DVC6200 or DVC2000 Digital

Valve Controller on 1051 and 1052

Mounting Instructions

D103449X012

May 2010

Size 40-70 Actuators

Window Mount

Use these instructions to mount a Fisher®FIELDVUE™

DVC6200 or DVC2000 digital valve controller on Fisher

1051 and 1052 Size 40-70 actuators.

Avoid personal injury or property damage from

sudden release of process pressure or bursting of

parts. Before performing any installation

operations:

Always wear protective clothing, gloves, and

eyewear.

Do not remove the actuator from the valve while

the valve is still pressurized.

Disconnect any operating lines providing air

pressure, electric power, or a control signal to

the actuator. Be sure the actuator cannot

suddenly open or close the control valve.

Use bypass valves or completely shut off the

process to isolate the control valve from

process pressure. Relieve process pressure

from both sides of the control valve.

Vent the pneumatic actuator loading pressure

and relieve any actuator spring

precompression.

Use lock-out procedures to be sure that the

above measures stay in effect while you work

on the equipment.

Check with your process or safety engineer for

any additional measures that must be taken to

protect against process media.

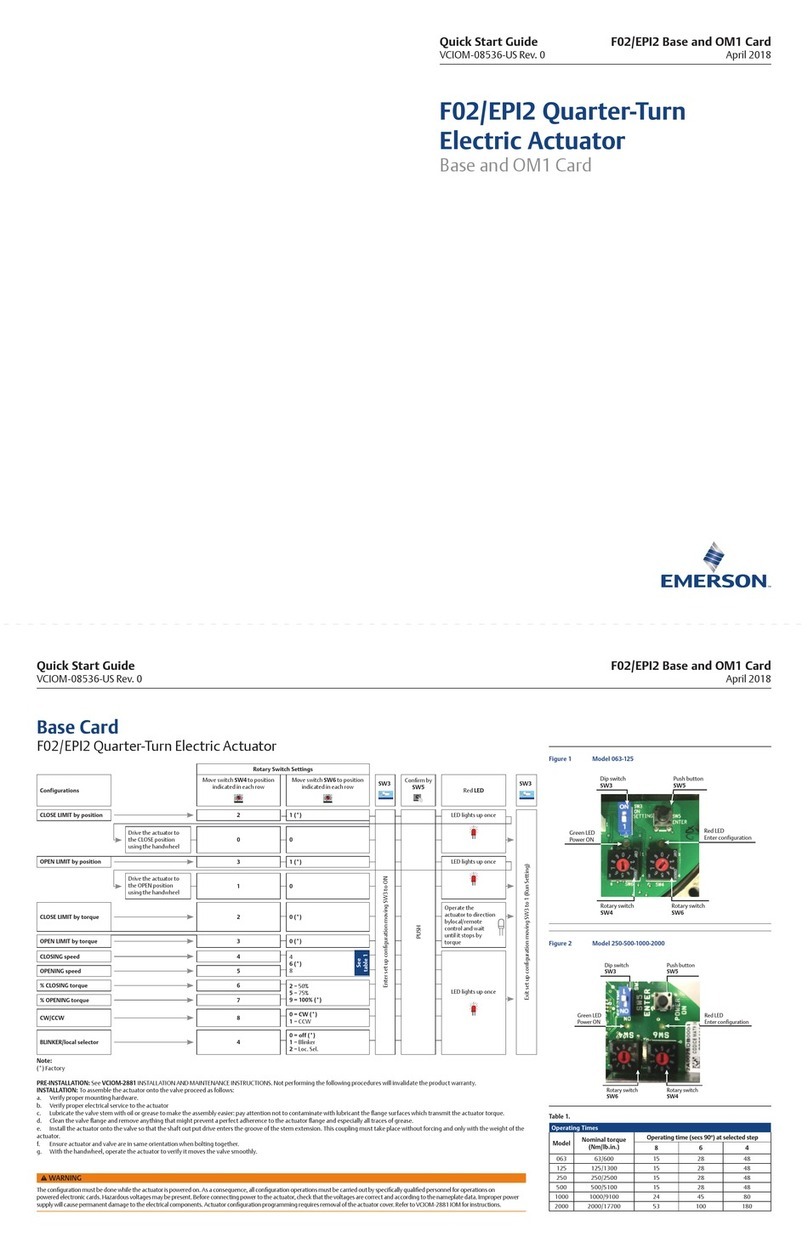

Refer to figure 2 and the parts list for mounting parts

identification. Refer to the DVC6200 or DVC2000 digital

valve controller instruction manual for digital valve

controller parts identification. Refer to the appropriate

actuator instruction manual for actuator installation,

operation, maintenance, and parts identification.

Figure 1 shows the arced feedback assembly.

1. Isolate the control valve from the process line

pressure and release pressure from both sides of the

valve body. Shut off all pressure lines to the actuator,

releasing all pressure from actuator.

Use lock-out procedures to be sure that the above

measures stay in effect while you work on the

equipment.

2. Remove the cover plate screws and cover plate from

the actuator, if present.

3. Install the cam (key 1) on to the lever of actuator using

hex head mach screws (key 2). It will be necessary for

use of the arced feedback mechanism. Consult the

appropriate actuator instruction manual for proper

actuator disassembly and reassembly. Ensure that the

cam is oriented as shown in figure 2.

4. Attach the digital valve controller to the arced

feedback assembly (key 3) and tighten the hex socket

cap screws (key 4).

5. Attach the arced feedback assembly (key 3), along

with the digital valve controller to the actuator yoke using

hex socket cap screws (key 5) as shown in figure 2.

Ensure that the roller of arced feedback assembly is

centered and resting on the cam surface.

6. Make pneumatic and electrical connections to the

digital valve controller as described in the digital valve

controller instruction manual.

7. It may be necessary to fine tune the placement of the

cam so that the digital valve controllers receives the

proper feedback.

8. Setup and calibrate the digital valve controller as

described in instruction manual or quick start guide.

For additional information concerning mounting, setup,

calibration, and maintenance of the DVC6200 or

DVC2000 digital valve controller, refer to the appropriate

instruction manual.

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use or maintenance of any

product. Responsibility for the selection,

use and maintenance of any product

remains with the purchaser and end user.

_____________________________________________________________________________________________________

www.Fisher.com