROCEDURE

[ffi

BENDRICKSON

_7,?e

N/07#

;pves

Oh

Us

®

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Introduction 2 17730-285

SECTION 1

Introduction

This publication is intended to acquaint and assist maintenance personnel in the preventive

maintenance, service, repair and rebuild of the HN®FR Series suspension system for Fire/

Rescue vehicles.

NOTE Use only Hendrickson parts for servicing this suspension system.

It is important to read and understand the entire Technical Procedure publication prior to

performing any maintenance, service, repair, or rebuild of this product.The information in this

publication contains parts lists, safety information, product specifications, features, proper

maintenance, service, repair and rebuild instructions for the HN FR Series suspension.

Hendrickson reserves the right to make changes and improvements to its products and

publications at any time. Contact Hendrickson Tech Services for information on the latest ver-

sion of this manual at 1-866-755-5968 (toll-free U.S. and Canada), 1-630-910-2800 (outside

The latest revision of this publication is also available online at

www.hendrickson-intl.com

SECTION 2

Product Description

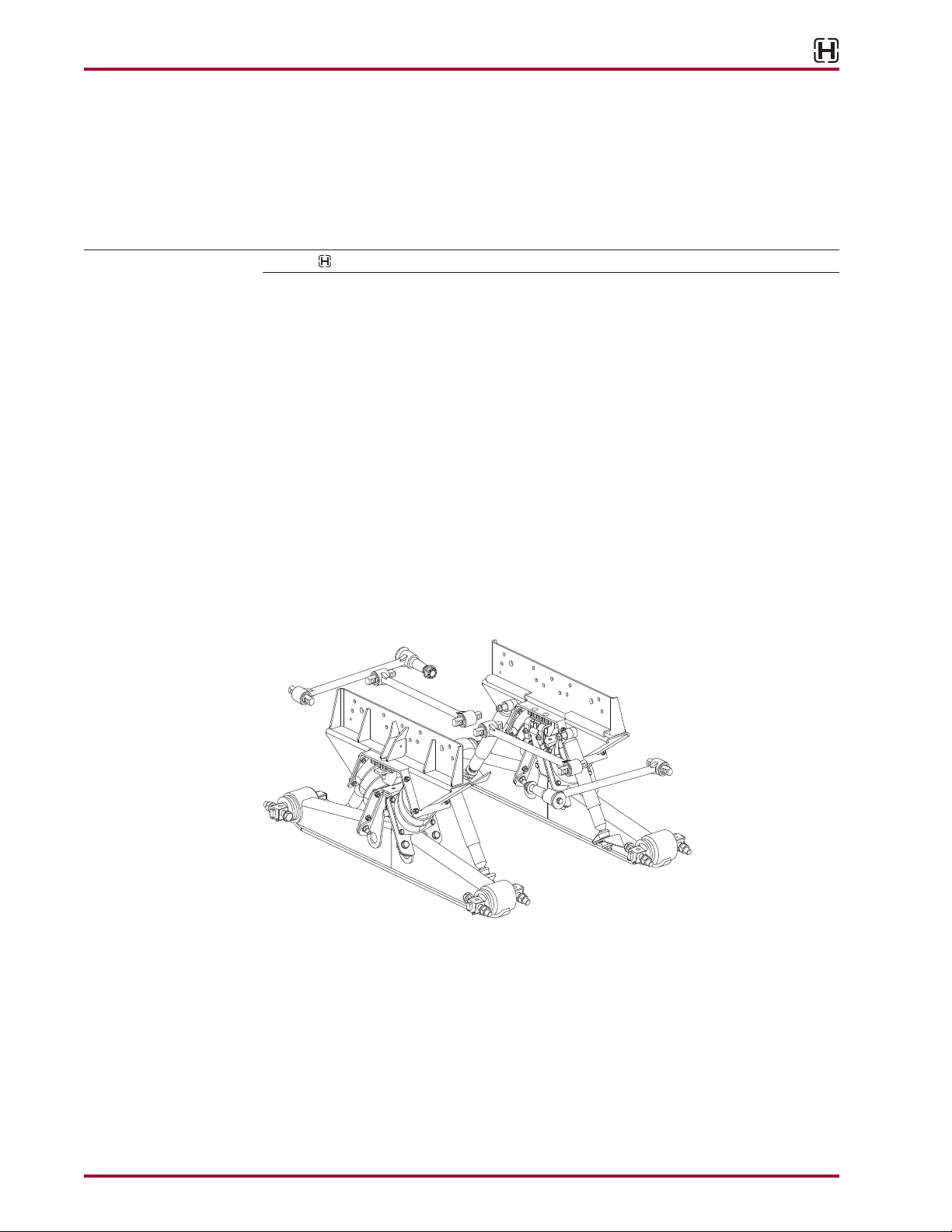

FIGURE 2-1

HN FR Series Suspension System offers an ideal combination of stability, ride quality, light

weight, and articulation.With over a century of experience in the design and manufacturing

of heavy-duty truck suspensions, Hendrickson introduces yet another landmark product for the

fire and rescue industry.The HNFR family of rubber suspensions delivers the exceptional per-

formance that the industry has come to expect from the leader in suspension technology.With

ratings up to 58,000 pounds,the HNFR Series offers a full range of rubber suspensions to meet

the unique needs of the fire and rescue industry.

The innovative spring system allows the equalizing beam to pivot without a need for cen-

ter bushings.The bolster springs, together with rubber bushings in the equalizing beam

ends, accommodate the articulation of the axles without friction or metal-to-metal contact.

'H

l!!J

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 3 Product Description

Subsequently, the HNFR Series suspension reduces scheduled maintenance, which helps lower

operating costs.

■ VariRate®Spring System — Delivers a combination of superior stability, articulation and

ride.System can be tailored to meet the specific needs of unique vehicle applications

■ Rubber bolster springs — Diagonally-mounted rubber bolster springs deliver a smooth

ride and outstanding articulation.Wide spring centers enhance stability and eliminate the

need for the cross tube.

■ Auxiliary springs — Engage to provide added stability for more demanding applications.

■ Equalizing beam — Formed and robotically-welded equalizing beam eliminates center

bushings and lubrication requirements — significantly reducing scheduled maintenance;

provides a narrow profile for weight savings; distributes load equally between both axles for

improved traction; and establishes a solid axle connection for improved handling.

■ Bar pin beam end connection — Rugged axle connection extends bushing life and allows

easy axle alignment and serviceability.

■ Saddle / frame brackets — Weight-saving,high-strength design increases carrying capac-

ity and durability.

■ Rebound Control Strap — Protects bolster springs from severe rebound tension

■ Torque Rods — Enhance handling during braking and cornering.Transverse rods ensure

axle position and lateral stability. Longitudinal rods engineered to optimize resistance to

axle wind-up.

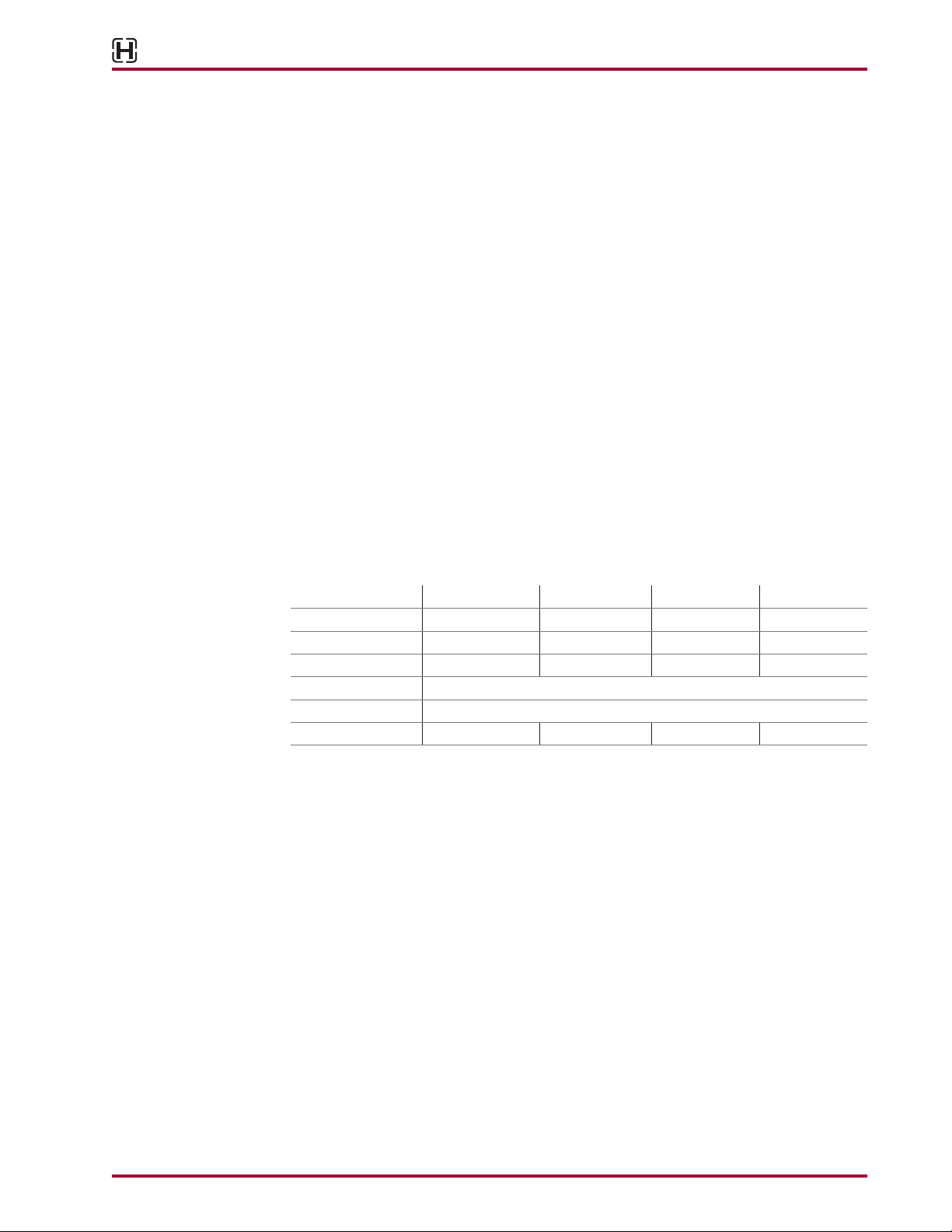

HN®FR SPECIFICATIONS

HN 422FR HN 482FR HN 542FR HN 582FR

Installed Weight1888 lbs. 911 lbs. 991 lbs. 1,011 lbs.

Suspension Rating242,000 lbs. 48,000 lbs. 54,000 lbs. 58,000 lbs.

GVW Approval373,000 lbs. 80,000 lbs. 80,000 lbs. 90,000 lbs.

Diagonal Articulation417"

Ride Heights 9.5", 10.5", 11.5", 13.25", 15.5"

Axle Spacing552", 54" 54" 54", 60" 54", 60"

1. Installed weight includes complete suspension at 9.5" ride height and 54" axle spacing.

2. Capacity ratings approved for fire and rescue applications only.

3. Contact Hendrickson for applications that may exceed GVW approval ratings.

4. Suspension articulation may exceed vehicle’s capability and may be limited by vehicle manufacturer; vehicle

manufacturer installed axle stops may restrict suspension’s articulation.

5. Additional beam lengths available, contact Hendrickson Application Engineering.

'H

l!!J

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Important Safety Notice 4 17730-285

SECTION 3

Important Safety Notice

Proper maintenance,service and repair is important to the reliable operation of the suspension.

The procedures recommended by Hendrickson and described in this technical publication are

methods of performing such maintenance,service and repair.

The warnings and cautions should be read carefully to help prevent personal injury and to

assure that proper methods are used. Improper maintenance, service or repair may damage

the vehicle,cause personal injury, render it unsafe in operation, or void manufacturer’s warranty.

Failure to follow the safety precautions in this manual can result in personal injury and/or

property damage. Carefully read and understand all safety related information within this pub-

lication, on all decals and that provided by the vehicle manufacturer before conducting any

maintenance, service or repair.

EXPLANATION OF SIGNAL WORDS

Hazard“Signal Words” (Danger-Warning-Caution) appear in various locations throughout this

publication. Information accented by one of these signal words must be observed to help mini-

mize the risk of personal injury to service personnel,or possibility of improper service methods

which may damage the vehicle or render it unsafe.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

Additional Notes or Service Hints are utilized to emphasize areas of procedural importance and

provide suggestions for ease of repair.The following definitions indicate the use of these signal

words as they appear throughout the publication.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

SERIOUS INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, CAN RESULT IN SERIOUS

INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH,IF NOT AVOIDED,MAY RESULT IN MINOR OR

MODERATE INJURY.

NOTE An operating procedure,practice condition,etc.which is essential to emphasize.

SERVICE HINT A helpful suggestion that will make the servicing being performed a little easier and/or faster.

Also note that particular service operations may require the use of special tools designed for

specific purposes.These special tools can be found in the Special Tools Section of this publication.

The torque symbol alerts you to tighten the fasteners to a specific torque value. See Torque

Specifications section of this publication.

'H

l!!J

m

A

DANGER

A

WARNING

A

CAUTION

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 5 Important Safety Notice

■ SAFETY PRECAUTIONS

FASTENERS

DISCARD USED FASTENERS.ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR. FAILURE TO DO

SO COULD RESULT IN FAILURE OFTHE PART,OR MATING COMPONENTS,LOSS OF VEHICLE CONTROL,

PERSONAL INJURY,OR PROPERTY DAMAGE.

LOOSE OR OVER TORQUED FASTENERS CAN CAUSE COMPONENT DAMAGE, LOSS OF VEHICLE

CONTROL,PROPERTY DAMAGE,OR SEVERE PERSONAL INJURY.MAINTAIN CORRECTTORQUE VALUES

AT ALLTIMES.CHECKTORQUE VALUES ONA REGULAR BASISAS SPECIFIED USINGATORQUE WRENCH

THAT IS REGULARLY CALIBRATED.TORQUE VALUES SPECIFIED IN THIS TECHNICAL PUBLICATION ARE

FOR HENDRICKSON SUPPLIED FASTENERS ONLY. IF NON HENDRICKSON FASTENERS ARE USED,

FOLLOW TORQUE SPECIFICATION LISTED IN THE VEHICLE MANUFACTURER’S SERVICE MANUAL.

LOAD CAPACITY

ADHERE TO THE PUBLISHED CAPACITY RATINGS FOR THE SUSPENSION.ADD-ON AXLE ATTACHMENTS

AND OTHER LOAD TRANSFERRING DEVICES CAN INCREASE THE SUSPENSION LOAD ABOVE ITS

RATED AND APPROVED CAPACITIES, WHICH CAN RESULT IN COMPONENT DAMAGE AND LOSS OF

VEHICLE CONTROL, POSSIBLY CAUSING PERSONAL INJURY OR PROPERTY DAMAGE.

MODIFYING COMPONENTS

DO NOT MODIFY OR REWORK PARTS WITHOUT AUTHORIZATION FROM HENDRICKSON. DO NOT

SUBSTITUTE REPLACEMENT COMPONENTS NOT AUTHORIZED BY HENDRICKSON.USE OF MODIFIED,

REWORKED, SUBSTITUTE OR REPLACEMENT PARTS NOT AUTHORIZED BY HENDRICKSON MAY NOT

MEET HENDRICKSON’S SPECIFICATIONS,AND CAN RESULT IN FAILURE OFTHE PART,LOSS OF VEHICLE

CONTROL, POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, AND WILL VOID ANY APPLICABLE

WARRANTIES. USE ONLY HENDRICKSON AUTHORIZED REPLACEMENT PARTS.

TORCH/WELDING

DO NOT USE A CUTTING TORCH TO REMOVE ANY FASTENERS.THE USE OF HEAT ON SUSPENSION

COMPONENTS WILL ADVERSELY AFFECTTHE STRENGTH OFTHESE PARTS.A COMPONENT DAMAGED

IN THIS MANNER CAN RESULT IN THE LOSS OF VEHICLE CONTROL AND POSSIBLE PERSONAL INJURY

OR PROPERTY DAMAGE.

EXERCISE EXTREME CARE WHEN HANDLING OR PERFORMING MAINTENANCE IN THE AREA OF THE

EQUALIZING BEAM.DO NOT CONNECT ARC WELDING GROUND LINE TO THE EQUALIZING BEAM. DO

NOT STRIKE AN ARC WITH THE ELECTRODE ON THE EQUALIZING BEAM AND AXLE. DO NOT USE HEAT

NEAR THE EQUALIZING BEAM ASSEMBLY. DO NOT NICK OR GOUGE THE EQUALIZING BEAM. SUCH

IMPROPER ACTIONS CAN DAMAGE THE EQUALIZING BEAM ASSEMBLY, AND CAN CAUSE LOSS OF

VEHICLE CONTROL AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS WEAR PROPER EYE PROTECTION AND OTHER REQUIRED PERSONAL PROTECTIVE

EQUIPMENT TO HELP PREVENT PERSONAL INJURY WHEN PERFORMING VEHICLE MAINTENANCE,

REPAIR OR SERVICE.

PROCEDURES AND TOOLS

A TECHNICIAN USING A SERVICE PROCEDURE OR TOOL WHICH HAS NOT BEEN RECOMMENDED BY

HENDRICKSON MUST FIRST SATISFY HIMSELF THAT NEITHER HIS/HER SAFETY NOR THE VEHICLE’S

SAFETY WILL BE JEOPARDIZED BY THE METHOD OR TOOL SELECTED. INDIVIDUALS DEVIATING IN

ANY MANNER FROM THE INSTRUCTIONS PROVIDED WILL ASSUME ALL RISKS OF CONSEQUENTIAL

PERSONAL INJURY OR DAMAGE TO EQUIPMENT INVOLVED.

'H

l!!J

A

WARNING

A

WARNING

A

WARNING

A

WARNING

A

WARNING

A

CAUTION

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Important Safety Notice 6 17730-285

TRANSVERSE TORQUE RODS

HN FR SUSPENSIONS INCORPORATE TRANSVERSE RODS FOR VEHICLE STABILITY. IF THESE

COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE SHOULD NOT BE

OPERATED. FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING, LOSS OF VEHICLE

CONTROL, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT DAMAGE, OR

SEVERE PERSONAL INJURY.

SUPPORT THE VEHICLE PRIOR TO SERVICING

DO NOT AT ANY TIME WORK AROUND OR UNDER A VEHICLE SUPPORTED ONLY ON LIFTING DEVICES.

THE VEHICLE MUST BE SECURELY CHOCKED AND SUPPORTED ON RIGID STANDS OF SUFFICIENT

STRENGTH BEFORE WORK MAY COMMENCE.

PARTS CLEANING

SOLVENT CLEANERS CAN BE FLAMMABLE, POISONOUS, AND CAUSE BURNS. TO HELP AVOID

SERIOUS PERSONAL INJURY,CAREFULLY FOLLOW THE MANUFACTURER’S PRODUCT INSTRUCTIONS

AND GUIDELINES AND THE FOLLOWING PROCEDURES:

1. WEAR PROPER EYE PROTECTION.

2. WEAR CLOTHING THAT PROTECTS YOUR SKIN.

3. WORK IN A WELL-VENTILATED AREA.

4. DO NOT USE GASOLINE OR SOLVENTS THAT CONTAIN GASOLINE. GASOLINE CAN EXPLODE.

5. HOT SOLUTION TANKS OR ALKALINE SOLUTIONS MUST BE USED CORRECTLY. FOLLOW THE

MANUFACTURER’S RECOMMENDED INSTRUCTIONS AND GUIDELINES CAREFULLY TO HELP

PREVENT PERSONAL ACCIDENT OR INJURY.

DO NOT USE HOT SOLUTION TANKS OR WATER AND ALKALINE SOLUTIONS TO CLEAN GROUND OR

POLISHED PARTS.DOING SO WILL CAUSE DAMAGE TO THE PARTS AND VOID WARRANTY.

'H

l!!J

WARNING

WARNING

WARNING

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 7 Special Tools

SECTION 4

Special Tools

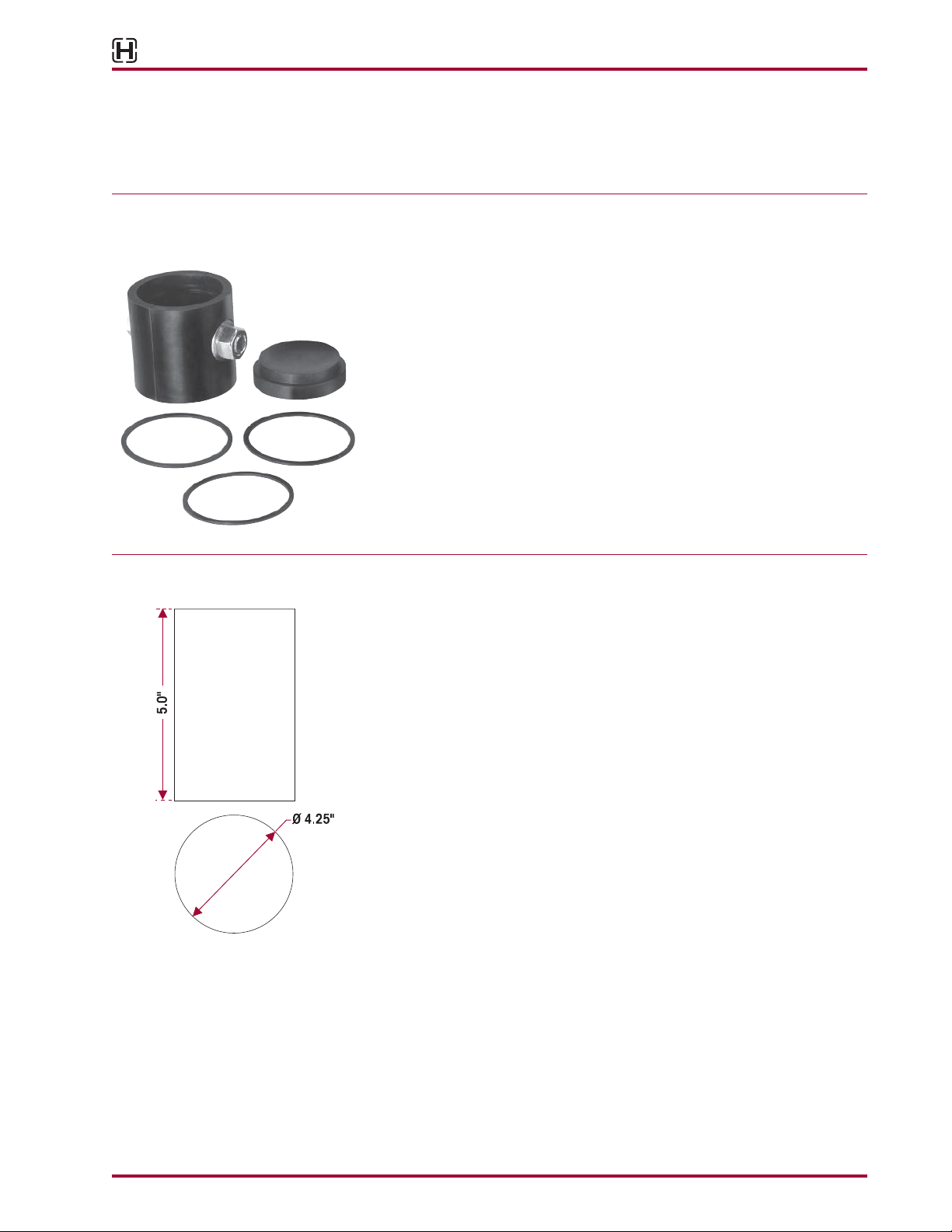

BAR PIN ADAPTER SET INSTALLATION TOOL

OTC Tool No. 1757

Servicing bar pin end bushings used on HN FR equalizing beam suspensions

requires the use of special tooling. OTC’s No. 1757 adapter set is used with

the beam removed from the truck, and in conjunction with OTC No. 51100

press plate and a 100-ton hydraulic shop press.

To order, contact OTC,507.455.7000 or

visit: www.otctools.com for

an OTC distributor.

BAR PIN END BUSHING RECEIVING TOOL

This shop made tool is designed to receive bar pin end bushing. Bushing tool

is made from cold rolled steel or equivalent. Drawing is for reference only.

Hendrickson does not supply this tool.

'H

l!!J

C)C)

C)

l

i!::,

Iii

J

,,r

0

4.25"

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

Parts Lists 8 17730-285

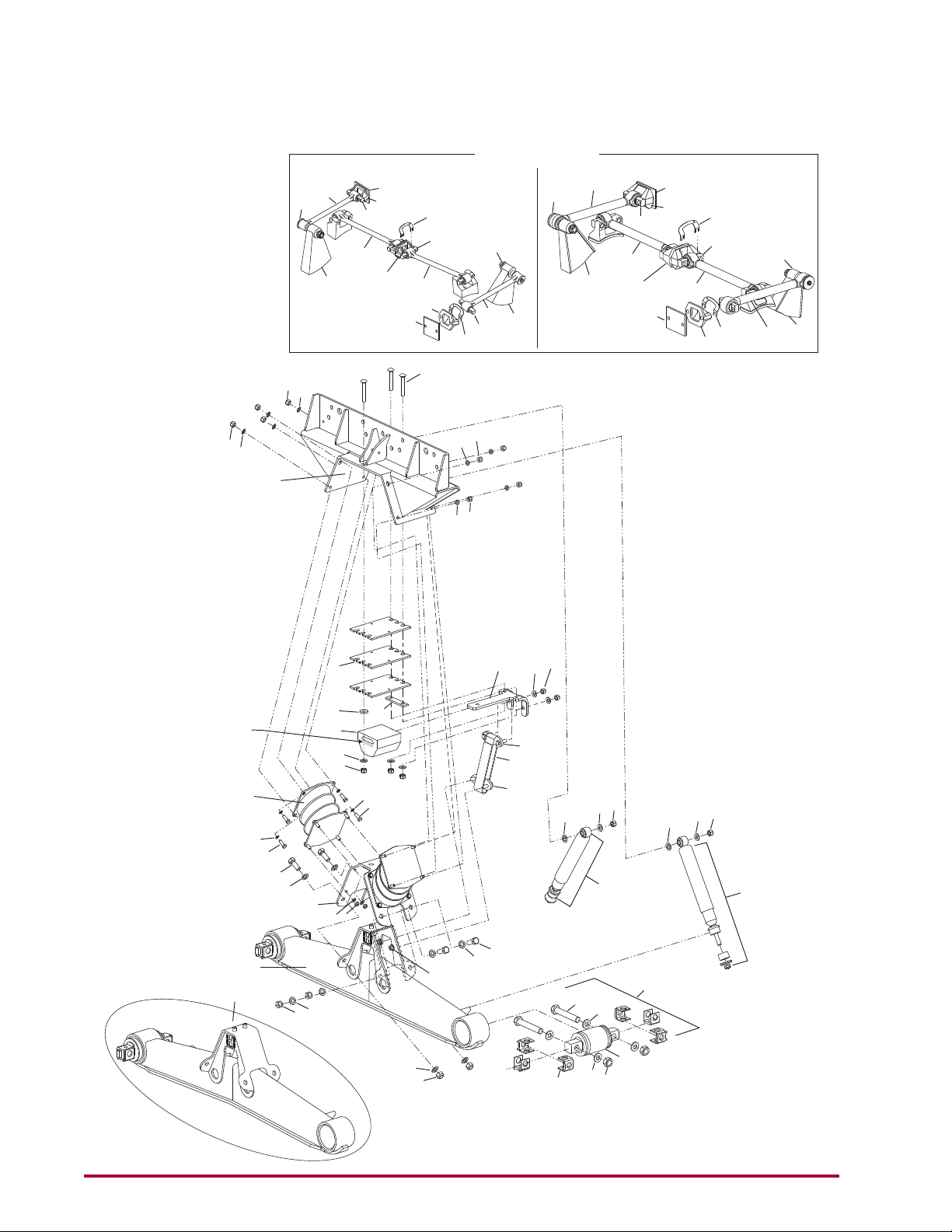

SECTION 5

Parts Lists

■ HN FR Series

ULTRA ROD®ULTRA ROD PLUS

®™

40

Torque Rod Assembly

45

1

8

5

54

7

16

17

6

9

53

10

2

5

3

19

20

18 54

26b

26a

20

21

20

21

15 14

13

12

11

12

23 25 24

23 25 24

22 22

20 19

13,14

28

29

30

31

45

31

32

27

4

33a,37a

33a,37a

34a

34a

35a

35a

35a

36a

36a

38

38

39

39

41

41

33b,37b

33b,37b

34b,37c

34b,37c

35b

35b

36b

36b

38

38

39

39

41

41

38

Location of

Auxiliary Spring

Part Number

40

40

38

40

----i

i --- ,

-r

--

j

\

.-e-<i>

----

: i

.

J,,._

_- I i

.

......

lj) i '

--

i !

I

)'

f . j [

·'

I

II\

.

.-

' . i

I ·

/,

1-·

\:

I

' i

/A

·I

!

>.

\1 I

I ' ·

Ii

I r).--r.

ii

·

i I I

t"--

I ii

,:

I

. I

;°

I I ! .j

I\

I

I :

:;

I I I I

II

. I

/·

· ' ·1

\.

I

I i I i ! I I

II

i

i '

I.

I II II '

' I I I

~

Ii

\:

I

//,·/~.,\

·/·

~11

1 I

I j

I.'

'i

\!

/ / i

1/·l

- n

··,\

~.;.-"''1

· .

I·

I\

I

__

-..--:::~

I . .I :

,\

. -

I

I:

I I __;,_:::-/_ I I I

I ' :I I

--'--:

-\J_: __, I '

. I I. - ®

L-

-

...

:.-Ii--,·_-<--

[ I I

I I

j/

I

--.l-t-'(1,

-lit

I

I·

·;

-1

-

--

,1

.--11

I

--

I

I .

--

j

\\

.

· I 1! - •

'1

, I

/

\,

\ - • •

l:

1

i t, -

_.

I I j

/

j!

\1\

\~

\i..J-

-4l

!

--

y

'I

(j

I

,_

'

.)~-\\

\

~

' ' /

\_.~

\

=

.-.-.

. I

~

•✓

\

',

,

~

' . I

/ ,.-.

-··\

\ :

.

·.

_

__..,

I

....

\''

__

1:-:-_:_

..

-

--

:rt-

-1

.--@c0---..

--

__

-,1.,<> '

~

-:i:bt~>

.

-....,,"\"""'.~,;.,--

$ >--

~

I

~

~

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 9 Parts Lists

KEY NO. PART NO. DESCRIPTION NO.REQ. KEY NO. PART NO. DESCRIPTION NO.REQ.

1 HN FR Saddle Assembly, See Figure 1 below 2

Includes Key Nos. 2-18

60686-0XX 16½", 17½", 18½" or 19"

58650-0XX 17½ or 22½"

60879-000L Bolster Spring Kit, One Side, (2 pcs),Includes

Key No. 2

2 *Bolster Spring 4

3 25114-011

7⁄16"-20 UNF 1.25" Bolt 32

4 48949-000

7⁄16"-20 UNF-2B Locknut 32

5 22962-027

7⁄16" Washer 64

6 Auxiliary Spring Assembly, See part no. 2

located on the component

60314-000 33⁄8" Height

65902-003 21⁄8" Height

7 58960-003 Auxiliary Spring Shim 6

8 58196-006 ½"-13 UNC-2A Round Head Square Neck Bolt 6

9 22962-011 ½" Washer 6

10 49846-000 ½"-13 UNC-2A Locknut 6

11 57878-003 Rebound Strap 2

60639-000 Anchor Plate Assembly, Includes Key Nos.12-14 4

12 *Anchor Plate 4

13 *½" Washer 8

14 *½"-13 UNC-2A Locknut 8

15 58948-001 Auxiliary Spring Mounting Plate 2

16 58949-000 Auxiliary Spring Mounting Plate Shim 2

(Inboard - ¼" thick)

17 22962-020 ½" Washer (Outboard - ¼" thick) 2

18 58343-001 Saddle Vee Bracket 2

58440-001 Vee Bracket Fastener Kit, One Side,

Includes Key Nos. 19-21

19 50764-006 ¾"-10 UNC-2A Hex Head Bolt 8

20 22962-001 ¾" Washer 16

21 49842-000 ¾"-10 UNC-2B Locknut 8

22 60680-003L Shock Absorber 4

23 22962-001 ¾" Washer 4

24 30585-000

5⁄8" Upper Shock Locknut 4

25 22962-004

5⁄8" Upper Shock Washer 4

26 Equalizing Beam Assembly 2

a 58494-002 54" Shim Type HN 482FR

a 59973-003 54" Shim Type HN 542FR / 582FR

a 59973-005 60" Shim Type HN 542FR / 582FR

b 57889-002 54" Shim Type HN 422FR

b 57889-005 52" Shim Type HN 422FR

27 Bar Pin End Bushing Service Kit, One Wheel End,

Includes Key Nos. 28-32

34013-087L Non-Shim Type

34013-088L Shim Type

34013-188L Rotating, Shim Type

28 *Bar Pin End Bushing 4

29 Bar Pin Shim 8

50130-000 0.19" /0.19"

50131-000 0.25"/0.12" (Not shown)

57026-000 0.375"

56659-001 Bar Pin Beam End Mounting Fastener Kit,

Axle Set, Includes Key Nos.30-32

30 48941-000 1"-8 UNC 6.0" Hex Bolt 8

31 22962-008 1" Hardened Washer 16

32 48942-000 1"-8 UNC Locknut 8

33 Two-Piece Longitudinal Torque Rod Kit,

Straddle/Straddle, Includes Tube End, Spacer End

a 60218-000 ULTRA ROD, 27" Max., Includes Key Nos. 35a

b 60223-000 ULTRA ROD, 35" Max., Includes Key Nos. 35a

34 **Two-Piece Transverse Torque Rod Kit,

Straddle/Taper, Includes Tube End,Spacer End

a 60215-000 ULTRA ROD, Includes Key Nos.35a-36a

b 65781-000 ULTRA ROD PLUS,Includes Key Nos.35b-36b

35 Straddle Bushing 2

a 47691-000H ULTRA ROD

b 64400-002L ULTRA ROD PLUS

36 Taper Bushing 2

a 64697-000H ULTRA ROD

b 64400-004L ULTRA ROD PLUS

37 **One-Piece Torque Rod Assembly, Includes

Bushings,See selection guide on page 10

a ULTRA ROD

b ULTRA ROD PLUS Straddle/Straddle

c ULTRA ROD PLUS Straddle/Taper

38 Torque Rod Frame Bracket 4

22186-000 43⁄8"

46015-000 5¼"

39 Backup Plate 2

45045-003 43⁄8"

46869-005 5¼"

40 Torque Rod Shim, See selection guide 8

on page 10

41 ***Transverse Rod Axle Bracket 2

NOTE: Equalizing beam axle brackets for drive axles are supplied by the axle manufacturer.

* Item included in assembly/kit only, part not sold separately.

** Transverse rods are mandatory for HN Suspension regardless of axle spacing. See Literature No. 59310-004 for more information.

Hendrickson’s part number is stamped on the rod for identication. Be sure and include sufx number when ordering,this number indicates rod

length.The Hendrickson 2-piece ULTRARODS®can be used to create the desired length, see Torque Rod Selection Guide Literature No.45745-148.

*** Not supplied by Hendrickson, used for reference only. Refer to vehicle manufacturer for more information. Hendrickson is not responsible for components

supplied by vehicle manufacturer. For assistance with maintenance and rebuild instructions on these components, see vehicle manufacturer.

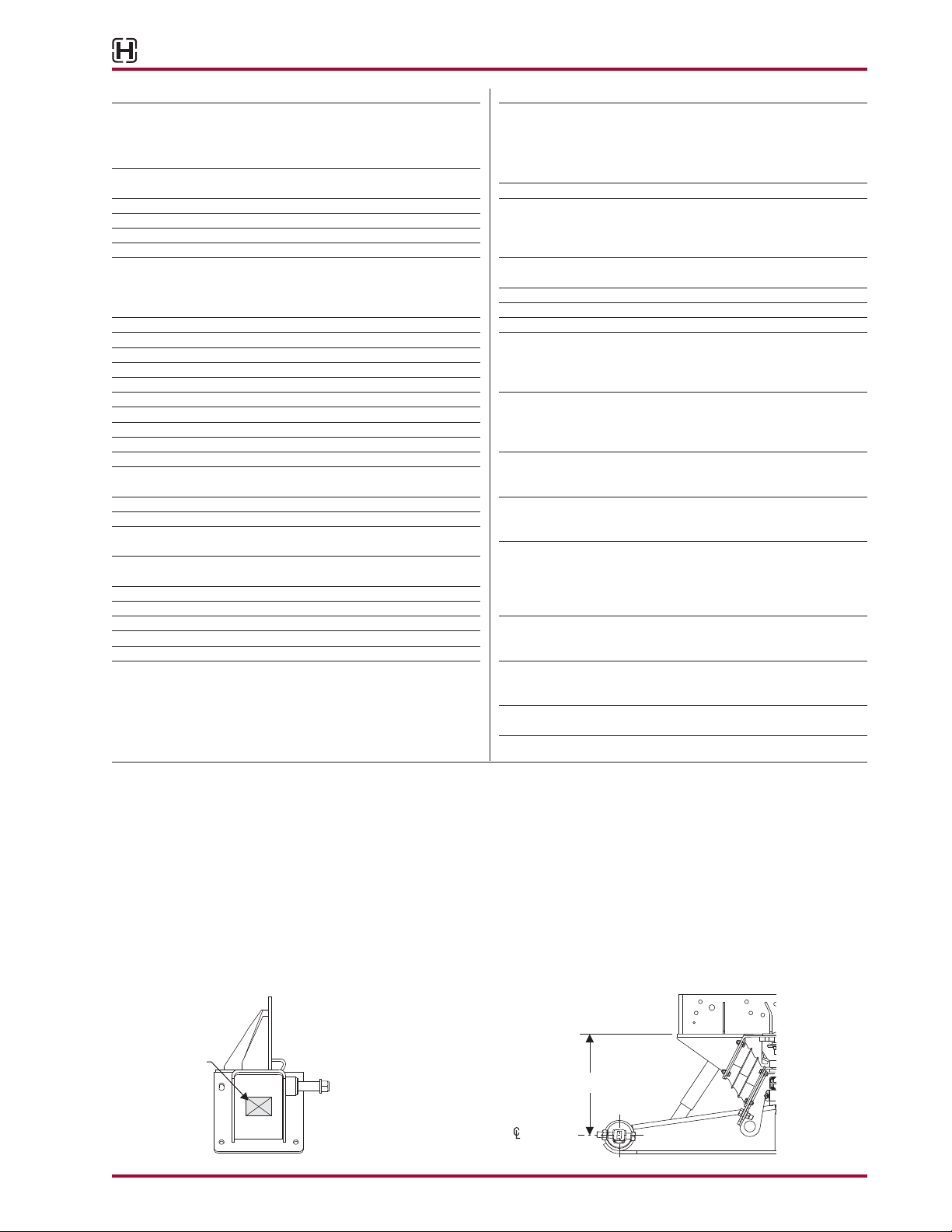

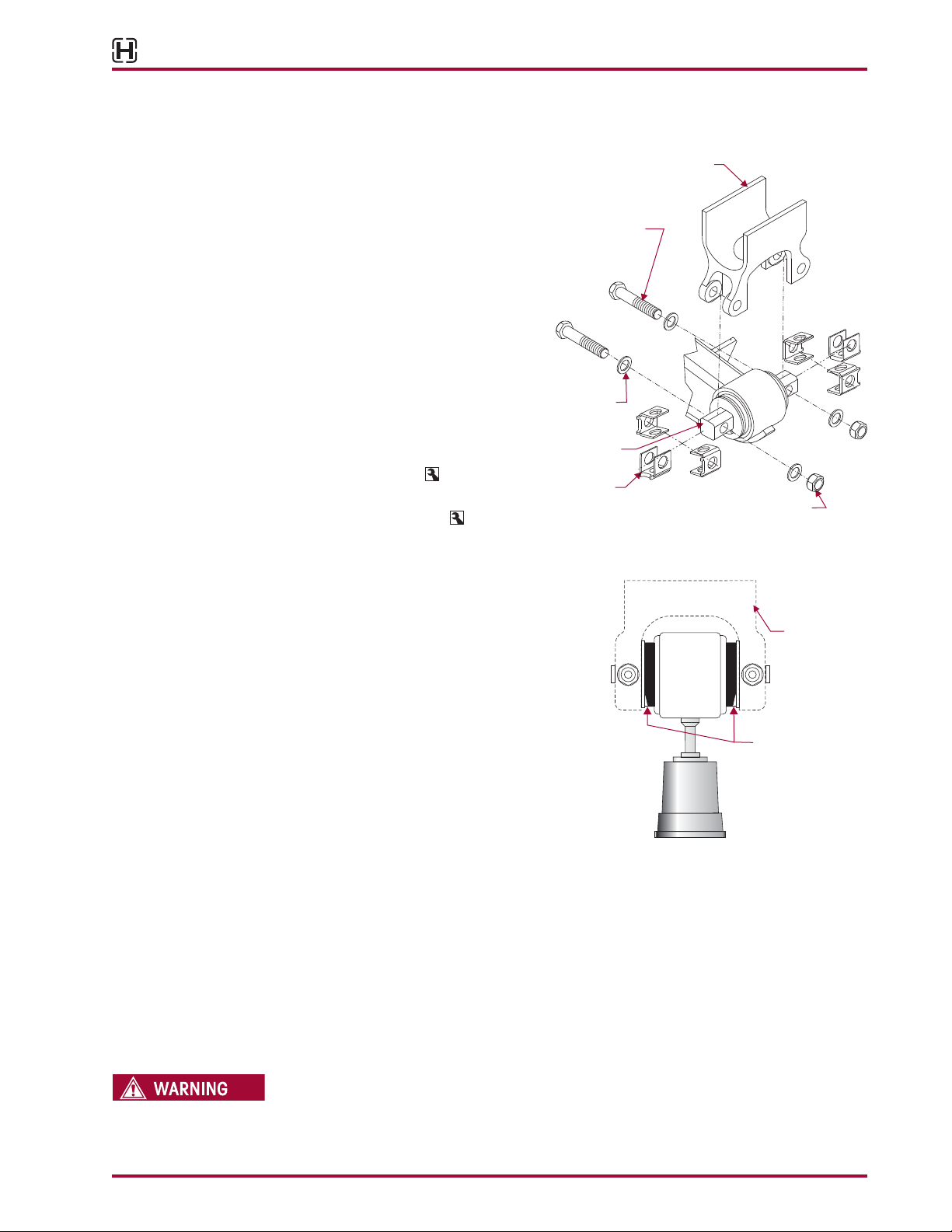

FIGURE 1

SADDLE ASSEMBLY (KEY NO. 1)

Bottom of Frame

of End Hub

Saddle Height

SIDE VIEW

Location of

Saddle Assembly

Part Number

Locate the part number on the saddle assembly

If the saddle assembly number is not legible or available,have the VIN number and

saddle height (for part verification) and contact vehicle manufacturer for part number.

Questions? Contact Hendrickson Truck Parts

OR

'H

l!!J

=====================-

=====================-

=====================-

e

u------1

e

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Parts Lists 10 17730-285

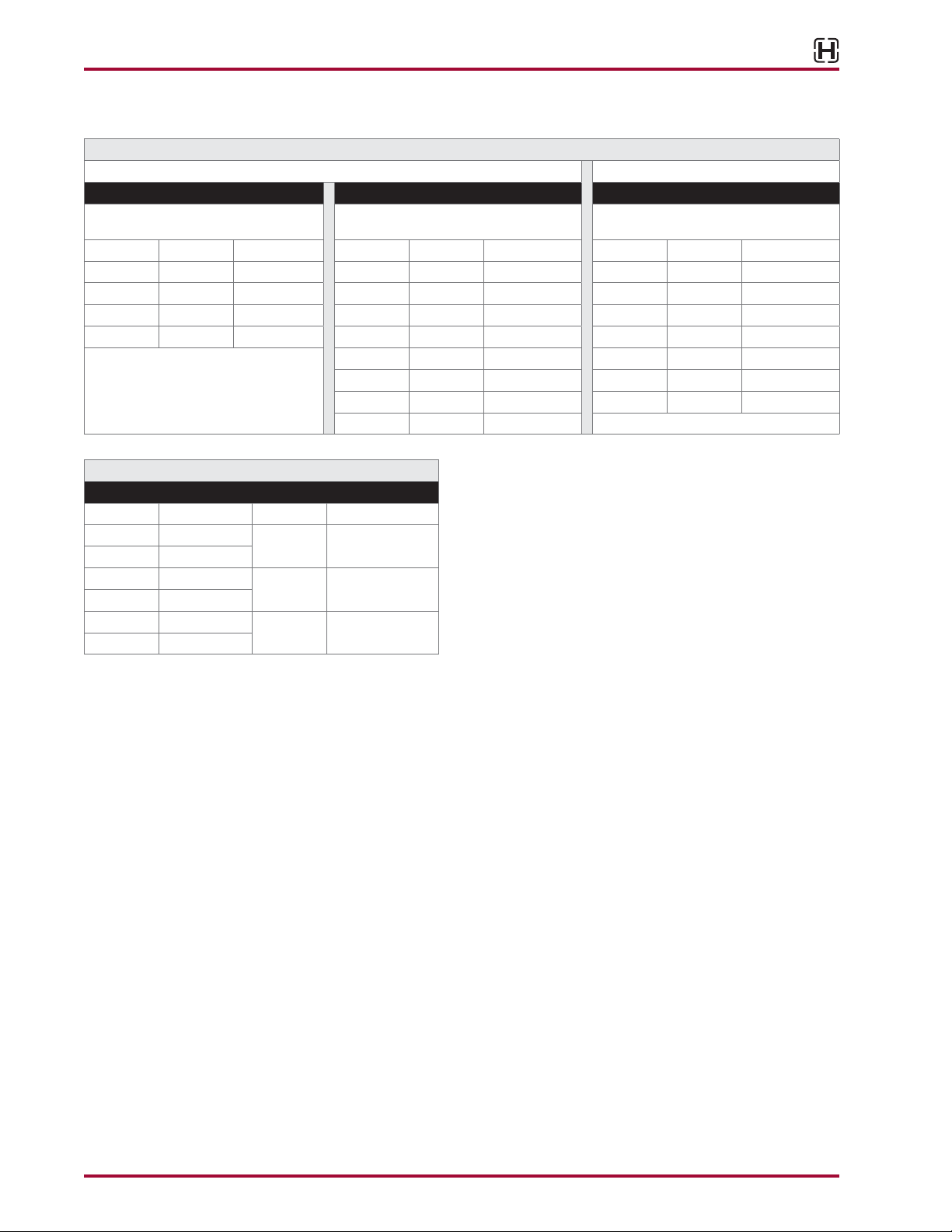

■ SELECTION GUIDE

ONE PIECE TORQUE ROD ASSEMBLY

Longitudinal Torque Rod Transverse Torque Rod

Key No. 37a Key No. 37b Key No. 37c

ULTRA ROD

Straddle/Straddle Assembly

ULTRA ROD PLUS

Straddle/Straddle Assembly

ULTRA ROD PLUS

Straddle/Taper Assembly

Length Part No. Capacity Length Part No. Capacity Length Part No Capacity

22.83" 62001-580 HN 422FR 19.49" 72100-495 HN 542FR/582FR 19.69" 72950-500 HN 522

23.82" 62000-605 HN 482FR 22.05" 72100-560 HN 522 19.88" 72950-505 HN 522

28.15" 62000-715 HN 422FR 23.03" 72100-585 HN 542FR/582FR 24.02" 72350-610 HN 542FR

29.13" 62001-740 HN 482FR 23.62" 72400-600 HN 542FR 24.02" 72950-610 HN 542FR/582FR

25.00" 72100-635 HN 542FR/582FR 24.21" 72950-615 HN 542FR/582FR

26.97" 72100-685 HN 522 24.41" 72350-620S HN 422FR/482FR

28.54" 72100-725 HN 542FR/582FR 25.43" 72350-630S HN 422FR

28.94" 72401-735 HN 542FR

TORQUE ROD SHIMS

Key No. 40

Part No. Shim Thickness Shim Length Fasteners

49689-000 0.060" 43⁄8" ¾" and 5⁄8" Fasteners

49689-001 0.080"

65640-002 0.060" 5¼" ¾" and 5⁄8" Fasteners

65640-003 0.120"

67779-002 0.060" 5¼" 7⁄8" Fasteners

67779-003 0.120"

'H

l!!J

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 11 Preventive Maintenance

SECTION 6

Preventive Maintenance

Hendrickson recommends that preventive maintenance be performed on a regular basis to

help ensure all components function to their highest efficiency. Proper preventive maintenance

programs can also help control repair costs and eliminate downtime.All new equipment should

undergo an initial pre-service inspection,and be inspected at the following intervals.

HENDRICKSON RECOMMENDED

PREVENTIVE MAINTENANCE INTERVALS

■ PRE-DELIVERY INSPECTION

1. Visually inspect suspension for proper assembly.

2. Check all fasteners for proper torque with special attention to the equalizing beam end

connections.

3. Set auxiliary spring shims to required specifications, the number of shims is dependent on

the following criteria:

■ Vehicle empty weight

■ Vehicle application

■ Roll stability versus ride requirements

4. Verify the lateral alignment of axles are within the vehicle manufacturer’s tolerances (con-

sult the applicable vehicle manufacturer’s instructions).

■ INSPECTION AT ONE (1) MONTH

1. Visually inspect suspension components, check for:

■ Proper suspension function

■ Signs of unusual movement,loose or missing components

■ Signs of abrasive or adverse contact with other components

■ Damaged, bent or cracked parts

2. Check all fasteners for proper torque with special attention to the equalizing beam end

connections.

■ PREVENTIVE MAINTENANCE

1. Every three months inspect auxiliary springs and bolster springs.

2. Every six months inspect equalizing beam end connections and Torque rods.

3. Every twelve months:

a. Visually inspect suspension for proper assembly

b. Check all fasteners for proper torque with special attention to the equalizing beam end

connections.

c. Verify the lateral alignment of axles are within the vehicle manufacturer’s tolerances

(consult the applicable vehicle manufacturer’s instructions)

d. Visually inspect suspension components. Check for all of the following and replace

components as necessary:

■ Proper suspension function

■ Signs of unusual movement,loose or missing components

■ Signs of abrasive or adverse contact with other components

■ Damaged, bent or cracked parts

'H

l!!J

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Preventive Maintenance 12 17730-285

SAFETY REMINDER

All applicable warnings and cautions should be read carefully to help prevent personal injury

and to assure that proper methods are used. Improper maintenance, service or repair may

damage the vehicle, cause personal injury, render the vehicle unsafe in operation, or void

manufacturer’s warranty.

Failure to follow the applicable safety precautions can result in personal injury and/or property

damage. Carefully read and understand all safety related information within the applicable

Hendrickson publications,on all decals and those provided by the vehicle manufacturer before

operating the vehicle, or conducting any maintenance, service or repair.

OVERLOADED SUSPENSIONS CAN CAUSE COMPONENT FAILURE, LOSS OF VEHICLE CONTROL,

SEVERE PERSONAL INJURY OR DEATH.

• DO NOT EXCEED SUSPENSION CAPACITY RATINGS.

• DO NOT OPERATE AUXILIARY LIFT AXLES OR OTHER LOAD TRANSFERRING DEVICES IN ANY WAY

THAT CAN OVERLOAD THE SUSPENSION.

COMPONENT INSPECTION

The following inspection should be performed at recommended maintenance intervals.Visually

inspect all parts of the suspension for signs of wear, damage or movement. Look for bent or

cracked parts.Replace all worn or damaged parts.

IMPORTANT NOTE Replace all worn or damaged parts.

■ Auxiliary spring and Bolster spring — See Auxiliary Spring Assembly and Bolster Springs

in this section.

■ Equalizing beam assembly — Check the overall condition of the equalizing beam for

cracks,dents,dings,or other damage on the outer edges of the beam.Check the beam end

connections every six months for tearing or extreme bulging.Check for any metal-to-metal

contact in the bushed joints. Replace all worn or damaged parts.

■ Fasteners — All fasteners must be inspected at pre-delivery,after the first month,and every

twelve months thereafter. Look for any loose or damaged fasteners on the entire suspen-

sion. Make sure all fasteners are tightened to a torque value within the specified torque

range. See Torque Specification Section of this publication for Hendrickson recommended

torque requirements. Use a calibrated torque wrench to check torque in the tightening

direction.As soon as the fastener starts to move, record the torque. Correct the torque if

necessary. Replace any worn or damaged fasteners.

NOTE Hendrickson recommends the use of Grade 8 bolts,Grade C locknuts and hardened washers for

all suspension component attachments.

■ Saddle assembly — Check all attaching fasteners for proper torque.Visually inspect the

saddle for signs of movement on the frame rail or damage and welds for cracks.Inspect the

area around the saddle gussets for cracks.

■ Torque rods — All torque rods should be inspected every six months.Check for wear,dam-

age and proper function.Visually inspect for signs of unusual movement,loose,or missing

fasteners.The torque rods must be connected and in good working condition when operat-

ing the vehicle.

■ Vee Bracket — Raise the vehicle frame and visually inspect the Vee bracket for wear or

damage. Look for excessive wear or cracks on the Vee bracket’s auxiliary spring contact

surface. Replace all worn or damaged parts.

■ Wear and Damage — Inspect all parts of the suspension for wear and damage. Look for

bent or cracked parts.Replace all worn or damaged parts.

See vehicle manufacturer’s applicable publications for other preventive maintenance requirements.

'H

l!!J

A

WARNING

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 13 Preventive Maintenance

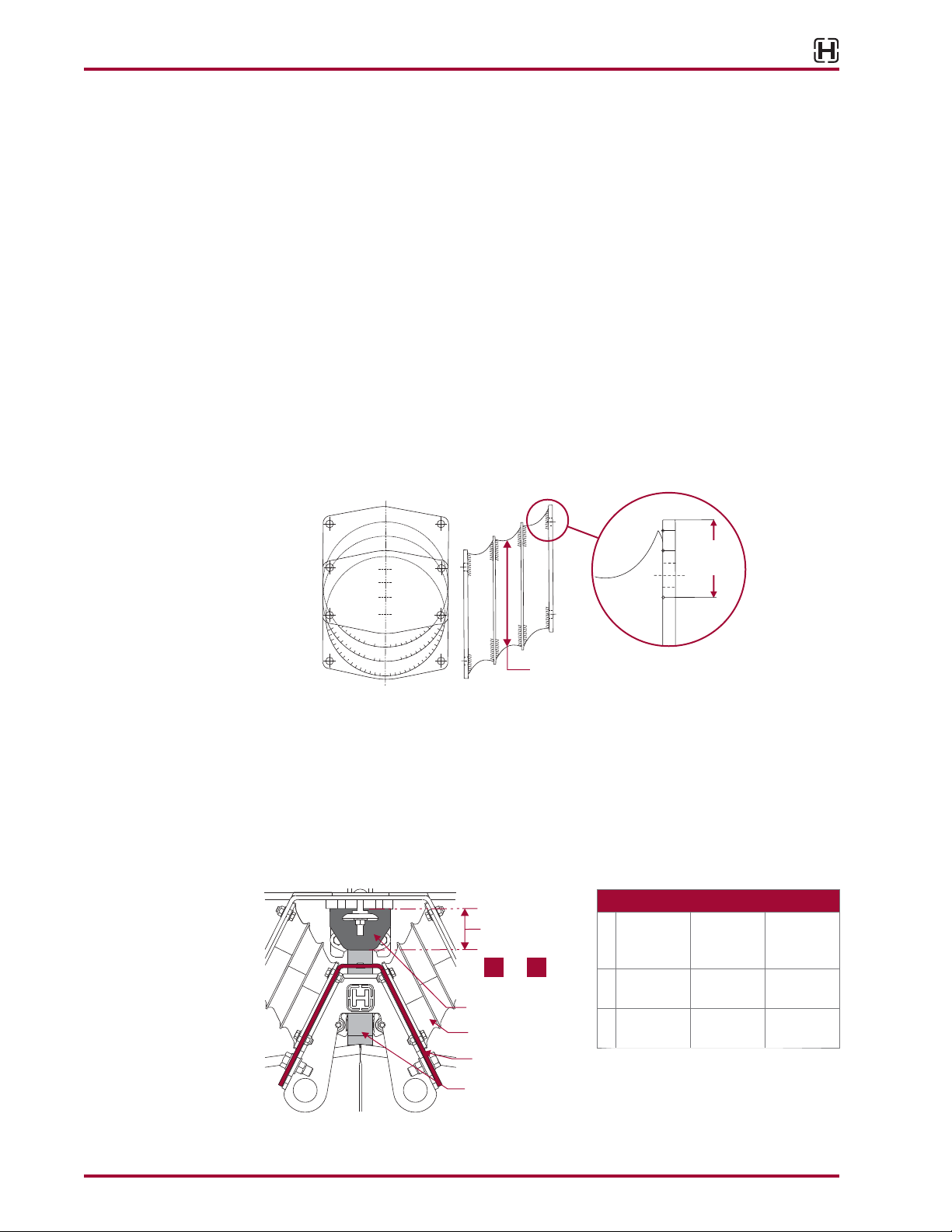

EQUALIZING BEAM END CONNECTION

FIGURE 6-1

The equalizing beam end connection

for the HNFR is bar pin style with a

rubber bushing and alignment shims

as shown in Figure 6-1.An inspection

of the equalizing beam end connec-

tion is necessary when a vehicle is in

the shop for major repair work or every

six months,whichever comes first.

This equalizing beam end connection

requires that the fasteners are kept

tight to maintain the clamp load of

the axle bracket legs to the bar pin.All

bushing motion is accommodated by

rubber deflection.Tighten the equaliz-

ing beam 1" end fasteners to:

■ At the locknut to 450-600 foot

pounds torque, or

■ At the bolt head to 500-650

foot pounds

FIGURE 6-2

INSPECTION

1. Chock the wheels.

2. Visually inspect suspension components for

signs of movement or excessive wear.

a. Inspect alignment shims in equalizing

beam end for looseness. Lightly tap on

the alignment shims to see if they can

be moved.

b. Inspect equalizing beam end connec-

tion for signs of excessive wear or loose-

ness.An equalizing beam end connec-

tion, which is visibly cleaner than the

other connections,may indicate a loose connection.

c. Look for worn, frayed, or distorted rubber in the equalizing beam end bushing.

d. Look for the equalizing beam to be lower in the beam hanger.

e. The gap on each side of the visible rubber at the lower end of the end bushing is

normal and not an indication to replace the bushing, see Figure 6-2. Because all rub-

ber end bushings are in compression,with the load bearing on the top side, the lower

side of the rubber is slightly relieved, allowing the rubber to move inward, and a gap

appears.

f. Place a jack under each equalizing beam end as shown. Raise the jack to check for

movement in the connection or rubber components, see Figure 6-2.

IF BAR PIN MOVEMENT OR LOOSENESS IS NOTED IN THE EQUALIZING BEAM END HUB, DO NOT

OPERATE THE VEHICLE. REPLACE THE RUBBER END BUSHINGS AND ALL CONNECTING PARTS.

THE ABOVE CONDITION CAN RESULT IN COSTLY REPAIR, DOWNTIME, POSSIBLE SEPARATION OF

COMPONENTS, LOSS OF VEHICLE CONTROL, PROPERTY DAMAGE, OR PERSONAL INJURY.

Axle Bracket

Supplied by vehicle

manufacturer

1" Locknut

Tightening Torque

450-600 ft. lbs.

1" Washer

1" Bolt

Tightening Torque

500-650 ft. lbs.

Bar Pin

Alignment

Shim

Bar Pin

Gap in rubber of

Bar Pin End Bushing

is normal

Axle Bracket

Supplied by

Vehicle

Manufacturer

'H

l!!J

~

,-

-

--

---------------

1

I I

' '

i ,----------

---,

}

:

//

~----._

'\

:,

\_

,,.,,

I \

\I

I I

~~ ~~

I I

I I

~

----

-)

A

WARNING

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Preventive Maintenance 14 17730-285

3. If bar pin movement or looseness is detected in the equalizing beam end hub, DO NOT

operate vehicle.Replace the equalizing beam end bushings and all connecting parts.Refer

to the Component Replacement Section of this publication.

4. Check and record torque values, as received, for each 1" bar pin fastener. Correct torque

values as required making sure all fasteners are tightened to:

■ At the locknuts to 450-600 foot pounds torque or

■ At the bolt head to 500-650 foot pounds

5. Recheck equalizing beam end connections for signs of looseness.

■ Inspect alignment shims in equalizing beam end for looseness. Lightly tap on the

alignment shims to see if they can be moved.

■ Inspect equalizing beam end connection for signs of excessive wear or looseness.

NOTE An equalizing beam end connection, which is visibly cleaner than the other connections, may

indicate a loose connection.

6. If bar pin looseness is still detected in the equalizing beam end hub, DO NOT operate the

vehicle. One or more components will require replacement, see Component Replacement

Section of this publication.

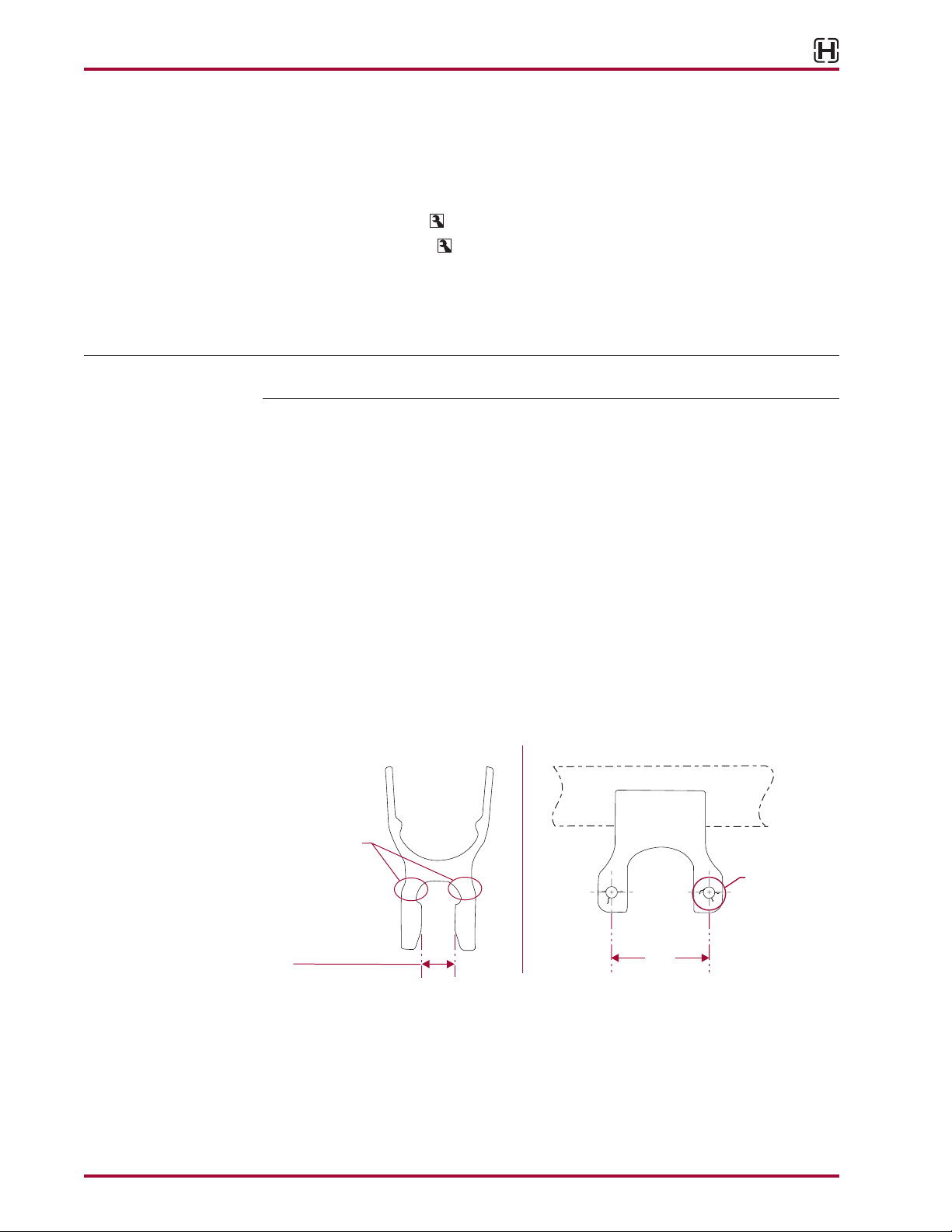

AXLE BRACKETS

The axle brackets are furnished and welded into position by the vehicle or axle manufacturer.

■ When inspecting the equalizing beam end connection also inspect the axle brackets for

damage or cracks,see Figure 6-3.Measure the dimension as shown in Figure 6-3,any axle

bracket that is found damaged or cracked must be repaired or replaced.Consult the vehicle

manufacturer for inspection, component repair and replacement instructions.

■ When an equalizing beam is removed for repair, or an inspection of the equalizing

beam end connection reveals movement, measure the distance between the axle bracket

legs for correct width. Refer to Figure 6-4 for measurement location and dimensions.An

axle bracket outside of the measurement range must be repaired or replaced.Consult the

vehicle manufacturer for inspection, component repair and replacement instructions.

FIGURE 6-3 FIGURE 6-4

8.5"

(216 mm)

2.313" (58.74 mm)

2.263" (57.48 mm)

Axle Bracket* Leg Dimensions Axle Bracket* Leg

Look for craks

in these locations

Axle

Typical

Crack

*Typical axle bracket shown

'H

l!!J

,~---------------------

1 I

I

I I

I

,

_____

_

~

___J

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 15 Preventive Maintenance

BAR PIN END BUSHING

FIGURE 6-5

An indication that the bar pin end bushing requires

replacement is when one or more of the following

conditions apply:

■ Visual inspection of contact area (the flat face

area where bar pin contacts the axle bracket) on

the bar pin reveals signs of excessive wear. If the

thickness of the bar pin in the contact area mea-

sures less than 1.874" (47.59 mm), bar pin end

bushing requires replacement, see Figure 6-5.

■ Visual inspection of the bolt holes in the bar

pin reveals signs of elongation or wear, see

Figure 6-5.

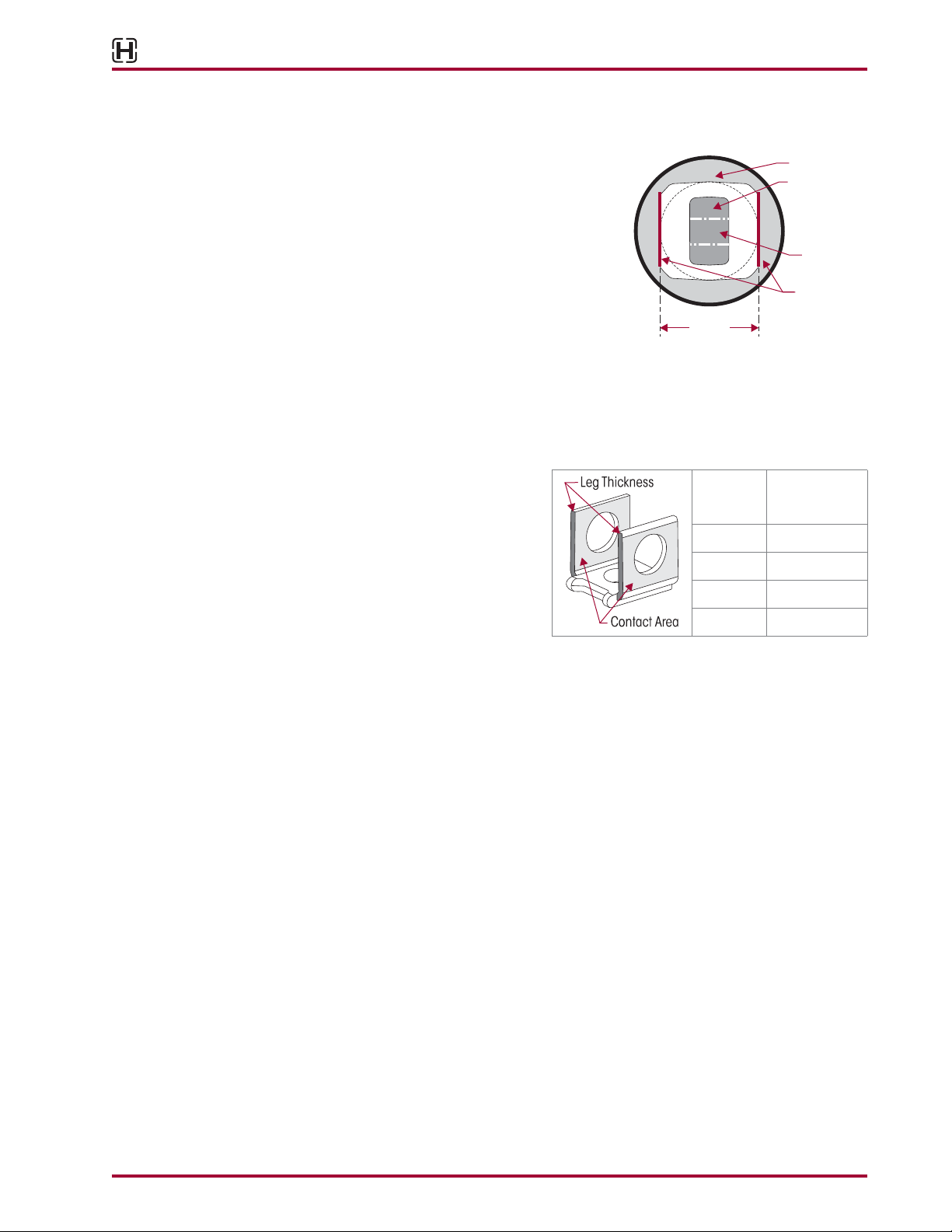

BAR PIN SHIM

FIGURE 6-6

An indication that the bar pin shims

require replacement is when one or

more of the following conditions apply:

■ Visual inspection of contact area

on the shim reveals signs of exces-

sive wear.

■ The thickness of any single leg on

the shim, is less than the measure-

ment shown in Figure 6-6,replacement of bar pin shim is required.

BOLSTER SPRINGS

Inspect all four bolster springs on a periodic basis.Actual bolster spring service condition and

performance may vary depending upon suspension and vehicle configuration, operation,

service and other factors.The following inspection guidelines are intended to assist vehicle

operators and maintenance personnel in examining the bolster springs and determining when

replacements may be needed. In the event one bolster spring on one equalizing beam assem-

bly shows signs of damage or excessive wear, Hendrickson recommends that both bolster

springs installed on that equalizing beam assembly be replaced.When the bolster springs are

replaced on one side only, the vehicle may lean slightly.The new bolster springs will tend to

settle to some degree,and return the vehicle to its original condition.The following procedure is

recommended for proper inspection.

1. Chock the front wheels to prevent movement of the vehicle during inspection of the

suspension.

2. Raise rear of vehicle approximately 4.0" - 5.0", (102 mm - 127 mm) just prior to lifting

wheels off ground, and support with stands.

3. Inspect all bolster springs using the following criteria. If cuts, splits, or bonding separation

are detected in the rubber, measure the depth of the damaged area using a six-inch ma-

chinist scale to determine if replacement is required.

■ Bent, burred or overhanging edges of the bolster spring metal plates may occur due

to mishandling in service. If the rubber is not trapped, and there are no sharp metal

edges in contact with the free surface of the rubber, this condition is acceptable.

■ Creases formed by folding of the rubber surface under load are acceptable.These creases

appear as stripes on the surface, polished by wear or covered with tacky rubber.

Bar Pin Mount

If bar pin measurement is less than

1.874" (47.59 mm), component

replacement is required.

1.874"

(47.59 mm)

Rubber

Contact Area

Bolt Hole

Thickness

of

Shim Leg

Minimum

Thickness

Required

1⁄8"0.123" (3.1 mm)

3⁄16"0.186" (4.7 mm)

¼" 0.248" (6.3 mm)

3⁄8"0.371" (9.4 mm)

'H

l!!J

I I

I I

~

------.1

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Preventive Maintenance 16 17730-285

■ Minor oil and grease contamination in the rubber due to vehicle operation is accept-

able. A slight change in shape of the rubber due to permanent set should not be

mistaken for oil and grease contamination. Certain softening of the rubber surface is

acceptable. However, unacceptable swelling due to contamination will require bolster

spring replacement.Measure bolster springs in the unloaded state.If the rubber diam-

eter of the bolster spring exceeds 8¾" (222.3 mm),see Figure 6-7,then bolster spring

replacement is necessary.

■ Cuts or Splits in the rubber of over 3.0" (76 mm) in length and an average depth of

1.0" (25.4 mm) are not acceptable and require bolster spring replacement. In par-

ticular, look for signs of cuts or splits in the rubber at points indicated in Figure 6-7 as

“///////”.

■ Bonding separation of the rubber from a bonded metal surface to a depth of up to

1½" (38 mm) is acceptable. If any bonding separation is more than 1½" (38 mm)

deep, both bolster springs should be replaced on the affected side of the vehicle (see

Figure 6-7). An unloaded bolster spring may be inspected for any bonding separa-

tion by measuring at points indicated in Figure 6-7 as “///////”. Any thin film or other

residual rubber material on the metal plates resulting from the molding process may

be ignored during inspection.

FIGURE 6-7

8¾" (222.25 mm) Maximum

1½"

(38 mm)

AUXILIARY SPRING ASSEMBLY

A visual inspection of the auxiliary spring is required every three months. It is acceptable to

have some scuffing on the bottom edges of the auxiliary spring due to contact with the bolster

springs and/or Vee bracket. If the auxiliary spring is damaged, replace the auxiliary spring as

outlined in the Component Replacement Section of this publication. See the following chart

for the new unloaded auxiliary spring height. If the minimum unloaded height decreases than

shown in the chart replacement is required, see Figure 6-8.

FIGURE 6-8

Auxiliary Spring

Part

Number

Unloaded

Height

Minimum

Unloaded

Height

A60314-000 33⁄8"

(85.7 mm)

3.0"

(76 mm)

B65902-003 21⁄8"

(53.9 mm)

115⁄16"

(49.2 mm)

Minimum

Height Unloaded

Auxiliary Spring

Rebound Strap

Bolster Spring

Vee Bracket

AB

or

'H

l!!J

■

■

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 17 Preventive Maintenance

REBOUND STRAP

Periodic inspection of the rebound strap, see Figure 6-8, is required every six (6) months. If the

rebound strap is torn, frayed, or not intact replace as outlined in the Components Replacement

Section of this publication.

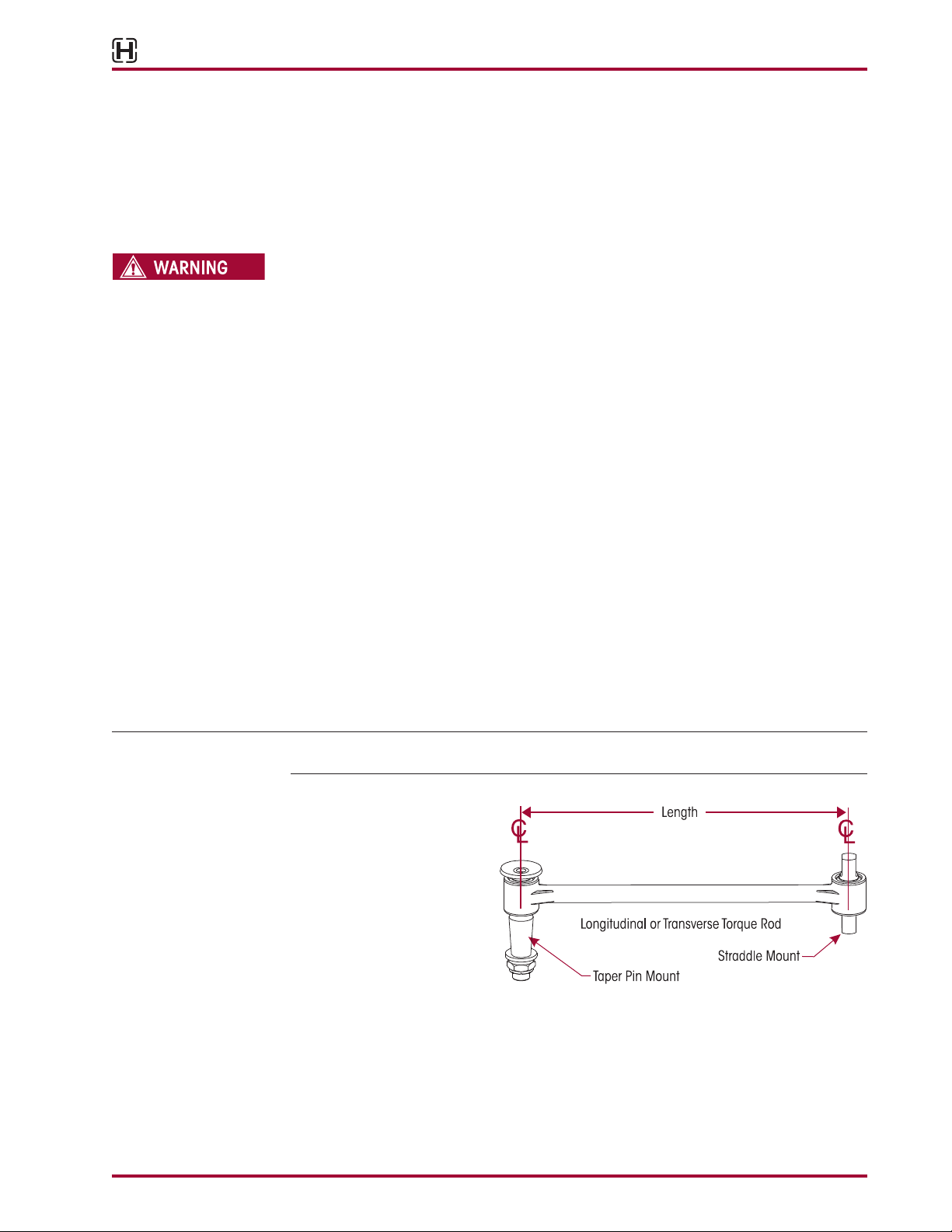

LONGITUDINAL AND TRANSVERSE TORQUE RODS

HNFR SUSPENSIONS INCORPORATE TRANSVERSE RODS FOR VEHICLE STABILITY. IF THESE

COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL,THE VEHICLE SHOULD NOT BE

OPERATED. FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING, LOSS OF VEHICLE

CONTROL, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT DAMAGE, OR

SEVERE PERSONAL INJURY.

All torque rods need to be inspected for looseness by one of the following methods.

■ Method 1 — For Tractor applications only with brakes applied, slowly rock the empty

vehicle with power while a mechanic visually checks the action at both ends.

■ Method 2 — with the vehicle shut down, a lever check can be made with a long pry bar

placed under each rod end and pressure applied.

Visually inspect torque rod bushings for torn or shredded rubber, inspect for bent, cracked, or

broken torque rods and also for end hubs that have an elongated “oval” shape.Any of these

conditions require component replacement.

The length of the torque rods is determined by the truck manufacturer for optimum drive line

angle and alignment.The longitudinal torque rods control pinon angles and also absorb accel-

eration and braking forces.The transverse torque rods control the side to side inputs such

as cornering.The mounting brackets at the axle ends of the torque rods are furnished and

welded into position on the axle housings by vehicle manufacturer or the axle manufacturer.A

two-piece torque rod is also available to cut and weld to the desired length, see Hendrickson

publication 45745-148.

Straddle mount torque rod end attaching fasteners are furnished by the vehicle manufacturer.

It is important that the tightening torque of the locknuts be checked during preventive mainte-

nance service. Follow the vehicle manufacturer’s specifications for torque values.

NOTE Hendrickson Suspension recommends Grade 8 bolts, hardened flat washer and Grade C

locknuts be used for all straddle mount torque rod attachments.

FIGURE 6-9

The longitudinal rod is strad-

dle/straddle mount, and the

transverse rod it straddle

mount / taper pin mount, as

shown in Figure 6-9.

Whether the bushings are

straddle mount or taper pin

mount, (see Figure 6-9) they

can be replaced by press-

ing out the worn bushing and

installing a new genuine Hendrickson bushing. Refer to the technical procedure for the proper

replacement instructions for your specific suspension system.

'H

l!!J

A

WARNING

Longitudinal

or

Transverse

Torque

Rod

Straddle

Mount

_/

Taper

Pin

Mount

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

Alignment & Adjustments 18 17730-285

SECTION 7

Alignment & Adjustments

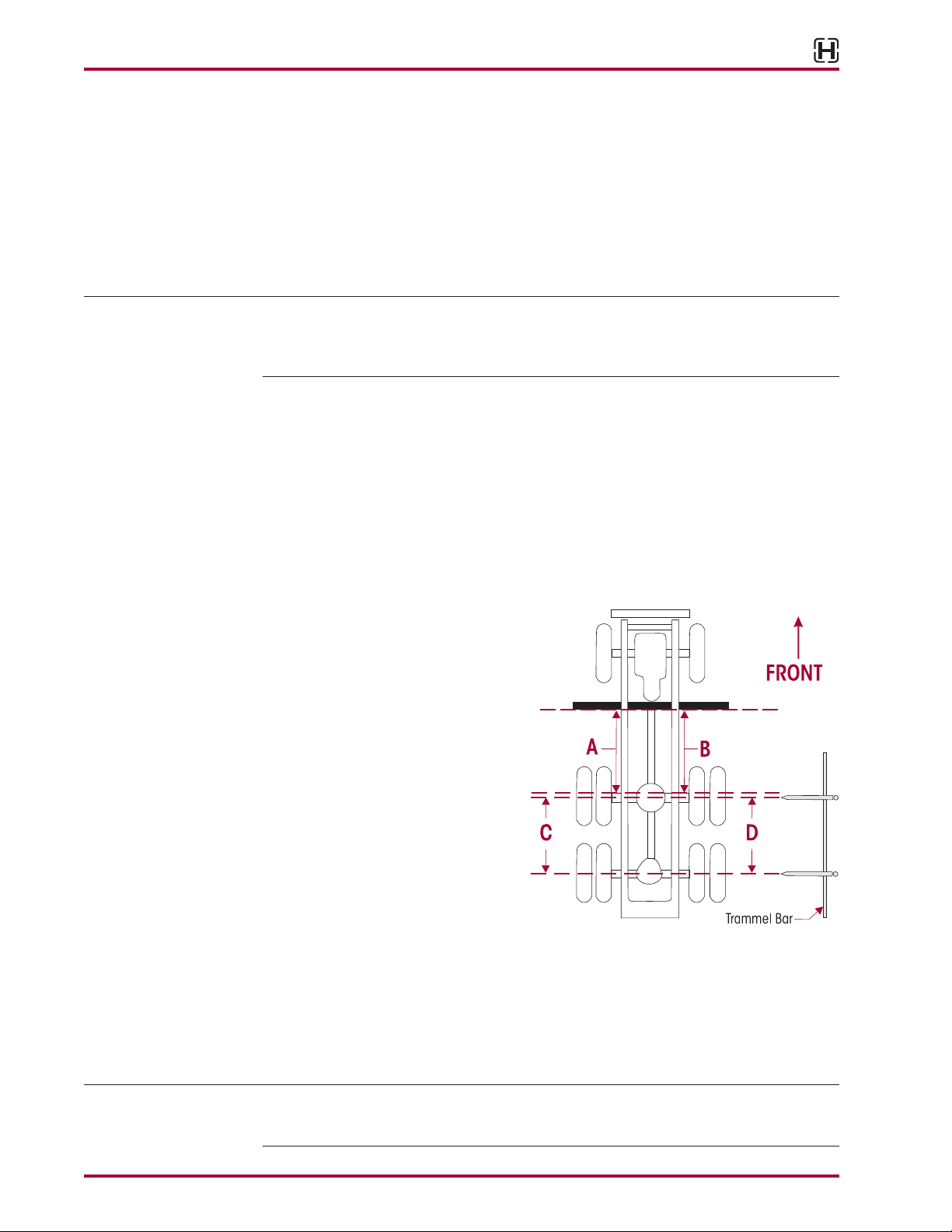

DRIVE AXLE ALIGNMENT INSPECTION PROCEDURE

Proper alignment is essential for maximum ride quality, performance, and tire service life.The

following recommended alignment procedure as described below, should be performed if

excessive or irregular tire wear is observed.

NOTE Proper vehicle alignment can only be achieved when all axles are aligned to the vehicle’s

centerline and the steering axle’s caster, camber and toe-in settings are within specifications.

If, however, axle alignment equipment is not available the alignment of the drive axles may be

checked by performing the following steps.

1. Use a work bay with a level, flat surface.

2. Relax the suspension by slowly moving the vehicle back and forth several times in a straight

line without using the brakes.This will slacken or loosen the suspension as the vehicle is

positioned. End with all wheels positioned straight ahead.

3. DO NOT set the parking brake.Chock the front wheels of the vehicle.

4. Verify and maintain the air system at full operating pressure.

5. Verify all suspension components are in good condition. Repair or replace any worn or

damaged suspension components before proceeding with the alignment process.

6. Ensure all drive axle tires are the same size.

FIGURE 7-1

7. Securely clamp a six-foot piece of

STRAIGHT bar stock or angle iron

across the lower frame flange as

shown in Figure 7-1. Select a loca-

tion for the bar stock or angle iron

as far forward of the drive axle as

possible where components will not

interfere.

8. Accurately square the bar stock or

angle iron to the frame using a car-

penter’s square.

9. Using a measuring tape, measure

from the straight edge to the forward

face of the front drive axle arms on

both sides of the vehicle as shown in

Figure 7-1, Aand B.

10. Calculate the difference between measurements Aand B.

a. If the front drive axle is within vehicle manufacturer’s specifications, proceed to check

the rear drive axle (Step 11).

b. If alignment of the front drive axle IS NOT within the vehicle manufacturer’s specifica-

tions, then the alignment of this axle MUST be corrected BEFORE measuring the rear

drive axle alignment (Step 11).Correct the alignment of this axle by following the bar

pin alignment instructions.

NOTE Since the remaining drive axle will be aligned relative to the front drive axle, it is essential

that the front drive axle is aligned within the vehicle manufacturer’s specifications prior to the

alignment of the remaining drive axle.

'H

l!!J

t

FRONT

Trammel

Bar

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

HN®FR Series

17730-285 19 Alignment & Adjustments

11. Using a trammel bar,measure the distance from the spindle center of the front drive axle to

the spindle center of the rear drive axle on both sides of the vehicle;see Figure 7-1,Cand D.

12. Calculate the difference between measurements Cand D.

a. If the measurements are within the vehicle manufacturer’s specifications,then the rear

drive axle alignment is acceptable.

b. If alignment of the rear drive axle IS NOT within the vehicle manufacturer’s specifica-

tions,then the alignment of this axle MUST be corrected. Correct the alignment of this

axle by following the bar pin alignment instructions.

13. Recheck measurements to confirm adjustments. Repeat Steps 9 through 12 until the cor-

rect alignment is achieved.

14. When all drive axle alignments are within the vehicle manufacturer’s specifications then

the alignment procedure is complete.

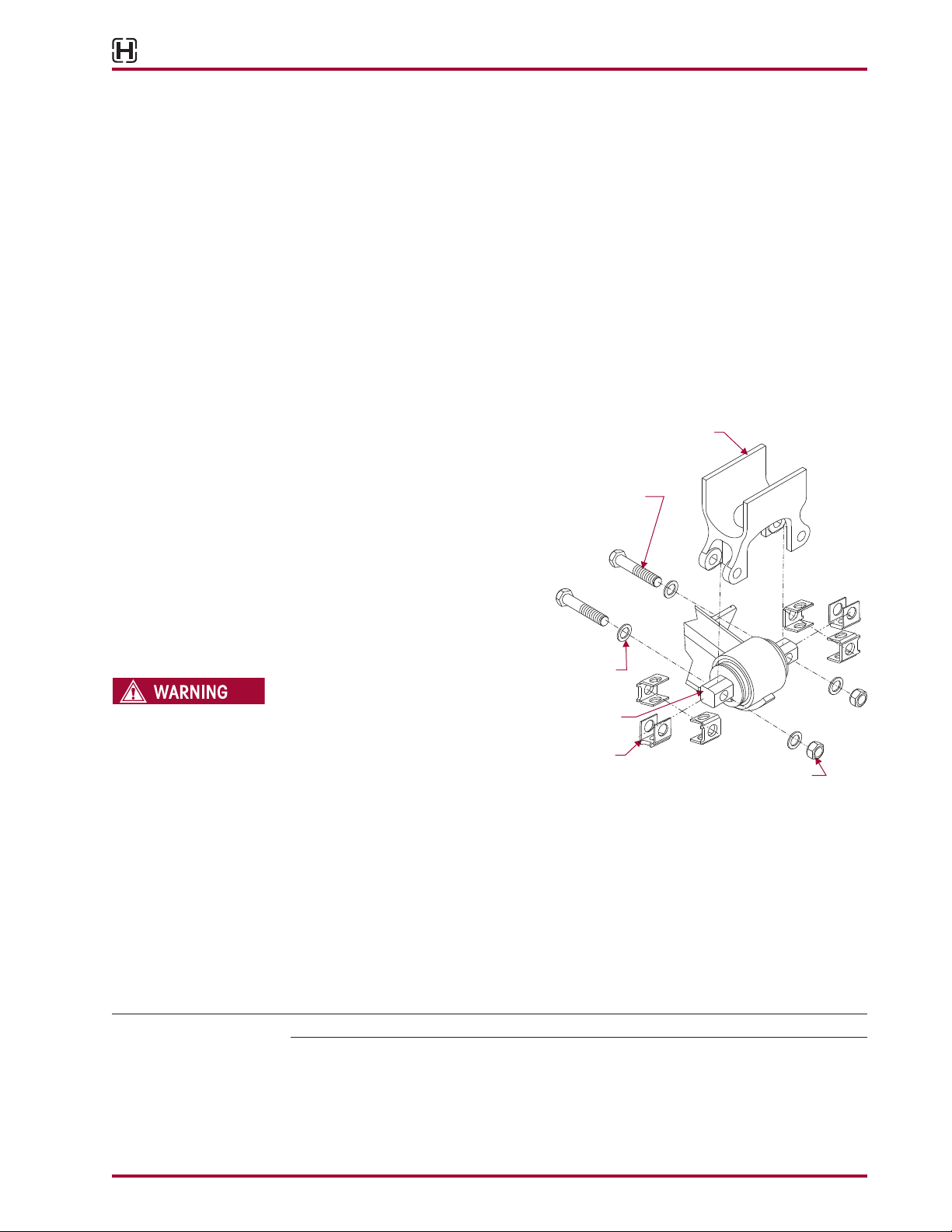

BAR PIN ALIGNMENT

FIGURE 7-2

The alignment feature consists of

specially designed, tightly tolerance

steel shims which fill the 3⁄8" (9.5 mm)

total gap between the bushing’s bar

pin and the axle bracket legs.The gap

must be filled by placing the shims on

the bushing assembly in one of the

positions shown in Figure 7-2 or 7-3.

Hendrickson has three shim designs

options for alignment, part number

50130-000 (provided), 50131-000

and 57026-000, see Figure 7-5.

A BAR PIN SHIM MUST BE INSTALLED AT

EACH BOLT LOCATION.THE SAME PART

NUMBER SHIM INTHE SAME ORIENTATION

MUST BE USED AT BOTH BOLT LOCATIONS

ON ANY ONE END BUSHING. DO NOT

INSTALL OR STACK MORETHAN ONE SHIM

AT EACH BOLT LOCATION. USE GENUINE

HENDRICKSON BAR PIN SHIMS, DO NOT

USE STANDARD WASHERS.FAILURE TO FOLLOWTHESE WARNINGS MAY RESULT IN IMPROPER VEHICLE

ALIGNMENT, FRACTURE OF THE AXLE BRACKET OR BAR PIN WHICH COULD RESULT IN THE LOSS OF

VEHICLE CONTROL AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

ALIGNMENT ADJUSTMENT

If alignment of the drive axles is required, as determined by an alignment inspection procedure,

the following steps will need to be performed.

1. Determine direction of axle thrust angle. Figure 7-4 illustrates the forward drive axle with a

thrust angle to the left (-negative thrust).

SERVICE HINT Axle movement is in the same direction as the increased shim thickness, see Figure 7-3.

Axle Bracket

Supplied by vehicle

manufacturer

1" Locknut

Tightening Torque

450-600 ft. lbs.

1" Washer

1" Bolt

Tightening Torque

500-650 ft. lbs.

Bar Pin

Alignment

Shim

Bar Pin

'H

l!!J

~/i

,

·,,.,,.-;,-y'

~

' ·,.

WARNING

Pro Gear and Transmission • 906 W. Gore St. Orlando, FL 32805 • 1 (877) 776-4600 / (407) 872-1901 • [email protected]

This manual suits for next models

4

Table of contents