Projecta DT1000 User manual

CLAMP MULTIMETER

P/No. DT1000

IMPORTANT SAFETY INFORMATION

Please read this manual thoroughly before use and store in a safe place for future reference

WARNING

• Do not exceed the maximum allowable input range of any function.

• Do not apply voltage to multimeter when resistance function is selected.

• Set the function switch OFF when the multimeter is not in use.

• Set function switch to the appropriate position before measuring.

• When measuring volts do not switch to current/resistance modes.

• Do not measure current on a circuit whose voltage exceeds 240V.

• When changing ranges using the selector switch always disconnect the test leads from the

circuit under test.

• Do not exceed the maximum rated input limits

• Improper use of this multimeter can cause damage, shock, injury, or death.

Read and understand this user manual before operating the meter.

• Always remove the test leads before replacing the battery.

• Inspect the condition of the test leads and the multimeter itself for any damage before operating the

multimeter. Repair or replace any damage before use.

• Use great care when making measurements if the voltages are greater than 25VAC RMS or 35VDC.

These voltages are considered a shock hazard.

• Remove the battery if the multimeter is to be stored for long periods.

• Always discharge capacitors and remove power from the device under test before performing Diode,

Resistance or Continuity tests.

• Voltagechecksonelectricaloutletscanbedifcultandmisleadingbecauseoftheuncertaintyof

connection to the recessed electrical contacts. Other means should be used to ensure that the

terminals are not “live”.

• Iftheequipmentisusedinamannernotspeciedbythemanufacturer,theprotectionprovidedby

the equipment may be impaired.

FUNCTIONS

CURRENT MEASUREMENT

Test AC/DC current up to 1000Amps without interfering with test circuit.Test wire up to 30mm in diameter

MULTI-TEST

Test everything from voltage and frequency, resistance, and continuity along with the ability to test diodes and

temperature

DATA HOLD FUNCTION

Freeze on screen data so you do not lose the recording

PRODUCT OVERVIEW

1. Current Clamp

2. Clamp Trigger

3. Data Hold/Backlight Button

4. Mode Button

5. Hz/% Button

6. LCD Display

7. COM Input Jack

8. Rotary Function Switch

9. ZERO Button

10.Range Select Button

11.VΩoC/oFJack

12.Battery Compartment on Rear

SYMBOLS USED ON LCD DISPLAY

AC DC Alternating Current

or Direct Current

Minus Sign

8.8.8.8 4000 count (0 to 3999)

Measuring Reading

AUTO Auto Range Mode

Diode Test Mode

Audible Continuity

HOLD Data Hold Mode

oC, oF, µ, m, Units of Measure

V, A, K, M, Ω List

METER FUNCTIONS

DC/AC CURRENT MEASUREMENTS

1. Set the rotary function switch to the 1000A or 400A or 40A ranges.

a. If the range of the measured is not known,

selectthehigherrangerstthenmovetothe

lower range if necessary.

2. Select AC or DC with the MODE button.

3. Press the trigger to open jaw and fully enclose one conductor to be measured.

4. The clamp meter LCD will display the reading.

WARNING: Ensure that the test leads are disconnected from the meter before making current clamp

measurements.

DC/AC VOLTAGE MEASUREMENTS

1. Insert the black test lead into the negative COM terminal and the red test lead into the positive V terminal.

2. Set the rotary function switch to the V position.

3. Select AC or DC with the MODE button.

4. Connect the test leads in parallel to the circuit under test.

5. Read the voltage on the display.

RESISTANCE AND CONTINUITY MEASUREMENTS

1. Insert the black test lead into the negative COM terminal and the red test lead into the positive terminal.

2. Set the rotary function switch to the Ωposition.

3. Select Resistance with the MODE button.

4. Touch the test probe tips across the circuit or component under test.

a. It is best to disconnect one side of the device under test so the rest of the circuit will not interfere with

the resistance reading.

5. For Resistance tests, read the resistance on the LCD display.

6. For Continuity tests, if the resistance is <100, a tone will sound.

DIODE MEASUREMENTS

1. Insert the black test lead banana plug into the negative COM jack and the red test lead banana plug

into the positive diode jack.

2. Set the rotary function switch to the Ωposition.

3. Select with the MODE button.

4. Touch the test probe to the diode under test.

a. Forward voltage will indicate 0.4V to 0.7V.

b. Reverse voltage will indicate “OL”.

c. Shorted devices will indicate near 0mV.

d. Open devices will indicate “OL” in both polarities.

CAPACITANCE MEASUREMENTS

1. Set the rotary function switch to the CAP position.

2. Insert the black test lead banana plug into the negative COM jack and the red test lead banana plug

into the positive V jack.

3. Touch the test leads to the capacitor under test.

4. Read the capacitance value in the display.

WARNING: To avoid electric shock, disconnect power to the unit under test and discharge all

capacitors before taking any capacitance measurements. Remove the batteries and unplug the line

cords.

FREQUENCY OR % DUTY CYCLE MEASUREMENTS

1. Set the rotary function switch to the V position.

2. Insert the black test lead banana plug into the negative COM jack and the red test lead banana

plug into the positive V jack.

3. Select Hz or % duty with the Hz/% button.

4. Touch the test probe tips to the circuit under test.

5. Read the frequency on the display.

TEMPERATURE MEASUREMENTS

1. Set the rotary function switch to the TEMP position.

2. Insert the Temperature Probe into the negative COM jack and the positive V jack,

making sure to observe the correct polarity.

3. Select oC or oF with the MODE button.

4. Touch the Temperature Probe head to the part whose temperature you wish to measure.

Keep the probe touching the part under test until the reading stabilizes (about 30 seconds).

5. Read the temperature in the display. The digital reading will indicate the proper decimal point

and value.

WARNING: To avoid electric shock, disconnect both test probes from any source of voltage before

making a temperature measurement.

WARNING: To avoid electric shock, be sure the thermocouple has been removed before changing to

another measurement function.

DATA HOLD AND BACKLIGHT BUTTON

• Press the DATA HOLD button to “freeze” the reading on the indicator.

• “HOLD” will appear when the reading has been “frozen”

• Press HOLD button again to return to normal operation.

NOTE: The HOLD feature will activate when the Backlight is turned on. Press HOLD button again to

exit hold.

• Press the HOLD button for 1 second to turn on the Backlight function.

• Press the HOLD again to turn off the Backlight.

MANUAL RANGING

• Press the RANGE button to go to manual ranging.

• Each press of the RANGE button will step to the next range.

• Range will be indicated by the units and decimal points location.

• Press and hold the RANGE button for 2 seconds to return to normal operation.

NOTE: Manual ranging does not function in the AC Current, Diode and Continuity Check functions.

GENERAL SPECIFICATIONS

Clamp Size Opening 1.2” (30mm) approx.

Diode Test Test current of 0.3mA typical; Open circuit voltage 1.5V DC typical

Continuity Test Threshold<100Ω;Testcurrent<1mA

Low Battery Indication “” is displayed

Over Range Indication “OL” is displayed

Measurement Rate 2 per second, nominal

Input Impedance 7.8MΩ(VDCandVAC)

Display 4000 counts LCD

AC Current 50/860Hz (AAC)

AC Voltage Bandwidth 50/60Hz (VAC)

Operating Environment 14 to 122oF (-10 to 50oC)

Storage Environment -14 to 140oF (-30 to 60oC)

Relative Humidity 90% (0 to 30oC); 75% (30 to 40oC); 45% (40 to 50oC)

Altitude Operating: 3000m; Storage: 10,000m

Over Voltage Category III 600V

Battery 1x “9V” Battery

Auto Off Approx. 35 minutes

Dimensions/Weight 229x80x49mm/303g

Safety For indoor use and in accordance with Overvoltage Category II, Pollution Degree 2. Category II

includes local level, appliance, portable equipment, etc., with transient overvoltages less than

Overvoltage Cat. III.

REPLACING THE BATTERY

1. Open the battery door by loosening the screw using a Phillips head screwdriver.

2. Remove the old battery and discard properly.

3. Insert the new “9V” battery into battery holder, observing the correct polarity.

4. Put the battery door back in place. Secure with the screw.

WARNING: To avoid electric shock, do not operate the multi meter until the battery door is in place

and fastened securely.

ELECTRICAL SPECIFICATIONS

Function Range

& Resolution

Accuracy

(% of reading)

DC Current

40.00 AAC ± (2.8% + 10 digits)

400.0 AAC ± (2.8 % + 5 digits)

1000 AAC ± (3.0 % + 5 digits)

AC Current

40.00 AAC ± (3.0% + 10 digits)

400.0 AAC ± (3.0 % + 5 digits)

1000 AAC ± (3.0 % + 5 digits)

DC Voltage

400.0 mVDC ± (0.8% + 3 digits)

4.000 VDC

± (1.5% + 3 digits)40.00 VDC

400.0 VDC

600 VDC ± (2.0% + 3 digits)

AC Voltage

400.0 mVAC ± (0.8% + 20 digits)

4.000 VAC

± (1.8% + 5 digits)40.00 VAC

400.0 VAC

600 VAC ± (2.5% + 5 digits)

Resistance

400.0Ω ± (1.0% + 4 digits)

4.000KΩ

± (1.5% + 2 digits)40.00KΩ

400.0KΩ

4.000MΩ ± (2.5% + 3 digits)

40.00MΩ ± (3.5% + 5 digits)

Capacitance

40.00nF ± (5.0% reading + 100

digits)

400.0nF ± (3.0% reading + 5 digits)

4.000μF ± (3.5% reading + 5 digits)

40.00μF

100.0μF ± (5.0% reading + 5 digits)

Frequency

5.000Hz ± (1.5% reading + 5 digits)

50.00Hz

± (1.2% reading + 2 digits)

Sensitivity: 10Vrms min.

500.0Hz

5.000kHz

50.00kHz

100.0kHz

Duty Cycle

0.5 to 99.0% ± (1.2% reading + 2 digits)

Pulse width: 100μs - 100ms, Frequency: 5.000Hz ~

100.0kHz

Temp (type-K)

(probe accuracy not included)

-20 to 1000°C ± (3.0% reading + 5°C)

-4 to 1832°F ± (3.0% reading + 7°F)

NOTE: No Auto Ranging & 400mV AC Voltage Range

WARRANTY STATEMENT

Brown&WatsonInternationalPtyLtd(“BWI”)of1500FerntreeGullyRoad,Knoxeld,Vic.,telephone(03)

9730 6000, fax (03) 9730 6050, warrants that all products described in its current catalogue will under

normal use and service be free of failures in material and workmanship for a period of three (3) years

from the date of the original purchase by the customer as marked on the invoice. This warranty does not

cover ordinary wear and tear, abuse, alteration of products or damage caused by the purchaser.

To make a warranty claim the consumer must deliver the product at their cost to the original place of

purchase or to any other place which may be nominated by either BWI or the retailer from where the

product was bought in order that the warranty assessment may be performed. The consumer must also

deliver the original invoice evidencing the date and place of purchase together with an explanation in

writing as to the nature of the claim. In the event that the claim is determined to be for a minor failure of

the product then BWI reserves the right to repair or replace it at its discretion. In the event that a major

failure is determined the consumer will be entitled to a replacement or a refund as well as compensation

for any other reasonably foreseeable loss or damage.

This warranty is in addition to any other rights or remedies that the consumer may have

under State or Federal legislation.

IMPORTANT NOTE

Our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

Distributed by

AUSTRALIA

Brown & Watson International Pty. Ltd.

KnoxeldVictoria3180

Phone: (03) 9730 6000

Fax: (03) 9730 6050

National Toll Free: 1800 113 443

NEW ZEALAND OFFICE

Grifths Equipment Ltd.

19 Bell Avenue,

Mount Wellington,

Auckland 1060, New Zealand

Phone: (09) 525 4575

Fax: (09) 579 1192

IS508

Issue 1 17/11/22

Table of contents

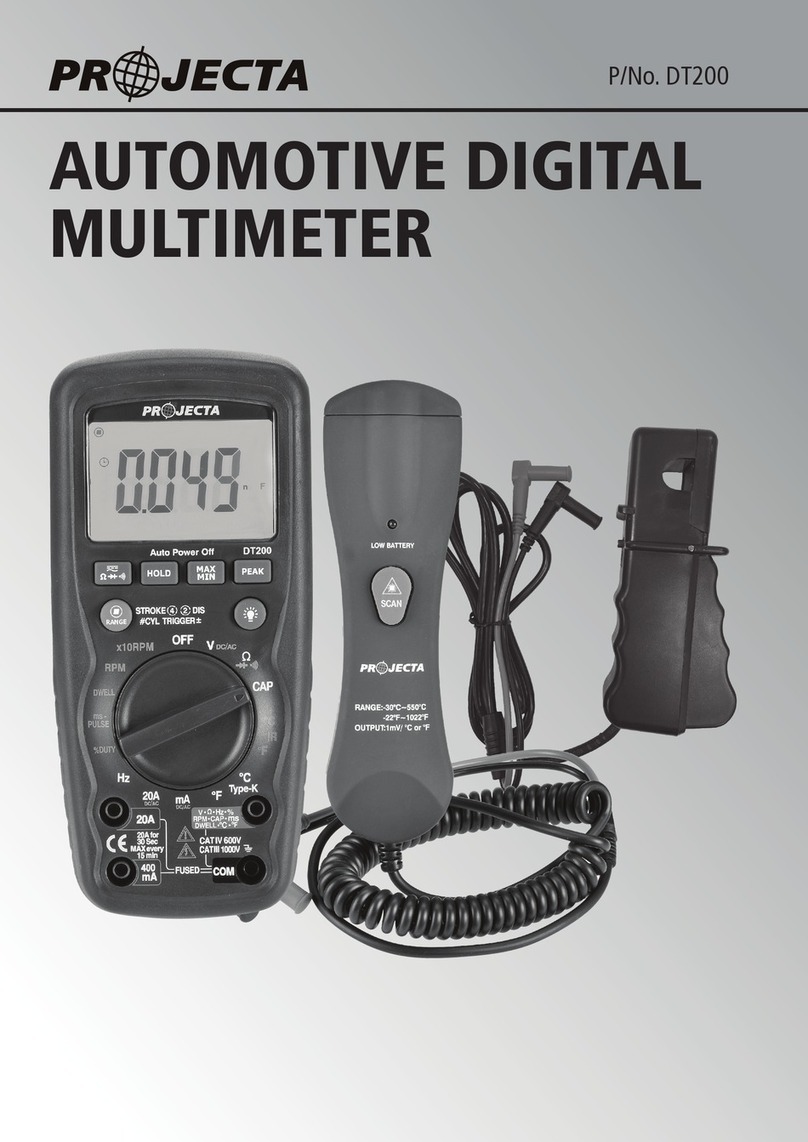

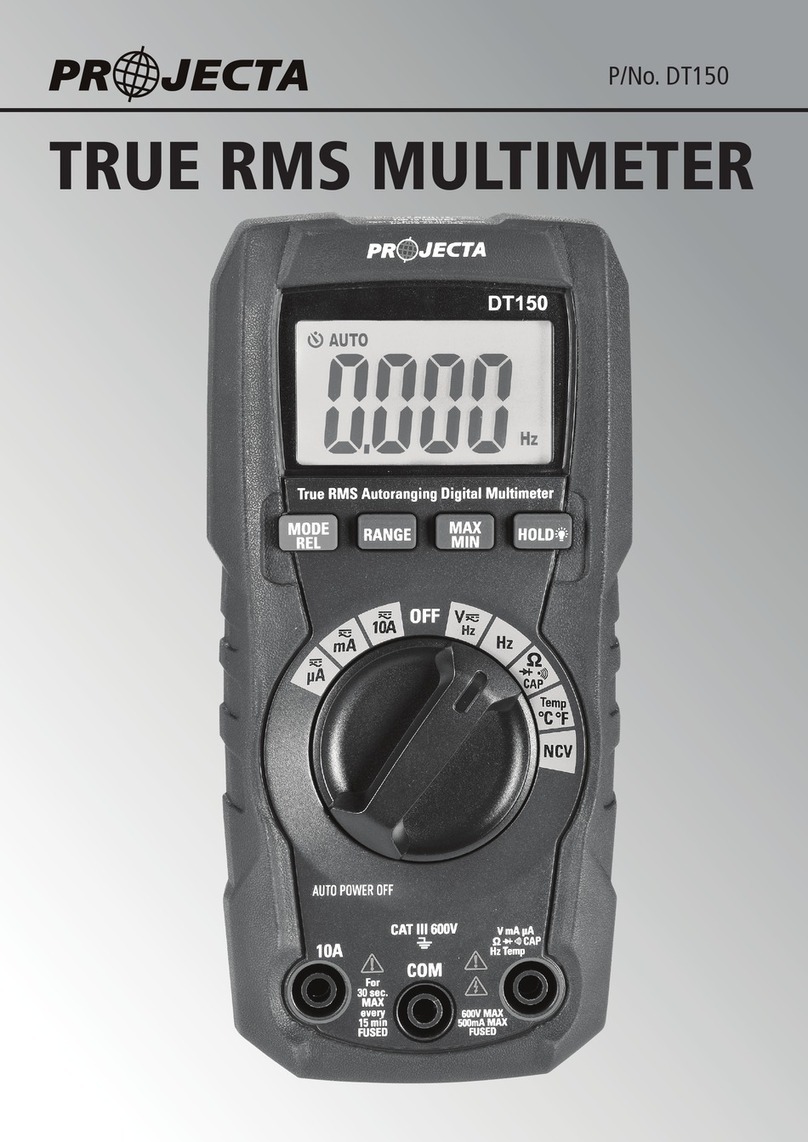

Other Projecta Multimeter manuals