Seametrics FT520-84 User manual

LT-10830-C

Page 1 of 4

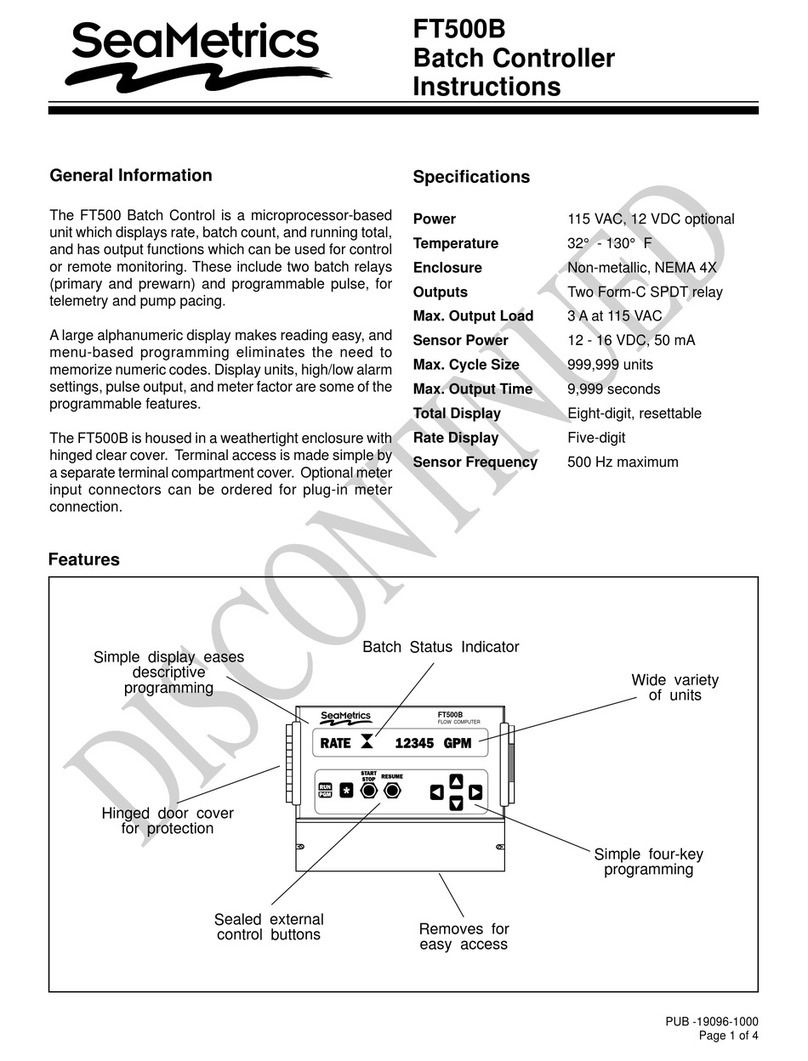

General Information Specifications

FT520-84 Regeneration

Control Instructions

Power 115 VAC (220 VAC optional)

50/60 Hz; 12-24 VDC

Temperature 32°- 130°F (0°- 55°C)

Enclosure Precision cast aluminum,

NEMA 4X

Initiation Outputs Two Form C SPDT relay,

115 VAC 5A max

Max Pulse Output 100 mA at 60 VDC

Memory Type Non-volatile EEPROM

auto-backup

Sensor Power 12 VDC, 10 mA

Totalizer 8 digit

Rate Display 5 digit

Volume Units Gallons, cubic feet, cubic

meters, liters, million gallons

Output Time 1-999 Seconds

Analog Output 4-20 mA, 0-5 VDC, 0-10 VDC,

opto-isolated

Sensor Input Open collector current sink,

ESD protected

Max Input Frequency 1,000 Hz

Shipping Weight 7 lbs

Features

Easy-read

backlit display

Remote control terminals

(inside housing)

Rugged cast aluminum

housing

(wall or panel mount)

Chemical pump

pulse LED

Regeneration

initiation

Regeneration volume

counts down

The FT520-84 is a version of the SeaMetrics flow

processor specially designed for regeneration control.

On the input side, it can be used with SeaMetrics flow

sensors and meters, as well as with water meters from

other manufacturers. The output can be used to initiate

regeneration in a variety of one-tank and two-tank water

treatment systems. In addition to the regeneration

functions, this unit features displays of flow rate and

accumulatedflow, aswellasprogrammable pulseoutput

and a 4-20 mA analog output, for use with remote

recorders.

There are two regeneration relays, which can be used

for alternating regeneration of two tanks. The outputs

remain on for a duration programmed by the user,

dependingon therequirements ofthe regenerationvalve

being used.

Aprogrammable pulse outputcan be usedas needed to

control a chemical metering pump, for controlled chem-

ical addition to the water stream.

SET REGEN. VOL.

1000.00 GAL

Installation

Wall Mounting. Usingthe four screwsprovided, attach

the two foot brackets to the sides of the enclosure. Then

attachthe unit toany secure surfacebyinserting screws

through the mounting holes in the foot brackets.

Panel Mounting. Follow the dimensions given for

“Panel Cutout”. Be sure to include the four corner screw

holes. After cutting and drilling, place the front plate on

the front side of the panel with its gasket against the

panel, and the remainder of the square housing on the

backside. Slide thescrews throughthefour holesdrilled

in the panel, and into the threaded holes in the housing.

Tighten until thegasket is firmlycompressed against the

panel.

Expose Terminals. Removethe fourscrews whichhold

the front plate to its flange. Remove the front plate. The

display board is attached to this front plate. It is also

connected to the power board by a ribbon cable. For

convenience, this cable can be disconnected while

making connections. Connections can be made inside

the enclosure, or the terminals can be unplugged for

easier access, by gently tugging on them.

Sensor Connection. Followthe “Connections”diagram

to connect either two or three wires from the flow meter

or flow sensor.

Regeneration Valve Connection. Connect the leads

which initiate the regeneration valve(s) to the terminals

marked Relay 1 and Relay 2. (See “Connections” dia-

gram.) If only one unit is being connected, use Relay 1.

(Relay 2 will operate only if “Alternate Relays” mode is

used.)

Analog Connection. This output can be configured 4-

20 mA, 0-10 V or 0-5 V by placing a jumper in the cor-

rect position on the analog header. The switch next to

the header selects active (powered) or passive

(unpowered) output. When using the 12 VDC powered

input you may only select passive output.

Power Connection. Connect AC or DC power as

2 of 4

Displays

Replace the front panel, taking care to reconnect the

ribbon cable. When power is switched on, the display

should light up immediately with meaningful letters or

digits.

Settings

Set Flow Rate. Press . Use to select volume

units.Use to selecttheparticular unitdesired(gallons,

liters, etc.). Then use to switch to time units.Again,

select the units desired. Press to move to the next

menu item.

Set Decimal. Use toselect zero,one, ortwodecimal

places on the flow units. Press to move to the next

menu item.

Set K-Factor. The unit will not function properly until

this number is entered. It is simply the number of pulses

which the flow meter or flow sensor puts out per gallon

of liquid. It is marked on the Model/Serial tag of

Caution: When the control is

powered up, relay or analog out-

puts may be present. If this

could be a hazard, wait to make

external connections until pro-

gramming is complete.

!

0.00 GPM

O.00 GAL

SETTINGS

OPERATION MODE

SET DECIMAL

SET

SET SET K-FACTOR

SET

SET

SET

SET

SET

SET

SET

SET REGEN. VOL.

1000.00 GAL

TO CLEAR TOTAL

PRESS UP & LEFT

SET 20mA RATE

0.00 GPM

return to

operation mode

Running

Totalizer

0.00 GPM

1.000

SET PULSE OUT

.00 GAL

SET REGEN. TIME

5 SEC'S

SET RELAY MODE

ALTERNATE RELAYS

SET GAL

MINUTE

FLOW

RATE

0.00 GPM

O.00 GAL

T

OR

T = Total

Volume

counts down

desired to the appropriate terminals. For safety, if using

AC power, be sure to connect the ground terminal

provided to a good earth ground. If using 12 VDC, use

a Seametrics PC3 or equivalent 12 VDC 500 mA power

supply.

3 of 4

Connections

SeaMetrics flow meters and flow sensor fittings. On

adjustableflow sensors, theK-factor mustbe taken from

the chart in the flow sensor instructions, based on pipe

size. Set the number with and . The underlined

digit is the one being set. moves one digit to the left

and increasesthe digit. Whentheappropriate number

has been set, press again to move to the next menu

item.

Set Pulse Out. An output pulse is activated at the

selected volume intervals if this feature is in use.

Otherwise,itdoes not needto be set. Press tomove

to the next menu item.

Set 20 mA Out. The “SET 20mA RATE”programs the

flow rate at which the output is 20 mA, 5 V or 10 V. Use

and to set the maximum flow rate desired for full

scale output. Press for next menu item.

Set Regeneration Volume. This is the volume (in the

units you have selected; typically gallons) at which the

relay energizes to initiate a regeneration cycle. Set to

thedesiredamount using and .Press to move

to the next menu item.

Set Regeneration Time. This is the length of time in

seconds that the relay remains energized to initiate

regeneration. Using ,set forslightly overtheminimum

timerequiredby the regenerationvalve to begin acycle.

Press to move to the next menu item.

Set Relay Mode. Choose between single relay (Relay

No.1) and dualrelay (AlternateRelays) operation, using

. In alternate relay mode, the first regeneration will

use relay 1, the next will use relay 2, and successive

regenerations will switch between the two. Press to

move to the next menu item.

Clear Total. This function resets the running total back

to zero. It is unrelated to the regeneration function, and

can be ignored unless it is needed. To reset to zero,

press and simultaneously. Press to return to

operation mode.

Operation

Choice of Displays. When allof the settings havebeen

entered, the next press of the SET Key puts the unit in

operation. If a T appears at the left side of the display,

thevaluesshown are flow rateand running total. Ifthere

is no T, the values shown are flow rate and units

remaining until regeneration. The total increases with

flow, and the regeneration quantity counts down. Use

tochoose the preferreddisplay,usuallyregeneration

Pulse 1

Alternate

12 VDC power

Pulse 2

Relay 2

Relay 1 NC

COM

NO

NC

NO

COM

Regeneration Outputs

Line

Neutral

Ground

Resume

0-5 V or

0-10 V or

4-20 mA

Signal

Start/Stop

–

+

–+

s1

+

–

s2

RESUME

COM

BATCH

Remote

Controls

Pulse Outputs

(for metering pumps)

Main

power fuse

250mA

part # 26926

AC Power

Ribbon connector

from display board

Meter

Power

RED

BLACK

Dry contact

Customer Supplies

1A Fuse

Ground

A

B

An Output

A

P

Passive

Active

Jumpers

5V

10V

4-20mA

PC1 power supply

P/N 05040

WHITE

Analog Switch

Analog Header

19026 72nd Ave South., Kent, WA 98032 USA

Phone: 253-872-0284 Fax: 253-872-0285

www.seametrics.com 1-800-975-8153

Connection for Alternating Tanks Panel cut-out dimensions

Alternating Tanks Application

!

Caution: Always disconnect

power to the unit before open-

ing the terminal cover. Do not

reconnect power until all con-

nections have been made and

the terminal cover has been replaced.

4 of 4

quantity.

Regeneration Initiation. When the regeneration

quantity number first reaches 0, relay 1 energizes for

thelength of timewhich has beenset.The regeneration

quantity immediately resets and begins counting down

again. If alternating mode has been selected, the next

time it reaches 0, relay 2 will energize, and the cycle

after that, will return to relay 1.

An output can be manually forced at any time by

pressing the Start/Stop key. The relay will energize for

the set time, and regeneration volume will return to its

original setting to begin counting down again.

Repair

The only field-repairable component on the FT520 is

the fuse. If failure is due to a cause other than a blown

fuse, it is necessary to replace the entire board stack.

Contact your distributor for information.

5.50"

gasket

PANEL

CUTOUT

5.50"

6.03"

6.03"

1/4" holes (4 required)

Relay 1

Relay 2

NC

COM

NO

NC

NO

COM

Tank 1

Tank 2

Flow Sensor FT520-84

Tank 1 Tank 2

Other manuals for FT520-84

1

Other Seametrics Controllers manuals