Page – 4/155 AF6ZP0CA – COMBIAC0 & ACE0 2uC – User Manual

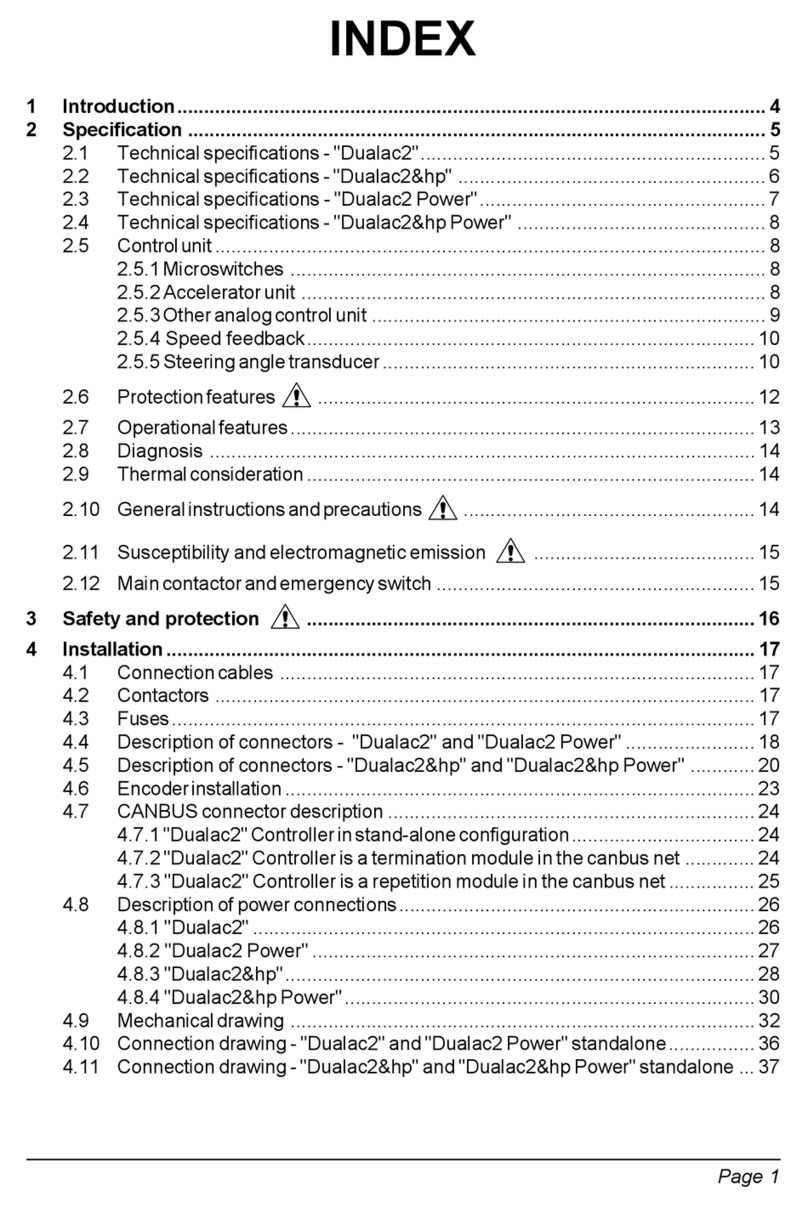

5.2Installation of the hardware ...................................................................................... 35

5.2.1Positioning and cooling of the controller.....................................................35

5.2.2Wirings: CAN bus connections and possible interferences ........................ 36

5.2.3Wirings: I/O connections............................................................................. 38

5.2.4Connection of an encoder .......................................................................... 39

5.2.5Connection of a sin/cos sensor ..................................................................40

5.2.6Connection of Hall sensors......................................................................... 40

5.2.7Connection of main contactor and key switch ............................................41

5.2.8Insulation of the truck frame .......................................................................41

5.3EMC .........................................................................................................................42

5.4Various suggestions .................................................................................................43

6FEATURES.........................................................................................................................44

6.1Operational features................................................................................................. 44

6.2Dual traction motor ................................................................................................... 45

6.3Pump motor.............................................................................................................. 45

6.4Torque mode ............................................................................................................45

6.5Speed mode ............................................................................................................. 45

6.6Protection and safety features.................................................................................. 45

6.6.1Protection features .....................................................................................45

6.6.2Safety features ...........................................................................................46

7START-UP HINTS...............................................................................................................47

7.1Check prior to initial power up .................................................................................. 47

7.2Configuring motor controller for the application........................................................ 47

7.3Set-up procedure for AC traction inverter.................................................................48

7.3.1Sin/cos-sensor case ...................................................................................48

7.4Set-up procedure for AC pump inverter....................................................................49

8PROGRAMMING & ADJUSTEMENTS ..............................................................................51

8.1Settings overview .....................................................................................................52

8.2Settings description ..................................................................................................53

8.2.1PARAMETER CHANGE............................................................................. 53

8.2.2SET OPTIONS ........................................................................................... 59

8.2.3ADJUSTMENTS ......................................................................................... 67

8.2.4SPECIAL ADJUST. .................................................................................... 72

8.2.5HARDWARE SETTING .............................................................................. 75

8.3TESTER function......................................................................................................77

8.3.1TESTER – Master microcontroller..............................................................77

8.3.2TESTER – Supervisor microcontroller........................................................ 85

9OTHER FUNCTIONS..........................................................................................................87

9.1PROGRAM VACC function ...................................................................................... 87

9.2PROGRAM LIFT / LOWER function......................................................................... 87

9.3PROGRAM STEER function .................................................................................... 88

9.4Acceleration time ...................................................................................................... 88

9.5Braking time ............................................................................................................. 89

9.6Acceleration smoothness ......................................................................................... 91

9.7Steering curve ..........................................................................................................91

9.8Description of the throttle regulation......................................................................... 92

9.9NMC & NEB output ..................................................................................................93

9.10Battery-charge detection ..........................................................................................94

9.11EVP Setup................................................................................................................ 95