Projector Phantom PPR/2000 Manual

Phantom

POWER ASSISTED RESPIRATOR PPR/2000 Model

Operating and Maintenance Instructions

GEBLÄSEFILTER-ATEMGERÄT MODELL PPR/2000

Betriebs- und Wartungsanleitung

AANGEDREVEN RESPIRATOR TYPE - PPR/2000

Gebruiks- en onderhoudsaanwijzingen

APPAREIL RESPIRATOIRE ASSISTE - MODELE PPR/2000

Instructions d'utilisation et d'entretien

RESPIRADOR ASISTIDO Modelo - PPR/2000

Instrucciones de Funcionamiento y Mantenimiento

RESPIRADOR COM POTÊNCIA AUXILIAR Modelo PPR/2000

Instruções Operacionais e de Manutenção

RESPIRADOR ASISTIDO Modelo PPR/2000

Instrucciones de Funcionamiento y Mantenimiento

ELFORSYNINGS ASSISTERET RESPIRATOR - PPR/2000 Model

Operations og vedligeholdelses instruktioner

BATTERIDRIVET ANDNINGSSKYDD - Modell PPR/2000

Bruksanvisning och skötselinstruktioner

KRAFTTILFØRT ÅNDEDRETTSVERN - Modell PPR/2000

Bruks- og vedlikeholdsveiledning

MOOTTOROITU HENGITYKSENSUOJAIN - Malli PPR/2000

Käyttö- ja huolto-ohjeet

.Part No.

084.575.00

Iss A Apr 98

2

Protector Respiratory

Protector Technologies Europe

Pimbo Road, West Pimbo,

Skelmersdale Lancashire WN8 9RA

United Kingdom

Tel: +44 (0) 1695 711711,

Fax: +44 (0) 1695 50819

1

WARNINGS.

Refer to BS 4275 1997 for guidance in

the selection of appropriate respiratory

devices. Do not use when

concentrations or contaminants are

unknown.

THIS RESPIRATOR DOES NOT

SUPPLY OXYGEN Do not use in an

oxygen deficient atmosphere

containing less than 19% by volume

under normal atmospheric pressure.

Do not use in an explosive atmosphere,

where the explosion hazard requires

the use of Intrinsically Safe respiratory

protective equipment.

The wearing of beards, sideburns,

moustaches or spectacles may

adversely affect sealing of the mask to

the wearers face or the operation of the

exhalation valve.

At very high work rates, pressure

inside the facemask may become

negative at peak inhalation.

Altering or modifying this respirator

invalidates all approvals and may

reduce wearer protection.

In the unlikely event of power failure

while in use, do not remove respirator,

breathe normally. The respirator will

continue to provide a high degree of

protection, acting as a standard

negative pressure filter equipment.

Exit the hazardous area immediately

and report the fault.

1. IMPORTANT POINTS TO NOTE

Please read carefully. Should you require clarification

of the instructions given in this manual, please contact

Protector or an approved Protector distributor.

The instructions for pre-use, donning, after use cleaning

service and maintenance given in this manual must be

fully understood and followed carefully to ensure wearer

protection. Special attention must be given to the notes,

important notes, cautions, warnings and labels on the

respirator before use. Failure to do so may reduce

respirator effectiveness and result in serious injury, or

death.

Notified Body

Inspec Certification Ltd (Number 0194),

Upper Wingbury Courtyard, Wingrave, Aylesbury,

Buckinghamshire, HP22 SLO, UK

1.1 GENERAL PRECAUTIONS TO BE

OBSERVED DURING SERVICING AND

MAINTENANCE.

1. All assemblies must be serviced and maintained

strictly in accordance with the instructions given in

this manual.

2. Use only Protector spare parts when servicing

and maintaining this respirator.

3. Use only the correct tools, as specified, taking

care to avoid damage to components.

4. Keep service and maintenance area clean. Make

certain that all components are clean before

reassembly.

5. Carefully examine each component for signs of

wear or damage, and replace where necessary.

6. Use only recommended lubricant where specified

and apply sparingly, wiping off all surplus.

7. For identification of items numbered in

instructions, refer to exploded views and parts list.

8. This respirator with filter (4) is only for protection

against solid and liquid aerosols of negligible

volatility and decomposition.

1.2 TRAINING AND SERVICING.

a) This manual is not suitable for the purpose

of training respirator wearers or

maintenance personnel who have no

previous practical experience of respiratory

protective equipment.

b) Training and servicing programmes are

available upon request. Please contact

Protector or your approved distributor for

further details.

2. GENERAL DESCRIPTION

Phantom is a TM3 power assisted respirator conforming

to prEN 147 Rev 1995 with a nominal protection factor

of 2000. It has been Type Approved by lnspec

Certification CE 0194. Certificate No. 069.

The respirator comprises: a full facemask with an

integral blower, a mask mounted filter and waist belt

mounted battery.

The blower draws air into the facemask through the filter

and directs the filtered air up to the left side of the visor.

2

The constant flow of air keeps the visor clear of misting,

removes perspiration and provides air to the face.

Exhaled breath leaves the facemask out through the

exhalation valve in the side of the mask.

Wearers are able to decontaminate and shower after

work, whilst still wearing the respirator.

Weight: Facemask, with blower and filter

755g.

Battery

745g.

Temperature:

Operating: -5 to +60°C.

Storage: -30 to +70°C.

In accordance with BS4275 it is advisable that

respirators of this class are not used in contaminant

concentrations exceeding 40 x Occupational Exposure

Limit.

2.1 Facemask

The facemask is moulded in non-dermatitic silicone

rubber.

The visor complies with the optical and impact

requirements of EN166 Grade 1B.

2.2 Flowrate

The constant flowrate of the standard Phantom when

used with a PF251/2 filter exceeds 160 litres/minute for

not less than 6 hours and a minimum flowrate of 120

litres/minute. Maximum duration 8 hours.

2.3 Blower

The blower has a radial fan driven by a DC motor,

connected by coiled cable to a polarised bayonet plug.

The airflow produced is directed by a contoured grill

over the inside of the visor eliminating the need for an

inner mask.

Motor Life: 1000+ hours.

2.4 Phantom Filters

Specially developed for the power assisted respirator the

filter has a deep pleated internal structure, giving a large

surface area, which minimises clogging and the

resistance to breathing.

The louvred entry port, which deflects water droplets

during showering, has a raised lip for attaching the air

flow indicator required for pre-use checks. The lip also

retains the filter sealing cap used during facemask

donning and filter disposal.

If required a pre-filter is available.

2.5 Tornado Gas and Combined Filters

Phantom may be used with gas and combined filters

from the Tornado range. They MUST be used in pairs,

attached to a PHA94 hose adaptor. Complete

instructions are provided with the hose adaptor.

WARNING

Gas or combined filters MUST NOT be fitted

directly to the facemask. This will endanger

wearers and invalidate all approvals.

2.6 Battery

The nickel cadmium re-chargeable battery, has a

polarised bayonet socket which ensures correct and

positive connection. Internal electronics extend battery

life by controlling the power output over the full duration

of discharge.

Battery Life: 500+ recharge cycles.

2.7 Battery Charger

The battery charge with polarised bayonet plug has a

light emitting diode (L.E.D.) charging indicator.

Charging Time: 14 hours approximately.

2.8 Spectacle Frames(Optional Extra)

For spectacle wearers an approved spectacle frame,

which fits wholly within the face mask without

interfering with the mask to face seal, is available from

Protector or a Protector distributor (Part No.

036.007.00).

3. PRE-USE PROCEDURES

3.1 Unpacking

Check that all the following are present:

1) Facemask

2) Blower

3) Filter TMP3

4) Battery

5) Flow Indicator

6) 0-ring/Seal tool

7) Grease

Battery Charger, Holdall and Waistbelt options will be

supplied with Phantom if ordered.

3.2 Preparation and Pre-Use Check List

NOTE:

Ensure that the user has read and fully

understands this operating and maintenance

instruction manual.

3.3 Battery:

To ensure full duration, the battery should be charged for

at least 14 hours.

3.4 Blower

Ensure that the 0-ring is lightly lubricated with grease

(13) and correctly positioned in the forward groove on

the outside of the blower assembly.

Ensure that the filter seal is in position at the bottom of

the threaded port in the blower assembly.

Install the blower by feeding the plug and cable from

inside the facemask through the front opening. Press the

blower fully into its housing at the front of the facemask

and lock in place by firmly screwing in the filter.

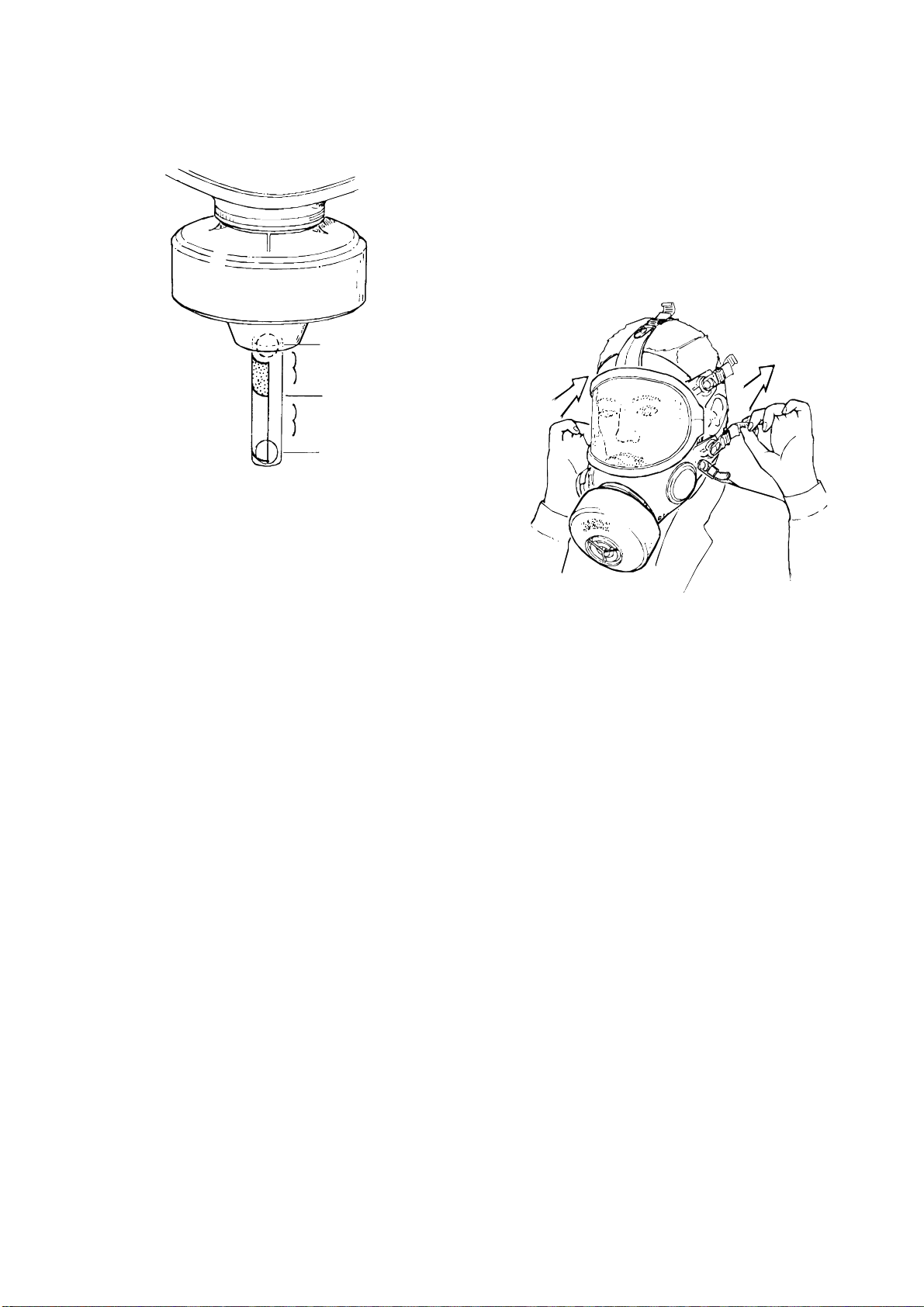

Blower O-Ring

Filter Seal

Connect the plug into the battery by aligning the larger

of the two bayonet ears on the plug, with the larger of the

two slots in the battery socket.

The plug is keyed so that it will only enter the socket in

the battery neck when correctly aligned.

3

Push down and turn the plug clockwise 45° to the OFF

intermediate position.

The plug is now retained in the socket, ready to be

switched ON.

3.5 Flow Test

Final

Fail

Start

Flow Indicator.

IMPORTANT:

The flow indicator is a measuring device. Check

for damage, ensure that it is clean and dry

before flow test.

Remove the filter cap and connect the end of the flow

indicator to the lip of the louvred port on the front of the

filter.

Hold the facemask such that the flow indicator is

pointing vertically downwards. The float should fall to

the bottom of flow indicator tube.

Operate Phantom by rotating the battery plug fully

clockwise to the ON position.

Correct functioning is shown by the float rising to the top

of the flow indicator tube.

If the float does not rise to the top of the tube a low flow

is indicated. To determine the probable cause carry out

the following fault analysis:-

i) Renew filter and re-test - If the test now indicates

sufficient air flow the original filter was clogged

and should be discarded.

ii) If the flow is still insufficient, replace the battery

with one that is freshly charged - If the test now

indicates sufficient flow the original battery should

be recharged.

iii) If the flow is still insufficient, return the complete

respirator to an approved distributor for repair.

The flow indicator is removed by grasping the tab and

pulling directly away from the filter.

Replace the filter cap.

WARNING:

DO NOT use respirators that fail the flow test.

4. DONNING PROCEDURES

IMPORTANT:

Before using the respirator, ensure that a new

filter has been firmly screwed into place, the

battery is fully charged and the flow test has

been satisfactorily completed.

4.1 Donning

Attach the battery to a waistbelt through the loop

retainer.

Insert the plug on the end of the cable into the battery

socket and rotate clockwise to the intermediate OFF

position.

Check that the filter is firmly attached to the facemask

and remove the filter cap.

Adjust all head harness straps to the fully slackened

position and put neckstrap around the neck.

With thumbs inside the facemask, put chin into facemask

first and pull straps over head. Position facemask so that

chin fits snugly into chin-cup.

Gently tighten the head harness, lower straps first. Do

not overtighten.

4.2 Check Facemask Leakage

Place the filter cap, or palm of the hand over the filter’s

louvred entry port.

Inhale gently until the facemask collapses slightly

against the face.

Hold breath for 10 seconds. If the facemask falls away

from the face a correct seal has not been achieved.

Remove the filter cap, adjust the facemask, re-tighten the

head harness strap and repeat previous procedure.

When a correct seal is achieved, remove filter cap. DO

NOT use facemasks that do not seal.

5. CLEANING

WARNING:

When cleaning the respirator, suitable

precautions must be taken against the

inhalation of any harmful dusts and

contaminants that may be present on the outer

surfaces.

Cautions:

DO NOT use abrasive cleaning materials.

DO NOT use: detergent, petroleum spirit,

chlorinated degreasing fluids (e.g.

trichloroethylene) or organic-based solvents to

clean any part of the apparatus.

At the end of each work shift, the respirator must be

cleaned and, if necessary, decontaminated. These

procedures must always be carried out in a safe area.

Disconnect the plug from the battery.

4

Replace filter cap on the used filter, remove and dispose

of safely in accordance with any plant or safety authority

instructions.

Gently push the blower assembly out of the facemask

and feed the cable through the mask opening.

5.1 Facemask

Caution: Wash the facemask in tepid soap and

water solution. Use toilet soap not detergent.

Rinse thoroughly in clean running water, paying

particular attention to the exhalation valve.

After rinsing, shake the mask vigorously to remove

excess water and allow to dry away from direct heat or

sunlight. To avoid damage to the visor, do not place the

mask face down on rough surfaces.

Caution:

Dry the respirator thoroughly if it is to be stored

at temperatures below freezing.

Note:

Where disinfection is required, after rinsing, use

TriGene solution. Rinse the facemask

thoroughly in clean water.

When dry, polish the visor inside and out with a clean

lint-free soft cloth. Replace the visorguard for

protection.

Inspect individual parts of the facemask and replace

missing or damaged parts. Fully slacken the head

harness ready for use.

5.2 Blower

Cautions:

DO NOT immerse the blower assembly.

The blower is a sealed unit and cannot be

serviced beyond o-ring and filter seal

replacement.

Wipe the blower with a damp cloth or disinfectant wipe.

Inspect the O-ring and filter seal and replace if damaged.

(Refer to Servicing and Maintenance)

5.3 Battery

Caution:

DO NOT immerse the battery assembly.

The Battery may be wiped with a damp cloth.

The battery is a sealed unit and cannot be serviced.

6. MAINTENANCE

6.1 Charging Battery

Batteries must be charged in a safe area.

Optimum performance with new battery packs is

achieved after they have completed three charge cycles.

To maintain the optimum performance Protector

recommend that the battery pack is fully discharged

approximately once every fifty uses.

Plug the battery charger into a suitable mains supply.

Plug the charging lead into the battery socket and turn

fully clockwise to the ON position.

The red LED on the battery charger should illuminate

indicating that the battery is being charged. After normal

use (8 hours working), the battery should reach a full

charge in approximately 14 hours.

IMPORTANT:

The battery charger is a sealed unit and cannot

be serviced.

Store the respirator in a clean, dry area protected from

direct sunlight and extremes of temperature.

6.2 Facemask

6.2.1 Exhalation Valve

To remove the cover (14f) grasp the edge of the cover

and pull off. Inspect the exhalation valve flap (14d) for

debris, damage, or to see that it is flat and correctly

seated. Replacement is necessary at least yearly

regardless of condition.

Replace the exhalation valve cover by aligning it with

the base and depressing until it snaps into place.

6.2.2 Visor Replacement

Unscrew the two visor clamp screws and remove clamps

(2) from facemask.

Remove the visor (1) from the facemask.

Replace in reverse order, ensuring that moulding witness

marks on the visor and clamps are in line with the centre

line of the facemask. Lubrication of the inside groove of

the visor clamps with a soap and water solution will

assist assembly.

Both facemask and visor must be perfectly clean to

prevent leaks. The mask should be leak tested by a

Protector agent after visor replacement.

6.3 Blower Seals

The respirator has an o-ring (14a) between the blower

and the facemask, and a seal (14c) between the filter and

the blower. Both must be inspected for wear after each

use and replaced annually.

To replace the O-ring (14a) between the facemask and

the lower, the respirator must be dismantled as described

in CLEANING.

Lightly lubricate the new O-ring with grease (13) and

push it into the forward groove of the blower assembly.

The seal between the filter and the blower (14c) is

replaced by loosening the seal inwards from its flange,

using the seal tool provided.

5

Position the new seal in the cavity with the moulded

number downwards (So that it cannot be seen). Using

the seal tool, push the seal until it slips over the flange

and snaps into place. Continue around the seal until it is

evenly seated.

6

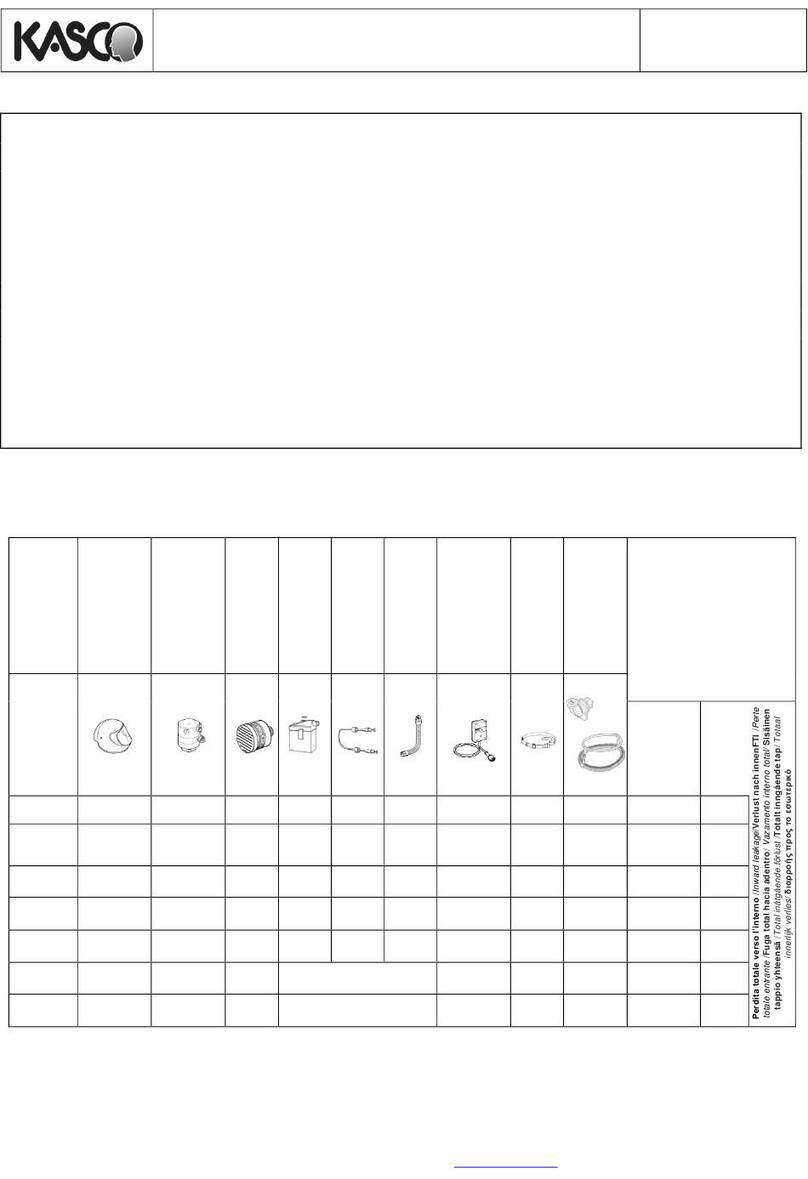

Phantom POWER ASSISTED RESPIRATOR

(Part No. PPR2000-Std)

62

1

3

4

14d

14c

11

16

10 57

9

8

14b

14a 15

Item Part No. Description

1071.102.90 Visor And Visorguard

2071.105.99 Clamp and Screw Pack, Visor

3071.345.03 Facemask

4PF251/2 Filter TMP3

5071.126.99 Neckstrap

6071.120.98 Head Harness

7071.270.99 Button Spares Pack (7)

8008.017.99 Buckle Spares Pack (5)

9PPR2000/Motor Blower

10 PPR/BATT/1 Battery

11 RXPBC/2000/3 Battery Charger for UK.

RXPBCM/2000/2 Battery Charger for Europe

13 074.101.02 Grease

Item Part No. Description

14 095.048.00 Service Pack Annual with:

14a Blower 0-ring (1)

14b Filter Seal (1)

14c Exhalation Valve Cover (1)

14d Exhalation Valve Flap (1)

14e Grease (1)

15 071.302.99 Support (5)

16 ECWB Waistbelt

17 BAG/PPR Holdall

089.176.02 Flow Indicator

071.151.99 Clear Visor Cover (20)

084.090.02 Instruction Manual

PHPF Prefilter (10)

7

Table of contents