Progressive Dynamics PD1210SV Operating instructions

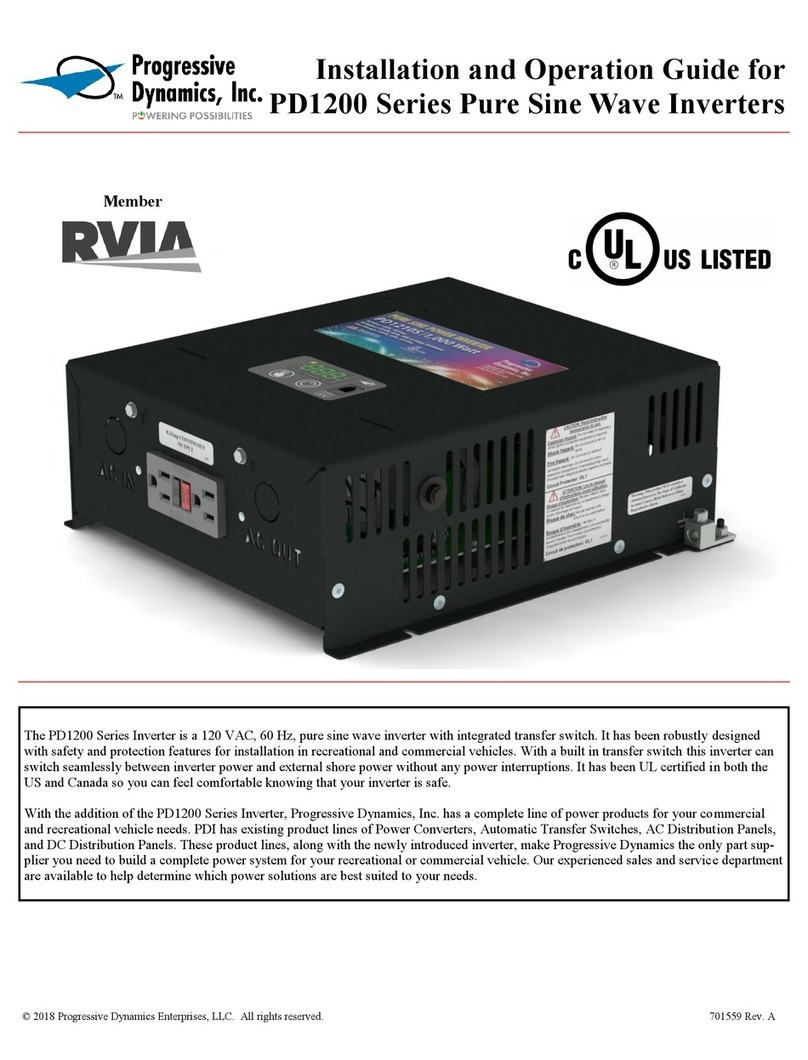

Installation and Operation Guide for

PD1200 Series Pure Sine Wave Inverters

© 2018 Progressive Dynamics Enterprises, LLC. All rights reserved.

Member

The PD1200 Series Inverter is a 120 VAC, 60 Hz, pure sine wave inverter with integrated transfer switch. It has been robustly designed

with safety and protection features for installation in recreational and commercial vehicles. With a built in transfer switch this inverter can

switch seamlessly between inverter power and external shore power without any power interruptions. It has been UL certified in both the

US and Canada so you can feel comfortable knowing that your inverter is safe.

With the addition of the PD1200 Series Inverter, Progressive Dynamics, Inc. has a complete line of power products for your commercial

and recreational vehicle needs. PDI has existing product lines of Power Converters, Automatic Transfer Switches, AC Distribution Panels,

and DC Distribution Panels. These product lines along with the newly introduced inverter make Progressive Dynamics the only part sup-

plier you need to build a complete power system for your recreational or commercial vehicle. Our experienced sales and service department

are available to help determine which power solutions are best suited to your needs.

701559 Rev. C

2

Table of Contents

Introduction ................................................................................................... 3

Key Features .................................................................................................. 5

RV Power System .......................................................................................... 6

Installation Instructions ................................................................................. 8

Display and User Interface ............................................................................ 13

Troubleshooting ............................................................................................. 15

Technical Specifications ................................................................................ 16

LIMITED WARRANTY

I. LIMITED WARRANTY: Progressive Dynamics Warrants its power inverters to be free from defects in material or workmanship under normal use and ser-

vice; and limits the remedies to repair or replacement.

II. DURATION: This warranty shall extend for a period of two years from the original date of purchase, and is valid only within the continental limits of the

United States and Canada.

III. WARRANTY EXCLUSIONS: This warranty does not apply to:

A. Any product which has been repaired or altered in any way by an unauthorized person or service station

B. Damage caused by excessive input voltage, misuse, negligence, or accident; or an external force

C. Any product which has been connected, installed, or adjusted or used other than in accordance with the instructions furnished, or has had the serial number

altered, defaced, or removed

D. Cost of all services performed in removing and reinstalling the power inverter

E. ANY LOST PROFITS, LOST SAVINGS, LOSS OF USE OF ENJOYMENT OR OTHERINCIDENTAL DAMAGES ARISING OUR OF THE USE OF,

OR INABILITY TO USE, THE PRODUCT. THIS INCLUDES DAMAGES TO PROPERTY AND, TO THE EXTENT PERMITTED BY LAW, DAM-

AGES FOR PERSONAL INJURY. THIS WARRANTY IN IN LIEU OF ALL OTHER WARRANTIES, INCLUDING WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSES.

IV. PROOF OF PURCHASE: A warranty claim must be accompanied by proof of the date of purchase.

V. CLAIM PROCEDURE: Upon discovery of a defect, Progressive Dynamics shall be supplied the following information a the address listed below:

A. Name and address of claimant

B. Name, model, and serial number of the product

C. Application in which product was installed. (Includes manufacturer, model, and model year where applicable).

D. Date of purchase

E. Complete description of the claimed defect

Upon determination that a warranty claim exists (a defect in material or workmanship occurring under normal use and service) the inverter shall be shipped postage

prepaid to Progressive Dynamics together with proof of purchase. The product will be repaired or replaced and returned postage prepaid.

Mail Returns to: Progressive Dynamics

507 Industrial Road

Marshall, MI 49068

For Warranty Service: serv[email protected]m

3

Materials

(1) PD1200 Series Inverter

(1) Quick Reference Guide—not shown

(1) Remote Display—not shown (optional)

(1) Remote Display Connection Cable (optional)

NOTE: If any of the items are missing, contact Progressive Dynamics for replacement.

Introduction

Figure 1 Inverter with Optional Remote & GFCI

*Optional Remote

4

Introduction

7

1 DC Input Port (negative): Used to connect to battery (-)

2 Ventilation Input: Ensure ventilation input is not blocked for proper operation

3 DC Input Port (positive): Used to connect to battery (+)

4 AC Input Knockout: Knockout to be removed when connecting transfer switch to external AC power

5 GFCI Output (optional): Optional AC Output selected at time of purchase. Not field removable

6 AC Output Knockout: Knockout to be removed when connecting to hardwired AC Output

7 AC Access Panel: Remove access panel to wire install AC wiring

8 15A Output Circuit Breaker: Protects equipment from excessive power draw when connected to AC Input Power. When

inverter is supplying power, internal circuitry limits output power to specified limits.

9 DC Access Panel: Remove access panel to wire install DC wiring

10 Equipment Ground Lug: Connect case to earth ground to ensure proper, safe operation

11 On-Board Display: Display monitors all relevant parameters of the PD1200 Series Inverter

Descriptions

9

8 10

1 3 4 6 5 2

11

Figure 2 PD1200 Series Inverter (DC End View) Figure 3 PD1200 Series Inverter (AC End View)

Figure 4 PD1200 Series Inverter (Side View)

Figure 5 PD1200 Series Inverter (Isometric View)

5

Integrated Automatic Transfer Switch

Built into the PD1200 Series Inverter is an automatic transfer switch

that engages whenever power is detected at the AC input port. In

recreational vehicles this is often used to switch over to shore or gen-

erator power when it is available, reserving the battery power for

later use. The transfer switch transition times are fast enough that

transitioning from one source to another will not impede operation

for most electrical loads.

Reverse Battery Protection

Reverse battery protection has been added to the inverter to protect

the equipment in the event that the positive and negative terminals of

the battery are incorrectly connected to the inverter. Unlike some

other inverters on the market, there is not a time delay associated

with the reverse battery protection. In the event that the inverter is

reverse wired it will not turn on.

Over-Load Protection

In order to protect the inverter from over-load conditions the power

draw is continually measured and should it exceed the rated output

power the inverter will automatically shutdown and display the error

code corresponding to an over-load error. This is a required feature

in all UL safety certified inverters. For additional protection the

PD1200 Series inverter includes a 15A circuit breaker on the output

to limit power that is passed through from the AC Input.

Easy Installation

When designing the PD1200 Series Inverter special attention was

paid to making it easy to install. The AC connection points are color

co-ordinate push-in terminals. When hard-wiring your new inverter

the installer can pull out the knockouts by hand, insert the Romex

cable, then push each conductor into place. The DC connections are

made directly to lugs instead of using large, expensive ring terminals.

The only tool required is a 5/32” hex key.

Short Circuit Protection

In any power system, a sustained short circuit can cause hazardous

conditions potentially resulting in over-heating and fire. To avoid

these conditions the inverter has been designed with short circuit

protection. It will detect any large current spikes caused by a short

circuit and shutdown immediately to avoid damaging the inverter and

output wiring.

2X Peak Power Rating

When starting inductive loads like compressors (found in common

household refrigerators) there is a large surge in power draw during

the initial startup. To supply this initial start up power the PD1200

Series Inverter has been designed to supply a peak power that is 2X

its rated power.

Under/Over Voltage Protection

To protect both the inverter and the battery bank the PD1200 Series In-

verter has been designed with integral under voltage and over voltage

protection. These voltage limits are designed to operate with a Lead-

Acid battery bank without damaging the batteries. The inverter may also

be used with a 12V lithium ion battery pack (LiFePO4) with a properly

configured BMS. See Specifications on page 16 for voltage limits.

Fully Functional Remote Display (Optional)

When purchasing your inverter an optional addition is the remote

display. The PD1200 Series Inverter has an optional remote display

that is fully functional at up to 25 feet away. This includes turning on

and off the inverter and monitoring battery voltage and power con-

sumption.

Hardwired AC Output/GFCI (Optional)

The PD1200 Series Inverter is capable of being used with a hard-

wired output. In installations designed to use this hard-wired output

there isn’t a need to select the optional Ground Fault Circuit Inter-

rupter. However, in installations that require a standard receptacle the

GFCI can be built into the unit to allow your devices to be plugged

into a standard receptacle. In GFCI installations the hard-wired out-

put is still available for additional loads.

Over Temperature Protection

A required feature for all UL safety certified inverters, over tempera-

ture protection is designed into every PD1200 Series inverter. When

the internal temperature of the inverter gets too high due to poor ven-

tilation or high ambient temperature the inverter will shutdown. The

output will automatically turn back on when the internal temperature

returns to safe operating temperatures.

Thermally-Controlled Variable Speed Fan

Using technology that is found in all Progressive Dynamics Convert-

ers, the PD1200 Series Inverter employs a thermally-controlled vari-

able speed fan. This fan will only turn on when the inverter is operat-

ing at a warmer than normal temperatures. Furthermore, when it does

turn on, the speed of the fan is smoothly controlled to only run as fast

as necessary to keep the inverter within safe operating temperatures.

This is designed to minimize disruptive audible noise

Pure Sine Wave Output

The output of the PD1200 Series inverter is a 120 VAC, 60 Hz, pure

sine wave. Unlike a modified sine wave, a pure sine wave is ideally

suited to drive all types of loads including refrigerators, motors,

power tools, and common household electronics.

Automatic Restart After DC Disconnect

The PD1200 Series Inverter will detect when the battery input con-

nections have been removed. When the DC disconnect switch is re-

engaged the inverter will automatically restart. Similar to a DC dis-

connect switch, this automatic restart also kicks in when the user

replaces the batteries. To avoid an automatic restart, simply turn off

the inverter prior to disconnecting the batteries.

Key Features

Neutral Bonding

In an RV the neutral should be tied to ground at the source of the

power. To safely accomplish this the PD1200 Series inverter ties the

neutral to ground only if the inverter is supplying the power. When

the transfer switch is engaged to pass AC Input power, the ground

connection is passed from AC input to AC output with the assump-

tion that the neutral is properly grounded wherever the power is be-

ing generated (generator or campground electrical post).

6

The PD1200 Series Inverter in a 30A RV Power System

MAIN NEUTRAL SUB NEUTRAL

HOT NEU HOT NEU HOT NEU

GENERATOR SHORE PANEL

12V BATTERY

BANK

PD9200 SERIES

CONVERTER

PD60 SERIES

DC DISTRIBUTION PANEL

MAIN SUB

PD51 SERIES

TRANSFER SWITCH

PD55 SERIES

AC DISTRIBUTION PANEL

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

GROUND

GROUND

TO DC LOADS DC GROUND

GROUND

AC OUT

PD1200 SERIES

INVERTER

AC IN

DC+ DC-

TO AC LOADS (HOT)

(SHORE/GENERATOR ONLY)

30A 15A

TO AC LOADS (HOT)

(SHORE/GENERATOR/INVERTER)

15A 15A

GENERATOR

SHORE CONNECTION

7

The PD1200 Series Inverter in a 50A RV Power System

PD52 SERIES

TRANSFER SWITCH

MAIN NEUTRAL SUB NEUTRAL

12V

Battery Bank

PD60 SERIES

DC DISTRIBUTION PANEL

MAIN SUB

PD55B006

AC DISTRIBUTION PANEL

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

GROUND

GROUND

TO DC LOADS DC GROUND

GROUND

AC IN AC OUT

PD1200 SERIES

INVERTER

DC+ DC-

TO AC LOADS (HOT)

(SHORE/GENERATOR ONLY)

TO AC LOADS (HOT)

(SHORE/GENERATOR/INVERTER)

15A 15A

50A

15A

GENERATOR

PD9200

SERIES

CONVERTER

SHORE

CONNECTION

8

Installation Location Requirements

The PD1200 series inverter should only be installed in locations that meet the following requirements:

Dry: The inverter should be installed in a compartment separated from the outside environment to avoid exposure to rain, drips, and

splashes that may damage the unit. The compartment should not be contain water or other fluids.

Cool: Air temperature of the inverter compartment should be between 4 degrees Fahrenheit and 104 degrees Fahrenheit (-20 degrees

Celsius and 40 degrees Celsius). Higher temperatures will result in a reduction of performance.

Ventilated: Do not block the opening for the fan. Do not allow the ventilation openings on the sides of the unit to be come ob-

structed. The inverter compartment should not be used for storage of any kind to maximize ventilation space. A minimum compartment

size of 3 cubic feet is recommended to avoid a reduction of performance.

Separated from Batteries and Flammable Materials: The PD1200 Series Inverter is not ignition protected. Do not mount

the inverter in the liquid propane gas compartment, battery compartment, or any other compartment that may contain sparks or flamma-

ble materials.

Adjacent to the Battery Compartment: It is required that the battery compartment is separate from the inverter compartment,

but the compartments should be adjacent to one another. Do not place the battery compartment directly above the inverter compartment

to avoid the potential for battery acid drips. In order to reduce cable losses and maximize system performance the DC input wires

should be kept as short as possible. See Figure 15 for recommended DC input wire sizes and lengths.

Orientated Properly: It is recommended that the PD1200 series inverter is mounted horizontally (with the display facing up). The

PD1200 series inverter may also be mounted vertically (with the AC access panel facing up). In vertical installation care should be

taken to avoid debris from falling into the inverter. For vertical installations it is recommended that a debris shield is installed 3 inches

above the DC Access panel to block debris from falling into the inverter while allowing adequate air flow.

Choosing a Location For Your Inverter

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

Inverter should only be installed by an electrician or a certified RV

technician.

Inverter is NOT ignition protected. Do not mount in the LP gas or bat-

tery compartments

Inverter should be mounted in a dry, well ventilated space with ade-

quate air flow

Failure to follow these instructions may result in serious injury or

death. Failure to follow these instructions may also damage the unit

and/or equipment.

9

Figure 6 Vertical Mounting Configuration

Mounting Instructions

Mounting Instructions

1. Remove the PD1200 series inverter from its packaging, verify that all components are present, and record the inverter serial number in

the quick reference guide contained within.

2. Select an appropriate mounting location and orientation (See Page 8 for additional details regarding acceptable installation practices).

3. Use the inverter as a drill guide by placing it flush against the mounting surface and marking the appropriate hole locations in the

mounting surface (see Figure 4). Horizontal mounting of the PD1200 series inverter is recommended (see Figure 3), although it can be

mounted in a vertical position that provides unobstructed ventilation to the fan and vent holes.

4. If mounting vertically, mount the PD1200 series inverter so that the DC wiring compartment is facing up (see Figure 6). This will en-

sure that the display will be oriented correctly. It is best to ensure that PD1200 series inverter is placed in an area that keep dust & de-

bris from entering the fan area. Debris may cause unexpected performance issues in your inverter.

5. Pilot-drill the mounting holes in the marked locations

6. Secure the PD1200 Series Inverter firmly to the mounting surface using standard fasteners

DC Access Panel

Figure 7 Horizontal Mounting Configuration Figure 8 Inverter Mounting Hole Pattern

Debris Shield (recommended)

WARNING: FIRE, SHOCK, AND ENERGY HAZARD

Inverter should only be installed by an electrician or a certified RV

technician.

Inverter is NOT ignition protected. Do not mount in the LP gas or bat-

tery compartments

Inverter should be mounted in a dry, well ventilated space with ade-

quate air flow

Failure to follow these instructions may result in serious injury or

death. Failure to follow these instructions may also damage the unit

and/or equipment.

10

Figure 10 AC Wiring Requirements

AC Connection Instructions

Figure 9 AC Connections Side View

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

Make sure wiring is disconnected from all electrical sources before

handling. All wiring must be done in accordance with local and national

electrical wiring codes.

DO NOT disassemble the inverter. It does not contain any user service-

able parts. Attempting to service the unit yourself could result in an

electrical shock or burn.

Failure to follow these instructions may result in serious injury or

death.

Hardwired AC Connection Instructions

NOTE: Hardwired AC connection is not necessary. To avoid un-necessary debris, only remove knockouts if your installation requires use

of the AC hardwired connections.

1. Ensure all power sources are disconnected from the inverter.

2. Remove the AC Wiring Cover by removing 2 AC access Panel Screws.

3. Verify that all power sources have been disconnected from the inverter by locating the green LED next to the both AC terminals. If

the LED is lit STOP, re-secure the AC access panel, then locate and remove the active power source before proceeding.

4. Remove AC Input knockouts and AC Output knockouts by pressing firmly on the AC knockout. Bend the tab back and forth several

times to weaken the metal attachment. Knockout should snap off easily.

5. Install 3/8” trade strain relief in AC Input and AC Output ports. See page 12 for suggested strain relief types.

6. Strip AC wiring. See Figure 6 for recommended wire size and strip lengths.

7. Connect AC Output terminal block (Ground, Neutral, and Line) to load wiring with properly sized wires. Terminal blocks are color

coordinated to minimize errors in installation (Black = Hot, Green = Ground, White = Neutral).

8. Connect AC Input terminal block (Ground, Neutral, and Line) to AC input wiring with properly sized wires. NOTE: Verify AC input

wiring is not connected to AC source during installation. Terminal blocks are color coordinated to minimize errors in installation

(Black = Hot, Green = Ground, White = Neutral).

2. Tighten strain relief (if applicable).

3. Re-install the AC Wiring Cover and secure 2 AC access panel

screws.

MINIMUM RECOMMENDED AC WIRE SIZE STRIP LENGTH

#14 AWG Solid Wire

Stranded wire may be used with a corresponding ferrule

Strip 0.6” (15 mm) insulation from

each cable prior to installation. Do

not leave excess copper exposed.

NOTICE: EQUIPMENT DAMAGE

Do not connect any AC source (such as generator or utility power) to

the AC output wiring of the inverter. Connecting an AC source to the

AC Output of the inverter will result in hazardous conditions.

Any directly wired AC Input and AC Output wiring must be protected

with properly sized circuit protection (fuses or circuit breakers)

Failure to follow these instructions may damage the unit and/or

equipment.

AC Input AC Wiring Cover AC Output GFCI Output (Optional)

Recommended GFCI for use with Inverter:

ZHANGJIAGANG CITY BAREP TECHNOLOGY CO., LTD

Model: YGB-094

11

Types of AC Strain Reliefs

Push-In Style

The PDI inverter includes knockouts for use with a standard 3/8” trade size strain relief. Use of a strain relief is required when hard wiring

your inverter. Neglecting to use a strain relief may cause undue stress and fatigue to the wiring connections on your unit. PDI lists examples

of some commonly utilized types of strain relief. Strain reliefs are not provided with purchase of the inverter, and must be provided by in-

staller at the time of installation.

Halex #27510 or equivalent

3/8” trade size push–in connector-

Material: Plastic

Installation Instructions

1. Insert strain relief into 3/8” trade size opening

2. Push wire into slotted opening the desired distance

3. Push stripped wires into terminals blocks

4. Install wiring into terminal blocks

Metal Clamp Style

Halex #20570 or equivalent

3/8” trade size clamp combination connector

Material: Zinc plated metal

Installation Instructions

1. Insert strain relief into 3/8” trade size opening

2. Slide wire through central opening

3. Push stripped wires into terminals blocks

4. Tighten the strain relief using screws on the side

The type of 3/8” trade size strain relief used is ultimately at the discretion of the installer. PDI can only recommend

types of strain relief for end use, and is not responsible for any misuse or absence of strain relief at installation.

Plastic Clamp Style

Halex #27515 or equivalent

3/8” trade size clamp combination connector

Material: Plastic

Installation Instructions

1. Insert strain relief into 3/8” trade size opening

2. Slide wire through central opening

3. Push stripped wires into terminals blocks

4. Tighten the strain relief by sliding retention clip into the slot

Figure 11 Recommend Strain Relief

12

DC Connection Instructions

MINIMUM RECOMMENDED DC WIRE SIZE STRIP LENGTH TORQUE DATA

Wire Length Wire Size

Strip 3/4” (19 mm) insulation from each

cable prior to installation. Do not leave

excess copper exposed.

Tighten all lugs to a torque of

100 in-lbs (11.3 N-m).

Do not over tighten.

0-5 ft. #2 AWG

5-10 ft. #1 AWG

10-15 ft. #1/0 AWG

DC Connection Instructions

1. Ensure all power sources are disconnected from the inverter.

2. Remove the DC Wiring Cover by removing 2 DC access panel screws.

3. Connect DC terminals (positive and negative) to battery with properly sized wires using a 5/32” hex key

4. When connecting DC wires a small spark may occur. This is normal

charging of the inverter’s internal capacitors.

5. Re-secure the DC Wiring Cover and re-secure 2 DC access panel

screws.

6. Connect equipment ground stud to a grounding point -typically the

vehicle’s chassis - using recommended wire.

NOTE: To ensure optimum performance all input wires should be as short as possible. Failure to meet minimum recommended wire size

will result in reduced performance

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

Make sure wiring is disconnected from all electrical sources before

handling. All wiring must be done in accordance with local and national

electrical wiring codes.

Failure to follow these instructions may result in serious injury or

death.

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

DC Input wiring must be protected with properly sized circuit protec-

tion (fuses or circuit breakers)

Never operate the inverter without properly connecting the equipment

ground.

Tighten the nuts on terminals properly. Loose connections cause exces-

sive voltage drop and may cause overheated wires and melted insula-

tion. DO NOT under tighten the screw on the terminal lugs. This will

cause the wires to lose connection.

Failure to follow these instructions may result in serious injury or

death. Failure to follow these instructions may also damage the

unit and/or equipment.

Figure 13 DC Connections Side View Figure 14 DC Connections (Wiring Cover Removed)

Figure 12 Connecting the Grounding Cable

Negative DC Lug Positive DC Lug Equipment Ground Lug DC Wiring Cover

Equipment Ground Cable

(not included)

3/4”

DC cable (Negative)

DC cable (Positive)

3/4”

Figure 15 DC Wiring Requirements

3/4”

Torque ground lug

to 30-50 In-lbs

13

Figure 19 Display Indicators

Display Interface

Select Button

Figure 17 Display Panel

Display Power Button Remote Display Port

Error Code Condition Description

E-1

Low battery volt-

age detected

Input voltage has dropped beneath 10.5V for

several seconds. The PD1200 Series inverter

will automatically restart when the input

voltage reaches 12.0V.

E-2

High battery volt-

age shutdown

Input voltage has surpassed 15.5V. The

PD1200 Series inverter will automatically

restart when the input voltage falls below

15.0V.

E-3

AC output over-

load shutdown

Output power has surpassed the continuous

power limit or the peak power limit. The

PD1200 Series inverter will not automati-

cally restart. A manual restart is necessary

E-4

Over-temperature

shutdown

Internal temperature of the inverter has ex-

ceeded its safe operating limit. The PD1200

Series inverter will automatically restart

when internal temperatures return to safe

operating conditions.

ERROR CODES

E-5

Internal Error An internal error has been detected. The

PD1200 Series inverter will not automati-

cally restart. A manual restart is necessary

Display Features

Power Button: Press to turn on; hold to turn off

Select Button: Cycles between display states:

Input Voltage, Output Voltage, Output

Power, Sleep, Error Code (if applicable)

Power Indicator: Lights up green when the inverter is on

Fault Indicator: Flashes red when an error has occurred

Shore Indicator: Lights up yellow when AC input is detected

Low Bat Warning Indicator: Lights up red when the battery

is nearing the end of its charge

Sleep: Lights automatically dim after 30 seconds

Remote port for externally mounted display

Figure 16 Inverter Display Location

Display Panel

Figure 14 Error Code Descriptions

Figure 18 Remote Display (optional)

Rear Remote Connection

NOTE: For all error codes consult page 16 in the Installation and Opera-

tion Guide for troubleshooting methods

NOTE: Remote display operates exactly the same as the dis-

play mounted to the inverter

Power Indicator Shore Power Indicator Low Bat Warning Indicator Fault Indicator

14

Display Operation

Figure 20 Display States

DC Input Voltage

Battery indicator is illuminated

Volts indicator is illuminated

DC Input Voltage measurement is always available

DC Input Voltage measurement is the default display state on start up

AC Output Voltage

AC indicator is illuminated

Volts indicator is illuminated

AC Output Voltage measurement is available only when the inverter is

supplying power (not when the inverter is in shore power mode)

AC Output Power

AC indicator is illuminated

kW indicator is illuminated

AC Output Power measurement is available only when the inverter is sup-

plying power (not when the inverter is in shore power mode)

Sleep

Only indicators that may be illuminated are: Power, Shore, Fault, and Low

Battery

Indicators in sleep mode will be noticeably dimmer than in any other state

The PD1200 Series inverter display automatically enters sleep mode when

neither of the control buttons have been pressed for 30 seconds

The PD1200 Series Inverter automatically exits sleep mode when any error

occurs or shore power is detected

To manually exit sleep mode press either button. Pressing the power button

will not turn off the inverter; it must be held for 5 seconds to power down.

Error

Error code display is only available if the PD1200 Series inverter is cur-

rently in an error state.

See page 14 for error code descriptions

See page 16 for troubleshooting guide if error code persists

NOTE: To cycle through the display states simply press the select button. Display states cycle in order as listed on this page. The display

will skip un-available display states (see display state descriptions above for additional details).

15

For further assistance contact :

PDI Service Department

(269) 781-4242

Troubleshooting

Troubleshooting Guide

Symptom Corrective Actions

PD1200 Series In-

verter has a flashing

fault light

The inverter has detected a fault condition (see Figure 20). 30 Seconds after the fault condition is detected the display enters

sleep mode.

Press the select button to view the error code. Press the select button again to view the battery voltage. Proceed to the

correct troubleshooting action below.

E-1 is displayed

The input voltage fell below 10.5 VDC. Inverter will automatically restart when DC Input voltage is increased to 12.0VDC

Re-charge batteries to at least 12.0VDC.

Ensure all DC input connections are tightened

Inverter is turning on

and off. E-1 is dis-

played when it is off

Likely, the batteries are nearly fully discharged. When a heavy load is being drawn from a battery the battery voltage will droop

causing an under voltage error. Then with the inverter turned off the battery voltage will slowly drift back up because there is

no load on the batteries. If the battery voltage drifts back up to 12.0VDC the inverter will turn back on. This cycle may repeat

several times. This behavior will be seen more often with batteries nearing the end of life.

Re-charge batteries to at least 12.0VDC.

Ensure all DC input connections are tightened

Make sure DC input wire size and length comply with Figure 15

Replace batteries

Batteries are fully

charged. Inverter dis-

plays E-1 immediately

after it is turned on

The batteries may be fully charged, but if the battery voltage is not properly connected to the DC Input terminals of the inverter

a low battery fault may be falsely triggered.

Ensure all DC input connections are tightened

Make sure DC input wire size and length comply with Figure 15

E-2 is displayed

The input voltage has exceeded 15.5VDC. Inverter will automatically restart when DC Input voltage is decreased to 15.0VDC

Turn off the inverter by holding down the power button. Locate DC source and verify it is properly connected for 12VDC

operation

E-3 is displayed

An over-load condition has been detected. This can be excessive power or a peak power that exceed 2X rated power. A manual

restart is required after the over-load issue has been resolved.

Check output wiring for a short circuit.

Determine what loads are connected to the output of the inverter. Remove un-necessary loads until power is below maxi-

mum rated power.

Determine peak power draw from inductive loads (refrigerators and other motor driven loads). If total peak power draw

exceeds 2X rated power loads remove loads until peak power is below 2X rated power

E-4 is displayed

An over temperature condition has occurred. The inverter will automatically restart when the internal temperature falls to safe

operating conditions.

Ensure that debris hasn’t fallen into the fan opening blocking its operation

Remove items surrounding the inverter to ensure adequate air flow.

Move inverter to a well ventilated space.

Lower ambient air temperature to room temperature.

Inverter is turning on

and off. E-4 is dis-

played when it is off

An over temperature condition has occurred. The inverter will automatically restart when the internal temperature falls to safe

operating conditions.

Ensure that debris hasn’t fallen into the fan opening blocking its operation

Remove items surrounding the inverter to ensure adequate air flow.

Move inverter to a well ventilated space.

Lower ambient air temperature to room temperature.

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

DO NOT disassemble the inverter. It does not contain any user service-

able parts. Attempting to service the unit yourself could result in an

electrical shock or burn.

Failure to follow these instructions may result in serious injury or

death.

16

Troubleshooting

Troubleshooting Guide

Symptom Corrective Actions

E-5 is displayed

During startup the inverter draws a small amount of current to charge the input capacitors. If that current exceeds a normal

range the inverter shuts down and reports an internal error. This is can be indicative of bad input wiring or an internal failure.

Ensure all DC input connections are tightened

Make sure DC input wire size and length comply with Figure 15

Inverter is off. Noth-

ing happens with

power button is

pressed

Likely, DC Input power is not being properly applied to the DC input terminals.

Ensure all DC input connections are tightened

Ensure that all any external DC disconnect switches are in the on position

Ensure that the DC input wires are connected to positive and negative correctly (not reversed)

If using the remote display panel, make sure that it is connected to the inverter using the provided 25’ cable.

Inverter turned off for

seemingly no reason

Something has interrupted the communication between the display and the inverter.

Ensure that the equipment ground wire is properly secured to the equipment ground lug

Inverter is making a

buzzing sound

A buzzing sound may be produced during large surges in output power. This will most commonly be observed on some refrig-

erators when the compressor is starting up. This buzzing sound is normal and should not last for more than 2 seconds.

SPECIFICATIONS

Physical Transfer Switch

Dimensions L = 11.6” (294.6 mm)

W = 10.6” (269.2 mm)

H = 4.0” (101 mm)

Transfer Voltage 100 VAC

Transfer Time < 50 msec

Net Weight 7 lbs (3.2 kg) Pass Through Ampacity 15 AAC

AC Output DC Input

Output Voltage 120 VAC Under-Voltage Shutdown 10.5 VDC

Output Power (Continuous) 1000 W Under-Voltage Restart 12.0 VDC

Output Power (Peak) 2000 W Over-Voltage Shutdown 15.5 VDC

Frequency 60 Hz Over-Voltage Restart 15.0 VDC

Waveform Pure Sine Wave Nominal Voltage 12.0 VDC

Peak Efficiency 90% Nominal Current @ max load 100 ADC

Specifications

For Further Assistance Contact:

PDI Service Department:

WARNING: FIRE, SHOCK, OR ENERGY HAZARD

DO NOT disassemble the inverter. It does not contain any user service-

able parts. Attempting to service the unit yourself could result in an

electrical shock or burn.

Failure to follow these instructions may result in serious injury or

death.

This manual suits for next models

1

Table of contents

Other Progressive Dynamics Inverter manuals

Progressive Dynamics

Progressive Dynamics PD1600 Series Operating instructions

Progressive Dynamics

Progressive Dynamics PD1618 Series Operating instructions

Progressive Dynamics

Progressive Dynamics PD1610 User manual

Progressive Dynamics

Progressive Dynamics PD1200 Series Operating instructions

Progressive Dynamics

Progressive Dynamics PD1200 Series User manual

Progressive Dynamics

Progressive Dynamics PD1600 Series User manual