Proheat X30 User guide

OWNER’S HANDBOOK

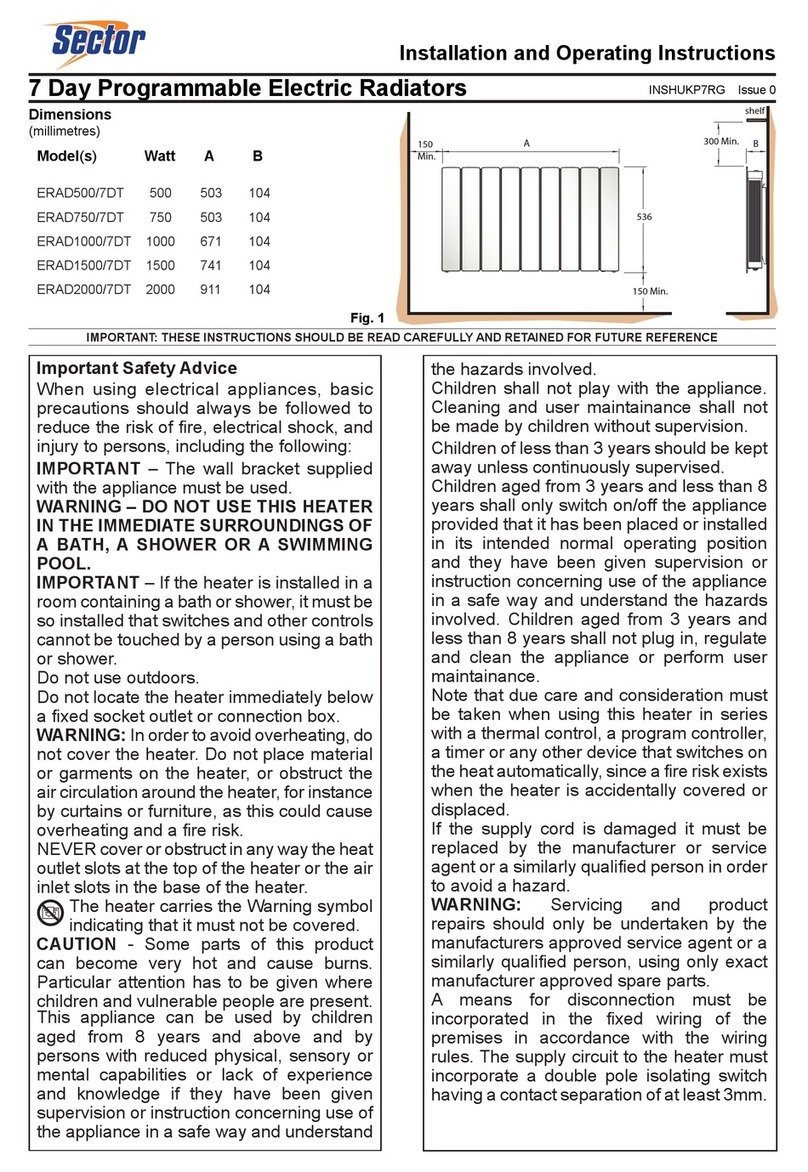

X30 Owner’s Handbook Page 1

Safety ................................................................................................................................. 2

Introduction ....................................................................................................................... 4

Operating your PROHEAT ................................................................................................... 5

Optional Sleeper Fan Operation ......................................................................................... 7

Toggle Switch – Timer – PFC ........................................................................................... 8

Timer Instructions .............................................................................................................. 9

PFC Instructions .............................................................................................................. 10

Caring for your PROHEAT ................................................................................................ 11

Troubleshooting ............................................................................................................... 17

Troubleshooting – Operation Indicators/Diagnostic Codes ............................................. 18

Troubleshooting – Function Diagnostics ......................................................................... 22

Warranty .......................................................................................................................... 25

Owner’s responsibility ...................................................................................................... 26

Contents

Page 2 X30 Owner’s Handbook

ELECTRICAL – Electric shock can cause severe personal injury, burns, and death. Before working

on any unit, disconnect the batteries. Use only approved materials and methods when working on the

electrical system and follow local electrical codes. Never work with electricity in wet conditions or

when you are feeling fatigued.

WARNING

POISONS/TOXINS – Fuel and coolant are toxic and in some cases, carcinogenic. Wear eye and hand

protection at all times. Remove contaminated clothing immediately and wash contaminated skin. Do not

breathe in vapors.

WARNING

MOVING/HOT PARTS – Moving/hot parts can cause severe injury and or death. Before working on

any unit, shut it off. Do not operate any unit until protective covers have been replaced. Always ensure

bolts and clamps are correctly torqued and secured. Inspect mechanical components periodically for

damage and corrosion.

WARNING

CALIFORNIA PROPOSITION 65 WARNING – Do not operate heater in garages or in other closed

or unventilated areas. Diesel exhaust and some of its constituents are known to the State of California

to cause cancer, birth defects, and other reproductive harm.

Electrical components in this product may contain lead, a chemical known to the State of California to

cause cancer and birth defects and other reproductive harm.

DANGER

COOLANT – Never remove the filler cap when the engine is hot – escaping steam or scalding water

could cause serious personal injury. The coolant level in the expansion tank should be checked at least

weekly (more frequently in high mileage or arduous conditions). Always check the level when the system

is cold. Unscrew the filler cap slowly, allowing the pressure to escape before removing completely.

Never run the engine without coolant.

Prevent anti-freeze coming in contact with the skin or eyes. If this occurs, rinse immediately with plenty

of water. Anti-freeze will damage painted surfaces.

Never top-up with salt water. Even when travelling in territories where the water supply contains salt,

always ensure you carry a supply of fresh (rain or distilled) water.

WARNING

Safety

X30 Owner’s Handbook Page 3

Throughout this manual, you will see notes labeled DANGER, WARNING, CAUTION and NOTICE

to alert you to special instructions or precautions concerning a particular procedure that would be

hazardous if performed incorrectly or carelessly.

Observe them carefully!

These safety alerts alone cannot eliminate all hazards. Strict compliance with these special

instructions and common sense are major accident prevention measures.

Safety

Information that is important to

proper installation or maintenance,

but is not hazard-related.

Notice

Immediate hazards that

will result in severe injury

or death.

DANGER

Hazards or unsafe practices

that could result in severe

personal injury or death.

WARNING

EXHAUST – Inhalation of exhaust gas (containing carbon monoxide) may cause severe personal injury

and/or death. Anyone suspected of suffering from CO inhalation should be removed from the

hazardous area and given medical assistance immediately.

WARNING

FUEL – Exercise extreme caution when working near fuel or fuel-filled equipment. Do not operate

heater during fueling operations. In addition, do not smoke or handle open flame equipment, such as

a blowtorch, around fuel.

WARNING

EXPLOSION HAZARD – Do not operate heater where combustible fumes or airborne particles, such

as sawdust, are present.

WARNING

Hazards or unsafe practices

that could result in minor

injury or product or

property damage.

CAUTION

Safety Considerations

FIRE HAZARD – Do not place any flammable items around the heater and exhaust pipe.

WARNING

BATTERIES – Wear hand and eye protection when working near batteries. Do not smoke or use

open flames near batteries.

WARNING

Page 4 X30 Owner’s Handbook

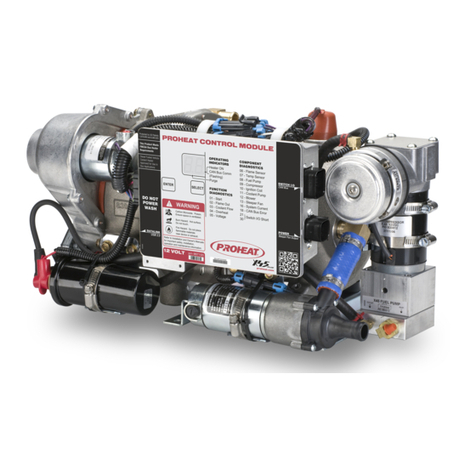

Congratulations on your purchase of a PROHEAT X30 diesel-fired heater. This handbook is provided to

summarize the operation and maintenance of the PROHEAT X30 for the Owner/Operator.

For complete information, please refer to the Installation and Service manual SL9211 at www.proheat.com

Although trucks have been used throughout this book, applications for PROHEAT are by no means

limited to trucks. PROHEAT heaters are designed to be used on any diesel equipped vehicle

including: trucks, buses (school, transit and coach), construction equipment, off road equipment,

military equipment and cargo.

PROHEAT heaters are used in the following applications:

• Preheats an engine block to ensure reliable cold weather starting.

It is recommended that PROHEAT is used year round (winter and summer) to reduce engine

wear associated with cold starting.

• With the engine off—supplies heat to the engine and sleeper for comfort and reduced idle time

resulting in cost savings through reduced fuel consumption and engine wear.

• With the engine running—adds heat to the coolant system when the engine does not provide

adequate reject heat for the vehicles interior.

• Provides heat to protect cargo from cold weather damage.

• With the engine off - supplies minimal heat to prevent freezing over long periods of time.

Introduction

Notice

eNgiNe Block heat

eNgiNe & Sleeper heat

SupplemeNtal heat

cargo heat

aNti-Freeze heat

X30 Owner’s Handbook Page 5

Your PROHEAT X30 is controlled by either an ON/OFF manual toggle switch or by an optional

PROHEAT 7-day timer. The timer can be controlled manually, or it can be set to start at a predetermined

time. Both devices have a light that indicates when the heater is operational as well as flashing to indicate an

error state

. Your installer may have enabled optional features and heating modes.

Please see the X30

Installation and Service manual SL9211 at www.proheat.com or your Dealer for more information.

1. SWITCH ON – The ON/OFF switch (or Timer) lamp and the Proheat Control Module (PCM) “ON”

LED will light. In addition, the Hour Meter (Auxiliary Output) will be powered. If the coolant

temperature is below 150°F (65°C) the PROHEAT enters Pre-check. If the coolant temperature is

above 150°F (65°C) the PROHEAT enters Standby.

2. PRECHECK – The PCM performs a short diagnostic cycle. This takes a few seconds to check

components for proper ranges, short-circuits and open circuits. If there are no errors indicated,

the PROHEAT goes to “Ignition”.

3. IGNITION –

The blower starts first, followed by the coolant pump, ignition spark, air compressor

and

fuel pump. The ignition electrode sparks for up to 60 seconds. Once a good flame is detected, the

PROHEAT goes to “Full Output”.

4. FULL OUTPUT – The PROHEAT runs at Full BTU Output until the coolant temperature reaches

185°F (85°C) at the heater outlet. If the time to heat the coolant to 185°F (85°C) is longer than

10 minutes the PROHEAT then shuts the flame off and goes to “Cool Down” (Purge). If the time to

heat the coolant to 185°F (85°C) is shorter than 10 minutes the heater will slow down and reduce

the heat output for the remainder of the 10 minutes.

5. MODULATING BTU OUTPUT – The PROHEAT may reduce the heat output up to 50% automatically

once the coolant temperature reaches 185°F (85°C) at the heater outlet.

Operating your PROHEAT

StaNdard mode

operatiNg SequeNce

Page 6 X30 Owner’s Handbook

The heating cycle will end once the 10 minutes have past OR the coolant temperature reaches

194°F (90°C) at the heaters outlet.

The PROHEAT then shuts the flame off and goes to “Cool down” (Purge).

6. COOL DOWN (Purge) – The air compressor and fuel pump shut off immediately. The blower

and coolant pump continue to run. After 3 minutes, the blower stops and the PROHEAT goes

to “Standby.”

7. STANDBY – The coolant pump circulates the coolant through the system until the temperature

drops to 150˚F (65˚C) at the heater outlet; then it will enter Precheck and repeat steps 2 to 6. The

PROHEAT will continue to repeat steps 2 to 5 until it is switched “off.”

8. SWITCH OFF – If PROHEAT is in Full Output, it will Cool Down (Purge) first, then shut “OFF”.

If PROHEAT is in Standby, it will shut “OFF” immediately.

When switched OFF, the Sleeper Fan (if equipped) output turns off.

When switched OFF, the Hour Meter (Auxiliary Output) will shut off.

Operating your PROHEAT

X30 Owner’s Handbook Page 7

Optional Sleeper Fan Operation

Today’s sleepers are designed for maximum comfort for the vehicle operator. Generally the units are

larger and have accessories that compete for battery power with auxiliary heaters. PROHEAT is a

cost-saving component by reducing fuel consumption and engine maintenance. Therefore, it should

be given priority over these accessories.

PROHEAT installation recommendations are designed to allow the operator to:

• Run the PROHEAT with the vehicle ignition key in the OFF position

• Set the desired sleeper ambient temperature using the dedicated Proheat thermostat

The vehicle operator’s responsibility is to ensure that:

• Coolant valves used in the heating system are open: These can be manually or electrically

operated (electrically operated valves must be opened before shutting the vehicle OFF)

• When operating the PROHEAT, power consuming accessories such as refrigerators, DVD’s, TV’s,

satellite receivers, heated mirrors, etc. are not used to ensure enough starting current for the engine

• Sleeper curtains are closed: The PROHEAT is designed to heat the sleeper and engine as efficiently

as possible – heating the cab, fuel tanks and batteries means longer run time which will require

more battery power

Notice

For more information on Sleeper Fan installation,

please refer to the Installation and Service manual

SL9211 at www.proheat.com

Page 8 X30 Owner’s Handbook

Up Arrow

Manual Mode

Solid Red Led = Heater Active

Flashing Red Led = Heater Fault

Timer Mode

Solid Green Led = Timer Active

Back Soft Key

Back (Default) Or No

Down Arrow

Select Soft Key

Select (Default), Set,

On, Off, Edit Or Yes

11:52AM

MON106F

STANDARD

M00:59T1 T2 T3

Toggle Switch – Timer – PFC

T-II Manual

Indicator Light

(Red)

Timer

Indicator Light

(Green)

timer

proheat FuNctioN coNtroller (pFc)

toggle Switch

X30 Owner’s Handbook Page 9

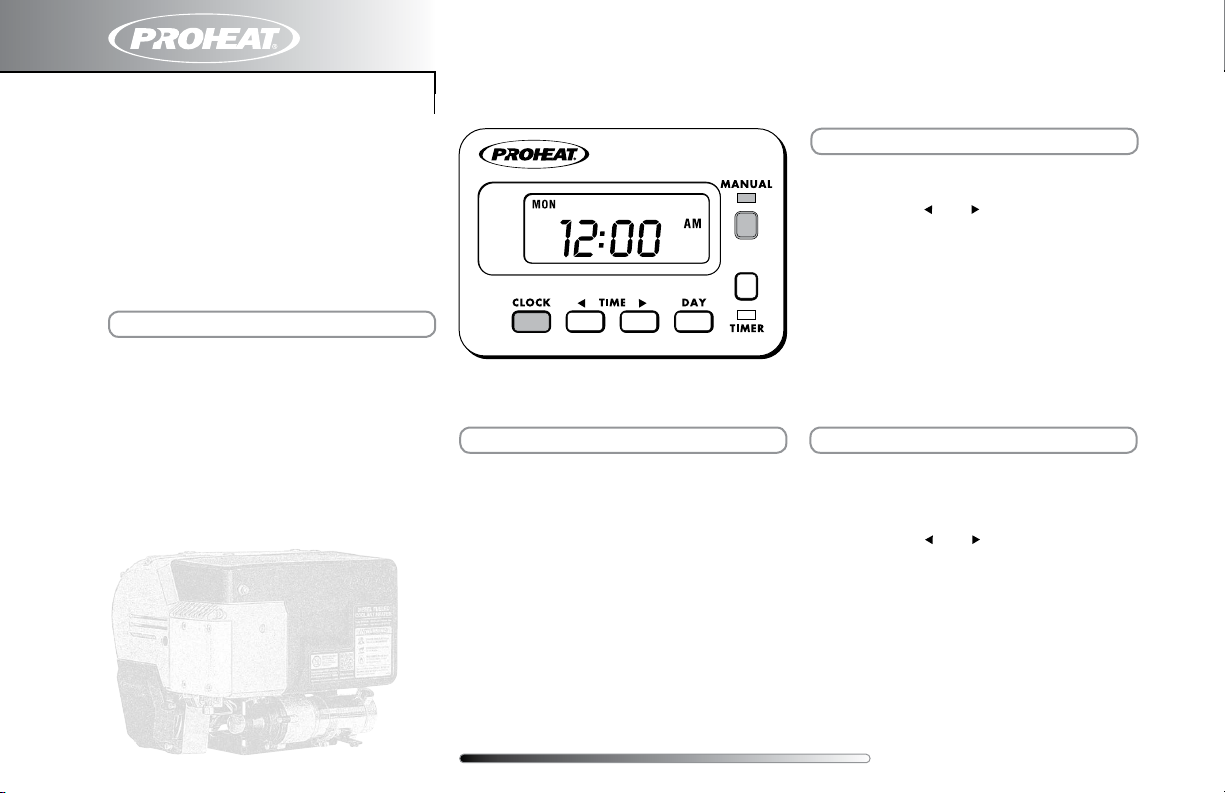

T-II

Timer Instructions

MANUAL button is used to turn the PROHEAT

On and Off when desired.

STEP 1 Press “MANUAL” to turn on the

PROHEAT (red light will go on and

the heater will operate indefinitely).

STEP 2 Press “MANUAL” again to turn Off

the heater (red light and the

PROHEAT will turn Off).

STEP 1 Press and Hold “TIMER” (green light

will turn on and “T1” will flash).

STEP 2 Press “ ” or “ ” to set time

STEP 3 Press “DAY” to advance the day.

STEP 4 Release “TIMER”. (green light and

“T1” will remain lit to activate timer).

STEP 1 Press and hold “CLOCK”

STEP 2 Press “ ” or “ ” to set time

STEP 3 Press “DAY” to advance the day.

STEP 4 Release “CLOCK”.

For complete Timer information, please refer

to the T-II Timer Installation and Operating

Instructions 958829 at www.proheat.com

Notice

maNual operatioN timed operatioN

SettiNg clock

Page 10 X30 Owner’s Handbook

PFC Instructions

11:52AM

STANDARD

M

00:59

T1 T2 T3

MON106F

00:59T1 T2 T3

The “”button is used to turn the heater on and

off when desired regardless of set Timers.

Press “”to activate the heater. The Red

Manual Button LED will turn on and the heater

will operate indefinitely (factory preset).

If the Manual Mode Runtime has been set you

will see the remaining time left before the heater

automatically turns off.

When the heater has an active Flame the icon will

change to a black background. Pressing “”

button again will de-activate the heater. (The Red

LED will go out and the heater will turn off.)

When a Timer Mode is enabled you may see a

number of different screens depending on how

the Timer was programed (see Timer settings).

Press the “”button repeatedly to toggle

through and activate T1, T2, T3 or Group Timers.

(Green Timer LED will turn on).

The Heater will switch on at the set program(s)

time, run for the set duration, then switch off

automatically.

If the heater has been turned on by a timer event,

Pressing “”button will turn the heater off but

leaves the timer(s) schedule active.

Pressing the

“ ”

Button repeatedly to toggle

through

and deactivate the current set timer

program(s) (Green Timer LED will go out and

screen will not show T1,T2,T3.

If a password has been set it may not be possible

to deactivate the scheduled timer(s).

For complete PFC information, please refer

to the PFC Installation and Operating

Instructions 949900 at www.proheat.com

Notice

“Manual” and “Timer” cannot be active at the

same time. If “”is active and the “ ” button

is pressed, the heater will turn off and the Red

Manual Button LED will go out.

Notice

maNual operatioN timed operatioN

X30 Owner’s Handbook Page 11

Caring for your PROHEAT

Your PROHEAT has been designed to operate with a minimum of maintenance. Always return to your

authorized PROHEAT dealer for major service. Your PROHEAT dealer has the specialized equipment

necessary to keep your PROHEAT running safely and reliably.

For more maintenance information, refer to the Installation and Service manual SL9211

at www.proheat.com

Operate the PROHEAT year round (winter & summer). Use the PROHEAT to preheat the

engine before starting. Savings will result from reduced engine idle time and maintenance.

This also keeps the PROHEAT components and fuel system in good running order.

PROHEAT weekley maintenance:

Visually inspect the Proheat, mounting brackets, fuel line, harnesses, coolant lines and

exhaust system for damage, loose parts and leakage.

Run the Proheat a minimum of once a week to keep new fuel in the heater’s critical components.

PROHEAT annual maintenance:

A higher duty cycle may require a more frequent

maintenance schedule.

Proper maintenance will result in the following benefits:

• Maximum heat transfer to the coolant

• Minimum battery power draw

• Long term cost savings

• Increased reliability

Notice

Notice

Check Combustion

Air Inlet for restrictions.

Clean as required.

Page 12 X30 Owner’s Handbook

check exhauSt SyStem • Make sure the exhaust pipe is fully installed,

vents outside of the engine compartment and

is clear of the underside of the vehicle.

• Check the pipe for dents, restrictions or severely

corroded areas and replace if necessary.

• Ensure exhaust pipe clamps are tight.

Caring for your PROHEAT

cleaN heater eNcloSure • Remove the heater enclosure cover.

• Clean any accumulated debris or dust from

the components.

• Blow out the compartment with compressed air.

• Do not pressure wash.

• Make sure the opening around the exhaust

pipe is clear.

• Visually inspect all the components for wear

or damage.

check Fuel Filter • Remove and inspect fuel filter.

Clean or replace as necessary.

Apply Diesel

to O-Rings

Fuel Filter

Torque to

150±10 In/Lbs

(17±1.1 Nm)

X30 Owner’s Handbook Page 13

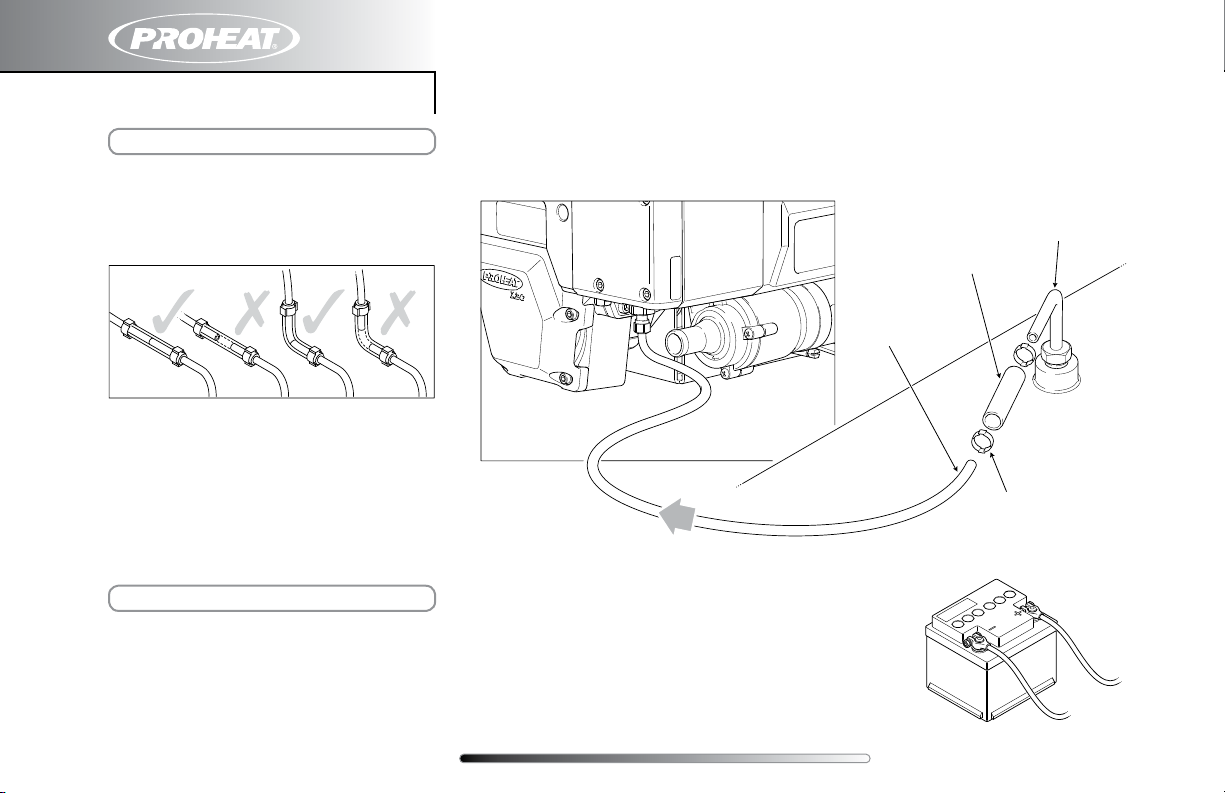

check BatterieS • Check the condition of batteries and the power connections.

The heater will not function properly with weak batteries or

corroded connections.

• Note For best results load test each battery individually.

Caring for your PROHEAT

check Fuel SyStem • Check fuel pick-up tube, clamps and line to the heater for damage, cracks from aging or leakage.

• Check fuel pump and fittings for damage or leakage.

Hose

Fuel Tank

Fuel Pick Up

Crimp Clamp x2

Hose Crimp Connection

Fuel In Line

Page 14 X30 Owner’s Handbook

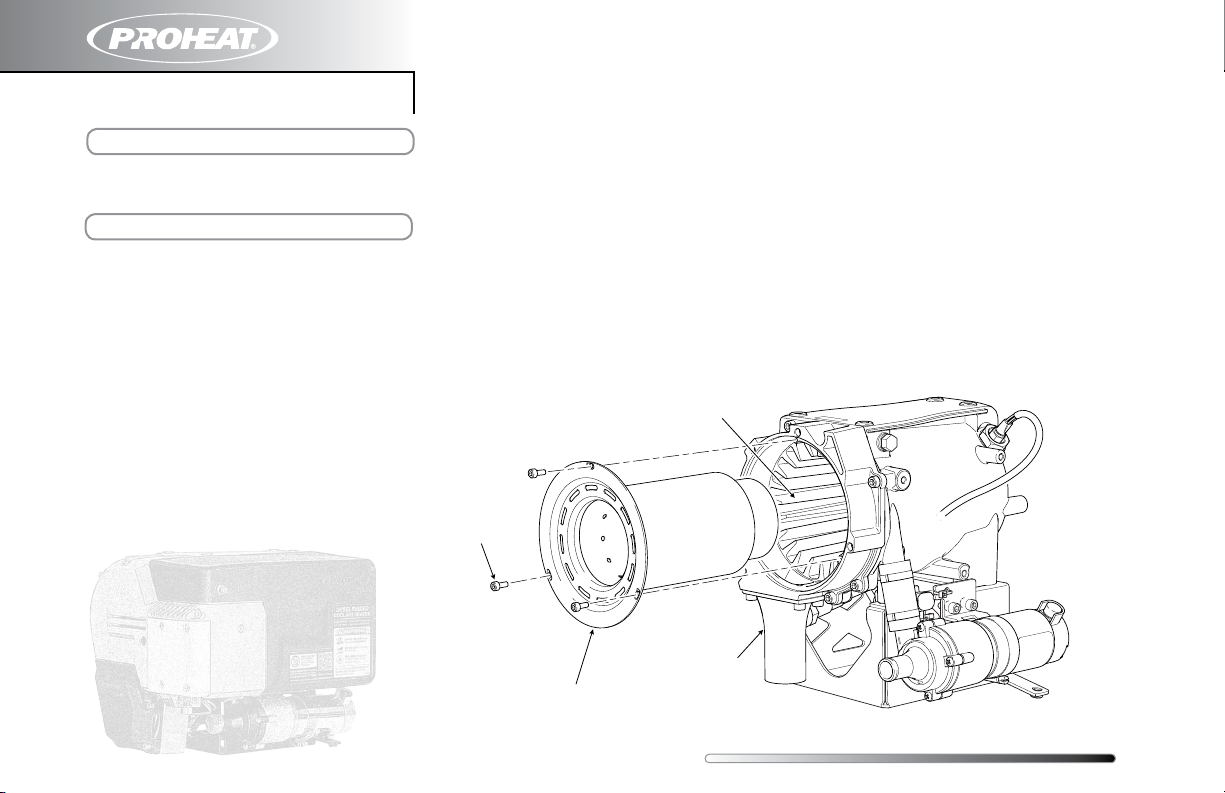

Caring for your PROHEAT

check heat exchaNger • To maintain optimum heat output, clean any combustion deposits that may have accumulated on

the heat exchanger fins.

• Remove the burner head assembly and combustion tube to access the inside of the heat exchanger.

• Ensure exhaust pipe is clean and free from restriction.

• Use a wire brush to loosen the deposits and a vacuum to remove debris.

• Torque securing screws to 12 ±3 in/lbs (1.4 ±0.3Nm).

Combustion Tube

Heat Exchanger Fins

Securing Screws

Exhaust Pipe

check cooliNg SyStem • Check coolant pump, all coolant hoses and connections for signs of leakage or damage.

• Repair or replace as required.

X30 Owner’s Handbook Page 15

cleaN Nozzle

Nozzle

Distributor

Apply Compressed Air

in this Direction

Holes & Grooves

Must be Clear

Stem

Inner

Rod

Outer

Barrel

Thread together

until flush. Do not

press together.

No Nicks in O-ring

Counter Bore

No Nicks in O-Ring

• Remove and install nozzle as per Installation & Service manual SL9211. Torque to 150 in/lbs. (17.35 Nm).

• To properly clean the nozzle use a degreaser/cleaner or carburetor cleaner in a spray can. This will

wash any dirt out and leave no residue. When using compressed air, blow into the nozzle orifice

from the head end ONLY.

Torque to 30 ±3 In/Lbs

(3.4 ±0.3 Nm)

HOLD NOZZLE

UPRIGHT TO

ASSEMBLE

Caring for your PROHEAT

Page 16 X30 Owner’s Handbook

compreSSor air Filter

electrical SyStem

timer / toggle Switch

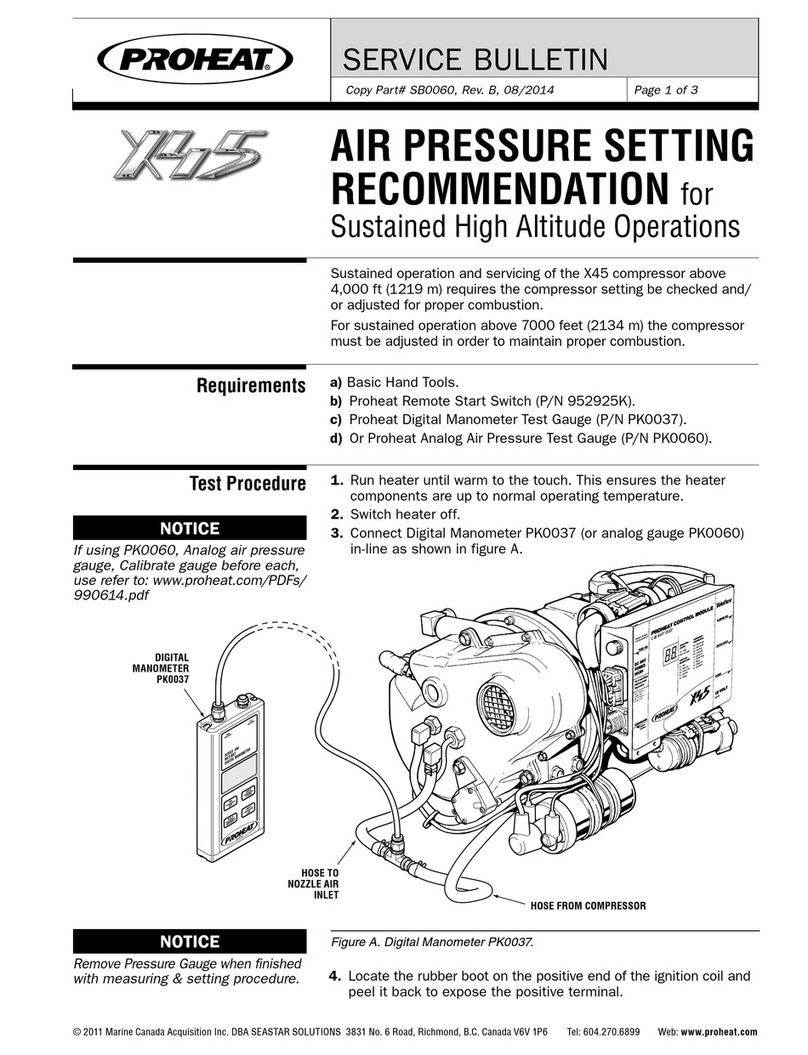

air preSSure check

operatioN teSt

• Replace the compressor inlet air filter

annually or more often if dusty conditions

are encountered.

• Check the internal and the external wire harnesses

for damage. Replace if required.

• Check to see that both operate as described in

the Operation Manual.

• Correct air pressure is important – refer to the X30 Installation and Service manual SL9211 for

further information.

• Run the system for at least 15 minutes

or until the heater cycles “OFF”

and then “ON” again.

• Alternate the thermostat

for the sleeper heater

(if connected) between

the lowest and highest

settings to ensure that

the sleeper heater fan

cycles “ON”and “OFF”.

Caring for your PROHEAT

Remove Plug and Connect Fitting

Digital Manometer PK0036

Torque to 50±5 In/Lbs

(5.6±0.7 Nm)

X30 Owner’s Handbook Page 17

The PCM (PROHEAT Control Module) has self diagnostics for reliable operation, safety and protection

of the PROHEAT. If a problem is detected it shuts the PROHEAT OFF and will start blinking the

diagnostic indicator light on the PCM cover, toggle switch, timer red manual light or OEM indicator

light (installation options). A diagnostic code number is also displayed on the PCM Diagnostic Panel

located under the PCM cover and the optional PFC.

PROHEAT will attempt one (1) re-start after a Function or Component Diagnostic Code has been

indicated. The re-start will not occur during a Cool Down (Purge) cycle or if the coolant temperature

is above 150°F (65°C). ALWAYS let the PROHEAT attempt two (2) starts so that the PCM can point

you to the problem area.

1. Switch the PROHEAT ON using the toggle switch, T-II Timer or PFC.

2. Check the diagnostic code indicator located under the PCM cover on the heater. The codes are as

a two digit code followed by a dash single digit code such as 01-1.

3. Function Diagnostic codes 01 to 05 are usually caused by vehicle system interface problems.

4. Components Diagnostic codes 13, 14, 19 and 21 to 29 indicate an electrical problem ONLY, with

PROHEAT components, wiring or the PCM. Refer to your Installation and Service manual SL9211

for further information.

5. For an up to date Installation and Service manual SL9211 or to locate a Distributor/Dealer near

you, go to www.proheat.com

Troubleshooting

Notice

trouBleShootiNg StepS

For more detailed troubleshooting information,

refer to the Installation and Service manual

SL9211 at www.proheat.com

Page 18 X30 Owner’s Handbook

PROHEAT CONTROL MODULE (PCM) DISPLAY PANEL DETAIL

Troubleshooting

Operation Indicators/Diagnostic Codes

Operation

Display Description

State

Code No.

Configuration

CC Configuration error or not selected.

Function Diagnostics

Start 01-1 O2low.

01-2 O2high.

01-3 EGT temp low.

Flame Out 02-1 O2low.

02-2 O2high.

02-3 EGT temp low.

02-4

Fuel command low.

02-5

Unstable flame.

Coolant Flow 03-1 Coolant flow.

Overheat 04-1 Coolant.

04-2 Exhaust.

Voltage 05-1 Voltage low.

05-2 Voltage high.

05-3 Voltage surge.

Operation

Display Description

State

Code No.

Component Diagnostics

Temp. 07-1

R

ange low.

Sensors 07-2

Outlet r

ange high.

07-3 No communication

.

07-4 Temperature mismatch.

Fuel Valve 08-1 Electrical.

Compressor 09-1 Short circuit.

09-2 Overload.

09-3 Open circuit.

09-4 Speed.

09-5 PCM damage.

Ignition 10-1 Short circuit.

Module 10-2 Not used.

10-3 Open circuit.

Coolant 11-1 Short circuit.

Pump 11-2 Overload.

Blower 12-1 Short circuit.

Motor 12-2 Overload.

12-3 Open circuit.

12-4 Speed.

12-5 PCM damage.

System 16-1 Short circuit.

Current 16-2 Overload.

Operation

Display Description

State

Code No.

Component Diagnostics Continued

O2Sensor 17-1 No communication.

17-2 Out of range.

17-3 Performance.

CAN 18-1 No heartbeat.

PCM Temp* 19-1 PCM temperature high.

Output 1-6 2

1 to 26

Short circuit.

PCM Battery 31-1 Supply low.

Power

EGT Sensor 32-1 Range low.

32-2 Range high.

Impact Switch 33-1 Active.

PCM 34-1 Hardware failure.

LOCKOUT MODE – After 6 consecutive start

faults (Code 01) or on the first occurrence of

Overheat (Code 04) the X30 PCM will go into

Lockout mode, Power to the X30 PCM must be

removed and reapplied to exit Lockout mode.

Notice

* Warning code. Heater will continue to operate.

X30 Owner’s Handbook Page 19

Troubleshooting

Operation Indicators/Diagnostic Codes

PCM Cover Status LED

The PCM continually monitors the PROHEAT operating conditions. When operating correctly the PCM

status LED will be Green. If the PCM detects a problem, the PCM status LED blinks Red, indicating a

diagnostic code(s) is being displayed on the PCM’s 7 segment display located under the PCM cover.

The diagnostic indicator light may also be located:

• In the toggle of the ON/OFF switch provided by PROHEAT (standard installation kit).

• In the PROHEAT T-II Timer manual ON light (red).

• In the PFC manual mode button ON light (red).

• In an OEM indicator light package.

PCM Status

State

Light Colour

GREEN Flash twice (fast) then off When power is first applied to the PCM the Green LED will flash (fast)

twice to indicate that the PCM has booted up

GREEN On solid Heater is switched on Via analog switch inputs and is operating normally

GREEN Off then two flashes, then

off again

Heater is connected to CANBus network and is communicating on the

network but is not switched on

GREEN On solid with two flashes

then on solid again

Heater is switched on Via Analog or CANBus switch inputs and is

operating normally and communicating on the network

RED On solid Software problem detected. Contact Proheat for further information.

RED Blinking Indicating a diagnostic code(s) is being displayed on the PCM’s 7

segment display located under the PCM cover

STATUS

LED

PCM

COVER

STATUS

LED

7 SEGMENT

DISPLAY

Table of contents

Other Proheat Heater manuals

Popular Heater manuals by other brands

Nibe

Nibe Heatrod Elements ThermTec HE A Series Fitting instructions

Narita

Narita NH-850 instruction manual

Toyostove

Toyostove Laser 530 Assembly, installation and operation instructions

Jaga

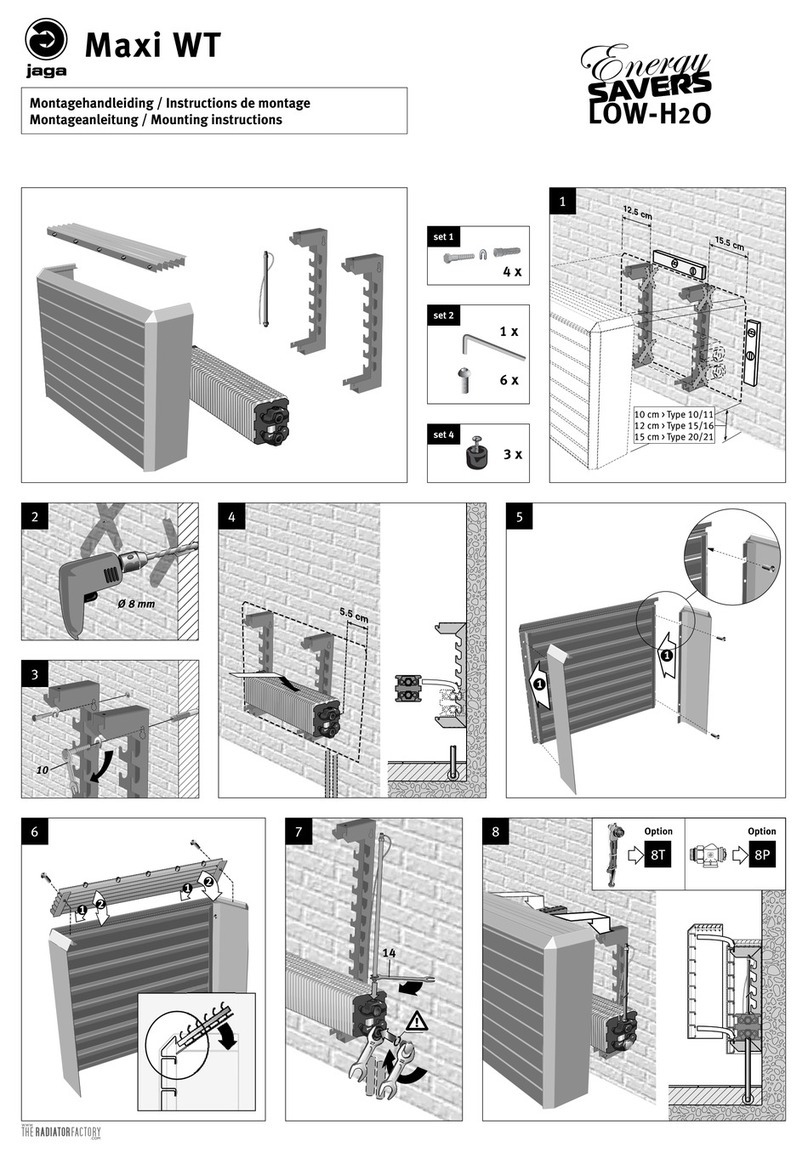

Jaga Maxi WT Mounting instructions

Sector

Sector ERAD500/7DT Installation and operating instructions

Jaga

Jaga eCAB instructions