PAS® Series

Airline respiratory protection equipment Instructions for Use

PAS®is a registered trade mark of Dräger 3352487 (A3-D-P) Page 1 of 2

3352487

© Dräger Safety UK Limited

Edition 07 – November 2018

Subject to alteration

Draeger Safety UK Limited

Ullswater Close Tel +44 1670 352 891

Blyth, NE24 4RG Fax +44 1670 356 266

United Kingdom www.draeger.com

1 For your safety

1.1 General safety statements

●Before using this product, carefully read the Instructions for Use.

●Strictly follow the Instructions for Use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the Intended Use section of this document.

●Do not dispose of the Instructions for Use. Ensure that they are

retained and appropriately used by the product user.

●Only fully trained and competent users are permitted to use this

product.

●Comply with all local and national rules and regulations associated

with this product.

●Only trained and competent personnel are permitted to inspect, repair

and service the product. Dräger recommend a Dräger service contract

for all maintenance activities and that all repairs are carried out by

Dräger.

●Properly trained service personnel must inspect and service this

product as detailed in the Maintenance section of this document.

●Use only genuine Dräger spare parts and accessories, or the proper

functioning of the product may be impaired.

●Do not use a faulty or incomplete product, and do not modify the

product.

●Notify Dräger in the event of any component fault or failure.

●The air supply shall meet the requirements for breathing air according

to EN 12021.

1.2 Definitions of alert icons

Alert icons are used in this document to provide and highlight text that

requires a greater awareness by the user. A definition of the meaning of

each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in physical injury or damage to the product or

environment. It may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

2 Description

2.1 Product overview

The Dräger PAS®Series of airline respiratory protection equipment

provides respiratory protection for working in a contaminated environment

using an airline.

The features of the equipment are:

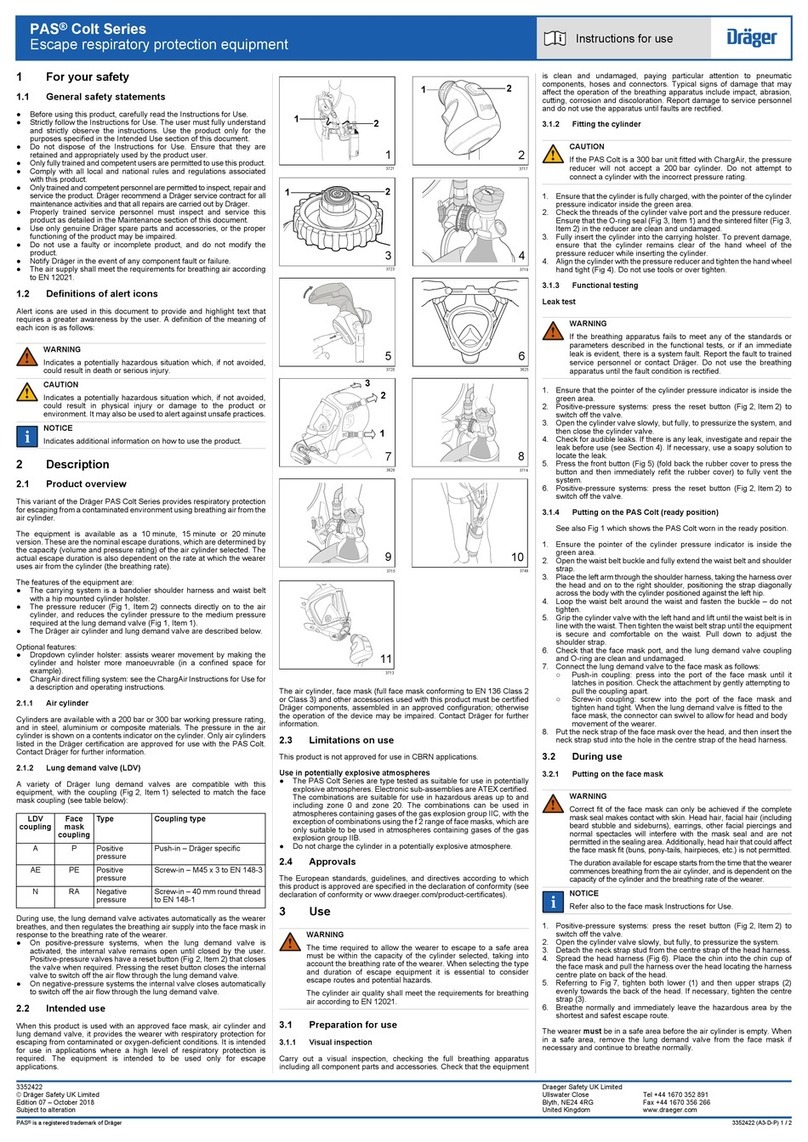

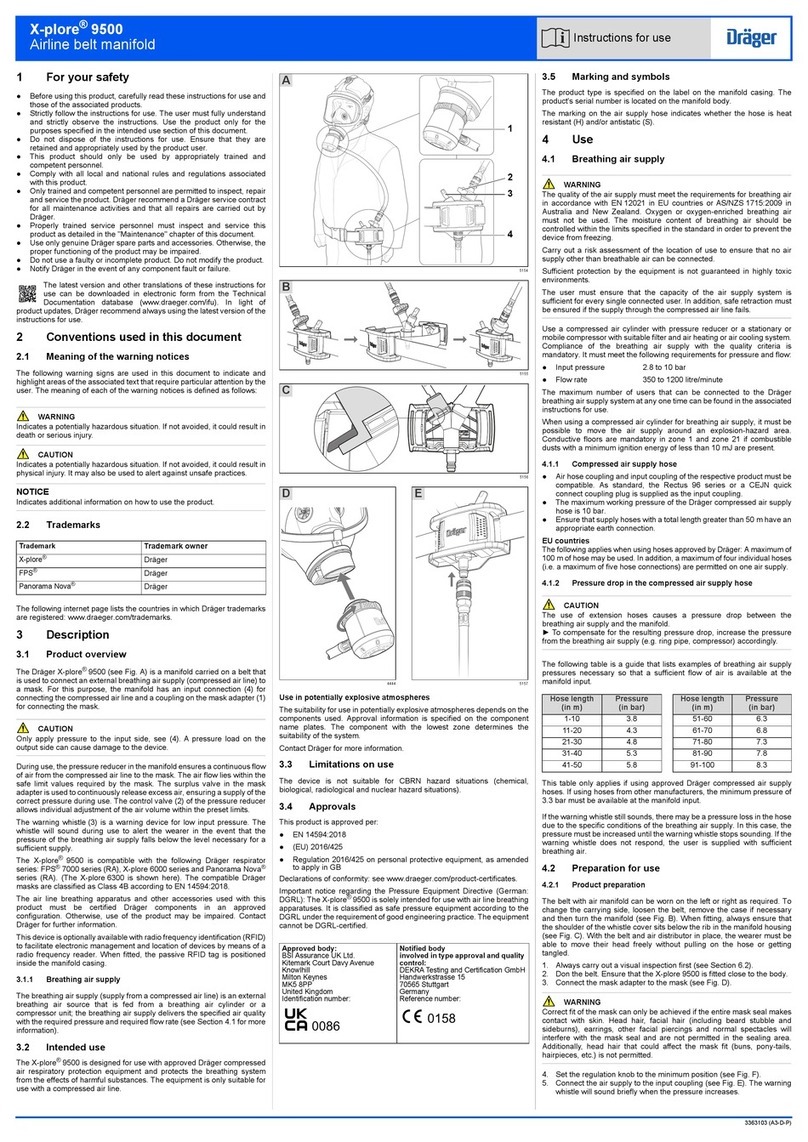

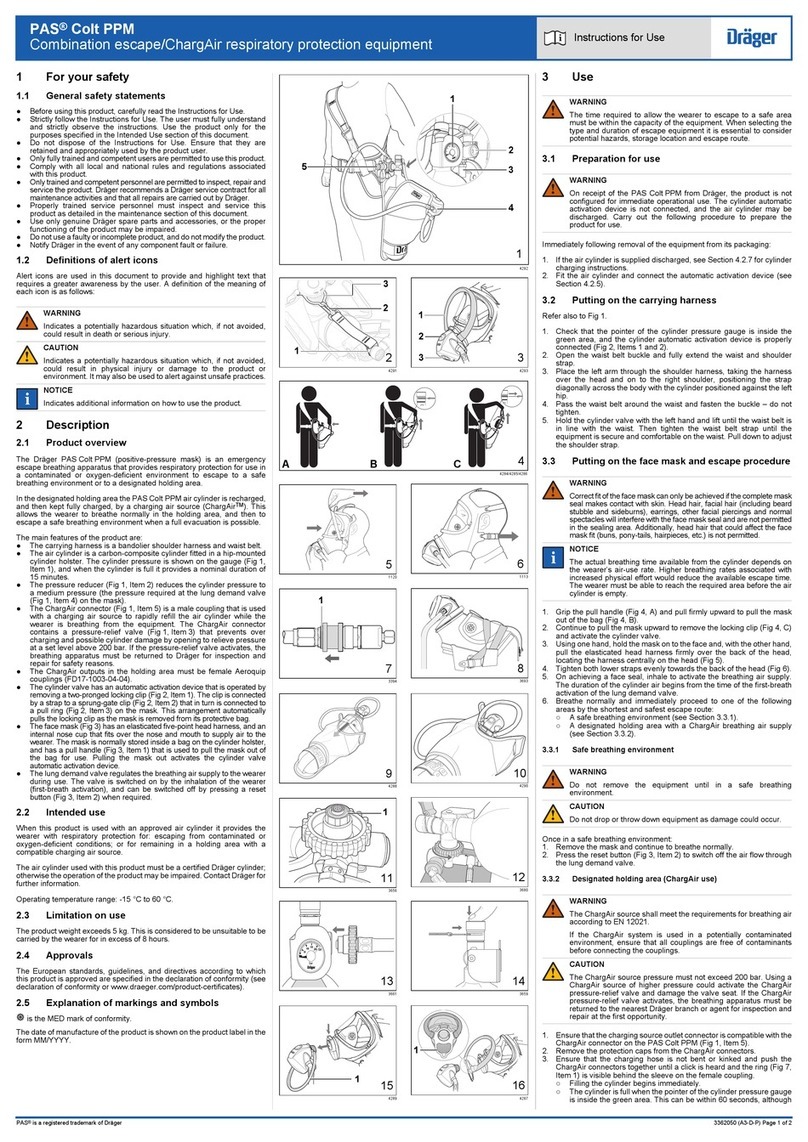

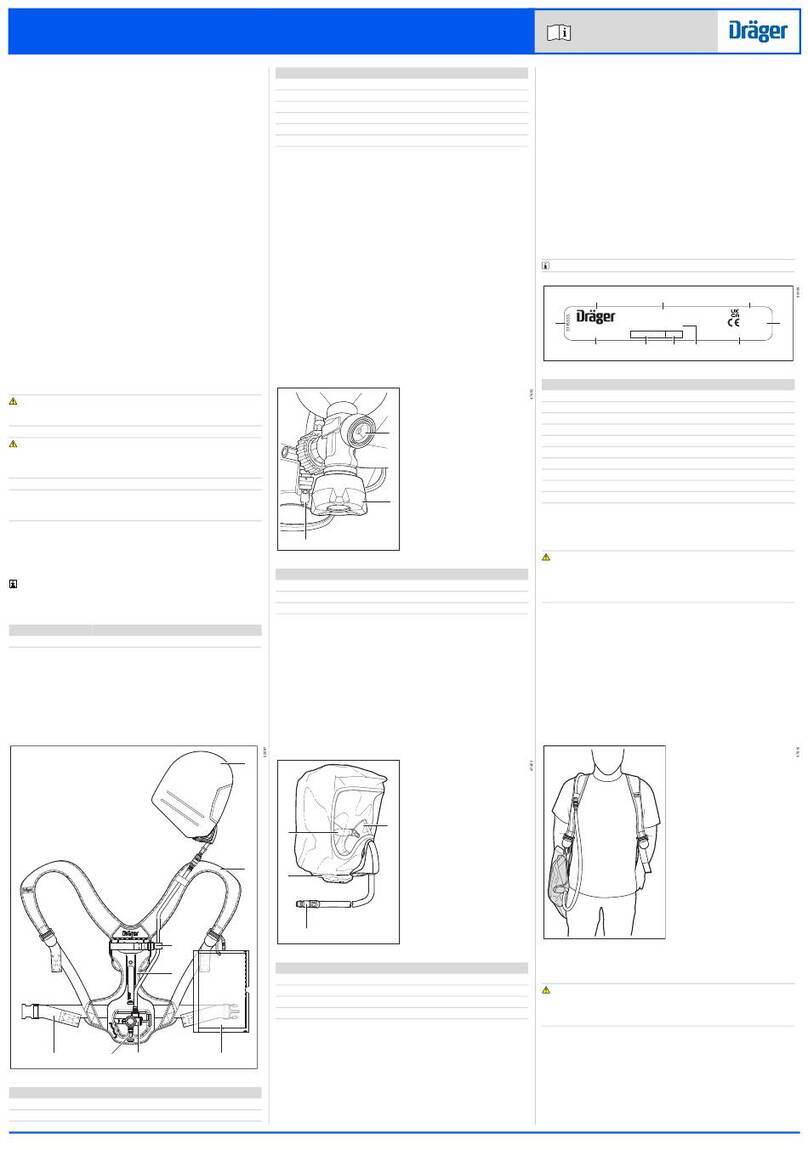

●There are two harness types available: a bandolier harness (Fig 1) that

has a waist belt and a shoulder strap, or waist belt only harness (Fig 2).

●The airline connector (Fig 1, Item 4) is a male quick coupling that is

used to connect an independent air supply.

●The equipment is available with or without a low-pressure whistle.

When the equipment has a low-pressure whistle, it is on the airline

manifold (Fig 1, Item 2), and sounds during use to warn the wearer that

the supply pressure from the airline is low.

●The medium-pressure hose is available with or without a quick

coupling (Fig 1, Item 3) (shown on the bandolier harness only). The

quick coupling allows rapid removal and fitting of the lung demand

valve when required.

●The lung demand valve (Fig 1, Item 1) is described below.

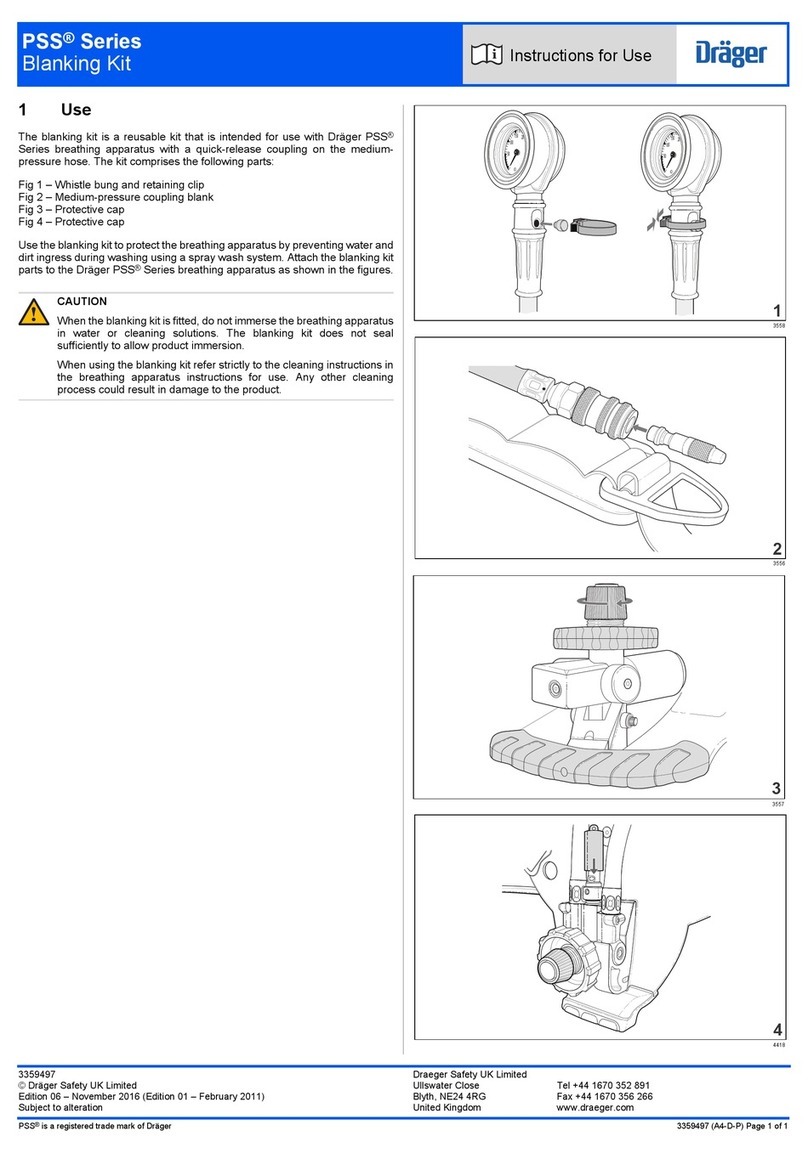

2.1.1 Lung demand valve (LDV)

A variety of Dräger lung demand valves are compatible with this

equipment, with the coupling (Fig 3, Item 1) selected to match the face

mask coupling (see table below):

During use, the lung demand valve activates automatically as the wearer

breathes, and then regulates the breathing air supply into the face mask in

response to the breathing rate of the wearer.

●On positive-pressure systems, when the lung demand valve is activated,

the internal valve remains open until closed by the user. Positive-pressure

valves have a reset button (Fig 3, Item 2) that closes the valve when

required. Pressing the reset button closes the internal valve to switch off

the air flow through the lung demand valve.

●On negative-pressure systems the internal valve closes automatically to

switch off the air flow through the lung demand valve.

The lung demand valve can also be activated manually by pressing the

front button (Fig 3, Item 3) to open the internal valve and activate air flow

when required. The front button can be pressed during use to deliver

additional air (supplementary air) into the mask when required by the

wearer.

2.2 Intended use

When this product is used with an approved face mask, lung demand valve

and independent air supply, it provides the wearer with respiratory

protection for working in, contaminated or oxygen-deficient conditions. It is

intended for use in applications where a high level of respiratory protection

is required. The equipment is intended to be used only for airline

applications.

The face mask (full face mask conforming to EN 136 Class 2 or Class 3)

and other accessories used with this product must be certified Dräger

components, assembled in an approved configuration; otherwise the

operation of the device may be impaired. Contact Dräger for further

information.

LDV

coupling

Face

mask

coupling

Type Coupling type

A P Positive

pressure

Push-in – Dräger specific

AE PE Positive

pressure

Screw-in – M45 x 3 to

EN 148-3

N RA Negative

pressure

Screw-in – 40 mm round

thread to EN 148-1

!

!

2.3 Limitations on use

This product is not approved for use in CBRN applications.

Use in potentially explosive atmospheres

The PAS®Series are type tested as suitable for use in potentially explosive

atmospheres. Electronic sub-assemblies are ATEX certified. The

combinations are suitable for use in hazardous areas up to and including

zone 0 and zone 20. The combinations can be used in atmospheres

containing gases of the gas explosion group IIC, with the exception of

combinations using the f 2 range of facemasks, which are only suitable to

be used in atmospheres containing gases of the gas explosion group IIB.

2.4 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

declaration of conformity or www.draeger.com/product-certificates).

PED Important note: The PAS®Series of airline respiratory protection

equipment is designed for use with airline breathing-air supply systems

only and is classified as safe and suitable for use under the PED

regulations – category SEP (Sound Engineering Practice). The equipment

cannot be certified to PED regulations.

2.5 Explanation of type-identifying marking and

symbols

Where appropriate, the marking “F” on the apparatus and

CAST (compressed-air supply tube) indicates that both can be used where

flammability may be a risk. Marking on the compressed-air supply tube

indicates that the tube is heat resistant (H) and/or antistatic (S).

3 Use

WARNING

The airline air quality shall meet the requirements for breathing air

according to EN 12021. Do not use oxygen or oxygen-enriched air.

The moisture content of breathing air should be controlled within

the EN 12021 limits to avoid freezing the apparatus.

Carry out a risk assessment of the workplace to ensure that it is

not possible to connect to any airline supply other than breathable

air (e.g. Nitrox).

Before using airline equipment, ensure that the independent air

supply meets the air quality requirements, and complies with the

airline pressure, flow and hose requirements in the technical

data (see Section 8), and has been issued with a permit for use if

necessary.

Position the source of the independent air supply in a safe and

uncontaminated area. Dräger recommend that a controller should

monitor and maintain the independent air supply throughout any

operation.

3.1 Preparation for use

3.1.1 Visual inspection

Carry out a visual inspection, checking the full breathing apparatus

including all component parts and accessories. Check that the equipment

is clean and undamaged, paying particular attention to pneumatic

components, hoses and connectors. Typical signs of damage that may

affect the operation of the breathing apparatus include impact, abrasion,

cutting, corrosion and discoloration. Report damage to service personnel

and do not use the apparatus until faults are rectified.

3.1.2 Functional testing

WARNING

If the breathing apparatus fails to meet any of the standards or

parameters described in the functional tests, or if an immediate

leak is evident, there is a system fault. Report the fault to trained

service personnel or contact Dräger. Do not use the breathing

apparatus until the fault condition is rectified.

1. Positive-pressure systems: press the reset button (Fig 3, Item 2) to

switch off the valve.

2. Connect the independent air supply to the male coupling (Fig 1,

Item 4), and if the independent air supply has a shut-off valve, open the

valve.

3. Check for audible leaks. If there is any leak, investigate and repair the

leak before use (see Section 4). If necessary, use a soapy solution to

locate the leak.

WARNING

Do not direct the air flow on to the face, eyes or skin.

4. Press the front button (Fig 3, Item 2) to activate air flow from the valve

for 3–5 seconds. Unobstructed air will flow from the outlet of the lung

demand valve.

5. Positive-pressure systems: press the reset button (Fig 3, Item 2) to

switch off the valve.

6. Isolate the independent air supply.

7. Leak test: Carry out this test only if the independent air supply has a

medium-pressure gauge and/or a high-pressure gauge; otherwise

proceed to Step 8.

○After isolating the independent air supply, wait one minute and

then observe the gauge and reapply the independent air supply.

○A medium-pressure gauge should not show an increase in

pressure of more than 1 bar. A high-pressure gauge should not

show an increase in pressure of more than 10 bar. If there is any

leak, investigate and repair the leak before use (see Section 4). If

necessary, use a soapy solution to locate the leak.

○After testing, again isolate the independent air supply.

8. Whistle test: Carry out this test only if the PAS®Series apparatus is

fitted with a low-pressure whistle; otherwise proceed to Step 9.

○Positive-pressure systems: cover and seal the lung demand valve

outlet with the palm of the hand. Press the front button (Fig 3,

Item 3) to activate air flow and then lift the hand to very slowly vent.

○Negative-pressure systems: carefully press the front button (Fig 3,

Item 3) to very slowly vent.

○The low-pressure whistle will briefly sound as the pressure

decreases. (If the independent air supply has a medium-pressure

gauge, check that the whistle commences in the range 5 bar to 4 bar.

Note also that if the independent air supply has a low-pressure

warning device, this may also activate/sound during this test.)

9. Press the front button (Fig 3, Item 3) to fully vent the system.

10. Disconnect the independent air supply.

11. Positive-pressure systems: press the reset button (Fig 3, Item 2) to

switch off the valve.

3.1.3 Putting on the PAS®Series equipment (ready position)

See also Fig 1 (bandolier harness) and Fig 2 (waist belt harness) which

show the PAS Series equipment worn in the ready position.

1. Put on the harness:

○Bandolier harness:

i. Open the waist belt buckle and fully extend the waist belt and

shoulder strap.

ii. Place the left arm through the shoulder harness, taking the

harness over the head and on to the right shoulder, positioning

the strap diagonally across the body.

iii. Loop the waist belt around the waist and fasten the buckle –

do not tighten.

iv. Grip the airline manifold with the left hand and lift until the waist

belt is in line with the waist. Tighten the waist belt strap until

the equipment is secure and comfortable on the waist. Pull

down to adjust the shoulder strap.

○Waist belt harness:

i. Open the waist belt buckle and fully extend the waist belt.

ii. Loop the waist belt around the waist and fasten the buckle.

iii. Position the belt strap on the waist and tighten the waist belt

strap until the equipment is secure and comfortable on the

waist.

2. Check that the face mask port, and the lung demand valve coupling

and O-ring are clean and undamaged.

3. Connect the lung demand valve to the face mask as follows.

○Push-in coupling: press into the port of the face mask until it

latches in position. Check the attachment by gently attempting to

pull the coupling apart.

○Screw-in coupling: screw into the port of the face mask and tighten

hand tight. When the lung demand valve is fitted to the face mask,

the connector can swivel to allow for head and body movement of

the wearer.

4. Put the neck strap of the face mask over the head, and then insert the

neck strap stud into the hole in the centre strap of the head harness.

3.1.4 Putting on the face mask

WARNING

Correct fit of the face mask can only be achieved if the complete

mask seal makes contact with skin. Head hair, facial hair (including

beard stubble and sideburns), earrings, other facial piercings and

normal spectacles will interfere with the mask seal and are not

permitted in the sealing area. Additionally, head hair that could

affect the face mask fit (buns, pony-tails, hairpieces, etc.) is not

permitted.

NOTICE

Refer also to the face mask Instructions for Use.

1. Positive-pressure systems: press the reset button (Fig 3, Item 2) to

switch off the valve.

2. Connect the independent air supply to the male coupling (Fig 1,

Item 4). If the independent air supply has a shut-off valve, open the

valve.

3. Detach the neck strap stud from the centre strap of the head harness.

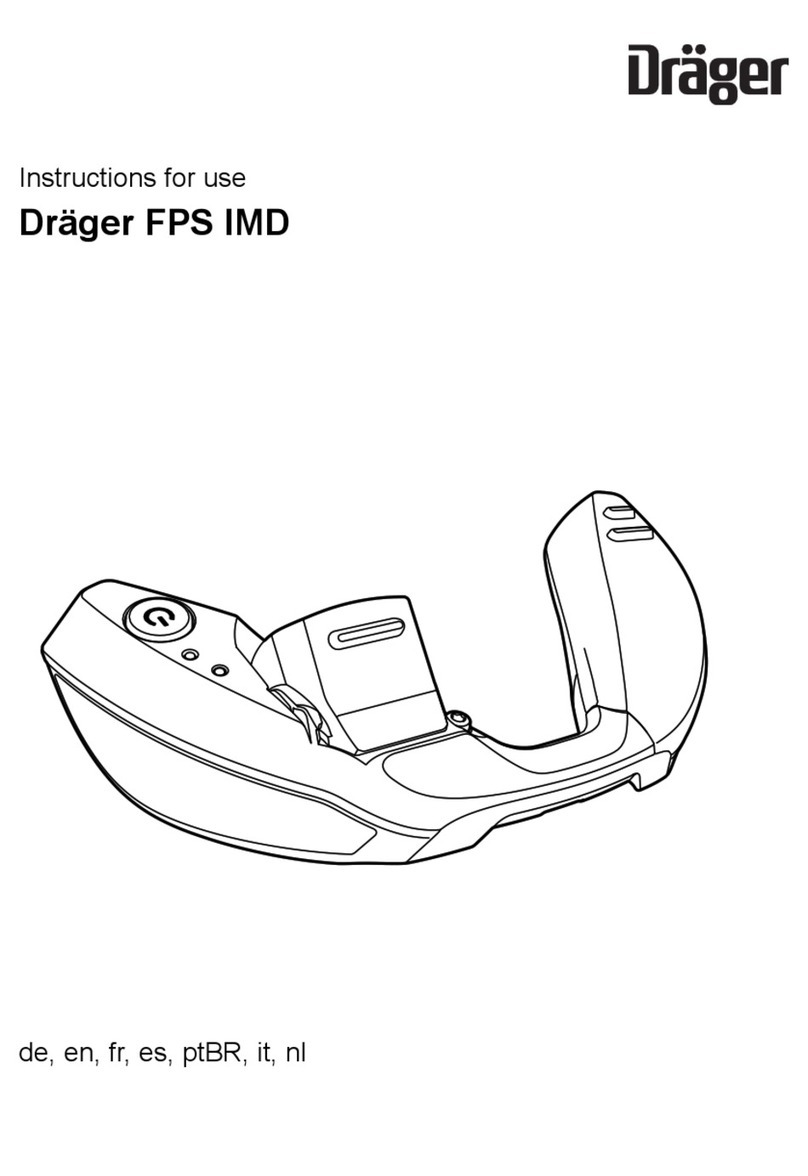

4. Spread the head harness (Fig 4). Place the chin into the chin cup of

the face mask and pull the harness over the head locating the harness

centre plate on the back of the head.

5. Referring to Fig 5, tighten both lower (1) and then upper straps (2)

evenly towards the back of the head. If necessary, tighten the centre

strap (3).

6. Breathe normally and carry out the mask function check.