Proheat Teleflex X45 Manual

INSTALLATION

AND SERVICE

MODEL X45

CONTENTS

INTRODUCTION...........................................................................i

1. OPERATING YOUR PROHEAT HEATER ..................................1-1

2. TECHNICAL SPECIFICATIONS

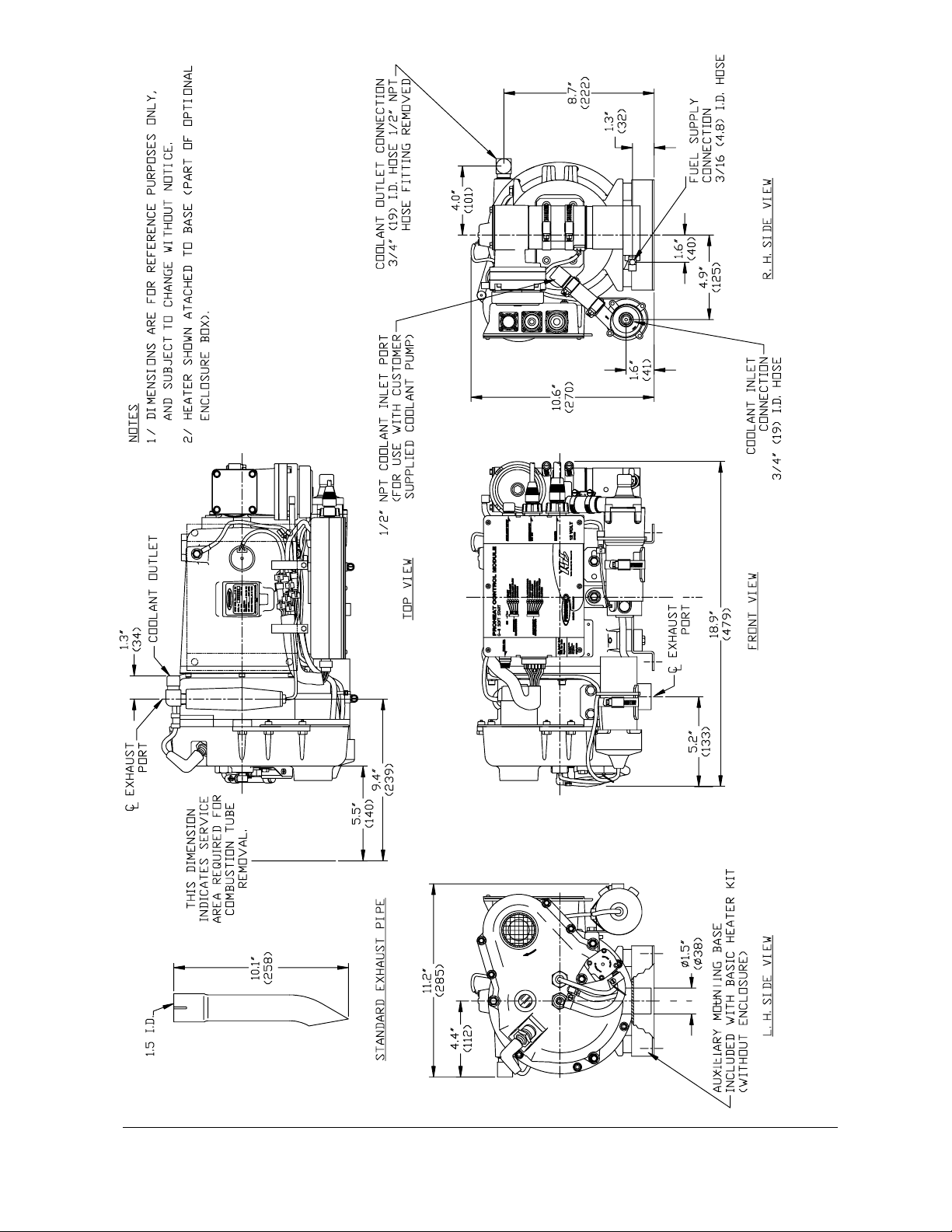

ENCLOSURE DIMENSIONS ..........................................................2-1

HEATER DIMENSIONS .................................................................2-2

3. INSTALLATION

LOCATING THE HEATER...............................................................3-2

MOUNTING THE HEATER .............................................................3-4

EXHAUST PIPE CONNECTION .......................................................3-6

PLUMBING THE SYSTEM .............................................................3-7

General Considerations.........................................................3-7

Option A – Engine Heat or Supplemental Heat ........................3-8

Option B – Engine & Sleeper Heat..........................................3-9

Engine Connection Details...................................................3-11

WIRING & ELECTRICAL CONNECTIONS .......................................3-13

General Considerations.......................................................3-13

Power Connection to Batteries.............................................3-14

Timer Connections..............................................................3-15

On/Off Switch ....................................................................3-16

Sleeper Heater Wiring Details..............................................3-17

Option A – OEM Heater & PROHEAT Thermostat....................3-17

Option B – OEM Heater & Thermostat ..................................3-18

Option C – Auxiliary Sleeper Heater ......................................3-19

Option D – Relay Sleeper Heater..........................................3-20

FUEL SYSTEM ..........................................................................3-21

General Considerations.......................................................3-21

Option A – 1⁄4" OR 1⁄2" NPT Port...........................................3-22

Option B – Existing Blank Fuel Sender Cover Plate ................3-23

Option C – Hole Drilled into Fuel Tank ..................................3-23

Installation.........................................................................3-24

FIRST TIME STARTUP ................................................................3-25

4. PRINCIPLES OF OPERATION

GENERAL DESCRIPTION ..............................................................4-1

NORMAL OPERATING SEQUENCE .................................................4-5

5. TROUBLESHOOTING & REPAIR

“ON” Indicator Light..............................................................5-1

FUNCTION DIAGNOSTICS.............................................................5-2

Start....................................................................................5-2

Flame Out ............................................................................5-3

Coolant Flow ........................................................................5-4

Overheat..............................................................................5-5

Voltage ................................................................................5-6

COMPONENT DIAGNOSTICS.........................................................5-8

Flame Sensor.......................................................................5-8

Temperature Sensor ...........................................................5-10

Fuel Pump..........................................................................5-12

Compressor .......................................................................5-13

Ignition Coil........................................................................5-15

Coolant Pump ....................................................................5-17

Blower ...............................................................................5-19

Sleeper Fan .......................................................................5-21

COMPONENTS..........................................................................5-22

Electrode Gap ....................................................................5-22

Fuse ..................................................................................5-23

Nozzle ...............................................................................5-25

Fuel Regulator ....................................................................5-26

FUEL SYSTEM ..........................................................................5-27

General..............................................................................5-27

OPERATIONAL PROBLEMS .........................................................5-29

Smoking Exhaust................................................................5-29

Low Heat Output.................................................................5-29

Engine Temperature Gauge .................................................5-29

Backfiring...........................................................................5-29

6. MAINTENANCE

Weekly Maintenance.............................................................6-1

Annual Maintenance .............................................................6-1

Clean Heater Enclosure.........................................................6-1

Heat Exchanger ....................................................................6-2

Exhaust System ...................................................................6-2

Electrical System..................................................................6-3

Clean Air intake ....................................................................6-3

Fuel System .........................................................................6-4

Vehicle Batteries ..................................................................6-4

Operation Test .....................................................................6-5

PCM: Pin-out Details .............................................................6-5

Proheat Wiring Diagram.........................................................6-6

7. WARRANTY .............................................................................7-1

8. APPENDICES

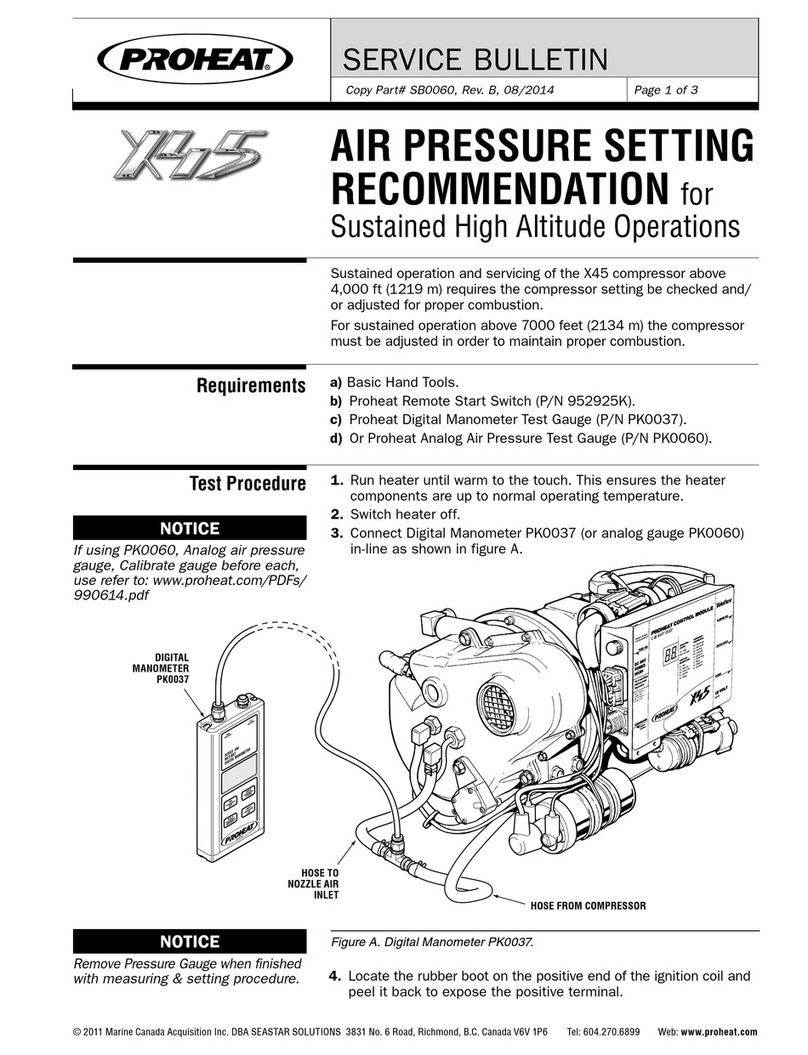

Service Bulletin #951528.........................................8-3

#967329.........................................8-5

SB0003...........................................8-7

i

INTRODUCTION

This manual is provided to assist an authorized

PROHEAT dealer to install and service a PROHEAT

heater. Although trucks have been used in the

examples, applications for PROHEAT are by no means

limited to trucks. PROHEAT heaters are designed to be

used on any diesel equipped vehicle including: trucks,

buses (school, transit and coach), construction

equipment, off road equipment, military equipment

and cargo.

PROHEAT heaters are used in the following applications:

(1) Engine Block Heat – PROHEAT will preheat an

engine block to ensure reliable starting in cold

weather. At the same time it may be used

throughout the year to reduce the wear associated

with cold starts.

(2) Cab or Sleeper Heat (engine off) – PROHEAT will

supply heat to the cab or sleeper. Drivers can

sleep in comfort not only in the cold of winter

but also in the spring and fall when the weather

is miserable. Substantial savings through reduced

fuel consumption and engine wear can be

obtained by not idling the engine.

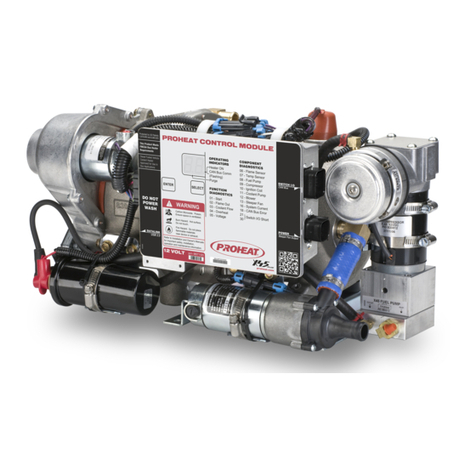

PROHEAT Model X45

(3) Supplemental Heat (engine running) – as the

efficiency of modern diesel engines are improved

there is no longer adequate reject heat available

to heat the vehicle’s interior. This is particularly

true for buses. PROHEAT can be used while

the vehicle is operating to provide supplemental

heat for the interior.

(4) Cargo Heat – PROHEAT can be used to provide

heat to protect valuable cargo such as produce

or beverages from damage due to freezing.

(5) Marine – Marine applications typically involve

the engineering and installation of a complete

hot-water heating system of which PROHEAT

is only one component. Teleflex recommends

that only an expert in marine hot-water heating

systems install a PROHEAT on a boat.

It is the installer’s responsibility to ensure

that the installation complies with all applicable

Coast Guard regulations.

OPERATING YOUR PROHEAT HEATER 1-1

OPERATING YOUR

PROHEAT HEATER

Engine Heat Only

1. Switch the ON/OFF switch located in the vehicle dash to “ON.”

The switch will light and the heater will fire. It will continue to fire

until the coolant reaches 185˚F (85˚C) at the heater outlet and then

cycle “OFF.”

When the coolant temperature falls below 150˚F (65˚C) at the heater

outlet, it will refire and repeat the cycle.

It will continue to cycle until:

a) the heater is switched “OFF,”

b) the heater runs out of fuel,

c) the vehicle battery voltage drops below 10.0 Volts, or

d) an error occurs and the switch light flashes

(See Troubleshooting & Repair, Section 5)

NOTE: The PROHEAT may be operated if the engine is running

or not running.

2. When engine preheat is no longer required,

switch the PROHEAT heater “OFF.”

Engine and Sleeper Heat

1. Switch the ON/OFF switch located in the vehicle dash to “ON.”

The switch will light and the heater will fire. It will continue to fire

until the coolant reaches 185˚F (85˚C) at the heater outlet and then

cycle “OFF.”

When the coolant temperature falls below 150˚F (65˚C) at the

heater outlet, it will refire and repeat the cycle.

It will continue to cycle until:

a) the heater is switched “OFF,”

b) the heater runs out of fuel,

c) the vehicle battery voltage drops below 10.0 Volts, or

d) an error occurs and the switch light flashes

(See Troubleshooting & Repair, Section 5)

NOTE: The PROHEAT may be operated if the engine is running

or not running.

2. For sleeper heat – set the thermostat in the sleeper to the desired

temperature. If the set temperature is higher than the temperature

in the sleeper the fan will cycle “ON.” When the air reaches the set

temperature the fan will cycle “OFF.” The fan will cycle “ON” and “OFF”

to maintain the set temperature.

3. When engine and/or sleeper preheat is no longer required,

switch the PROHEAT heater “OFF.”

1.0

NOTE:

Regular use of your PROHEAT

throughout the year will improve

its reliability. Weekly operation is

recommended.

NOTE:

The PROHEAT heater can be

operated by either using a toggle

switch or a 7 day timer.

Refer to Page 3-13 for WIRING &

ELECTRICAL CONNECTIONS.

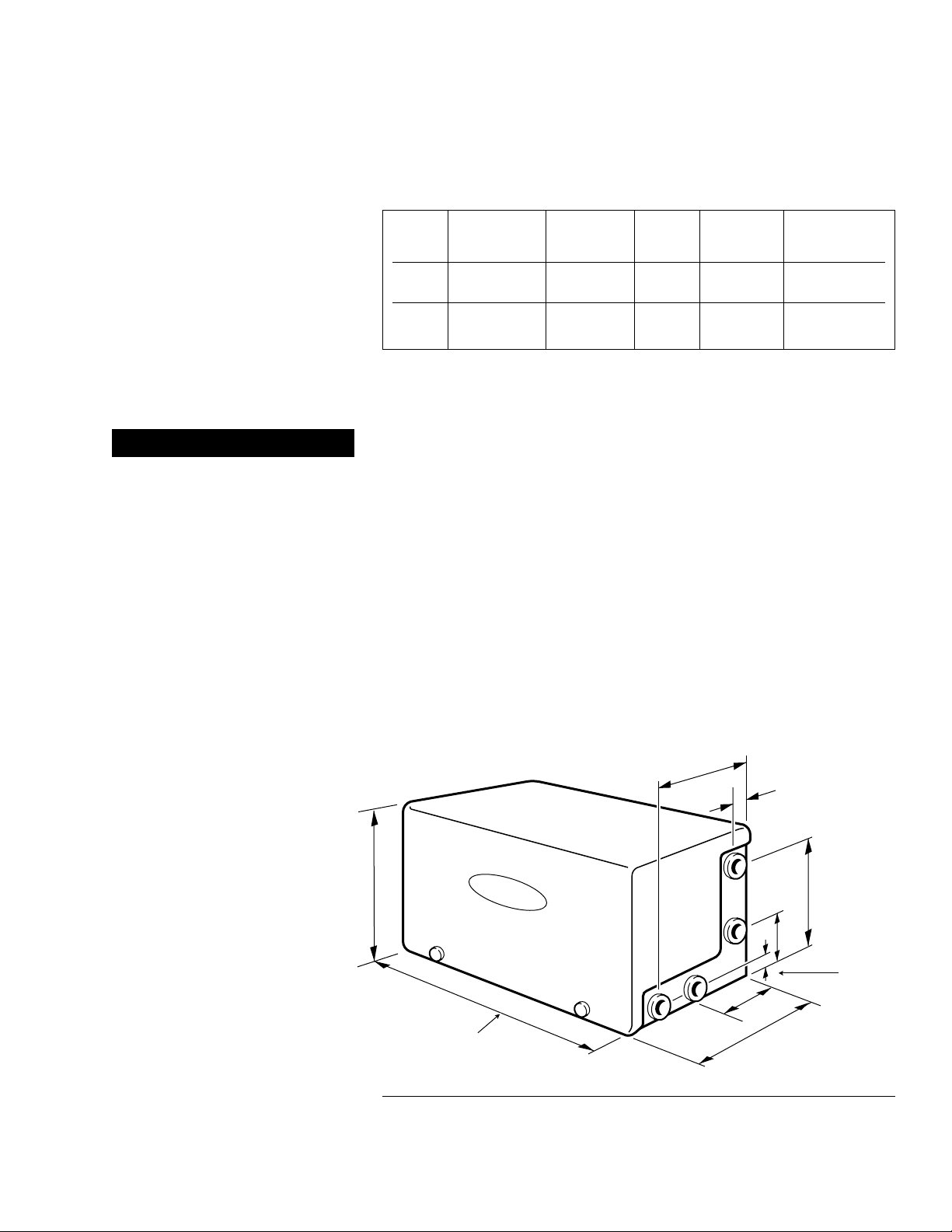

TECHNICAL SPECIFICATIONS

Model Heat Rating Volts Current Fuel Rate Coolant Flow

BTU/hr. (kw) Nominal Amps Gal/hr (l/hr) Gal/min (l/min.)

(range)

X45-12 45,000 12 7.5 .32 (1.2) 8.0 (30)

(13.0) (10.0 – 15)

X45-24 45,000 24 3.75 .32 (1.2) 8.0 (30)

(13.0) (20 – 30)

2-1

TECHNICAL

SPECIFICATIONS

Ignition Type: .................................Electronic spark ignition

Fuel Types:.....................................Diesel #1, #2, Kerosene

Coolant Temperature: .....................150˚ to 185˚F (65˚ to 85˚C) @ heater

Enclosure Dimensions: X45...........12 1⁄2 W x 11 H x 20 1⁄2 L inches

(318 x 280 x 521 mm)

Weight, Heater only: X45...........40 lbs. (18 kg)

Weight, with Enclosure: X45...........55 lbs. (25 kg)

Operating Temperature Range:........-40˚ to 122˚F (-40˚ to 50˚C)

Heat Exchanger Capacity:...............1 quart U.S. (0.97 litre)

WARNING

DO NOT use gasoline

2.0

Figure 2-1 Enclosure Dimensions

10 1/8"

(241 mm)

1 1/4"

(31 mm)

8 1/2"

(216 mm)

3 7/8"

(92 mm)

1 7/16"

(36 mm)

7 5/16"

(186 mm) 12 1/2" (318 mm)

20 1/2" (521 mm)

11"

(280 mm)

Figure 2-2 Heater Dimensions X45

PROHEAT INSTALLATION & SERVICE

2-2

INSTALLATION 3-1

INSTALLATION

There are seven major steps that must be completed to successfully

install the PROHEAT heater.

1. LOCATING THE HEATER ......................................................3-2 to 3-3

2. MOUNTING THE HEATER.....................................................3-4 to 3-5

3. EXHAUST PIPE CONNECTION ........................................................3-6

4. PLUMBING THE SYSTEM.....................................................3-7 to 3-9

5. WIRING & ELECTRICAL CONNECTIONS.............................3-13 to 3-20

6. FUEL SYSTEM................................................................3-21 to 3-24

7. FIRST TIME STARTUP......................................................3-25 to 3-26

NOTE: The installation details described in this manual may not cover

all of the application possibilities. In these cases this manual

should be used as a guideline only. If additional installation

information is required please contact your PROHEAT Dealer

regarding your specific application.

Prior to the installation of your PROHEAT, consult your engine owner’s

manual or engine manufacturer for any restrictions or changes that may

apply to plumbing into the engine coolant system.

3.0

Figure 3-3 Allow minimum 6" clearance

for hose connections.

PROHEAT INSTALLATION & SERVICE

3-2

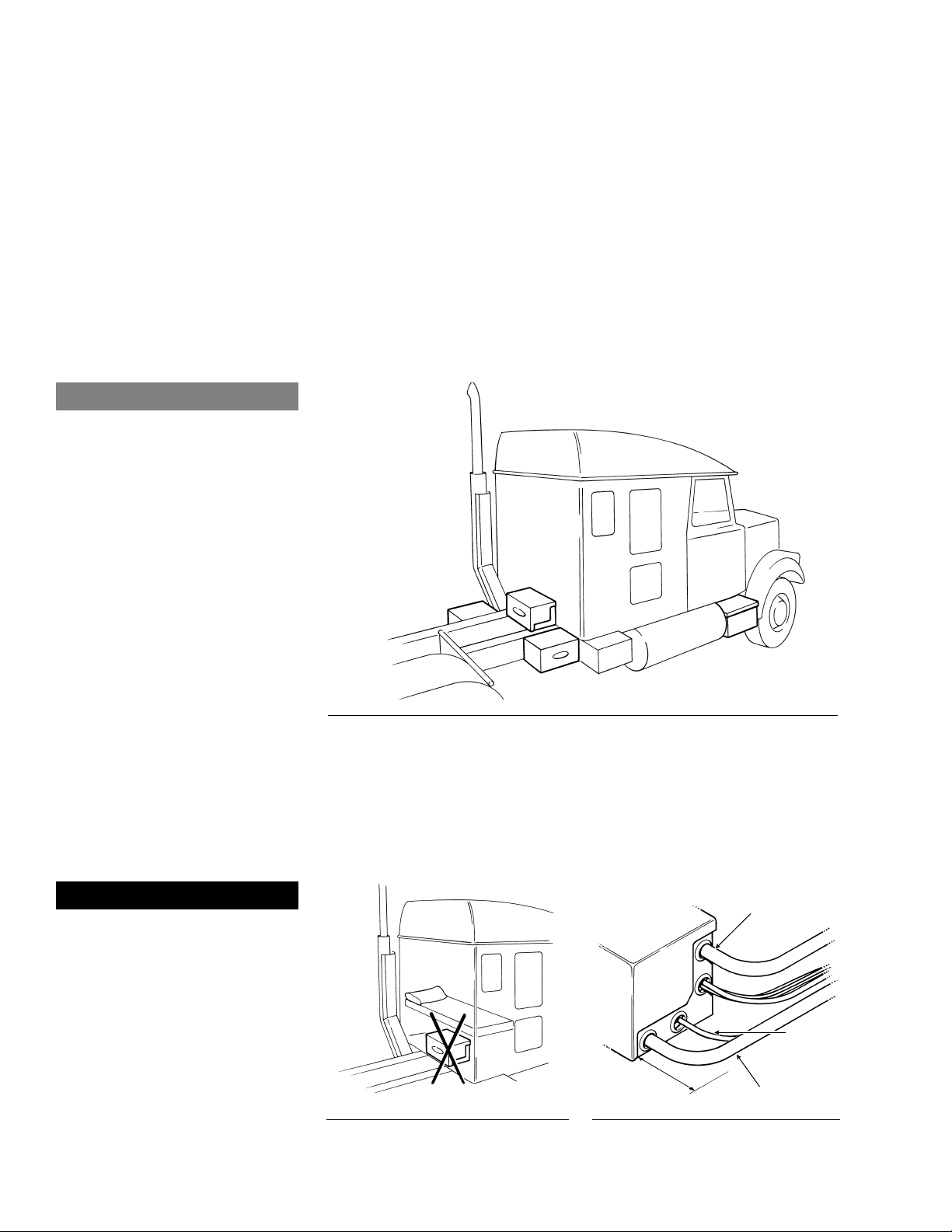

Select Your Location

The most suitable location for mounting the heater will vary depending

on the type of vehicle. Recommended mounting locations are:

• Behind the cab across the frame rails (1).

• On either side of the frame rails (2).

• In an existing enclosure on the vehicle (step or toolbox) (3).

Locating the Heater

GENERAL CONSIDERATIONS

• Never mount the heater to two separate parts of the vehicle.

• Avoid mounting the heater to fenders or areas of excessive vibration.

• Do not mount the heater directly to the engine.

Figure 3-1 Recommended Mounting Positions

Caution

Do not weld PROHEAT heater

mounting brackets to the

vehicle frame.

If repairs to the vehicle require

welding, disconnect the PROHEAT

power cable at the PCM. This will

prevent damage to the PROHEAT

electronics.

You Choose ☞

Figure 3-2

WARNING

Never locate the heater inside

the vehicle cab. (See Figure 3-2)

1

2

2

3

COOLANT OUT

COOLANT IN

MINIMUM

CLEARANCE 6"

FUEL IN

Figure 3-5 Adequate Air Flow

Figure 3-4 Height Requirement

INSTALLATION 3-3

Heater must be mounted below the highest point in the cooling system.

Mounting the PROHEAT heater in an enclosure

Do not locate the heater in an

airtight enclosure. If the heater

is to be mounted in an enclosure

other than the PROHEAT enclosure,

adequate air flow must be provided

to ensure proper combustion.

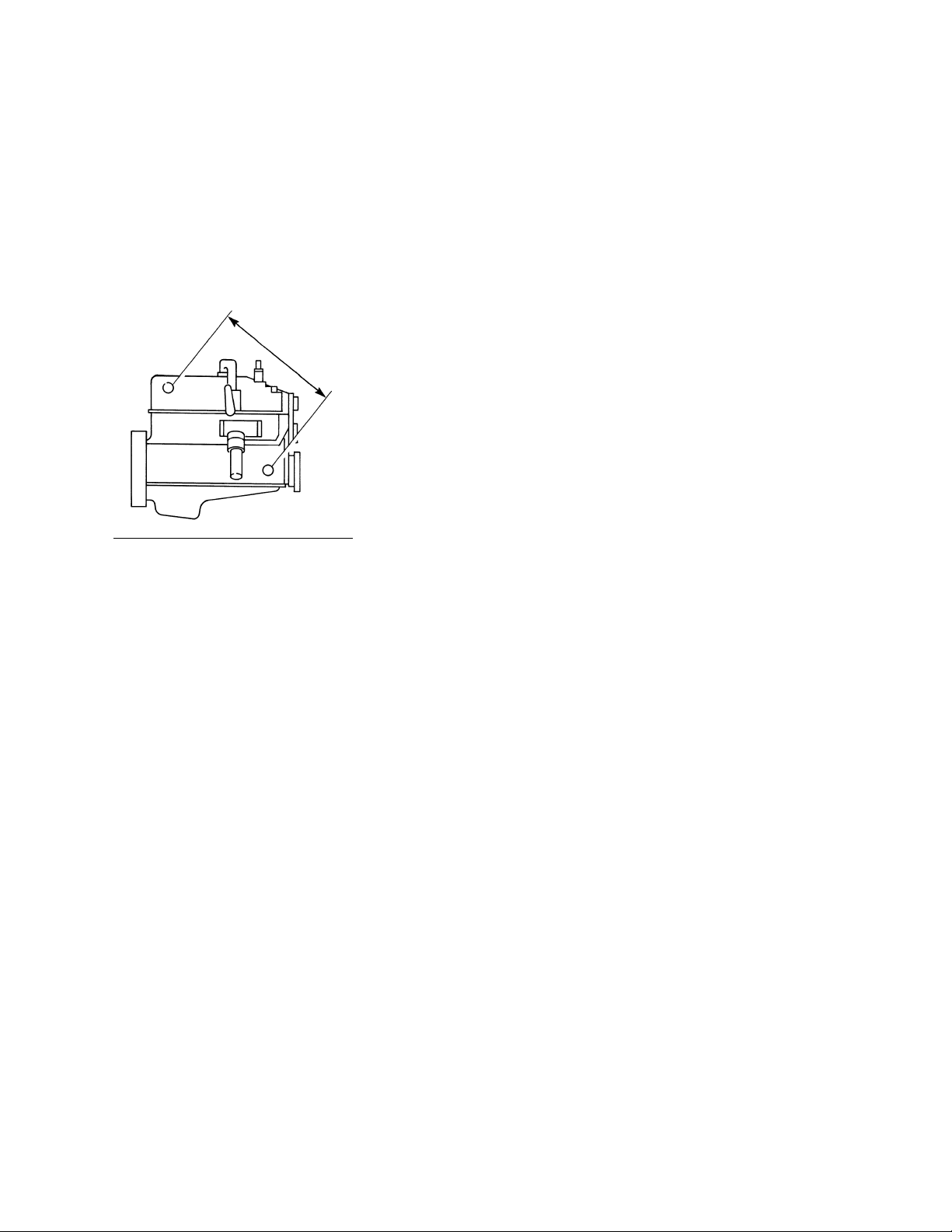

Figure 3-6 Mounting Angle

Heater must be mounted within 5˚ of horizontal, as shown.

HIGHEST POINT IN

COOLING SYSTEM

HEATER MUST

BE MOUNTED

BELOW

HIGHEST POINT

PROHEAT ENGINE OR RADIATOR

5˚

5˚

5˚

5˚

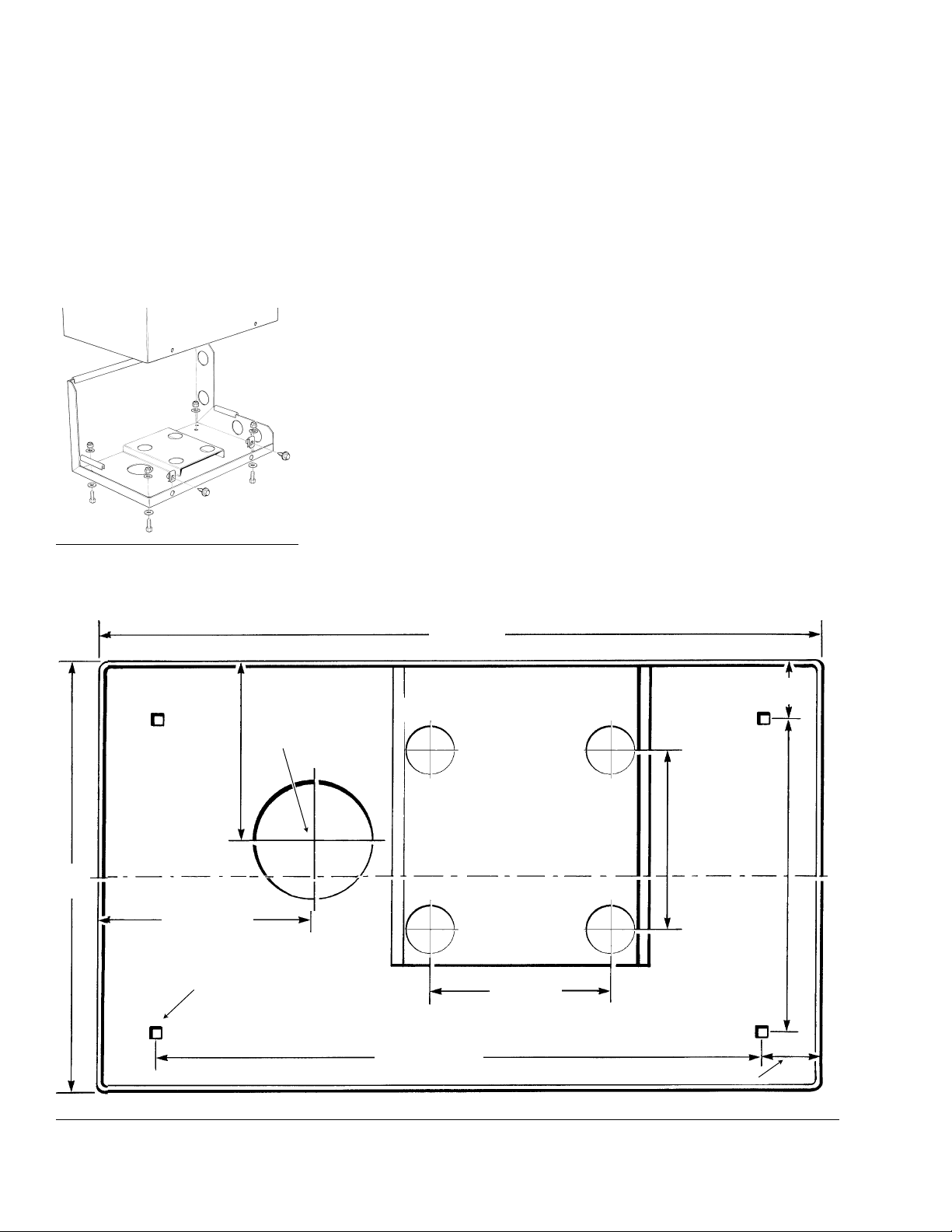

Figure 3-8 X45 Enclosure Base Dimensions

PROHEAT INSTALLATION & SERVICE

3-4

Mounting the Heater

Select Your Mounting Option

Heater supplied with an enclosure.

1. Remove the enclosure cover.

2. Drill the (4) mounting holes and exhaust pipe clearance hole.

3. Using the bolts supplied, fasten the enclosure to the mounting

tray or brackets.

4. Ensure that the combustion tube can be removed for service.

Minimum of 5 1⁄2" from fan end casting face is required.

NOTE: Use anti-seize compound on fasteners to prevent galling

and corrosion.

OPTION A:

Figure 3-7 Mounting Tray

8 13/16"

(223 mm)

5 3/4" (146 mm)

3/4" (20 mm) MOUNTING HOLES

(4 REQUIRED)

16 11/16" (427 mm)

12"

(306 mm)

20" (508 mm)

5" (127 mm)

3" (76 mm) Dia.

5" (127 mm)

CENTERLINE OF ENCLOSURE

5" (127 mm)

1 5/8"

(45 mm)

1 5/8" (45 mm)

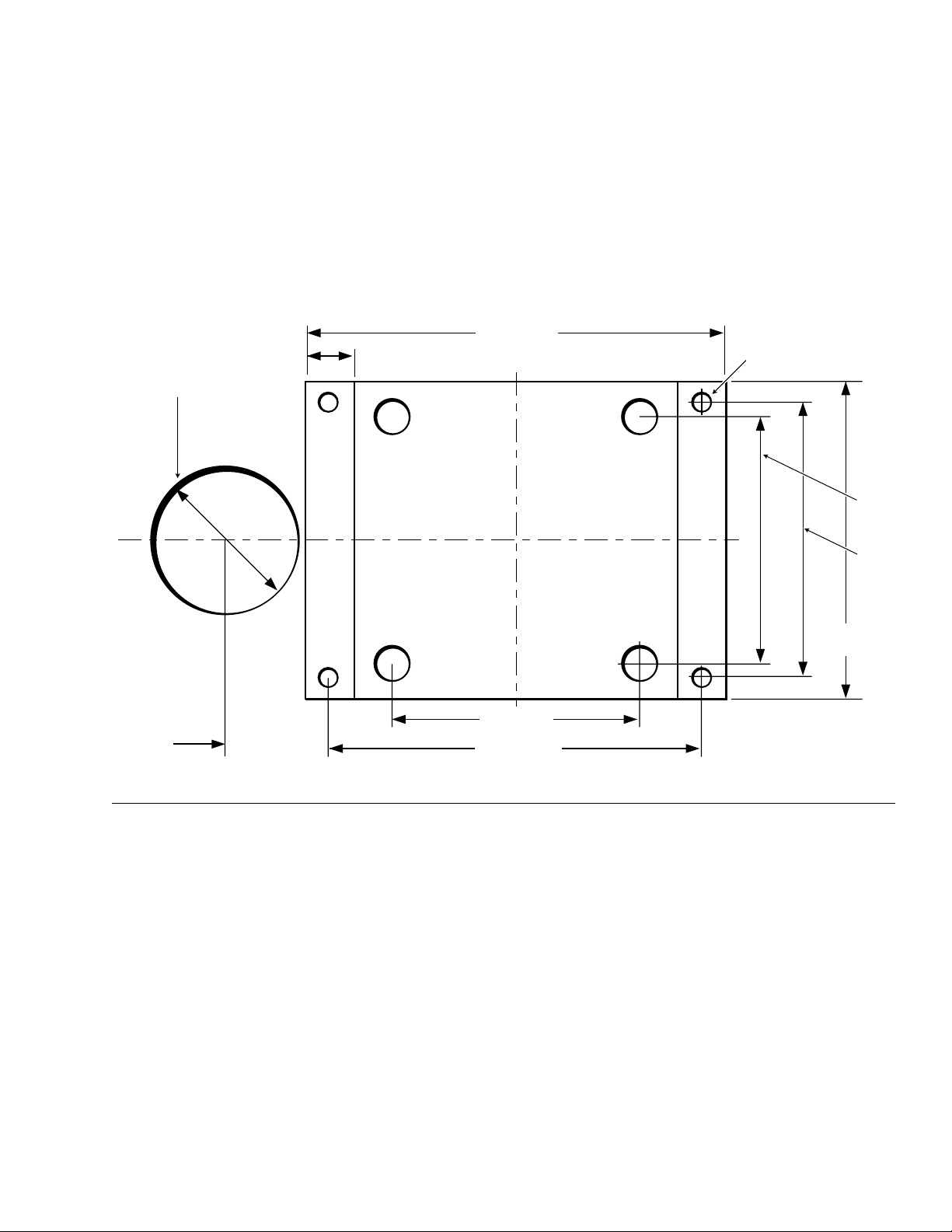

Figure 3-9 X45 Mounting Plate Dimensions & Exhaust Hole

INSTALLATION 3-5

Heater supplied without an enclosure (mount in an existing enclosure on

the vehicle ie. tool box). Heater supplied with an auxiliary mounting plate.

1. Ensure that the proposed enclosure is big enough for the heater.

12 1⁄2W x 11H x 20 1⁄2L inches (318 x 280 x 521 mm)

2. Using the indicated dimensions, drill the (4) mounting holes

and exhaust pipe clearance hole.

3. Ensure that the combustion tube can be removed for service.

Minimum of 5 1⁄2" from fan end casting face is required.

OPTION B:

2.02"

(51 mm)

3" (76 mm) Dia.

5.5"

(140 mm)

1.0" (25 mm)

8.5" (216 mm)

5"

(127 mm)

5" (127 mm)

7.5" (191 mm)

4 X .38" (10MM)

MOUNTING HOLES

6.4"

(163mm)

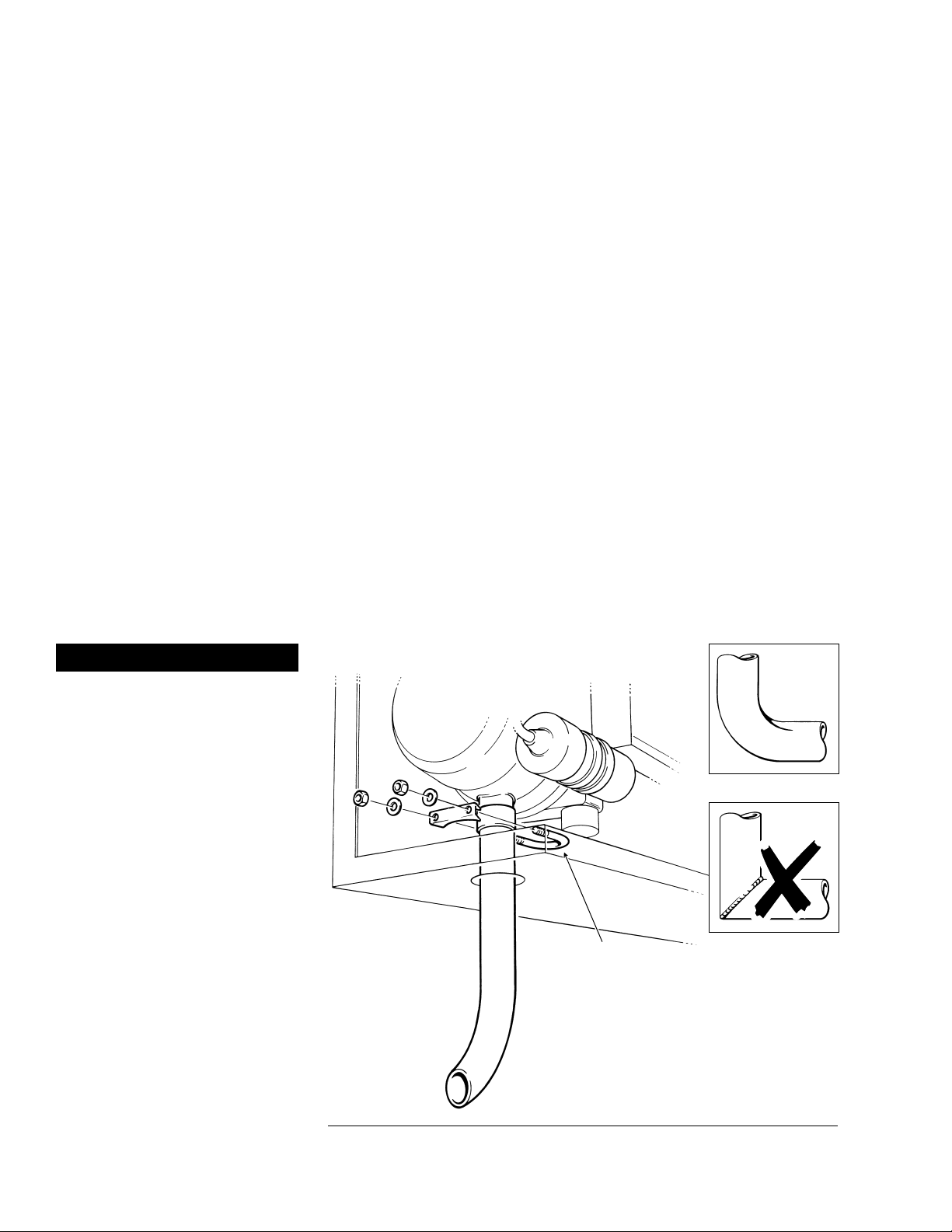

Figure 3-10 Exhaust Pipe

PROHEAT INSTALLATION & SERVICE

3-6

Exhaust Pipe

Connection

1. Push the exhaust pipe through the hole in the enclosure and onto

the exhaust outlet port of the heater. Ensure that the pipe is pushed

onto the spigot at least 11⁄2" (38 mm).

2. Route the exhaust pipe such that:

a) It does not rest against or be directed toward any parts.

of the vehicle that may be damaged by heat (i.e. brake lines,

seals, wires, rubber hoses).

b) Debris and snow will not plug the outlet.

c) Moisture from combustion will drain out of the pipe.

d) It does not face forward.

3. Disassemble the exhaust pipe clamp and apply anti-seize compound

to the threads.

4. Assemble the exhaust clamp over the exhaust pipe (clamp goes

inside the enclosure) and tighten the nuts.

NOTE: 11⁄2" exhaust pipe should not exceed 5 ft and have no more than

180 degrees of bends. The bends must be formed for best results.

Do not use 90 degree welded pipe to turn corners.

NOTE: For installations requiring special exhaust systems, consult your

PROHEAT Dealer.

WARNING

Exhaust gases must not enter

the vehicle interior. Direct

exhaust pipe away from

vehicle.

EXHAUST CLAMP

U BOLT

(APPLY ANTI-SEIZE

COMPOUND TO

THREADS)

Use formed elbows.

Do not use welded

90˚ elbows.

INSTALLATION 3-7

GENERAL CONSIDERATIONS

Coolant flow must be maintained throughout the coolant system

under all conditions.

• Keep the engine inlet and outlet ports as far apart as possible

to maximize cross-flow through engine.

• Ensure that no sharp kinks or bends exist in the hoses

which may restrict coolant flow.

• Avoid high points in the hose routing to prevent air traps.

• For systems requiring more than 50 feet of coolant line,

consult factory for coolant pump recommendations.

For plumbing the system use:

1⁄2" NPT pipe fittings or bigger.

3⁄4" ID heater hose.

NOTE: Use of silicone hose requires special hose clamps.

Shut-off valves are not required at the engine inlet and outlet connections

but may be used if desired. They should be left open at all times so that

the heater can be operated throughout the year.

Select Your Plumbing Option

OPTION A: Engine heat or supplemental heat.

The PROHEAT heats the engine block only.

NOTE: When the engine block is preheated you will have

nearly instant heat from the dash heat exchanger.

OPTION B: Engine and sleeper heat.

The PROHEAT heats the engine block and the sleeper.

NOTE: Plumbing the PROHEAT through the dash fan

is not recommended.

Plumbing the System

You Choose ☞

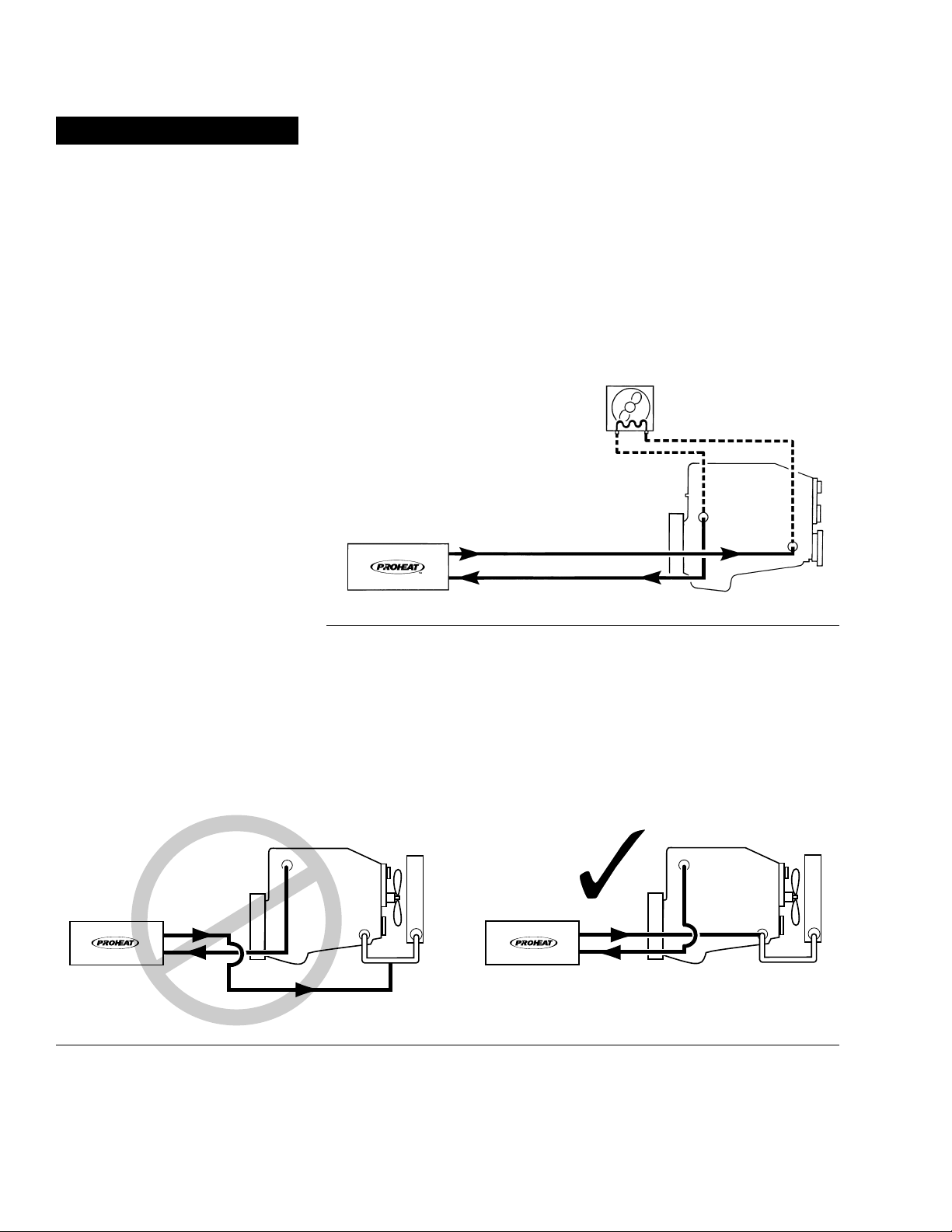

Figure 3-11 Maximize cross-flow

MAXIMUM CROSS-FLOW

Figure 3-12 Engine Heat or Supplemental Heat

PROHEAT INSTALLATION & SERVICE

3-8

Engine Heat or Supplemental HeatOPTION A:

WARNING

Opening the radiator cap when

the engine is hot may cause

serious injury.

Instructions for Options A and B

1. Remove the radiator cap to release the system pressure.

2. Drain the coolant system.

3. Plumb the system as per Figure 3-12 or Figure 3-14

4. Add engine coolant to the system as per the specific engine

manufacturer’s recommendations and re-install the radiator cap.

NOTE: Plumbing the PROHEAT through the dash fan is not recommended.

NOTE: On coolant systems where the return from the PROHEAT is plumbed

to the bottom of the main coolant supply line from the radiator to

engine pump, the return line must be moved to avoid loss of heat

through the radiator.

DASH HEATER

ENGINE

RETURN TO ENGINE

SUPPLY TO PROHEAT

NOTE: Specific engine

connection details by

manufacturer and model

can be found at the end of

this section.

Figure 3-13 Correct Return Line Plumbing

®®

ENGINE

ENGINE

SUPPLY TO PROHEAT

RETURN TO ENGINE

SUPPLY TO PROHEAT

RETURN TO ENGINE

Figure 3-15 Engine and Sleeper Heat

Figure 3-14 Engine and Sleeper Heat

INSTALLATION 3-9

OPTION B: Engine and Sleeper

For vehicles with solenoid

valves in the normally closed

position.

Western Star

For best results these vehicles

should use an auxiliary heater.

International with single heater

NOTE: Vehicles equipped with a combination heater/air-conditioner will

have a solenoid operated shut-off valve in the heater unit. Typically

this valve is normally open with the truck engine turned off and the

key removed. (See Figure 3-15 for plumbing)

Due to the many options available in vehicle heating and air conditioning

systems, the installer should be looking for any restrictions that may affect

coolant flow, with vehicle ignition in the “OFF” position.

DASH HEATER

ENGINE

SUPPLY TO PROHEAT

RETURN TO ENGINE

OEM OR AUXILIARY

SLEEPER HEATER

SOLENOID VALVE

OEM COMBO HEATERS

ONLY (NORMALLY OPEN)

NOTE: Specific engine connection details by

manufacturer and model can be found

at the end of this section.

DASH HEATER

SUPPLY TO PROHEAT

RETURN TO ENGINE

SLEEPER HEATER

SOLENOID VALVE

(NORMALLY CLOSED)

ENGINE

NOTE:

The PROHEAT PCM sleeper fan

circuit has a one minute delay

during ignition. Power to open a

sleeper fan coolant valve must be

taken from another source such

as the wire for the hour meter.

(See PROHEAT Wiring Diagram

page 6-6)

Other manuals for Teleflex X45

2

Table of contents

Other Proheat Heater manuals

Popular Heater manuals by other brands

Vornado

Vornado Vortex Heater VH2 user guide

EUROM

EUROM GOLDEN 2000 AMBER SMART instruction manual

Stelpro

Stelpro SDHR Series Installation and user guide

Clarke

Clarke 6933980 Operation & maintenance instructions

VOLTOMAT HEATING

VOLTOMAT HEATING FH-110692.1 instruction manual

Dimplex

Dimplex R23DH Series quick start guide