Progeny 2059 User manual

Doc Number MAN0013 Date 05/08/09 Issue 04

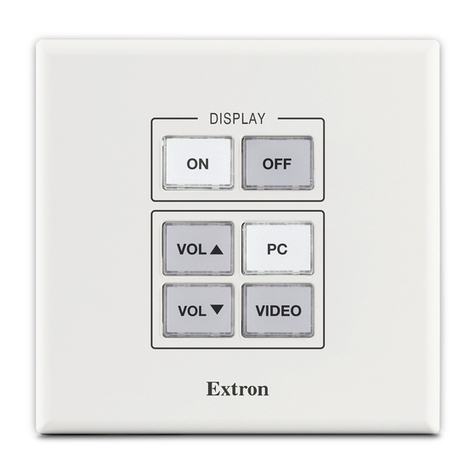

COMPACT KEYBOARD CONTROLLERS

MANUAL

SPECIFICATION

Two independent channels

Up to 50 access codes per

channel

Access Codes can be 4, 5

or 6 digits in length

Timed lock drives from 1 to

99 seconds

Lock timers can be latched

open at the keyboard

Lock timers can be set to 0

for toggle operation

Anti Tailgate feature on both

channels

Separate door monitoring

and RQE inputs for each

channel

Separate door forced alarm

outputs

Volts free NC Tamper

switch

Duress output

Integral Prolonged Door

Open Alarm

Separate three colour

indicators for each channel

User definable 6 digit

programming code

Simple menu driven

programming procedure

4 menu functions per

channel

Incorrect code penalty delay

timer

Voltage free changeover

contacts for lock control

Doc Number MAN0013 Date 05/08/09 Issue 04

OPERATION

INDICATORS

A coloured indicator is provided for each channel. The colours of these indicators have the

following meanings.

LED Colour

Meaning

Red

Lock Closed

Green

Lock Open

Amber

PDO Alarm

Flashing Off

Programming

Short blink to Off

Keyboard Key Push

SOUND

Sound is used to give the user additional feedback on the status of the controller and

progress during programming.

Sound

Meaning

Continuous Two Tone, High Volume

PDO Alarm

Four Notes “Low – High - Low –High”

Programming Mode

Two Notes “Low - High”

Confirm Programming Change

Two Notes “High - Low “

Programming Error

Single Short Note “High”

Keyboard Key Push

USING ACCESS CODES

Access codes can be four, five or six digits in length. To operate one of the channels simply

enter one of the programmed access codes for that channel. If a correct code is entered then

the LED indicator for that channel will change to green and the output relay will activate.

Access codes can be changed to indicate Duress. Note this feature must be enabled if

required. See “RESTORING FACTORY DEFAULT SETTINGS” later in this manual.

HOLDING A CHANNEL OPEN

If a channels lock timer is programmed for timed operation, the operator can override this and

hold the output open. To do this, simply enter the access code for that door. Once the output

is activated and the LED indicator is showing green, push and hold the 1 & 2 keys as a pair.

This will hold open channel A. Use the 2 & 3 keys for channel B. To cancel the latched state

of a channel simply enter a valid access code again.

TOGGLE MODE

If the lock time for a particular channel has been set to zero then each time a correct code is

entered for that door or the RQE input activated, the output relay will “Toggle” to the opposite

state. And stay in that new state until another code or RQE is detected.

Each channel has its own lock time thus either or both channels can be selected to “toggle” or

“timed” operation. One channel can be used to open a door, and the other channel used to

turn on and off a piece of equipment.

1

2

3

HOLD OPEN A

1

2

3

HOLD OPEN B

Doc Number MAN0013 Date 05/08/09 Issue 04

ALARMS

PDO

The purpose of the Prolonged Door Open (PDO) alarm is to act as a reminder that a door is a

security door and should not be wedged or held open for too long. If the door sensor has

been connected then each time the door is detected opening a PDO timer starts. If this timer

reaches a pre set value before the door closes, a two-tone PDO alarm will be heard from the

keyboard.

PDO alarm cancels automatically when the door is closed. The PDO alarm is not active if the

door is open due to Toggle or Keyboard command. The PDO alarm sound can be muted by

using program function * 8.

DOOR FORCED

The operation of the door forced alarm depends on the ability of the controller knowing when

the door has been opened legitimately or not. In order to do this both the door sensor input

and the ReQuest to Exit (RQE) inputs must be wired. Thus if the door is detected as opening

without the lock being released then a Door Forced alarm will go active and latch. Door forced

alarms can only be cancelled by entering a valid access code for that door.

DURESS

If the duress feature is turned on, a duress alarm is generated when one enters an access

code with the last digit incremented. For example if your access code is “1 2 3 4” then if you

enter “1 2 3 5” the door will be released as normal but also the duress alarm output will go

active and latch. A duress alarm can only be cancelled by entering the valid programming

code. If the duress feature is turned off, then “1 2 3 5” would not open the door. See

“RESTORING FACTORY DEFAULT SETTINGS” later in this manual.

Safety Notes and Disclaimers

Please read this manual carefully before attempting to install, program or operate the PROGENY PCAx00

range of combined keyboard controllers. At the back of this manual there is a quick reference to

programming command sequences.

This equipment must be installed in line with all relevant regulations and standards.

This equipment should be powered by a power supply classed as SELV, as defined in BS EN 60950. All

connections to this unit must also be SELV.

Make sure that wiring is rated according to fuses and current limits of relevant power supplies.

Every effort is made to ensure that this manual is complete and free from errors. However we reserve the

right to make changes to these products and this manual without notice.

No liability is accepted for loss damage or injury as a consequence of using these products or instructions.

Copyright BSB Electronics Ltd 1997 All rights reserved.

Doc Number MAN0013 Date 05/08/09 Issue 04

PROGRAMMING

Programming is achieved by entering the programming code at the keyboard followed by a

menu selection code. Depending on the menu option selected data can then be entered at

the keyboard. The menu functions available and default settings are as follows:

MENU #

DESCRIPTION

DEFAULT SETTINGS

* 0

PROGRAMMING CODE

6 5 4 3 2 1

* 1

ACCESS CODE FOR CHANNEL A

NONE

* 2

LOCK TIME FOR CHANNEL A

3

* 3

PDO TIME FOR CHANNEL A

0

*4

NOT USED

NOT USED

* 5

ACCESS CODE FOR CHANNEL B

NONE

* 6

LOCK TIME FOR CHANNEL B

3

* 7

PDO TIME FOR CHANNEL B

0

* 8

PDO ALARM MUTE

0ff

* 9

PENALTY TIME

0

Each menu is described in detail in the following sections. The general programming

procedure is shown below:

*6 5 4 3 2 1

*2

#

Programming Tone

& Flashing LED’s

Enter Programming code

Enter Menu Number

Press * to select a

new menu function.

Press # to finish

Programming Tone &

Flashing LED for channel A

3

Enter new value.

*

A rising two-tone note

indicates SUCCESS.

A falling two-tone note

indicates ERROR.

Doc Number MAN0013 Date 05/08/09 Issue 04

ACCESS CODES

Access codes are used to open a door. Up to 50 access codes can be programmed for each

door or channel of the controller. The codes are held in slots or pigeonholes that are

numbered 01 through to 50. You can record access codes for these slots using the form at

the back of this manual.

Adding Access Codes

Note: avoid duplicating access codes especially between the two channels e.g. ‘1 2 3 4’ for

channel A and ‘1 2 3 4 5 6’ for channel B.

REMOVING ACCESS CODES

Removing Individual Access Codes

Follow the same procedure as for adding access codes except after select the slot containing

the access code in question simply press * or #. This will clear the code contained at that slot.

Removing All Access Codes for Channel A and B

All access codes for channel A can be removed by removing power to the controller then

while holding the number 2 key apply power only releasing the key when a beep is heard from

the control unit.

Removing All Access Codes for Channel A

All access codes for channel A can be removed by removing power to the controller then

while holding the number 1 key apply power only releasing the key when a beep is heard from

the control unit.

Removing All Access Codes for Channel B

All access codes for channel A can be removed by removing power to the controller then

while holding the number 3 key apply power only releasing the key when a beep is heard from

the control unit.

* 6 5 4 3 2 1

*1

#

Enter Programming code

Select Menu 1,access code door A

Select Menu 5,access code door B

Press * to select a

new menu function.

Press # to finish

1 2 3 4 5 6

To add or change code

Enter new access code.

*

0 6

Enter Slot Number

To remove code

DO NOT enter a code

Doc Number MAN0013 Date 05/08/09 Issue 04

LOCK TIME

Lock time is the amount of time that the locking device is released following the entry of a

correct access code or the triggering of the RQE input. This may be from 0 to 99 seconds. If

set to zero, then each time a correct code is entered the relay will “ Toggle” to the opposite

state. If a door sensor is fitted then the anti tail gate feature means that the lock time will be

cut short once the door closes again.

Programming the Lock Time

PROLONGED DOOR OPEN (PDO)

There are connections on the control unit to allow the monitoring of the door open status.

PDO is the amount of time the door may be open before triggering an audible alarm from the

control unit. This may be from 0 to 99 seconds. If set to zero PDO sensing for that channel is

disabled.

Programming PDO Time

*6 5 4 3 2 1

* 2

#

Enter Programming code

Select Menu 2, Lock Time door A

Select Menu 6, Lock Time door B

Press * to select a

new menu function.

Press # to finish

*

2 0

Enter new value

*6 5 4 3 2 1

* 3

#

Select Menu 3, PDO Time door A

Select Menu 7, PDO Time door B

Press * to select a new

menu function.

Press # to finish

*

1 5

Enter new value

Enter Programming code

Doc Number MAN0013 Date 05/08/09 Issue 04

PDO ALARM MUTE

This is the means by which the PDO alarm tone sound can be muted. By using the following

procedure the PDO sound will “toggle” between muted and alarm sounding.

PDO Alarm Mute Procedure

PENALTY TIME

Penalty Time is delay that is incurred if an error is made while entering an access code. This

slows down potential hackers to the system. This may be from 0 to 99 seconds. If set to zero,

the penalty feature is disabled.

Programming Penalty Time

*6 5 4 3 2 1

* 9

#

Enter Programming code

Select Menu 9, Penalty Time

A

Press * to select a

new menu function.

Press # to finish

*

1 0

Enter new value

*6 5 4 3 2 1

* 8

#

Enter Programming code

Select Menu 8 PDO Mute

Press * to select a

new menu function.

Press # to finish

*

Doc Number MAN0013 Date 05/08/09 Issue 04

PROGRAMMING CODE

The programming code is the means by which the systems operator gains access to the

programming functions. This is a 6-digit number and can be changed by using the following

procedure.

Changing the Programming Code

RESTORING FACTORY DEFAULT SETTINGS

Factory defaults can be restored in a number of different ways. Each method offers different

results. The procedure consists of first removing power to the controller, then while holding

one of the keys, re-apply power. Release the key when a beep is heard from the control unit.

*6 5 4 3 2 1

* 0

#

Enter Programming code

Enter Menu Number

Press * to select a

new menu function.

Press # to finish

9 8 7 6 5 4

Enter New Code Again

*

9 8 7 6 5 4

Enter New Code

KEYS 1,2 & 3 CLEAR CODES ONLY

With keys 7, 8 & 9 the programming code is returned to

654321 as well as restoring the default Lock, PDO &

Penalty Times

1

2

3

4

5

6

7

8

9

Clears channel A

codes only

Clears channel B

codes only

Clears both

channel Aand

Bcodes only

Duress feature

Disabled

FULL RESET

Duress feature

Enabled

Doc Number MAN0013 Date 05/08/09 Issue 04

INSTALLATION

MOUNTING

The ideal mounting height for the telephone style readers (2059, 2061, 2064) is between 1.0

and 1.5 metres from the floor. In the case of the ashtray style PCA 800 (product code 2067) is

between 0.8 and 1.2 metres from the floor. Choose a position that will be natural for users to

be able to enter an access code in secrecy and then open the door.

The mounting procedure for all the controllers is simple. However in the case of PCA 800 and

PCA 500 it is a good idea to fully test the system before attaching the final cover or front label.

The PCA 700 and the PCA 500 may be mounted internally or externally. If these are being

mounted externally, spread silicon compound over the terminals, after connecting and testing.

Ordinary multi core cable may be used. Cable runs should be no greater than 100 metres.

There is an earth connection on all the controllers but it is most important to connect this in

the case of the two metal units “2064 PCA 700” and “2067 PCA 800”. The earth connection

should be connected to the electrical safety earth at the power supply.

All other connections are shown in the circuit diagram on the next page. If the locking device

does not provide a mechanical means of override for egress and the door forms part of an

emergency exit route then additional means of override should be connected. For example a

door magnet will only open if the supply is removed even though there may be an RQE button

connected for egress, an emergency break glass or fire relay should be wired to break the

circuit to the magnet in the case of an emergency. If in doubt consult the local fire officer.

QUICK START GUIDE

Once all the connections are made the following procedure will allow you to test an access

code for channel A.

*6 5 4 3 2 1 Both LEDs will flash

*1 Channel A LED only will flash

0 1 Slot number

1 2 3 4 # Access code for slot 01

Now test the code by entering:

1 2 3 4

Channel A LED will turn green and the relay for channel A will open for 3 seconds

Doc Number MAN0013 Date 05/08/09 Issue 04

ACCESS CODE & SETUP RECORD

PROGRAMMING

CODE

DURESS ON / OFF

CHANNEL A

CHANNEL B

LOCK TIME

LOCK TIME

PDO TIME

PDO TIME

No.

CODE*

NAME

No.

CODE*

NAME

01

01

02

02

03

03

04

04

05

05

06

06

07

07

08

08

09

09

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

Doc Number MAN0013 Date 05/08/09 Issue 04

Doc Number MAN0013 Date 05/08/09 Issue 04

This manual suits for next models

6

Table of contents

Other Progeny Controllers manuals

Popular Controllers manuals by other brands

Vicon

Vicon VAX-MDK-2 quick start guide

salmson

salmson Control EC-L Installation and starting instructions

Monte Carlo Fan Company

Monte Carlo Fan Company ESSWC-11 Installation and operation instruction

Technibel Climatisation

Technibel Climatisation K70D043Z installation instructions

Endress+Hauser

Endress+Hauser RA33 operating instructions

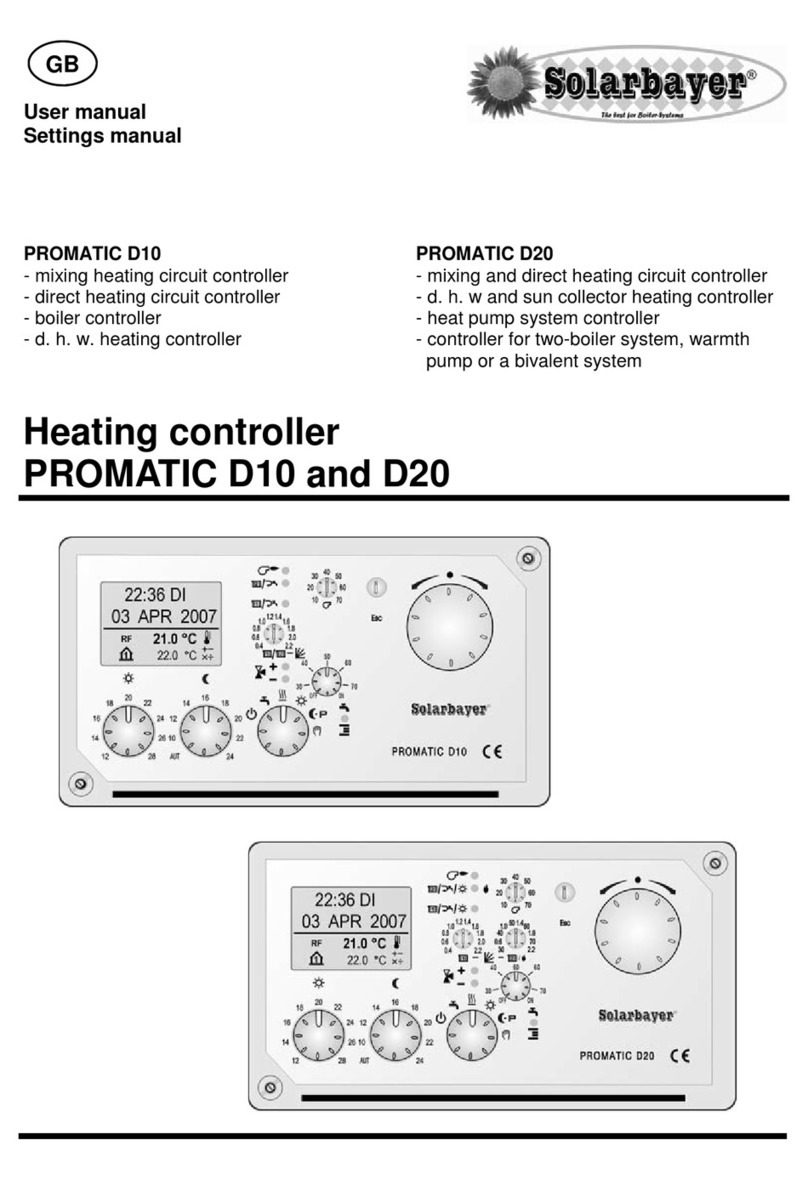

Solarbayer

Solarbayer PROMATIC D10 user manual