Compressor Adjustment If after performing the above checks and the air pressure is still

outside the recommended setting for your location, adjust the air

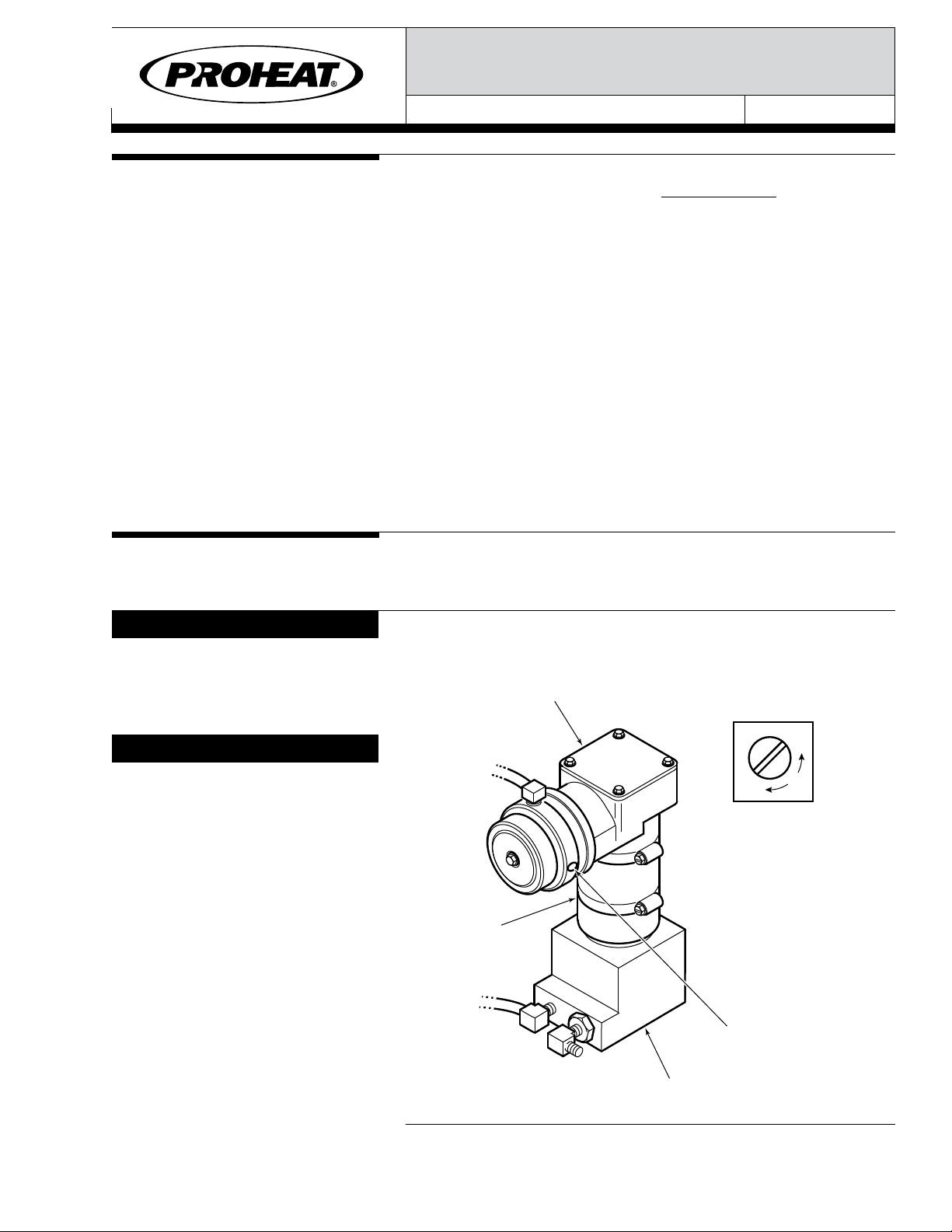

pressure by turning the screw as shown in figure D.

Altitude correction is needed above 7,000 feet (2134 m) (see figure C

on page 2).

If the air compressor pressure cannot

be adjusted back into normal range,

repair or replace air compressor.

Refer to parts manual.

NOTICE

Figure D. Compressor/Fuel Pump Assembly

END VIEW OF

ADJUSTMENT SCREW:

DECREASE

PRESSURE

INCREASE

PRESSURE

ADJUSTING

SCREW

COMPRESSOR

FUEL PUMP

ELECTRICAL

MOTOR

Air Pressure Checks If air pressure is outside the recommended setting for your location

please perform the following checks before adjusting the compressor:

Low Pressure Reading – Check:

Ensure the coil voltage is nominally 12 ±1V for 12V models and 24 ±1V

for 24V models. If voltage is low, charge batteries and check compressor

reading again.

i) Inspect air line from compressor outlet to fan end inlet for leaks,

kinks or other restrictions.

ii) Check condition of air compressor filter. Retest with the filter

removed.

High Pressure Reading – Check:

Ensure the coil voltage is nominally 12 ±1V for 12V models and 24 ±1V

for 24V models. If voltage is high, stop charging batteries (turn engine

off) and check compressor reading again.

i) Nozzle and cavity for blockage. Refer to Step 5 on page 5-10 of

the X45 service manual.

NOTICE

Copy Part# SB0060, Rev. B, 08/2014 Page 3 of 3

© 2011 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

SERVICE BULLETIN